Patents

Literature

31results about How to "Less prone to wrinkling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood drying process

InactiveCN105202870AIncrease temperatureIncrease moisture contentDrying solid materials with heatHearth type furnacesSurface stressHigh humidity

The invention discloses a wood drying process. The wood drying process comprises the steps of 1, preheating; 2, high-temperature and high-humidity treatment; 3, drying; 4, maintenance. When the wood drying process is adopted for drying wood, the surface stress and internal stress of wood can be eliminated, surface cracking or internal cracking of wood can be prevented, the original quality of wood is maintained, defects such as air shrinkage, bending, crinkling and deformation do not occur easily, the rate of wood damage caused by improper drying is reduced greatly, and meanwhile, energy is saved and drying time is shortened.

Owner:王璐

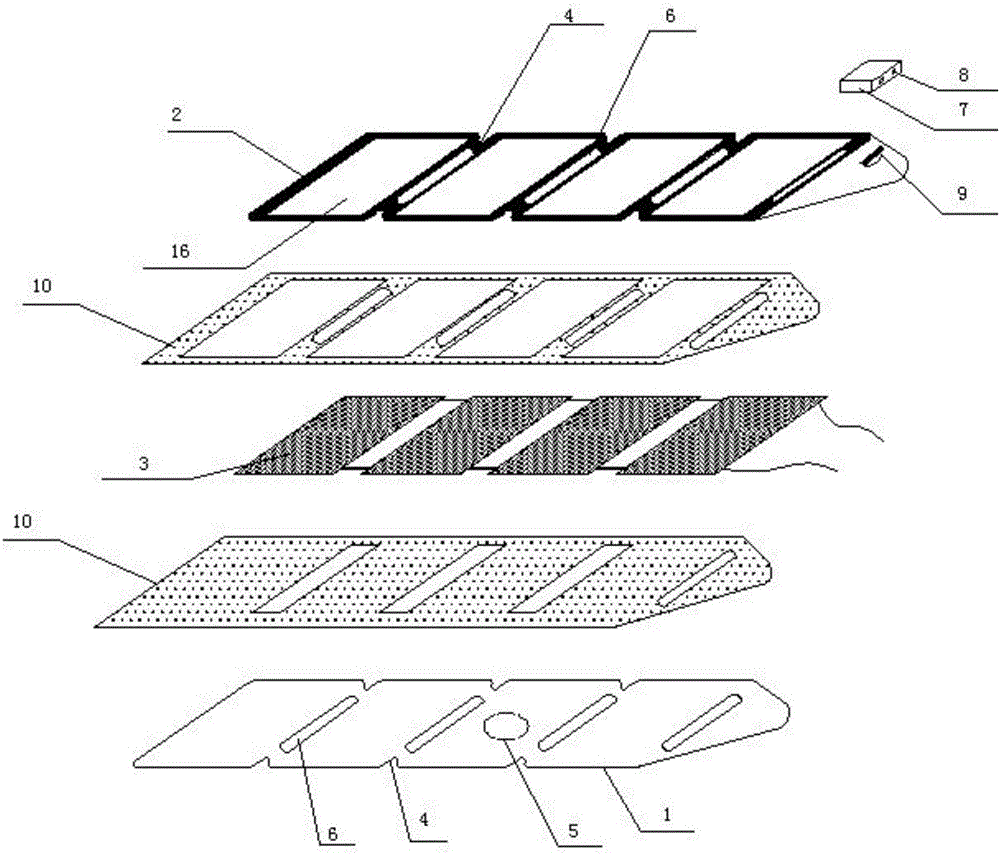

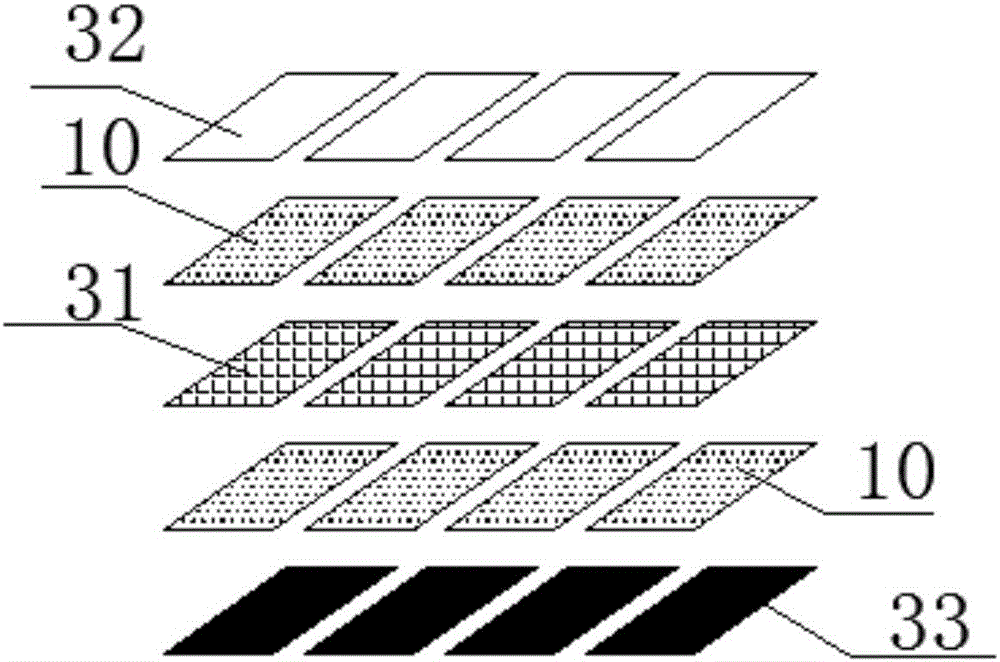

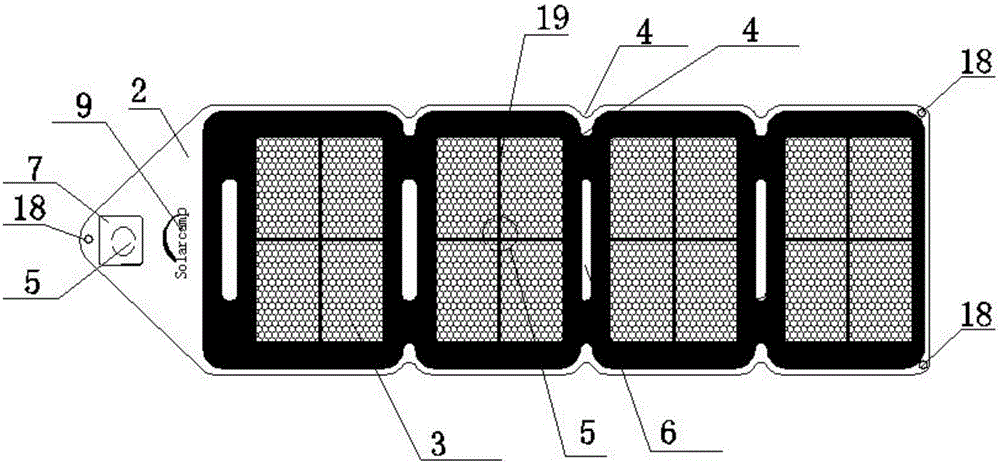

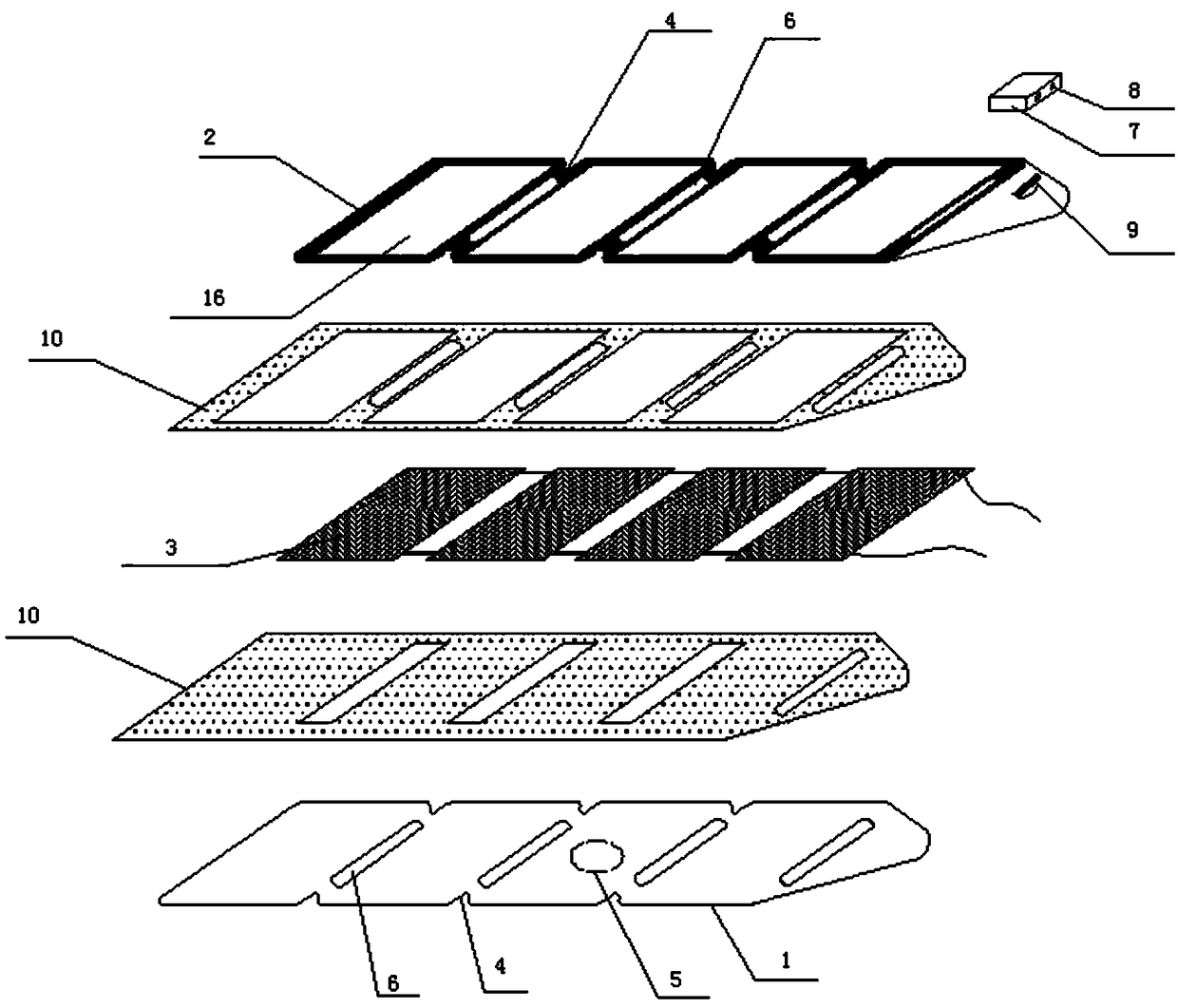

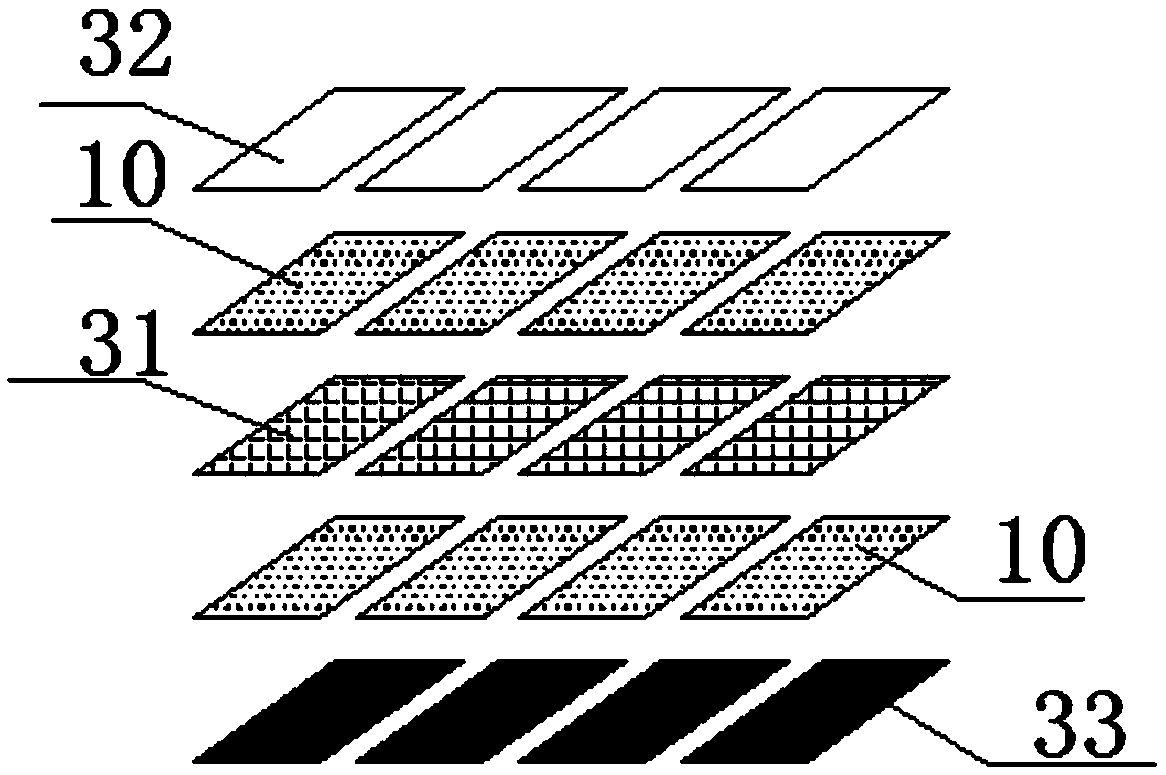

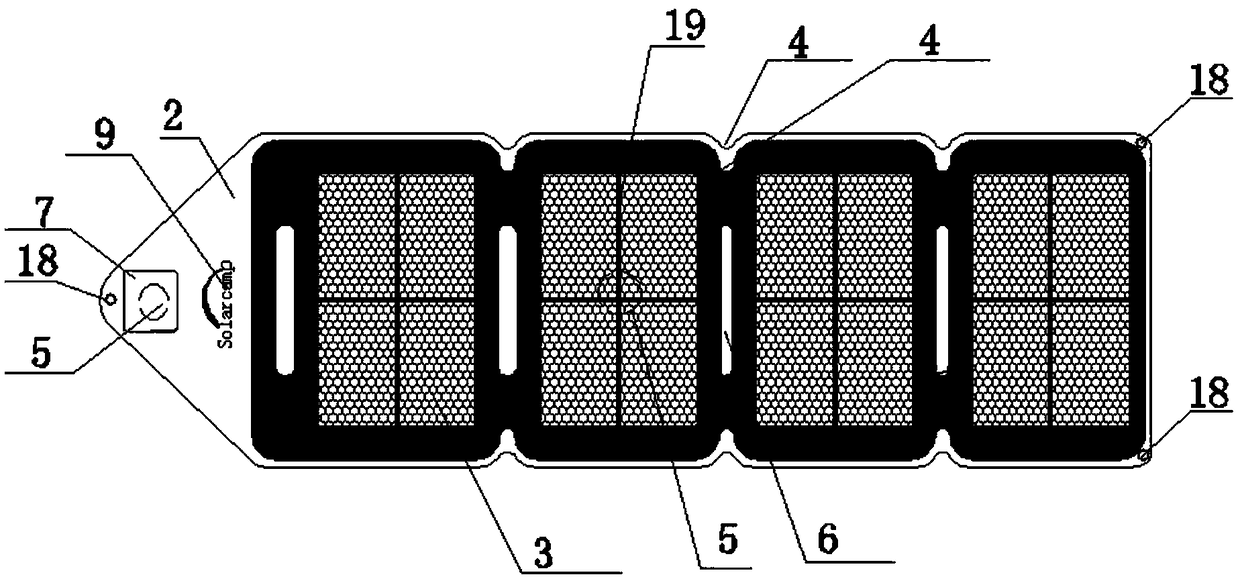

Flexible thin film folded dazzling solar charger and fabrication process thereof

ActiveCN106653908AAbsorb sunlight wellGood waterproof protectionBatteries circuit arrangementsPhotovoltaicsSolar chargerEngineering

The invention discloses a flexible thin film folded dazzling solar charger and a fabrication process thereof, and relates to the field of a solar charger. The flexible thin film folded dazzling solar charger comprises an upper package dazzling cloth layer, a flexible thin film solar cell module layer and a lower package dazzling bottom layer, wherein the flexible thin film solar cell module layer is arranged between the upper package dazzling cloth layer and the lower package dazzling bottom layer by a package adhesive film, a plurality of U-shaped gaps are formed in both of two sides of the upper package dazzling cloth layer and the lower package dazzling bottom layer, the U-shaped gaps are arranged at positions where adjacent flexible thin film solar cell modules are connected, and a waist-shaped hole is formed between opposite U-shaped gaps and penetrates through the upper package dazzling cloth layer and the lower package dazzling bottom layer. By such a design, the flexible thin film folded dazzling solar charger has versatile functions, is attractive, is easy to fold and carry and is light in weight.

Owner:虎瑞玲

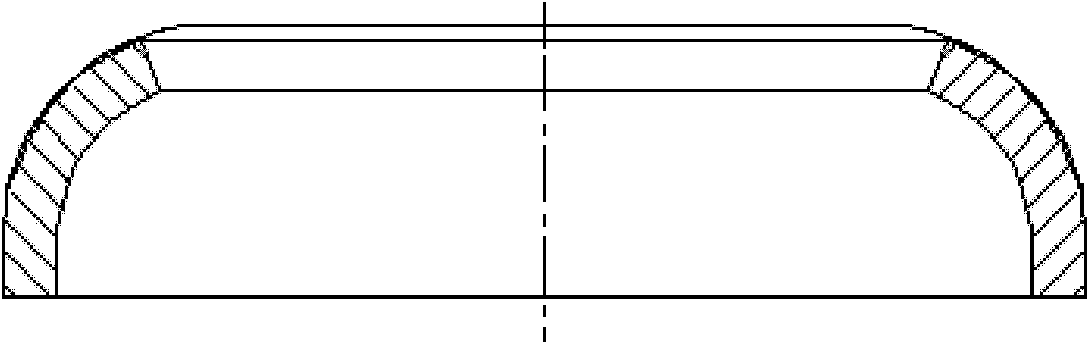

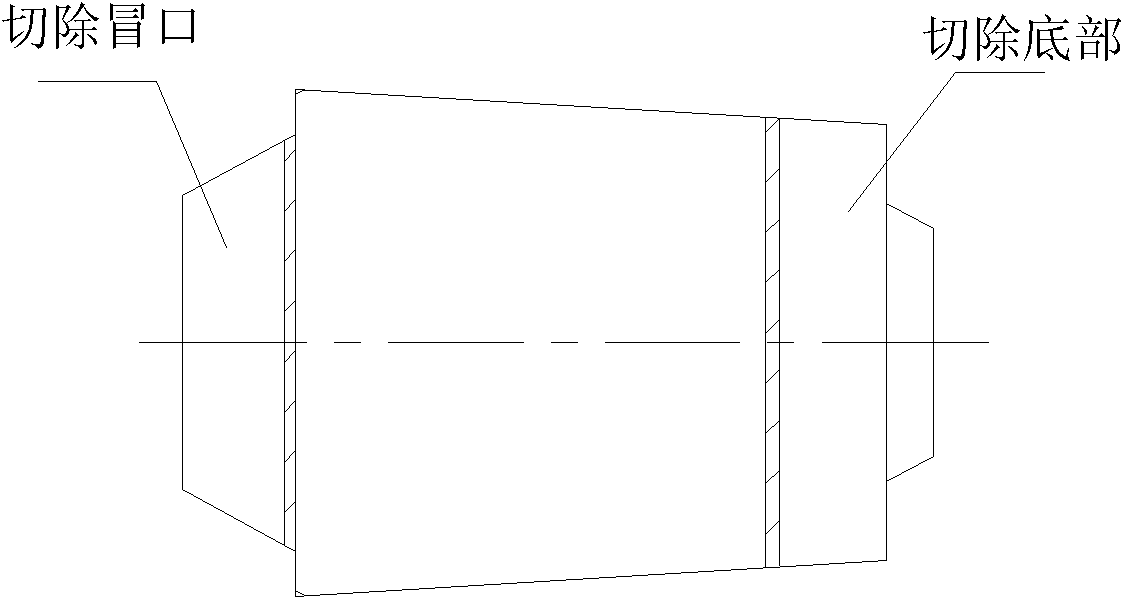

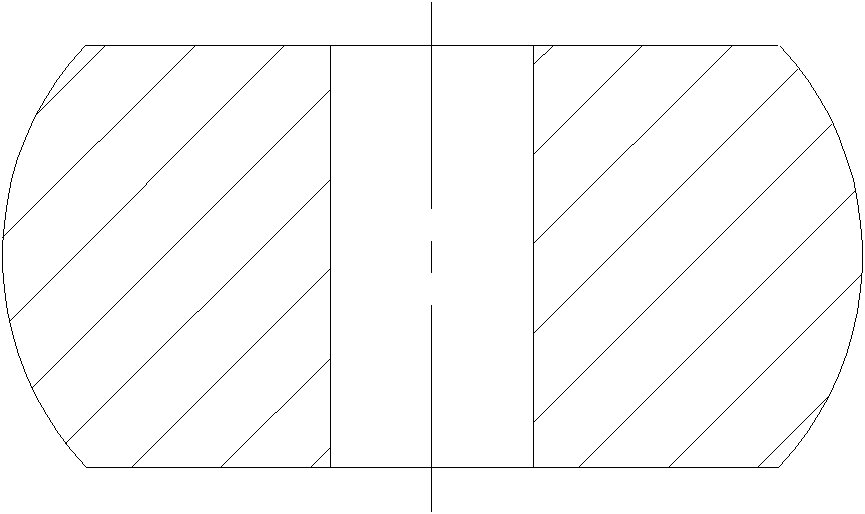

Forging method for ellipsoidal head ring forge piece of third generation nuclear power plant steam generator

