Simple hot pressing method

A simple and iron technology, applied in the field of automatic machinery and equipment, can solve problems such as affecting the relative position of plastic parts and metal parts, complex process equipment, damage to plastic parts, etc., to achieve the effect of simple structure, convenient operation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

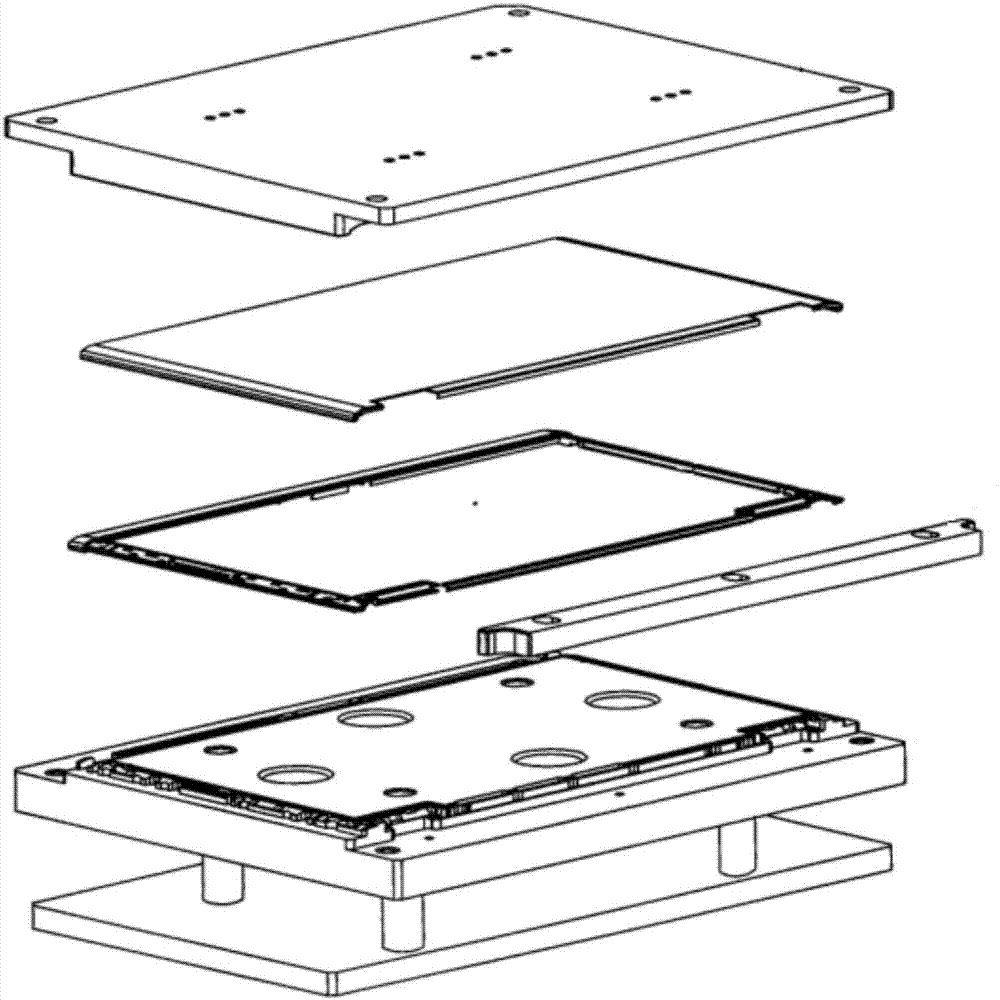

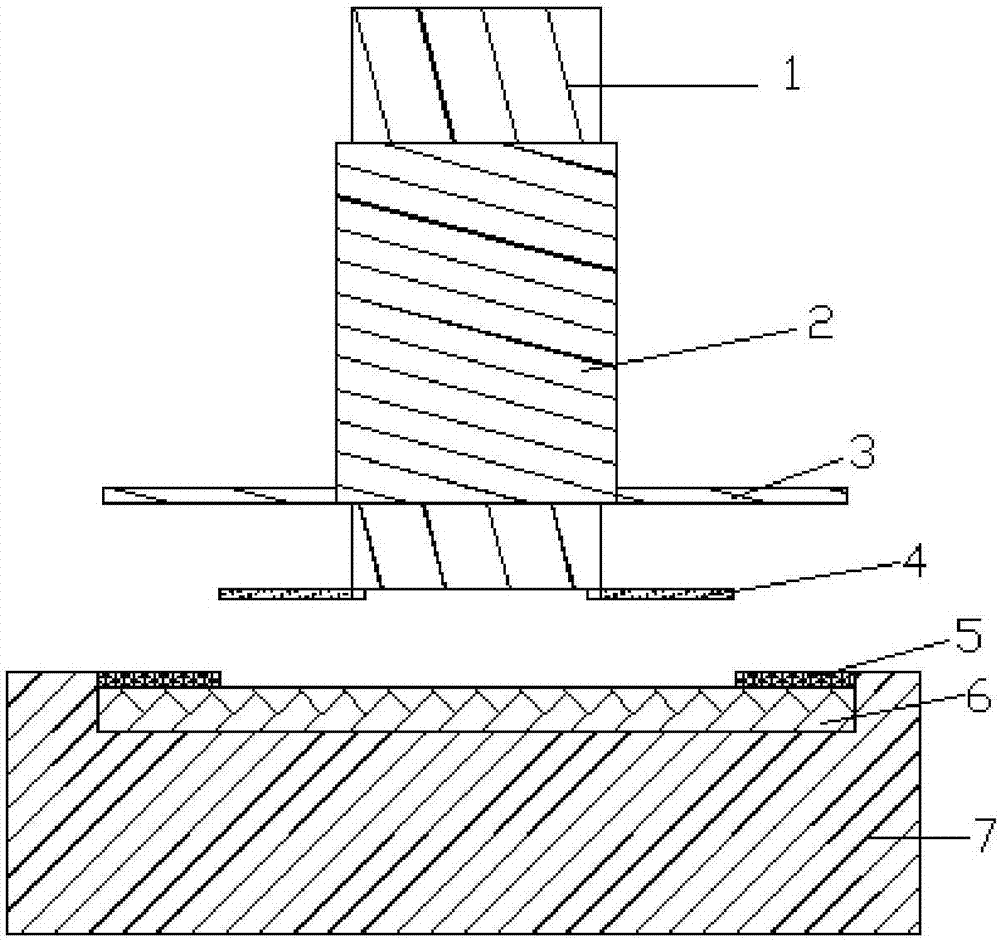

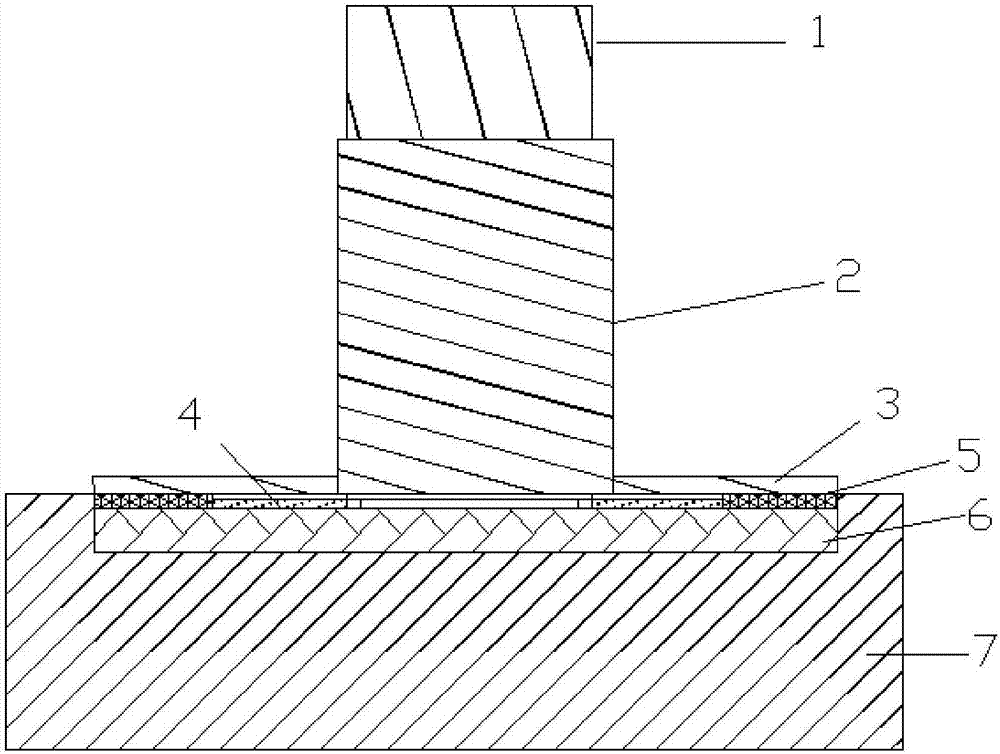

[0032] as attached figure 2 , 3 A simple thermocompression bonding device shown includes a fixed seat, a rotating rod arranged above the fixed seat, and a pressing part, wherein the centerlines of the rotating rod, the pressing part and the fixing seat are on the same straight line ;

[0033] There is a groove on the fixing seat, the depth of the groove is not less than the sum of the height of the iron part and the plastic part, and the groove can realize the limit of the iron part; in specific use, the groove can realize the complete limit of the iron part , can also realize partial limit of plastic parts;

[0034] Such as Figure 4 , 5 The rotating rod shown can rotate around its own axis under the action of external force. The rotating rod is provided with a rotating blade near the end of the fixed seat. The rotating blade can rotate with the rotation of the rotating rod and realize the gluing of pushing the plastic part to the iron part. location;

[0035] The pres...

Embodiment 2

[0049] The difference from Example 1 is that in order to adapt to plastic parts of different specifications, the rotating blade is installed on one end of the rotating rod through the rotating shaft; the rotating blade can rotate within the range of -30°-30° around the rotating shaft (further, The rotating blade is mounted on one end of the rotating rod through the rotating shaft and the torsion spring. The function of the torsion spring is that when the rotating blade rotates around the rotating shaft beyond the range of -30°-30°, it can bring the rotating blade back and make the rotating blade return to its original position). The preferred rotating blades are fan-shaped. When the rotating blades have different angles around the rotating shaft, the linear distance between the rotating blades and the plastic parts will also be different, so that the thermocompression bonding of plastic parts and iron parts of different sizes can be realized.

[0050]Further, there are two rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com