Combine harvester

A combine harvester and machine body technology, which is applied to harvesters, cutters, agricultural machinery, etc., can solve the problems of reduced cutting performance of harvesting devices, slippage of transmission belts, and higher costs, so as to achieve efficient harvesting operations, realize the number of parts, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] (summary of combine harvester)

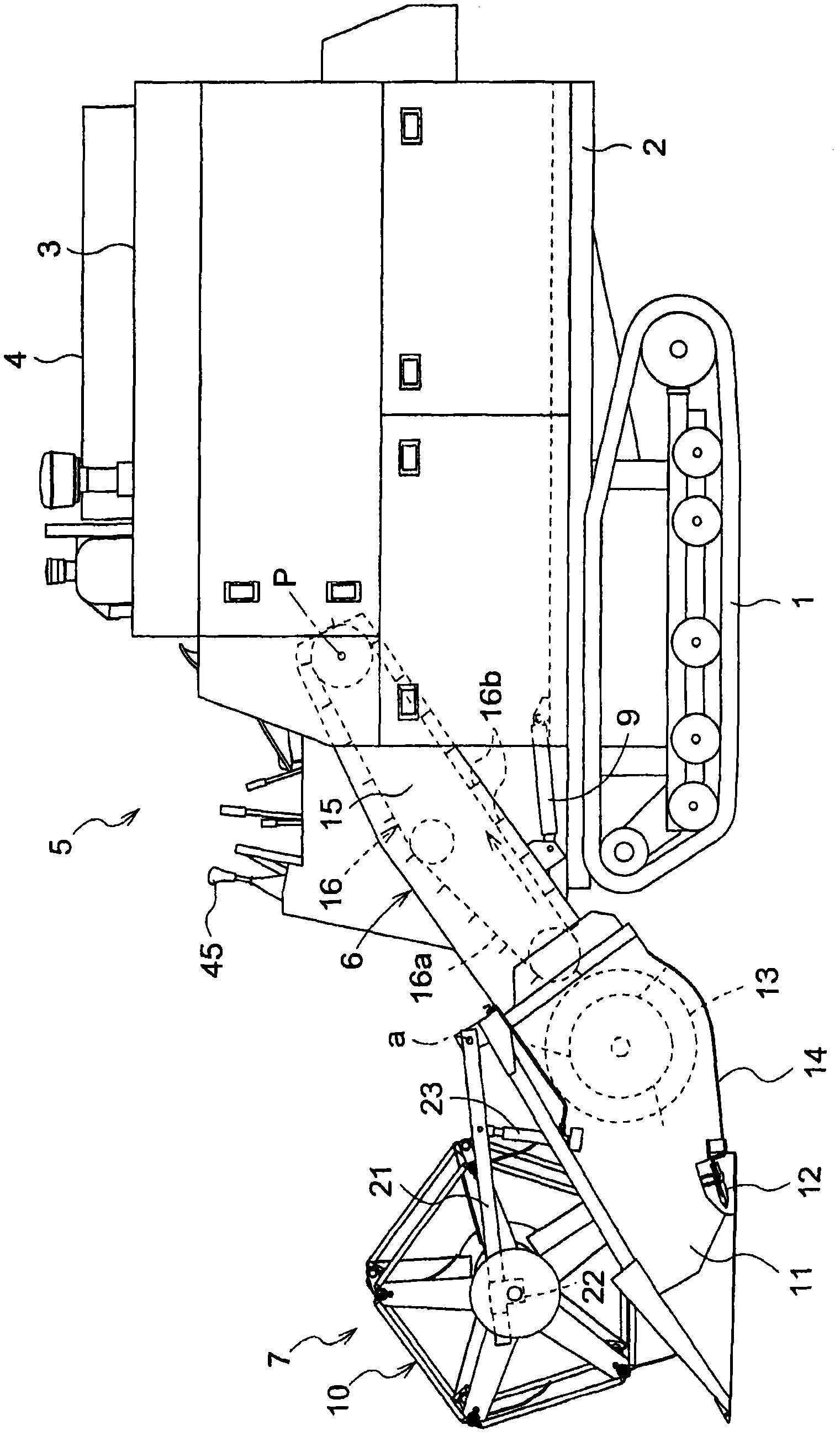

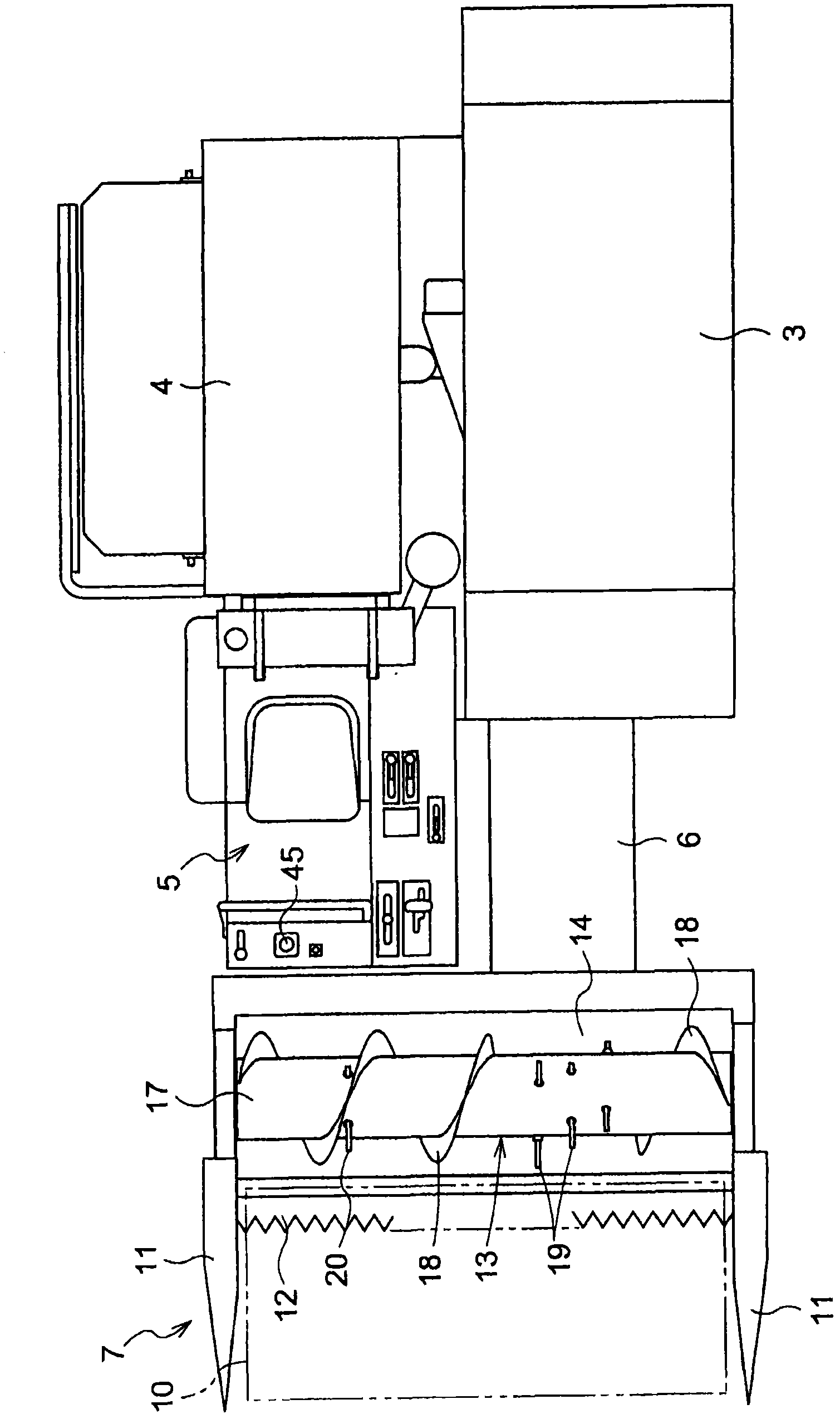