The invention discloses a forging method for an ellipsoidal head ring forge piece of a third generation nuclear power plant steam generator. The manufactured forge piece comprises a bending section and a straight section; the forging method is executed by using a megaton-level free forging press, forging a dual-vacuum steel ingot into a whole straight section and then forging the straight section into the bending section by rotary die pressing by a die; the forging process comprises the following steps of: firstly, cogging: cutting a feeder head and a bottom from the dual-vacuum steel ingot; secondly, upsetting: heating work pieces to be 1220 plus or minus 20 DEG C, so that the heights of the work pieces are reduced and the diameters of the work pieces are increased after the work pieces are subjected to upsetting; thirdly, chambering: heating the work pieces to be 1220 plus or minus 20 DEG C, so that the wall thicknesses of the work pieces are reduced and the diameters of the work pieces are increased after the work pieces are subjected to chambering; and fourthly, carrying out a rotary die pressing process: heating the work pieces to be 1200 plus or minus 20 DEG C, so that the diameters of the work pieces are reduced and the wall thicknesses of the work pieces are increased after the work pieces are subjected to the rotary die pressing process. By adopting a forge piece forged by the forging method, dense material, reasonable distribution of a metal flow line and low possibility of cracking of the ellipsoidal head ring forge piece can be guaranteed.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

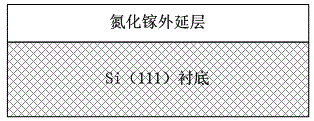

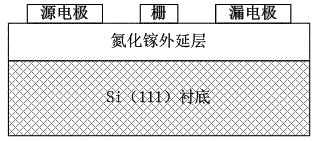

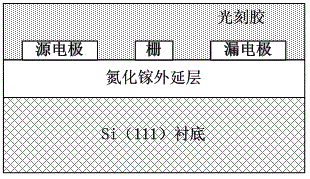

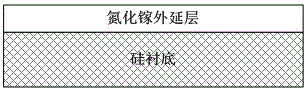

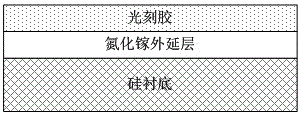

Method for making gallium nitride high electron-mobility transistor on silicon slice

InactiveCN104465373AQuality improvementBreak the inherent limitationsSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingLattice mismatch

The invention provides a method for making a gallium nitride high electron-mobility transistor on a silicon slice of a crystal face (100). The method includes the steps that (1) an epitaxial layer material of the gallium nitride high electron-mobility transistor grows on the silicon slice of a crystal face (111) through MOCVD in an epitaxial mode; (2) the making process of the gallium nitride high electron-mobility transistor is conducted; (3) spin coating and etching are conducted on a rubber protection device structure, and a wafer is temporarily arranged on a carrier piece in a bonding mode; (4) corrosion is conducted, (5) the exposed gallium nitride epitaxial layer is provided with a BCB in a spin coating mode; (6) natural cooling is conducted and thermocompression bonding is conducted in a bonder; (7) the temporary carrier piece is removed, and the front face of the wafer is cleaned thoroughly. The method has the advantages that the gallium nitride high electron-mobility transistor can be made on the face of the Si (100), the process is simple, the yield is high, and the problem that due to lattice mismatch, the epitaxial layer material of the gallium nitride high electron-mobility transistor cannot grow on the face of the Si (100) directly in an epitaxial mode is solved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

