A plastic shoe injection molding machine with strong stability

A technology with strong stability and injection molding machines, which can be applied to household appliances, other household appliances, household components, etc., can solve the problems that the injection molding machine cannot screen raw materials, the injection molding chamber cannot be done, and the injection molding machine is unstable, etc., to achieve realization Sealed, safe and convenient to use, time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

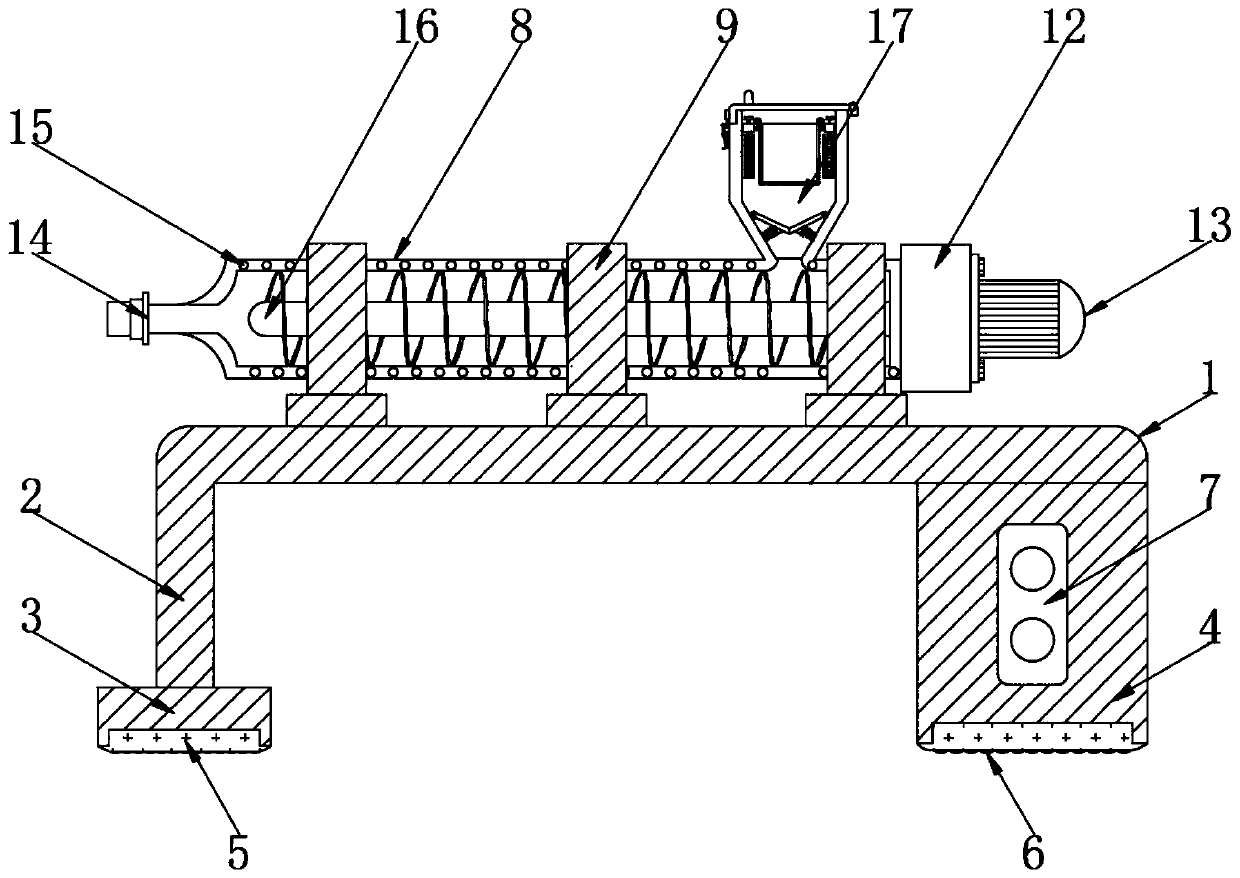

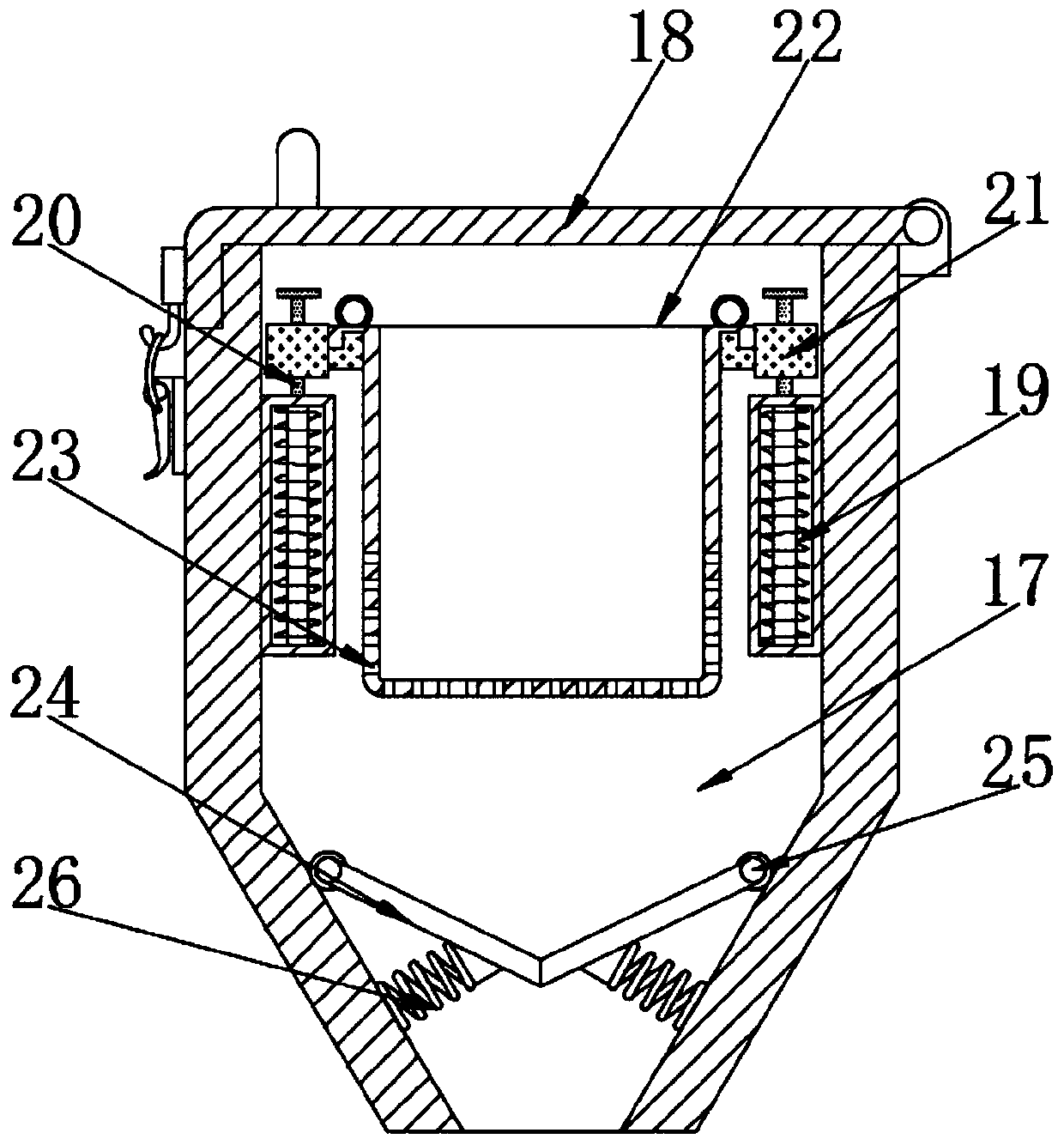

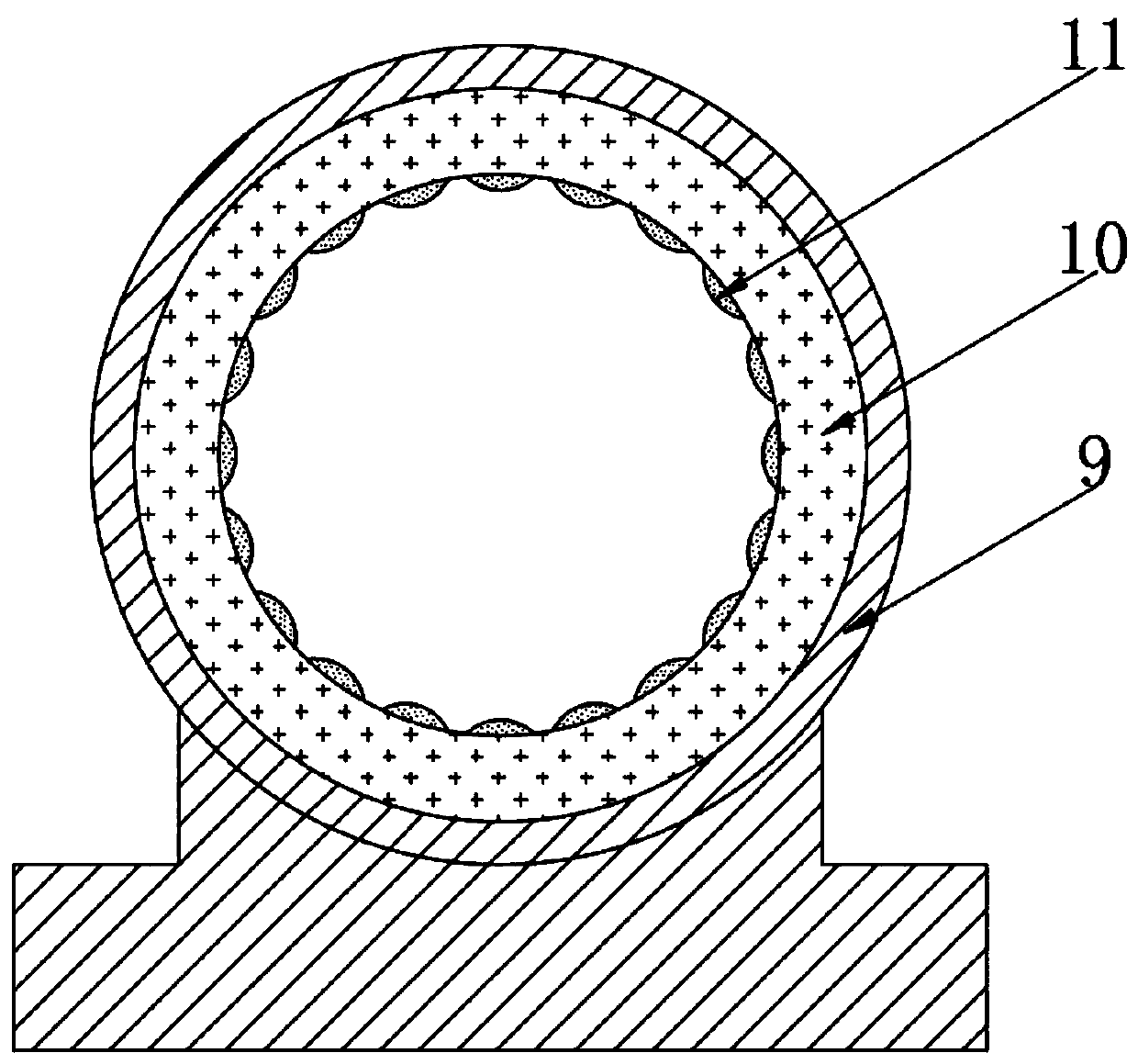

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0023] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a plastic shoe injection molding machine with strong stability, including an injection molding machine body 1, a support rod 2, a support plate 3, a support seat 4, an anti-slip rubber pad 5, an anti-slip pattern 6, a control Switch 7, injection molding chamber 8, fixed ring 9, fixed rubber ring 10, fixed rib 11, reduction gear box 12, drive motor 13, injection port 14, heating tube 15, screw propulsion rod 16, feed port 17, seal Cover 18, electromagnet 19, slide rod 20, magnet 21, screening basket 22, screening hole 23, baffle plate 24, rotating shaft 25 and return sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com