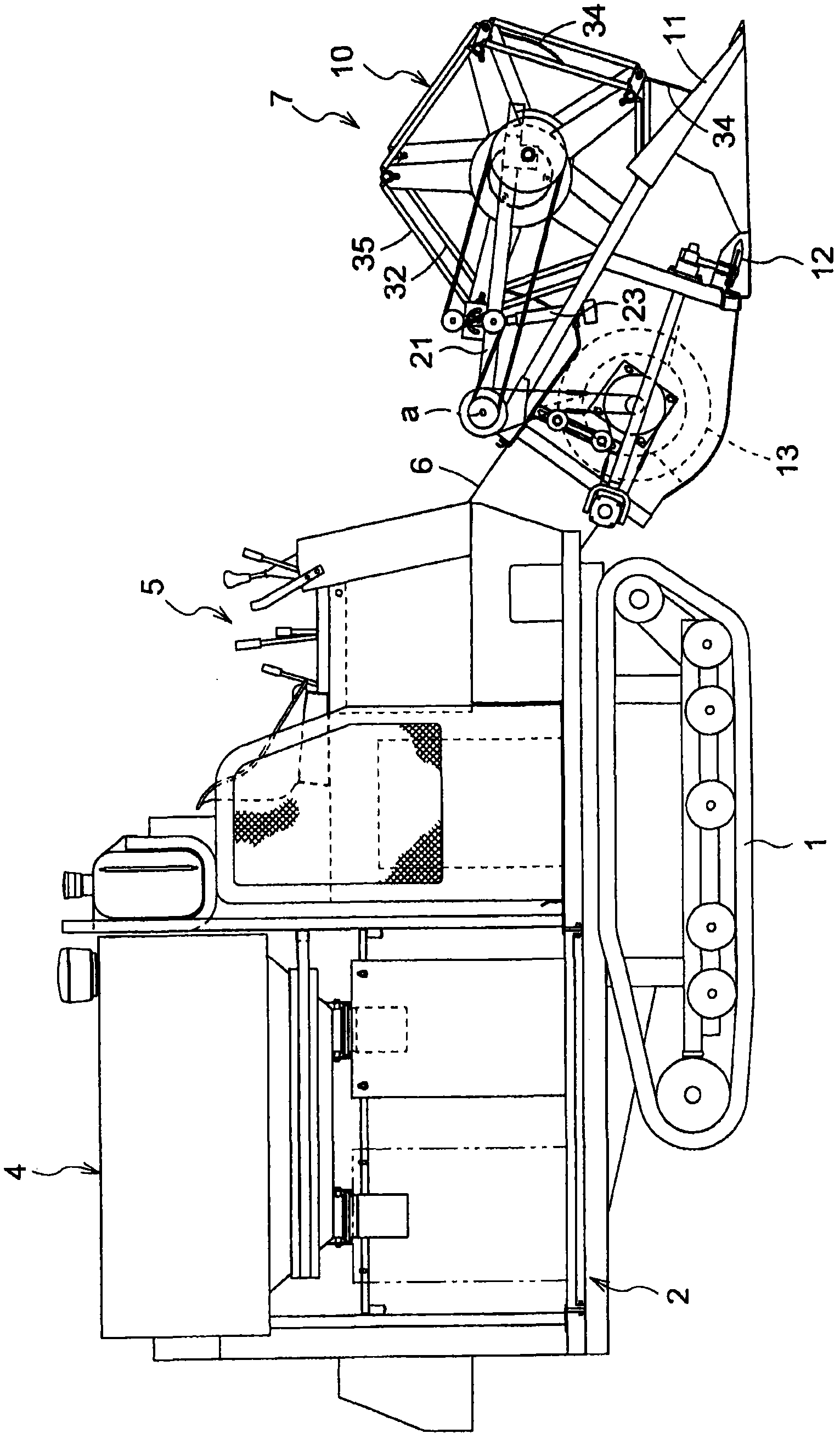

[0074] figure 1 shows the overall side of the common type combine harvester of the present invention, figure 2 Its overall top surface is shown. This combine harvester is equipped with an axial flow type threshing device 3 and a bagging type grain recovery part 4 side by side on the traveling body 2 equipped with a pair of left and right crawler belt traveling devices 1, and the grain recovery part 4 The front of is equipped with driving part 5. In the front part of the threshing device 3, a feeder 6 for conveying harvested straw is connected in a manner to swing freely around the fulcrum P up and down, and a feeder 6 having a harvesting width approximately equivalent to the lateral width of the machine body is connected to the front end of the feeder 6 . The harvesting section 7 is equipped with an engine 8 laterally below the driving section 5 .

[0075] A hydraulic cylinder 9 is erected between the front part of the traveling bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com