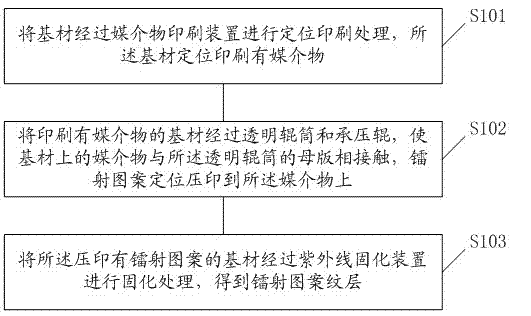

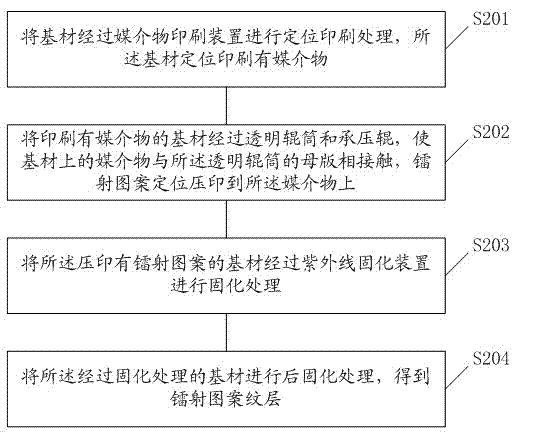

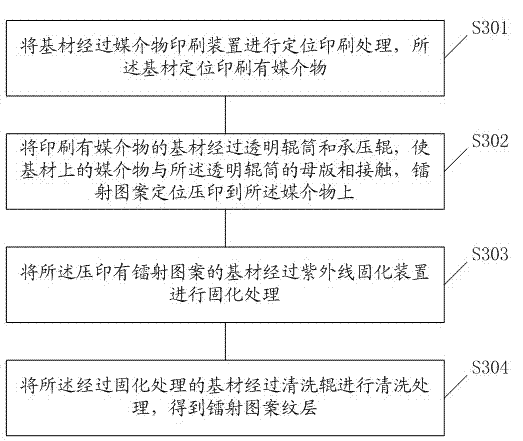

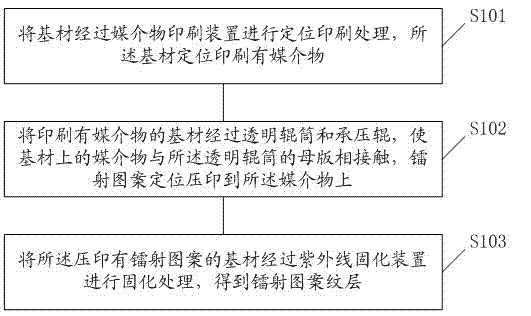

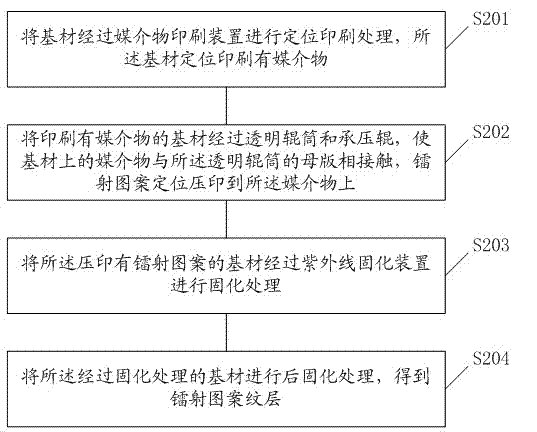

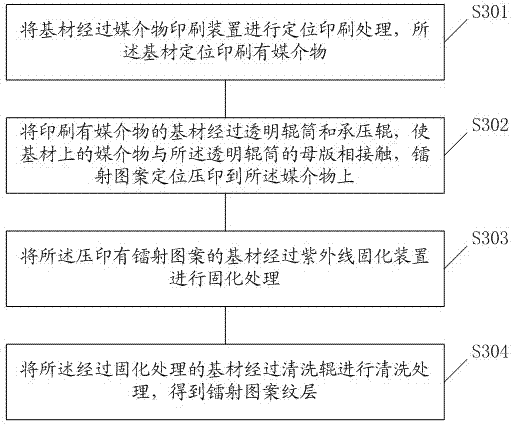

Laser pattern positioning impression transfer method

ActiveCN103707670AQuality improvementSimplify process production routePrinting after-treatmentInk transfer from master sheetUV curingLaser patterning

The invention discloses a laser pattern positioning impression transfer method. The method comprises the following steps: carrying out positioning printing treatment of a substrate through an intermedium printing device to obtain an intermedium position-printed substrate; allowing the intermedium position-printed substrate to go through a transparent roller and a bearing roller to make the intermedium on the substrate contact with a mother matrix of the transparent roller in order to impress a laser pattern on the medium in a positioning manner; and curing the substrate impressed with the laser pattern through an ultraviolet curing device to obtain a laser pattern laminae. The method has the advantages of realization of the point-to-point position special edition pattern impression transfer, elimination of the ghost phenomena of four edges of the transferred pattern, increase of the impression transferred pattern precision, and improvement of the surface quality of the pattern.

Owner:广东依明机械科技有限公司

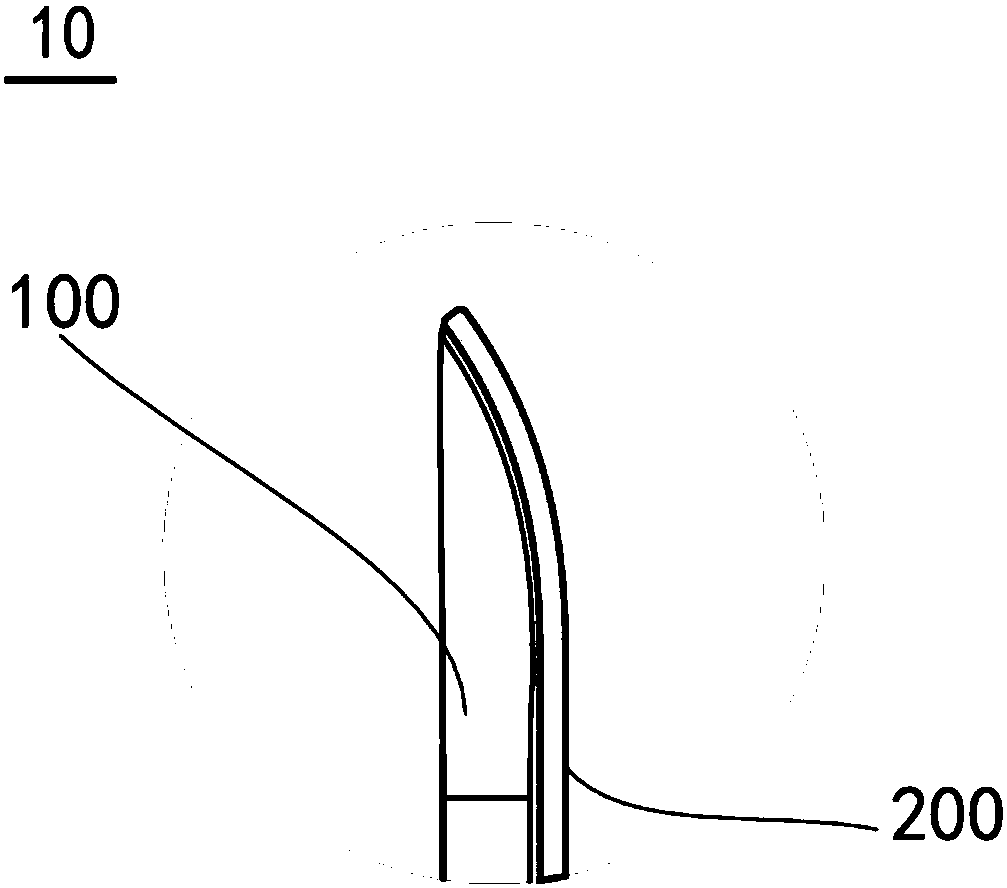

Method for sticking three-dimensional (3D) glass with decorative film assembly, and 3D laminated glass

PendingCN108215223AIncreased surface curvature rangeLow costSynthetic resin layered productsGlass/slag layered productsEngineeringSilica gel

The invention discloses a method for sticking three-dimensional (3D) glass with a decorative film assembly, and the 3D glass. The method for sticking the 3D glass with the decorative film assembly comprises the following steps: heating and pressurizing the decorative film assembly, wherein the heating temperature is 90-110 DEG C, the pressurizing pressure is 0.4-0.6MPa, and the time is 50-70S; positioning the heated and pressurized decorative film assembly and the 3D glass to form a positioned intermediate; transferring the positioned intermediate onto a silica gel mould for shaping so as to form a shaped intermediate; tearing off release film on the shaped intermediate to form a film-free intermediate; sticking the film-free intermediate under the vacuum condition to form a stuck intermediate; defoaming the stuck intermediate under the condition of high pressure to obtain the 3D laminated glass. The method for sticking the 3D glass with the decorative film assembly is high in yield and low in cost.

Owner:MAXFORD TECH LTD +1

Electroplating method for automobile trunk decoration strip

The invention provides an electroplating method for a trim strip of an automobile trunk, which includes electroplating pretreatment and electroplating, wherein the electroplating pretreatment includes performing the following steps in sequence: ultrasonic wax removal, ultrasonic oil removal, pre-roughening, hydrophilic treatment, roughening treatment, Neutralization treatment, surface adjustment treatment, pre-soaking treatment, activation, acid solution glue, alkali solution glue, electroless nickel plating; electroplating the substrate that has completed the electroplating pretreatment, electroplating includes performing the following steps in sequence: watt nickel plating, Acid copper plating, primary high-sulfur nickel plating, semi-gloss nickel plating, secondary high-sulfur nickel plating, light nickel plating, primary microporous nickel plating, pre-plating nickel plating, pearl nickel plating, secondary microporous nickel plating, triple plating Valence white chromium, trivalent black chromium plating, electrolytic activation, chrome plating, and passivation treatment. The process coefficients in each step are controlled to make the coating of the obtained plated parts stable and uniform, so that the coating is stable and not brittle, and the plating The parts are not prone to wrinkling, foaming, delamination and cracking, and have good corrosion resistance and strength.

Owner:珠海市春生五金工业有限公司

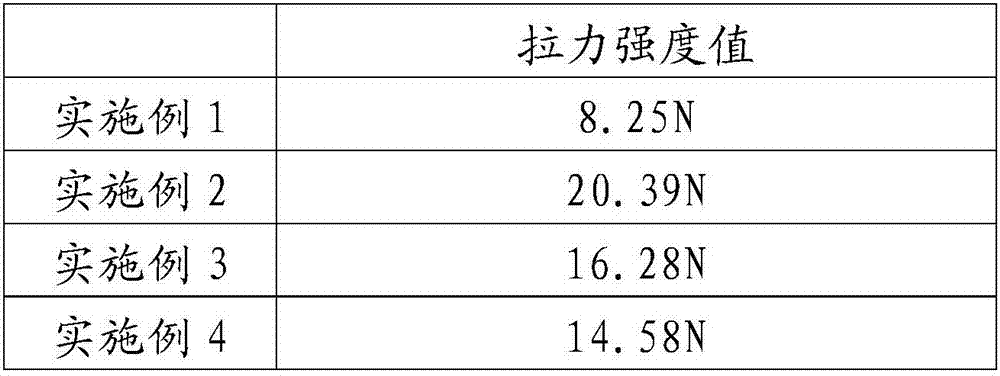

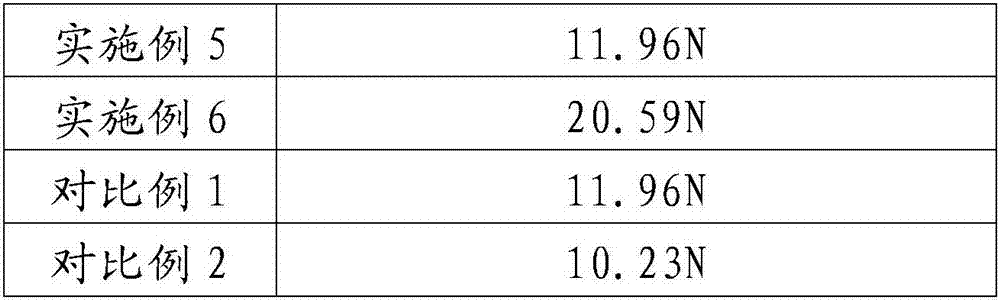

Preparation method for glutinous-rice adhesive with insusceptibility to wrinkling and good adhesion for paper lantern

InactiveCN107828352AImprove frost resistanceLess prone to wrinklingNon-macromolecular adhesive additivesStarch adhesivesEpoxyFiber

The invention discloses a preparation method for a glutinous-rice adhesive with insusceptibility to wrinkling and good adhesion for a paper lantern. The preparation method comprises the following steps: uniform mixing glutinous rice flour, starch sodium octenylsuccinate and water under stirring, adding Tween 60 and urea, and carrying out heating under stirring so as to obtain a first prefabricatedmaterial; uniformly mixing lignin fiber, diatomite and acetone, adding epoxidized soybean oil, carrying out uniform mixing under stirring, adding coco-hydroxyethyl sodium sulfate, water and maltitol,and carrying out heating under stirring so as to obtain a second prefabricated material; and adding the second prefabricated material, an epoxy resin adhesive, an antifoaming agent, glycol and a bactericide into the first prefabricated material, and carrying out uniform mixing so as to obtain the glutinous-rice adhesive with insusceptibility to wrinkling and good adhesion for the paper lantern. The glutinous-rice adhesive prepared by using the preparation method provided by the invention has high adhesion force; paper adhered by the glutinous-rice adhesive is not liable to generate the phenomenon of wrinkling after curing; meanwhile, the glutinous-rice adhesive has good toughness and high tensile strength, can effectively avoid artistic appearance of paper from decreasing due to high hardness after curing, has good wetting effect at the same time, and effectively prevents the phenomenon of crusting from occurrence.

