Transparent roller for laser imprinting and laser imprinting device

A transparent roller and laser technology, used in printing, stamping and other directions, can solve the problems of low pattern surface quality, long process route, low efficiency, etc., and achieve the effect of not easy to wrinkle, ensure high quality, and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

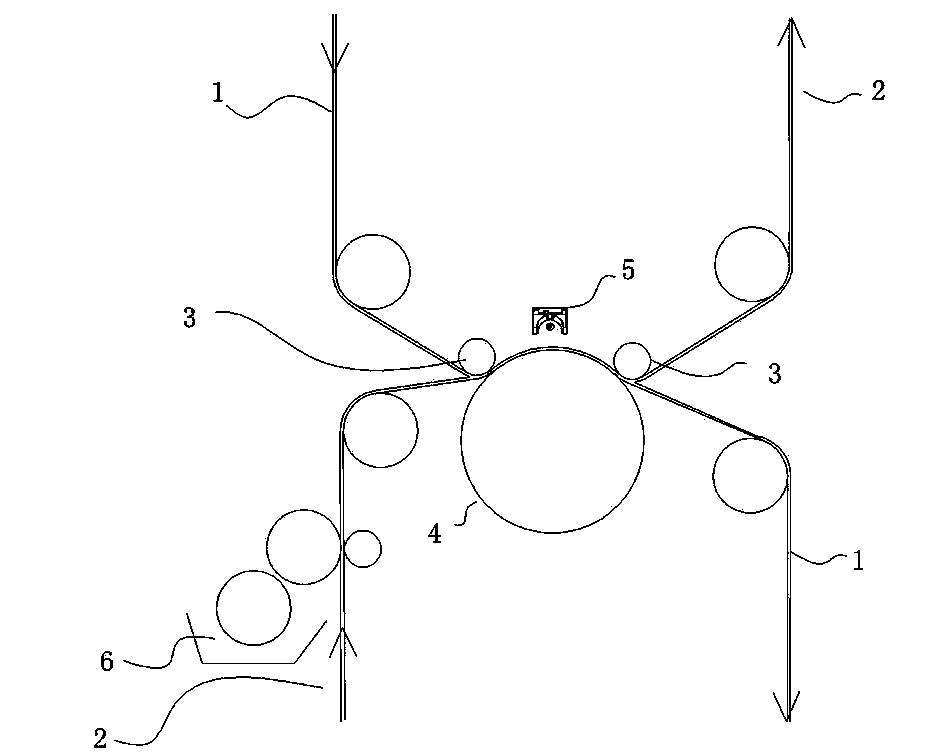

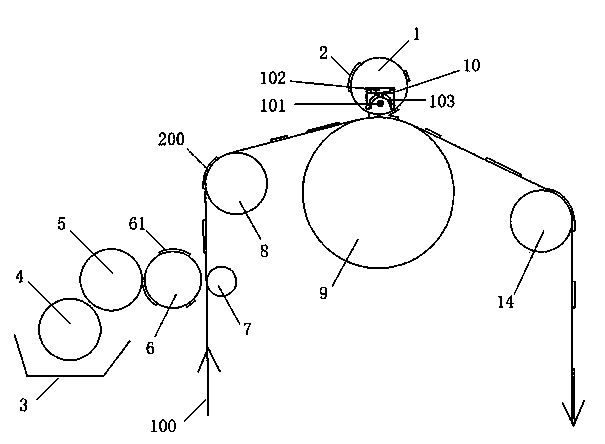

[0068] see image 3 , the present invention provides a first embodiment of a laser imprinting device, including: a medium printing device for printing a medium 200 on a substrate 100, and for embossing a laser pattern on the substrate 100 The embossing transfer device on the top, and the take-up roller 14. Wherein, the medium printing device includes: a medium loading device 3 for loading the medium 200; at least one transmission roller arranged on the medium loading device 3, in this embodiment, the transmission roller includes two One, respectively the first transfer roller 4 and the second transfer roller 5; a printing roller 6 and a printing roller 7 for printing the medium 200 on the substrate 100, and the printing roller 6 is provided with at least one printing plate 61 . The imprint transfer device includes a pressure roller 9 , a transparent roller 1 and an ultraviolet curing device 10 .

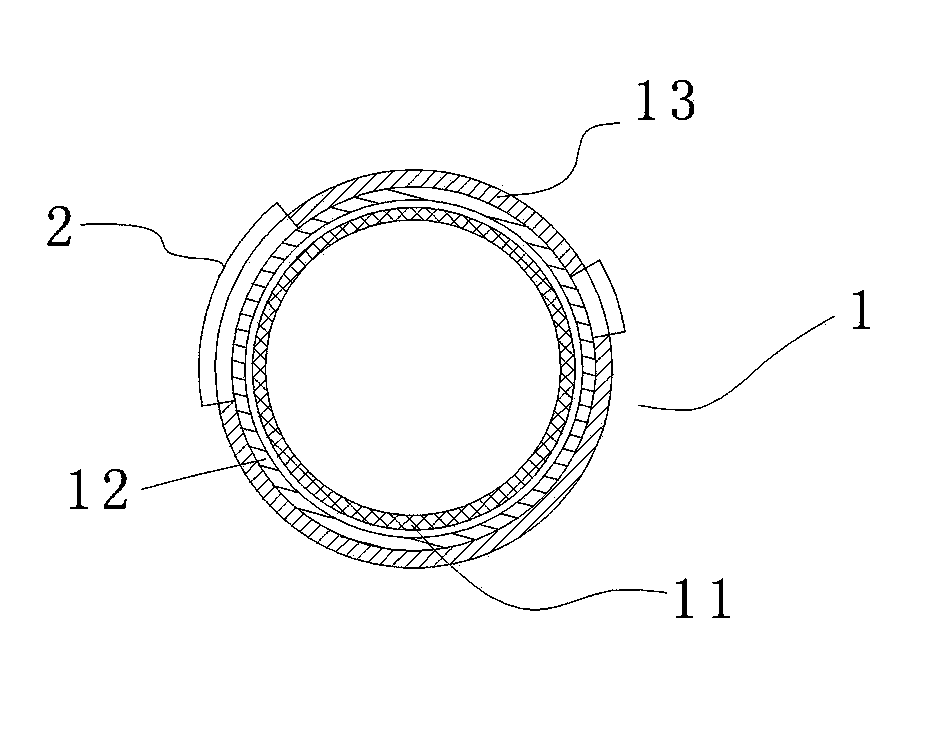

[0069] The transparent roller 1 includes a roller body, a hub and a roller sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com