Organosilicon coating rubber for rail transit, and preparation method thereof

A technology of rail transit and organic silicon, which is applied in the field of silicone rubber coating, anti-mildew silicone coating and its preparation, can solve the problems of silicone coating mildew and other problems, and achieve improved mechanical strength, simple operation, and wide The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 70 parts of 107 silicone rubber with a viscosity of 10000mPa·S, treated with silazane, has a specific surface area of 200m 2 Add 15 parts / g of hydrophobic fumed silica and 15 parts of MQ silicone resin into the high-speed mixer, heat up to 160°C and dry for 30 minutes; 3 parts of silane, 3 parts of vinyl tributylketoxime silane and 2 parts of dimethyl dibutylketoxime silane, mixed for 30 minutes under vacuum condition; then add 0.05 part of dibutyltin dilaurate, 1 part of triethoxysilane and 1.5 parts of 2-methyl-4-isothiazolin-3-one (MIT), mixed in vacuum for 40 minutes; finally, packaged and sealed under the protection of inert gas, which can be used in rail transit Anti-mildew silicone coating glue.

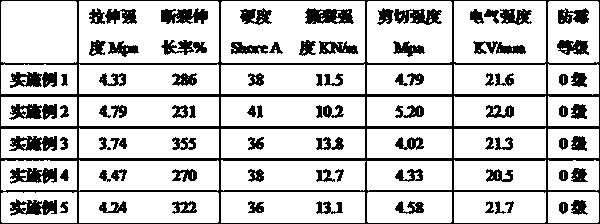

[0052] The obtained silicone coating glue is prepared according to GB / T 528-2009, GB / T 529-2008, GB / T 531-2008, GB / T 7124-2008, GB / T 1695-2005, HG / T4301-2012 Test the tensile strength, elongation at break, tear strength, and Shore A hardness of the mechanical, hardn...

Embodiment 2

[0054] 60 parts of 107 silicone rubber with a viscosity of 5000mPa·S and a specific surface area of 150m after silazane treatment 2 Add 20 parts / g of hydrophobic fumed silica and 20 parts of MQ silicone resin into the high-speed mixer, heat up to 160°C and dry for 20 minutes; 5 parts of silane, 1 part of vinyl tributylketoxime silane and 5 parts of dimethyl dibutylketoxime silane were mixed under vacuum for 30 minutes; then 0.1 part of dibutyltin dioctoate, N-(β- 1.5 parts of aminoethyl)-γ-aminopropyltrimethoxysilane and 2 parts of 2-n-octyl-4-isothiazolin-3-one (OIT), mixed in vacuum for 30min; finally, under the protection of inert gas The lower package is sealed, and the anti-mildew silicone coating glue for rail transit is obtained.

[0055] The obtained silicone coating glue is prepared according to GB / T 528-2009, GB / T 529-2008, GB / T 531-2008, GB / T 7124-2008, GB / T 1695-2005, HG / T4301-2012 Test the tensile strength, elongation at break, tear strength, and Shore A hardn...

Embodiment 3

[0057] Add 80 parts of 107 silicone rubber with a viscosity of 20000mPa·S, 10 parts of hydrophilic fumed silica and 10 parts of MQ silicone resin into a high-speed mixer, heat up to 160°C and dry for 25 minutes; then move it into a planetary mixer to vacuum and defoam for 60 minutes , then add 6 parts of methyl triacetone oximino silane and 1 part of dimethyl diacetone oximino silane, mix under vacuum condition for 60 min; then add 0.1 part of dibutyltin dilaurate, γ-aminopropyl triethyl 2 parts of oxysilane, 2 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane and 0.8 part of 1,2-benzisothiazolin-3-one (BIT), mixed in vacuum for 60 minutes; Finally, it is packaged and sealed under the protection of an inert gas, and the anti-mold silicone coating glue for rail transportation is obtained.

[0058] The obtained silicone coating glue is prepared according to GB / T 528-2009, GB / T 529-2008, GB / T 531-2008, GB / T 7124-2008, GB / T 1695-2005, HG / T4301-2012 Test the tensile strength, el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com