Owner:望江县红和木业灯饰有限公司

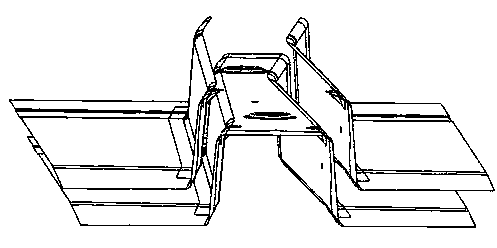

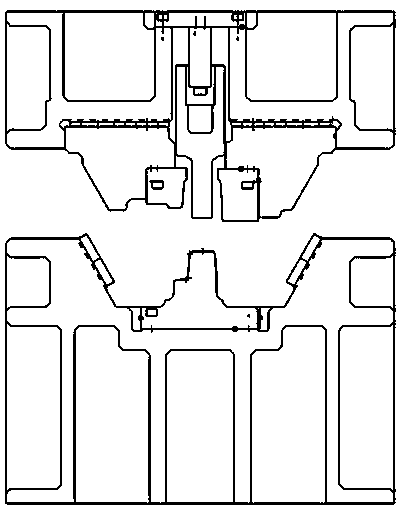

Method for stamping automobile beam piece

The invention relates to a method for stamping an automobile beam piece. A flanging process and a side rectifying process are adopted instead of the conventional drawing process; in the flanging process, a gap between a flanging cutter block and a male die is adjusted, and is 10-20 millimeters; in the side rectifying process, and the rectifying angle is 45-60 degrees. According to the method, the utilization ratio of materials is increased; a blanking die is used, so that the trimming procedure of a subsequent trimming die is reduced or the trimming die is removed; and the part quality is ensured by using the characteristics of a flange side rectifying composite die, and meanwhile the rectification of a rebounding section is facilitated. A first-order die can be reduced through flange composite side trimming, so that the die cost is saved by 10 percent; compared with direct molding, the flange side trimming composite procedure has the advantage that the defect of corrugation of parts can be reduced; and parts are shaped finally by side shaping, so that the rebounding correction of parts is facilitated.

Owner:YESUN SHANGHAI MOLD

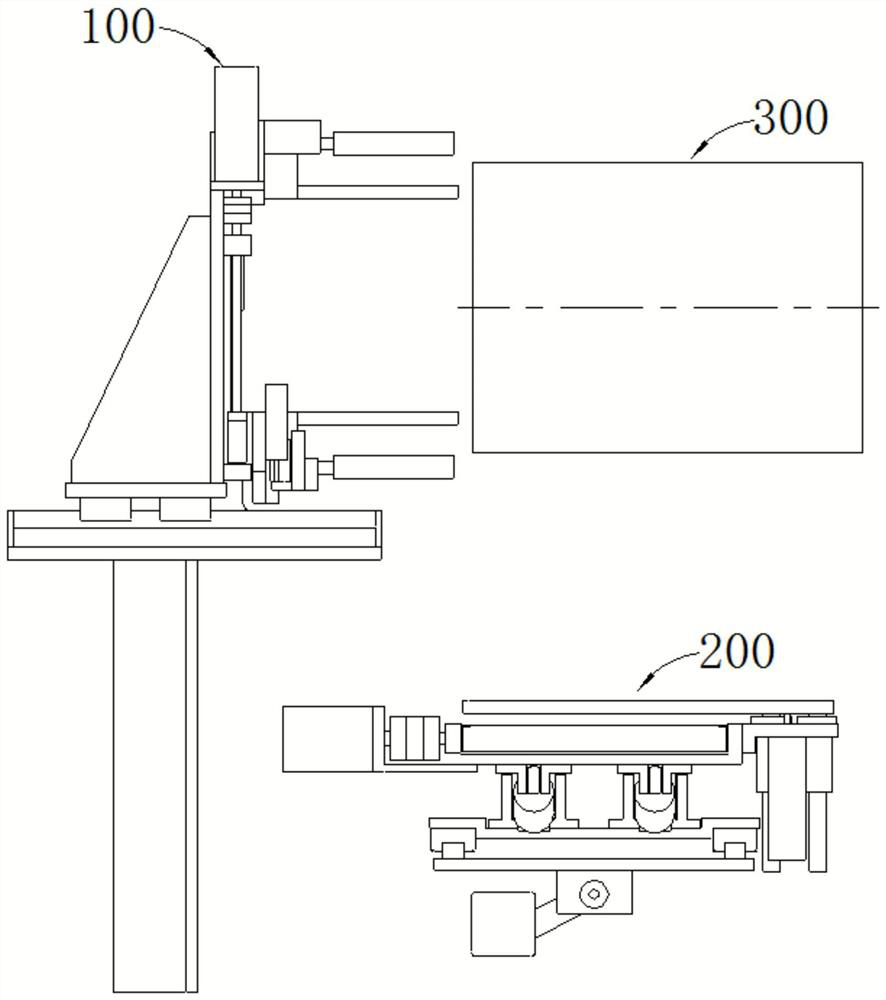

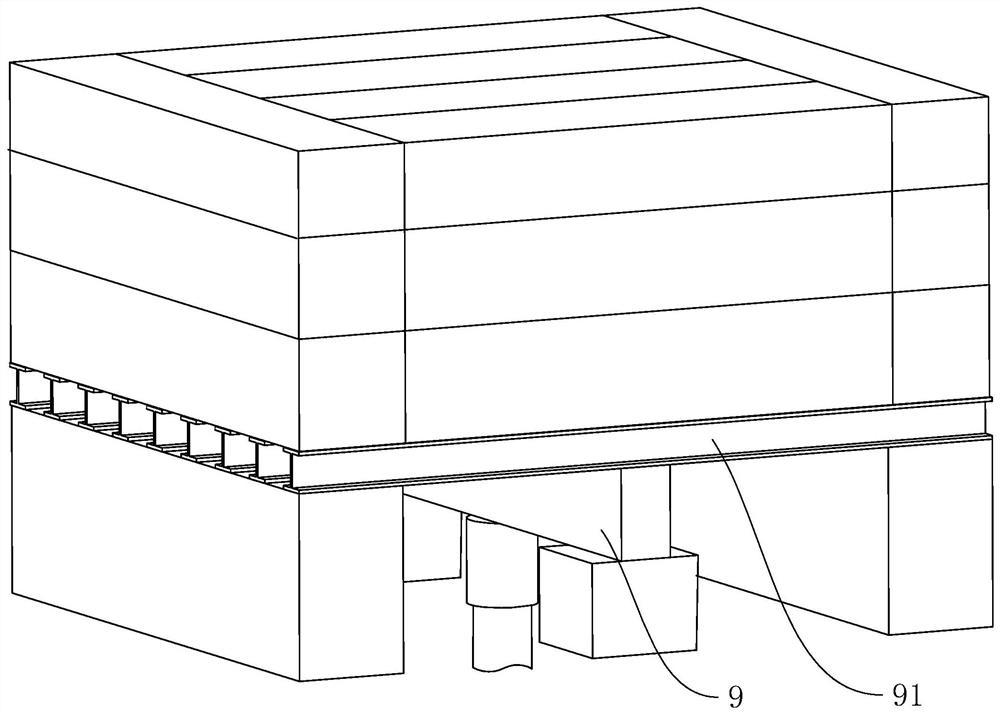

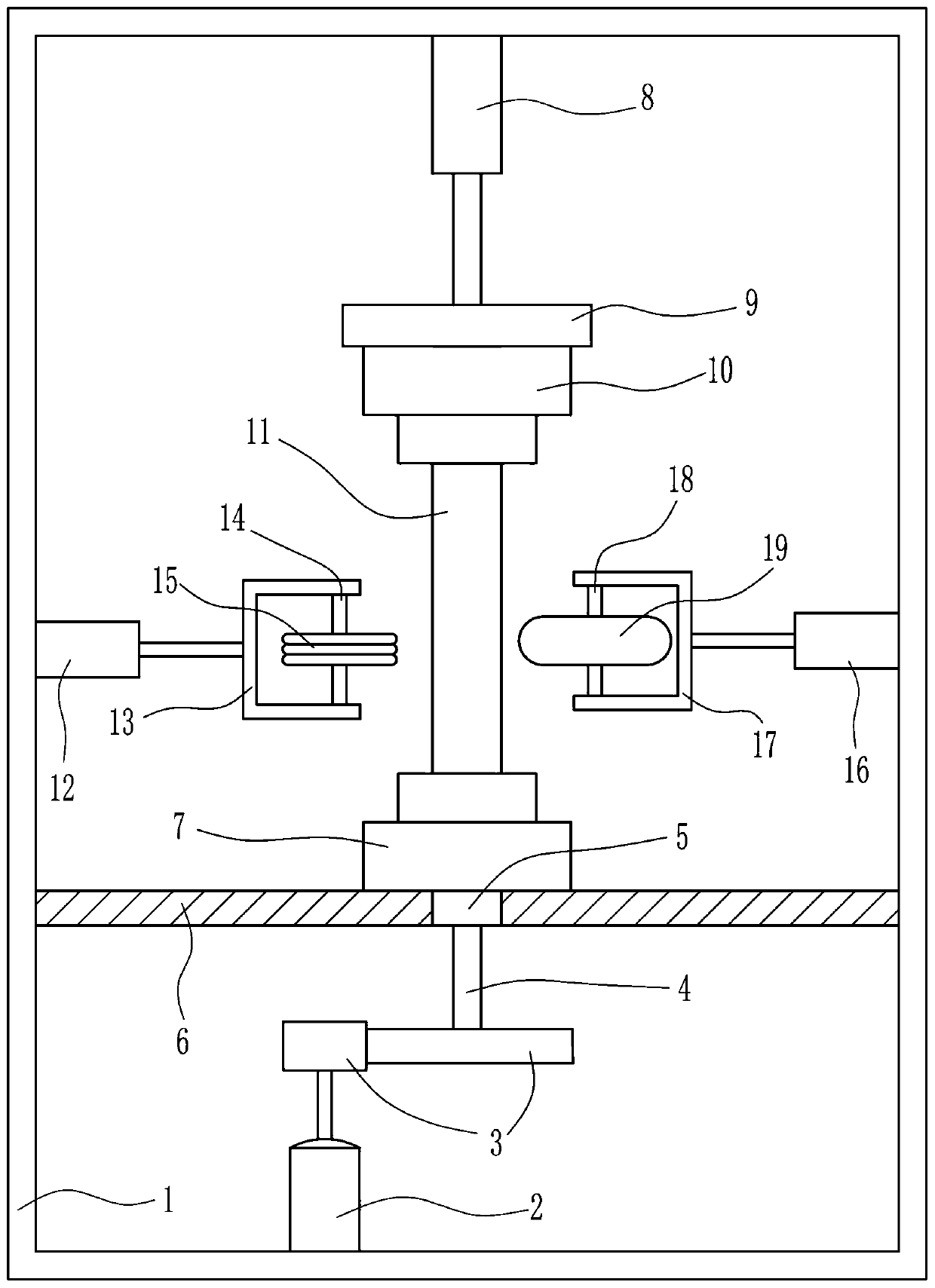

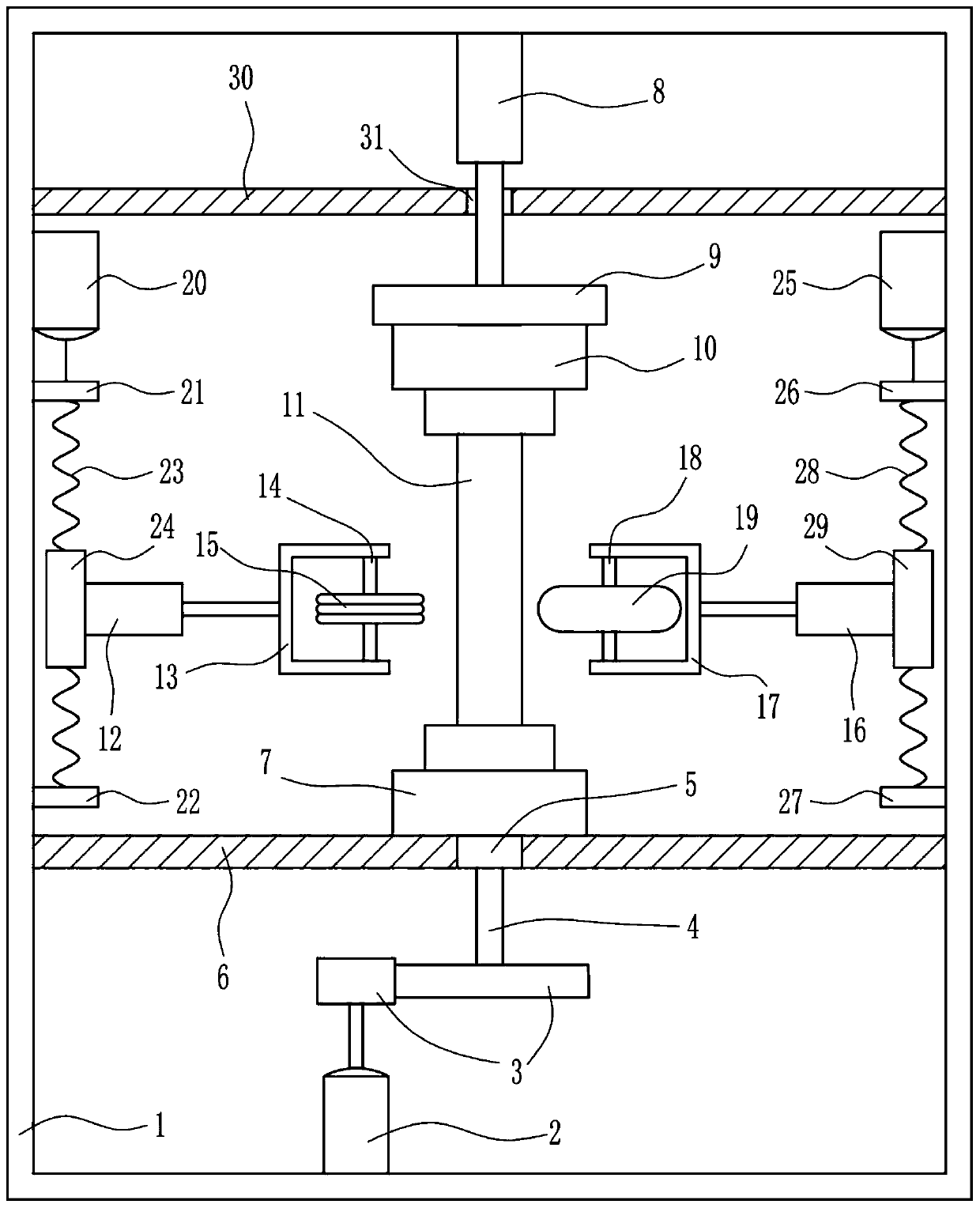

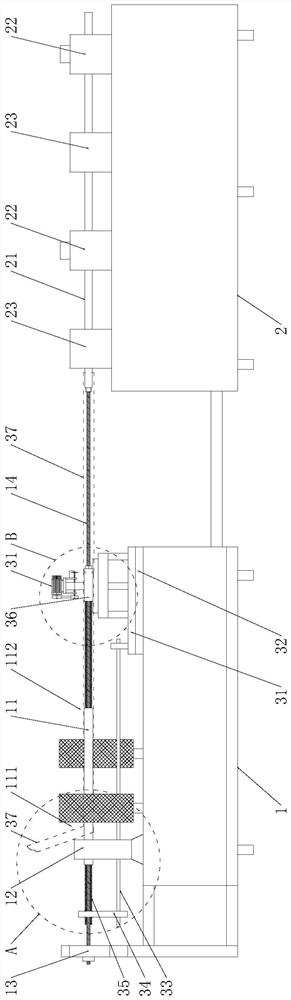

Battery cell discharging device and method

PendingCN112830298AQuality improvementEasy to eliminate redundancyFinal product manufactureSecondary cells manufactureMechanical engineeringBattery cell

The invention discloses a battery cell discharging device and method. The battery cell discharging device comprises a stretching mechanism and a flattening mechanism. The stretching mechanism is used for clamping the upper end and the lower end of a battery cell in the vertical direction and enabling the upper end and the lower end of the battery cell to move in the direction away from each other so as to stretch the battery cell. The flattening mechanism is used for receiving the stretched battery cell and flattening the battery cell in the thickness direction of the battery cell. According to the battery cell discharging device and method, the battery cell is stretched in the vertical direction, so that an inner-layer pole piece and a diaphragm of the battery cell are in a vertical state when a winding needle mechanism is pulled out, and the inner-layer pole piece and the diaphragm of the battery cell cannot droop due to the influence of self gravity; and compared with the manner of horizontally stretching the battery cell, redundancy of the pole piece and the diaphragm at corners is easily eliminated during flattening, the corners of the battery cell are not prone to wrinkling, and therefore the quality of the battery cell can be improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

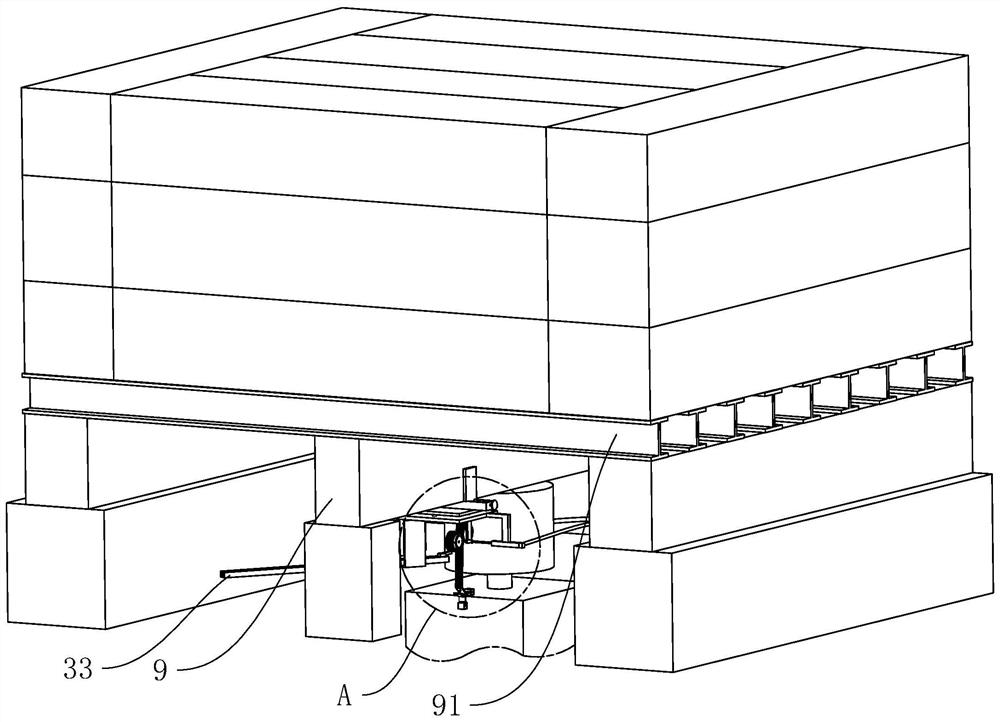

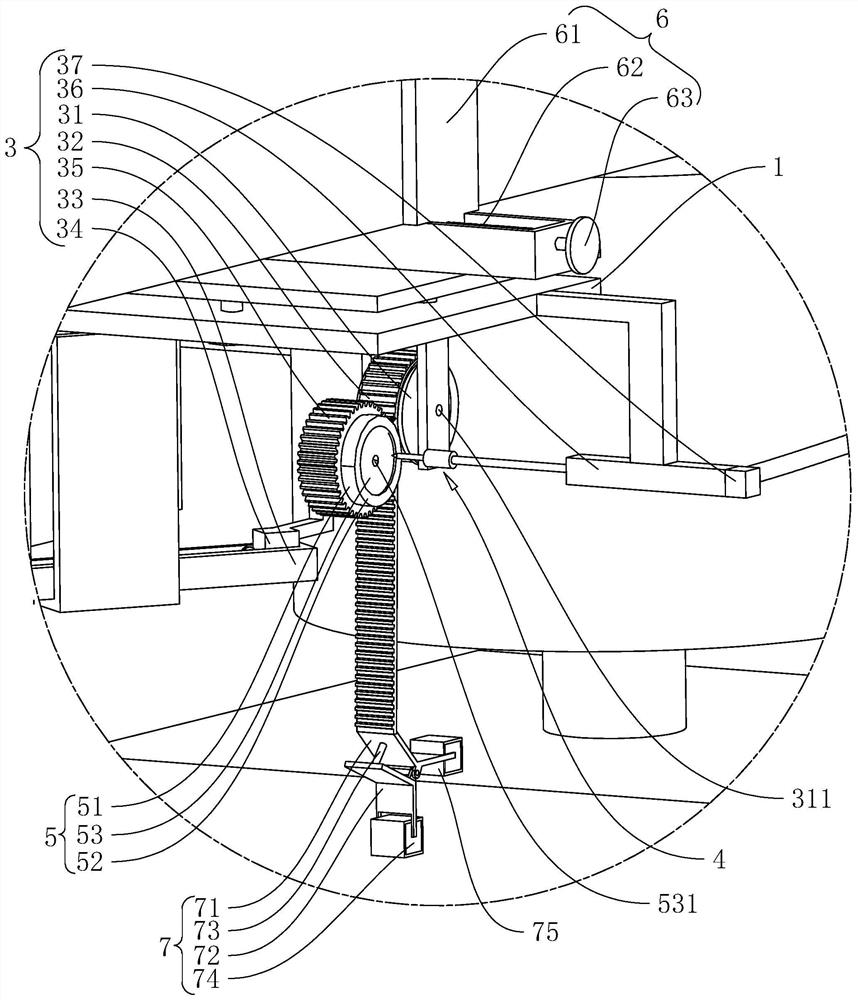

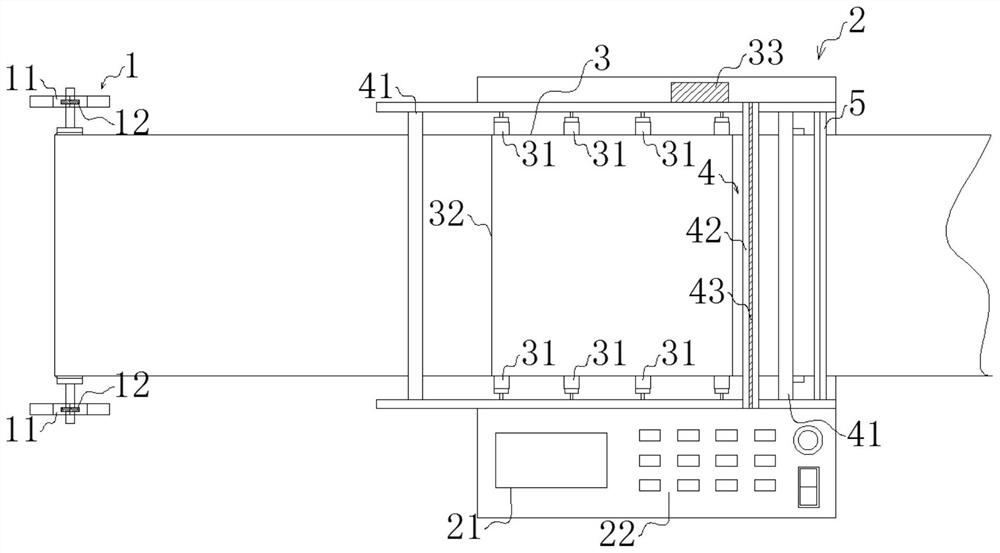

Static load detection equipment for concrete beam

ActiveCN113432996AHigh precisionLess likely to make mistakesMaterial strength using tensile/compressive forcesMeasurement deviceConcrete beams

The invention relates to concrete beam static load detection equipment, which comprises a mounting plate, the mounting plate is connected with a main beam, the mounting plate is provided with a measuring device which synchronously settles with an engineering pile, the mounting plate is provided with an oil cylinder, a piston rod of the oil cylinder clamps a marking pen through a first clamping piece, the oil cylinder is connected with an oil pump through an electromagnetic valve, and the electromagnetic valve is connected with a computer, when the piston rod of the oil cylinder extends out, the marking pen abuts against the measuring device. The measuring device is connected with the engineering test pile so that the measuring device and the engineering test pile can synchronously settle, the computer controls the electromagnetic valve to start the oil cylinder at fixed time, and the oil cylinder and the marking pen are used for carrying out fixed-time marking on the measuring device, a worker can calculate the settling velocity of each time period by combining the distance between the mark points with the timing duration, and the oil cylinder is controlled by the electromagnetic valve to carry out timing recording, so that the recording of the settling velocity is not easy to have errors, and the precision of a measurement result is improved.

Owner:浙江创新工程检测有限公司

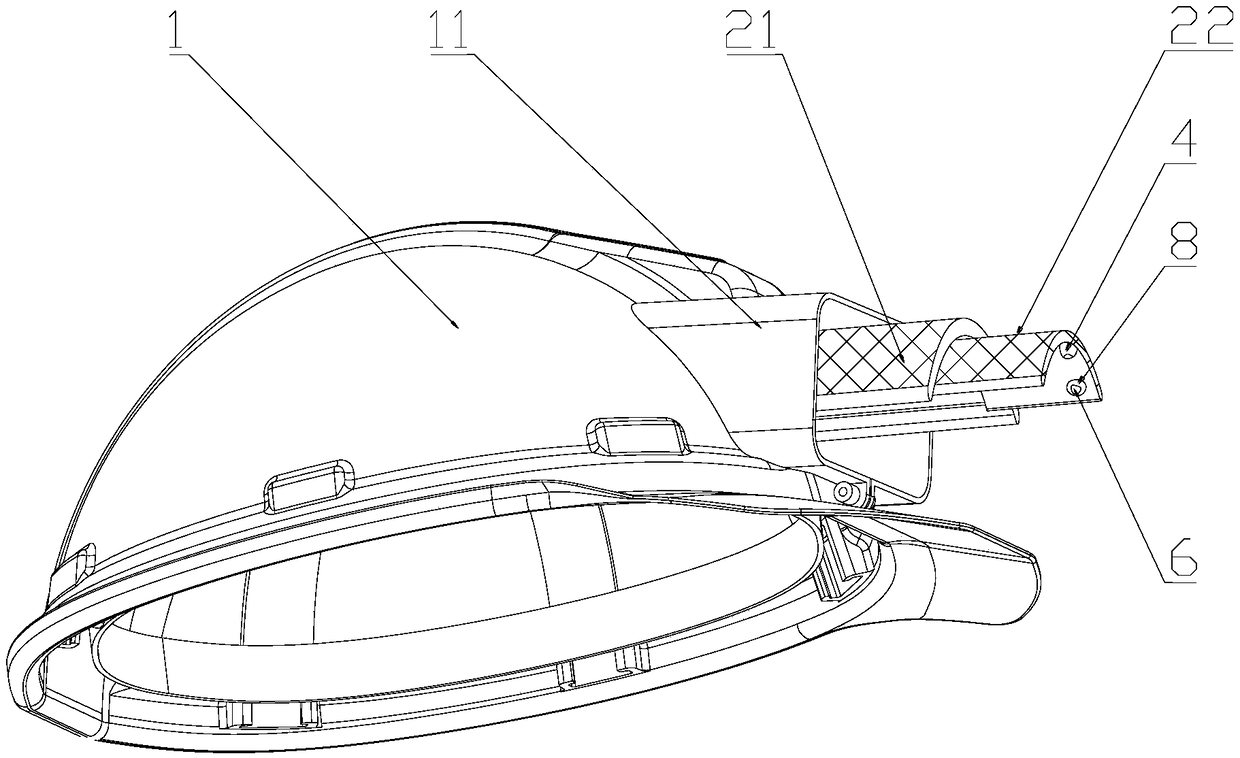

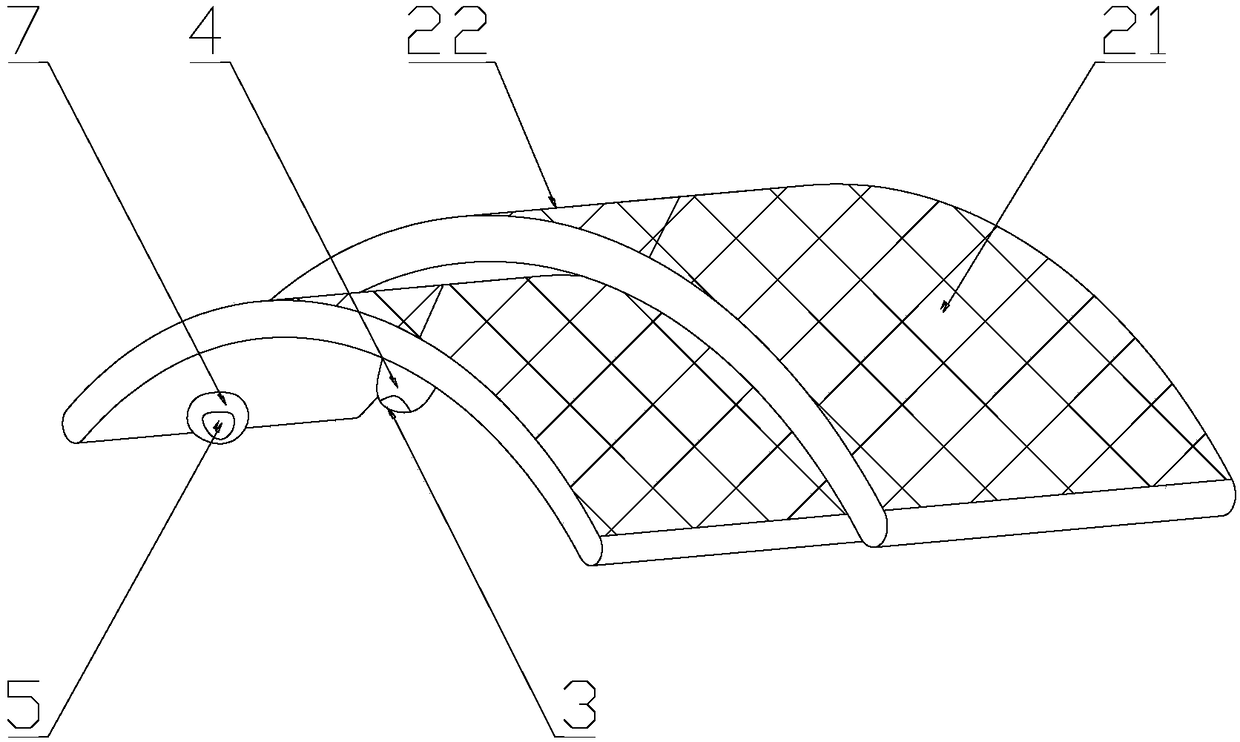

Electric wearable smart helmet

PendingCN108652116AGuaranteed photoelectric conversion efficiencyGuaranteed energy storage effectHelmetsHelmet coversEngineeringEnergy storage

The invention belongs to the technical field of electric safety equipment, and particularly relates to an electric wearable smart helmet. The helmet comprises a helmet body and an energy storage assembly. The front of the helmet body is provided with a mounting seat, and the energy storage assembly is telescopic and contained in the mounting seat when contracted. The energy storage assembly includes two or more curved plates movably sleeved to each other in the lateral direction of the mounting seat, and the tops of the curved plates are provided with a thin film solar panel. The thin film solar panel can be prevented from being scraped, the photoelectric conversion efficiency of the thin film solar panel is improved, the thin film solar panel is in the stable dry storage environment, andthe service life is prolonged.

Owner:WUHAN RAILWAY ELECTRIFICATION BUREAU GRP SCI & IND EQUIP CO LTD

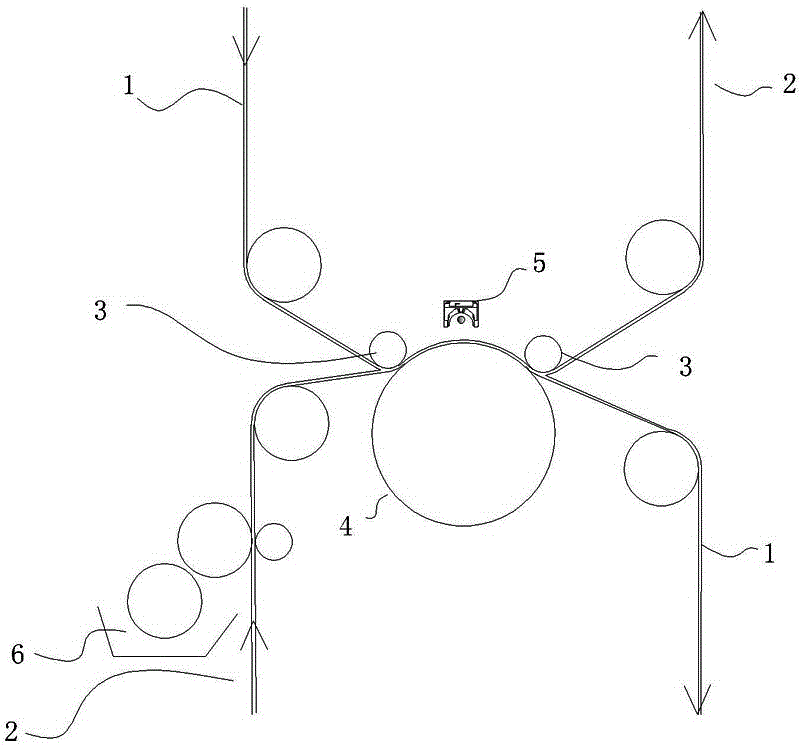

Laser pattern positioning impression transfer method

ActiveCN103707670BQuality improvementSimplify process production routePrinting after-treatmentInk transfer from master sheetUV curingLaser patterning

The invention discloses a laser pattern positioning impression transfer method. The method comprises the following steps: carrying out positioning printing treatment of a substrate through an intermedium printing device to obtain an intermedium position-printed substrate; allowing the intermedium position-printed substrate to go through a transparent roller and a bearing roller to make the intermedium on the substrate contact with a mother matrix of the transparent roller in order to impress a laser pattern on the medium in a positioning manner; and curing the substrate impressed with the laser pattern through an ultraviolet curing device to obtain a laser pattern laminae. The method has the advantages of realization of the point-to-point position special edition pattern impression transfer, elimination of the ghost phenomena of four edges of the transferred pattern, increase of the impression transferred pattern precision, and improvement of the surface quality of the pattern.

Owner:广东依明机械科技有限公司

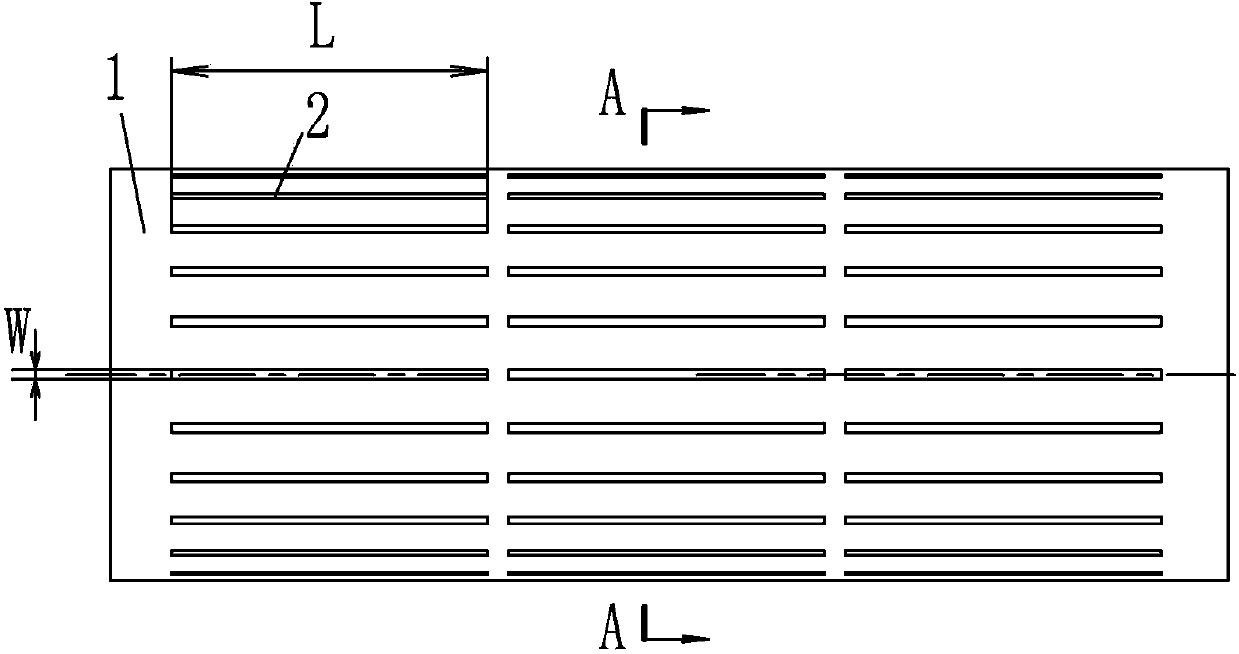

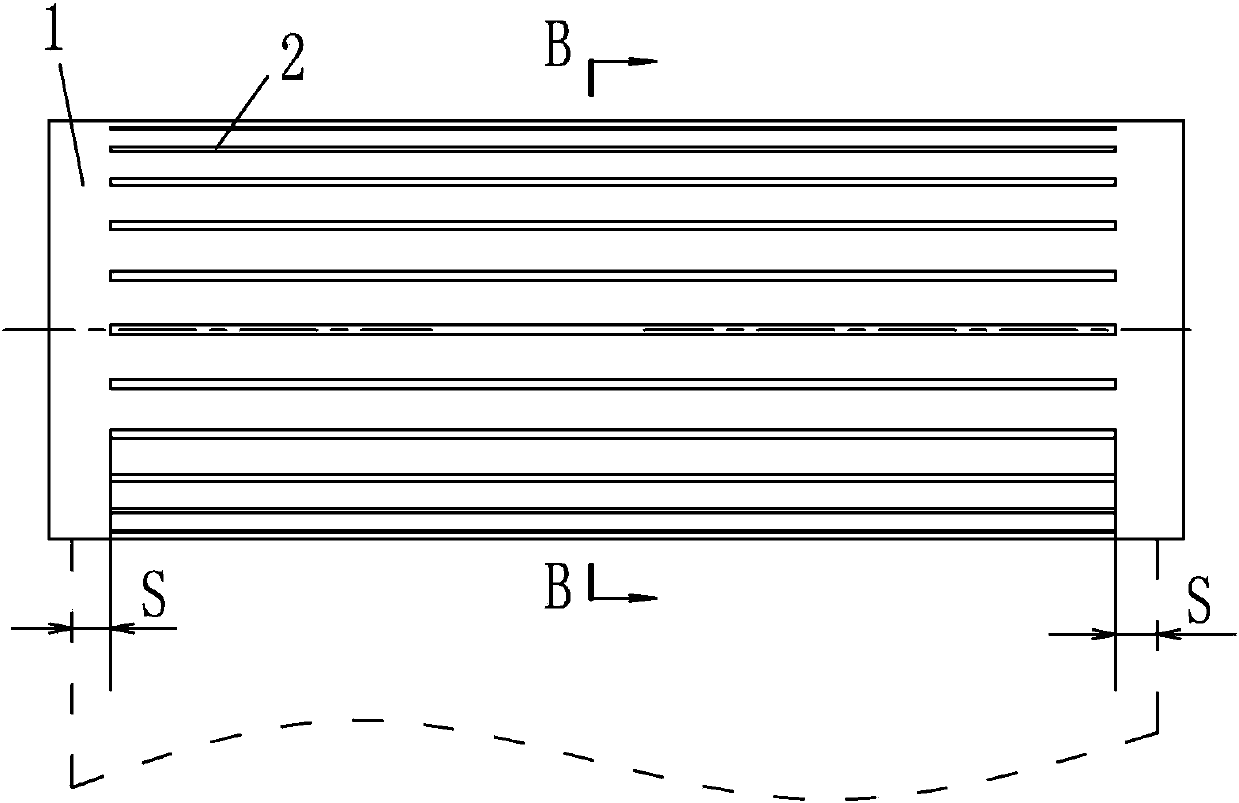

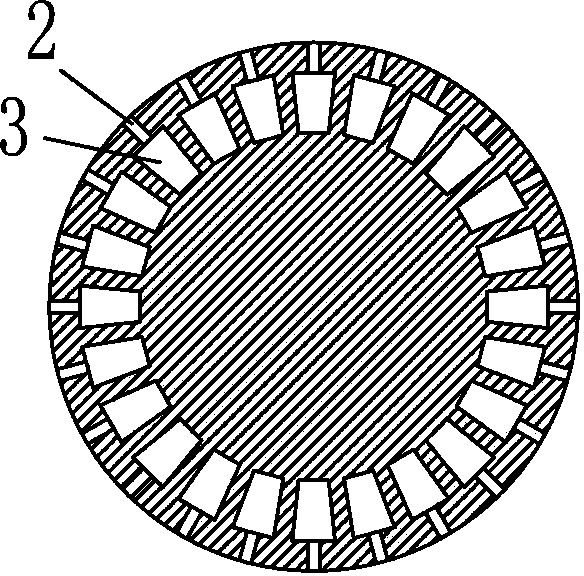

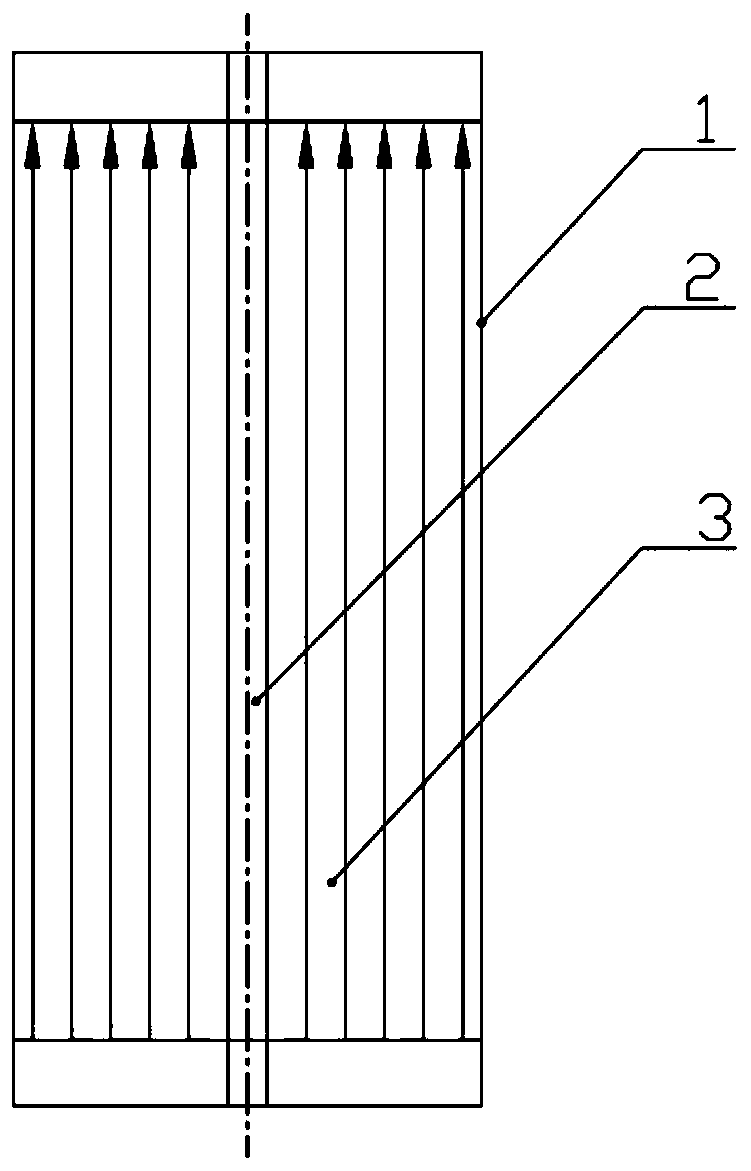

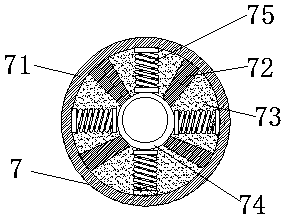

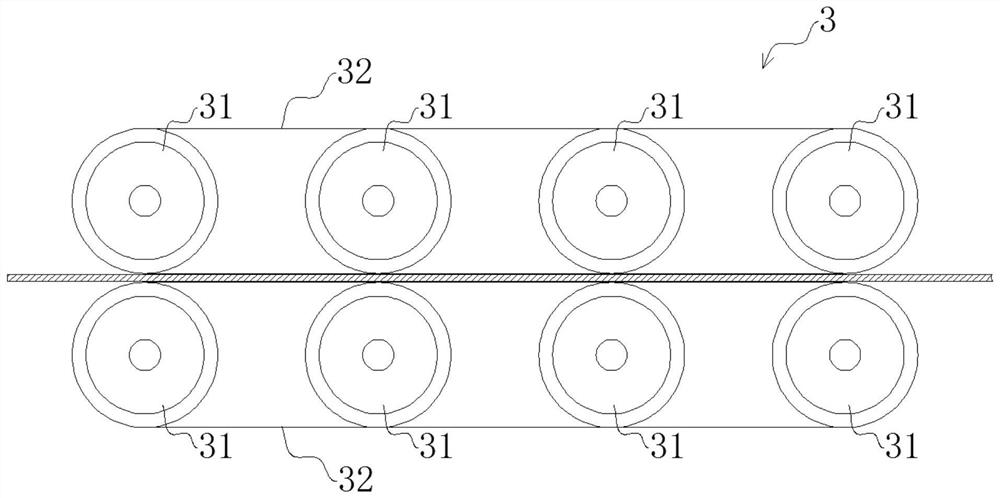

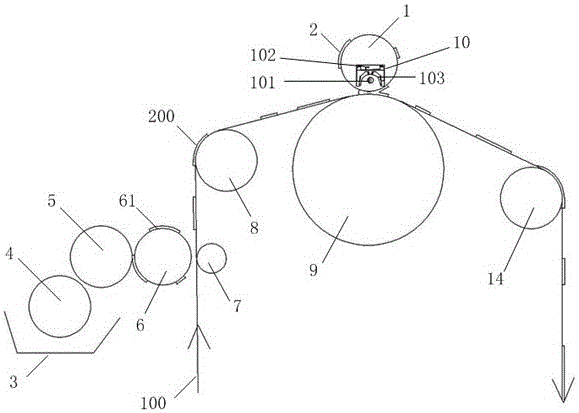

Rewinding roll for rewinding machine

InactiveCN104176535AReduce the non-suction areaAdsorption capacity continuousWebs handlingHigh densityPulp and paper industry

The invention discloses a rewinding roll for a rewinding machine. A plurality of air suction ports are formed in the cylindrical surface of the rewinding roll; each air suction port is of a slit type, and the length direction of each slit type air suction port is in parallel with the axis direction of the rewinding roll. Compared with an existing rewinding roll with a circular air suction port, the rewinding roll has the advantages that 1, under the condition that the axial dimension of the rewinding roll is the same, non-suction positions among the air suction ports are reduced, and the adsorbing force of the rewinding roll on paper becomes more successive in the width direction of the paper; 2, the axial force applied on the paper being adsorbed and wound becomes more uniform, and the situation of crinkly paper end cannot appear easily; 3, the rewinding roll can easily guarantee the winding roundness of the end part of the paper while driving the end part of the paper for winding, and the rewinding machine can continuously produce paper roll products with high-quality cores; 4, the adsorbing force of a single air suction is greater, the rewinding roll can easily adsorb paper in higher density and harder texture and smoothly rewind the paper, and the paper adaptability of the rewinding machine is reinforced.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

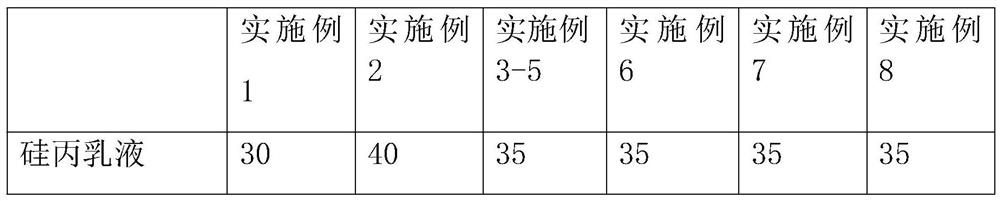

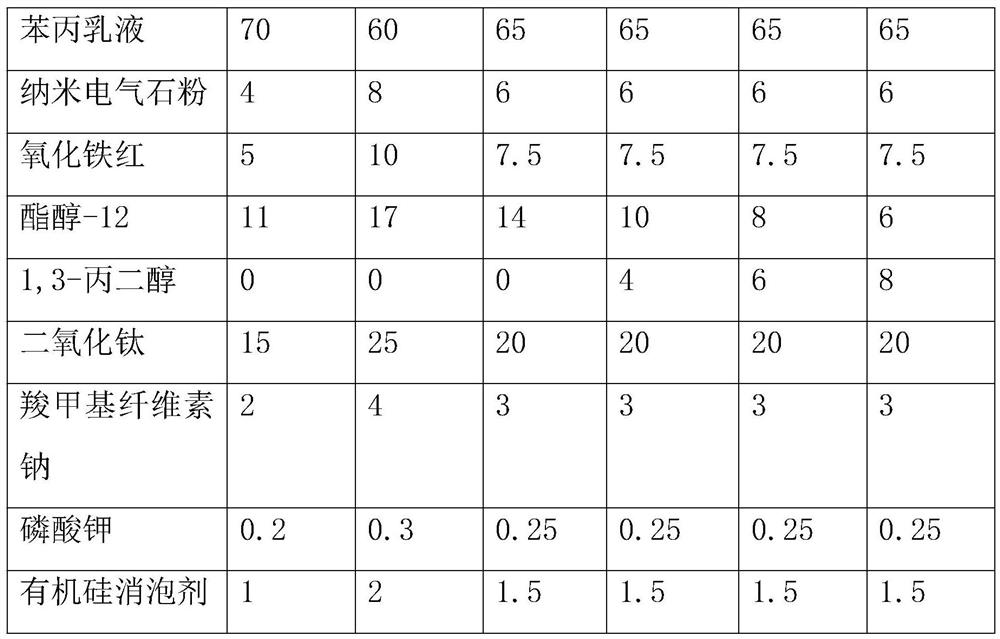

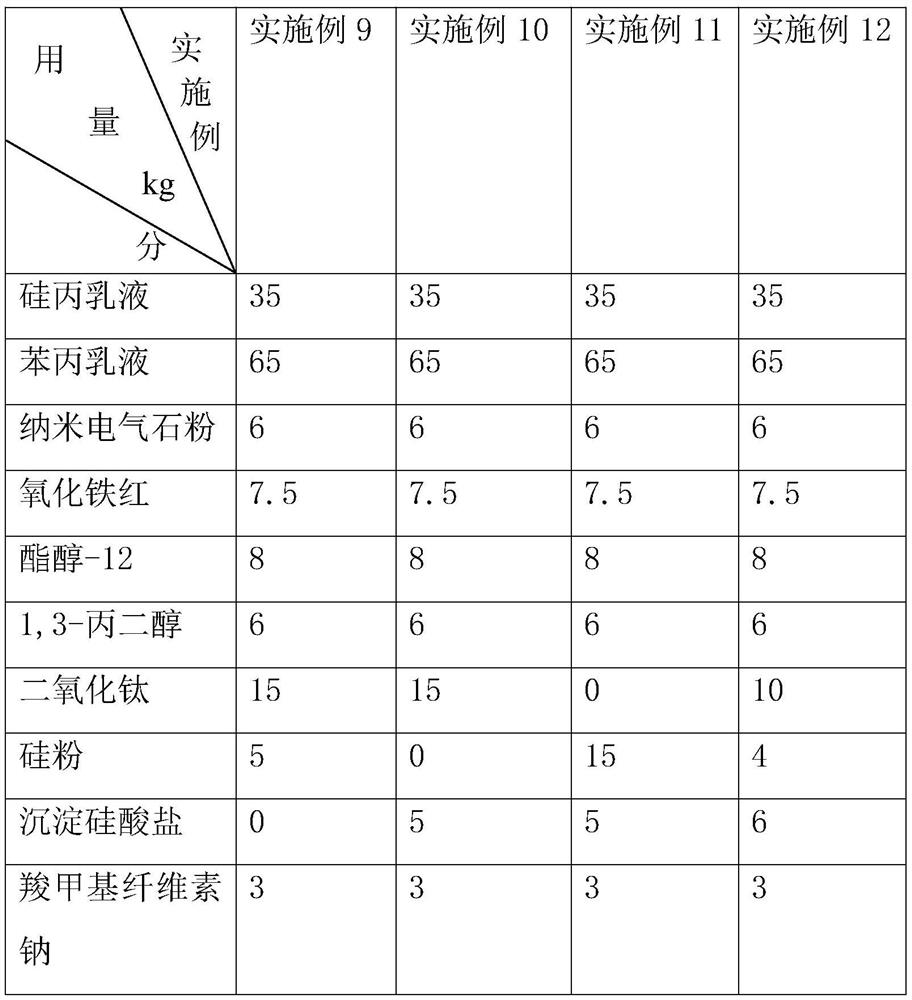

Coating for ancient building repair and preparation method thereof

InactiveCN113337162AImprove waterproof performanceAccelerated corrosionAntifouling/underwater paintsPaints with biocidesDefoaming AgentsSilicone

The invention relates to the field of ancient building repair, and particularly discloses a coating for ancient building repair and a preparation method thereof. The coating for ancient building repair is prepared from the following components: a pigment, styrene-acrylic emulsion, silicone acrylic emulsion, nano tourmaline powder, a coalescing agent, filler, a thickening agent, a pH regulator and a defoaming agent. The preparation method comprises the following steps: (1) mixing the pigment, the filler and the nano tourmaline powder, and uniformly stirring to obtain a pre-mixture; (2) uniformly mixing the pre-mixture with a part of silicone acrylic emulsion, grinding and dispersing to obtain a pigment color paste; and (3) adding the rest of the silicone acrylic emulsion, styrene-acrylic emulsion, the coalescing agent and the pH regulator into the pigment color paste, uniformly stirring, then adding the thickening agent, and uniformly stirring to obtain the coating for ancient building repair. The coating disclosed by the invention has the advantage of relatively good external environment corrosion resistance; in addition, the preparation method provided by the invention has the advantage that all the components are mixed more uniformly.

Owner:广东潮鑫建设工程有限公司

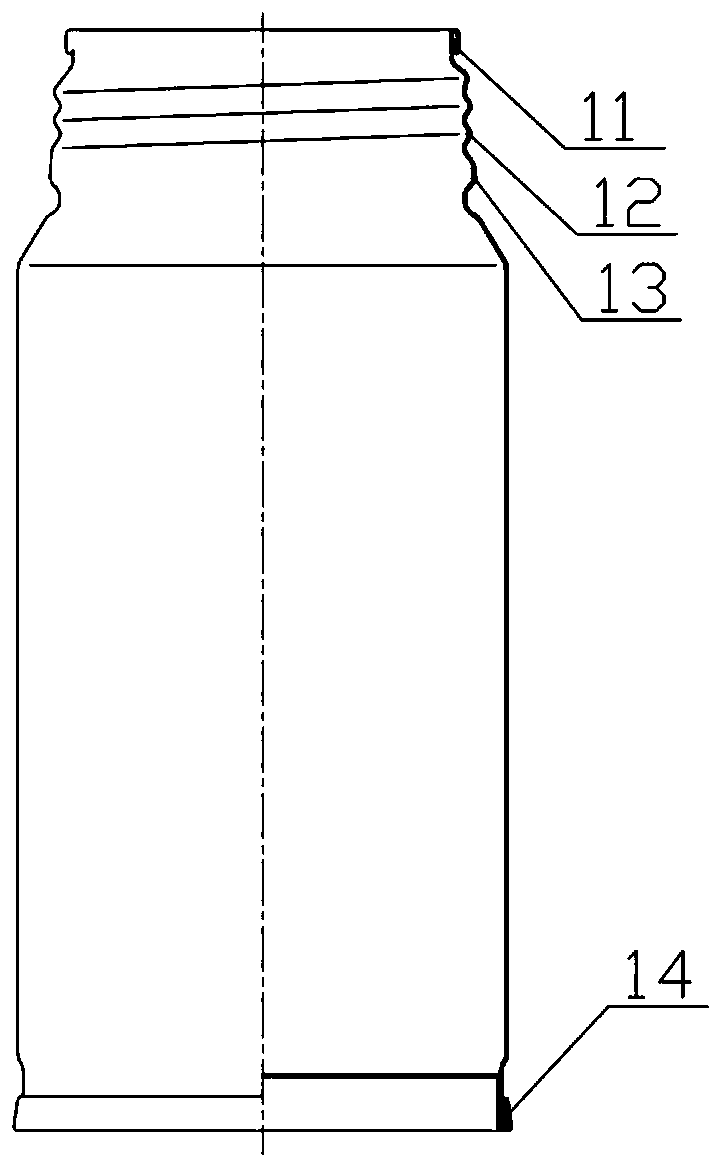

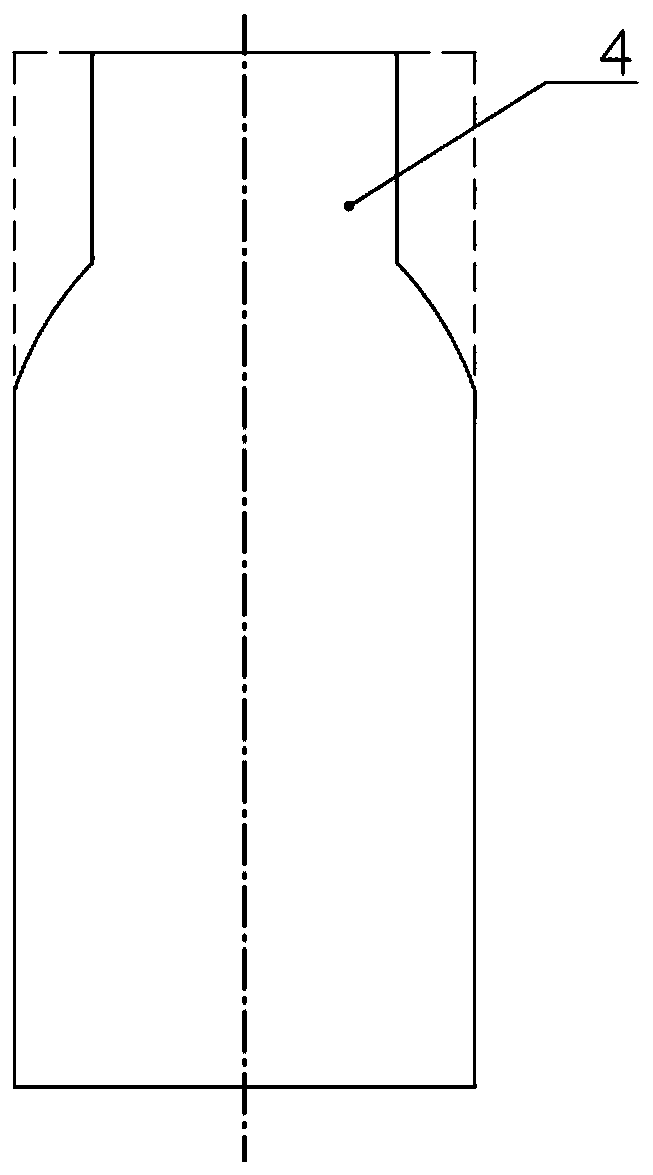

Welded metal bottle can and manufacturing method thereof

The invention discloses a welded metal bottle can and a manufacturing method thereof. The welded metal bottle can comprise a can body and a neck part on the can body, wherein the neck part comprises amiddle caliber part and a conical part arranged on the upper portion of the middle caliber part; the conical part is provided with an included angle alpha relative to a vertical plane, and the included angle alpha is 3-10 degrees; the manufacturing method comprises the steps of carrying out rolling and welding of a metal sheet after painting into a cylindrical tank body; reducing one open end ofthe can body to form the middle caliber part; and forming the middle caliber part to form the conical part on the upper portion of the middle caliber part, wherein the conical part is provided with anincluded angle alpha relative to a vertical plane, and the included angle alpha is 3-10 DEG. The welding metal bottle can and the manufacturing method have the advantages that the processing difficulty is greatly reduced; through three-layer folding process of a curling part and taper angle setting, the sealing performance of the manufactured welding metal bottle can is good, so that the coatingis not prone to peeling off; a screw cover rotates smoothly, and the sealing performance is good, so that the welding metal bottle can is not prone to rusting during containing liquid.

Owner:CHUZHOU JIAMEI PLATE PRINTING & CAN MAKING

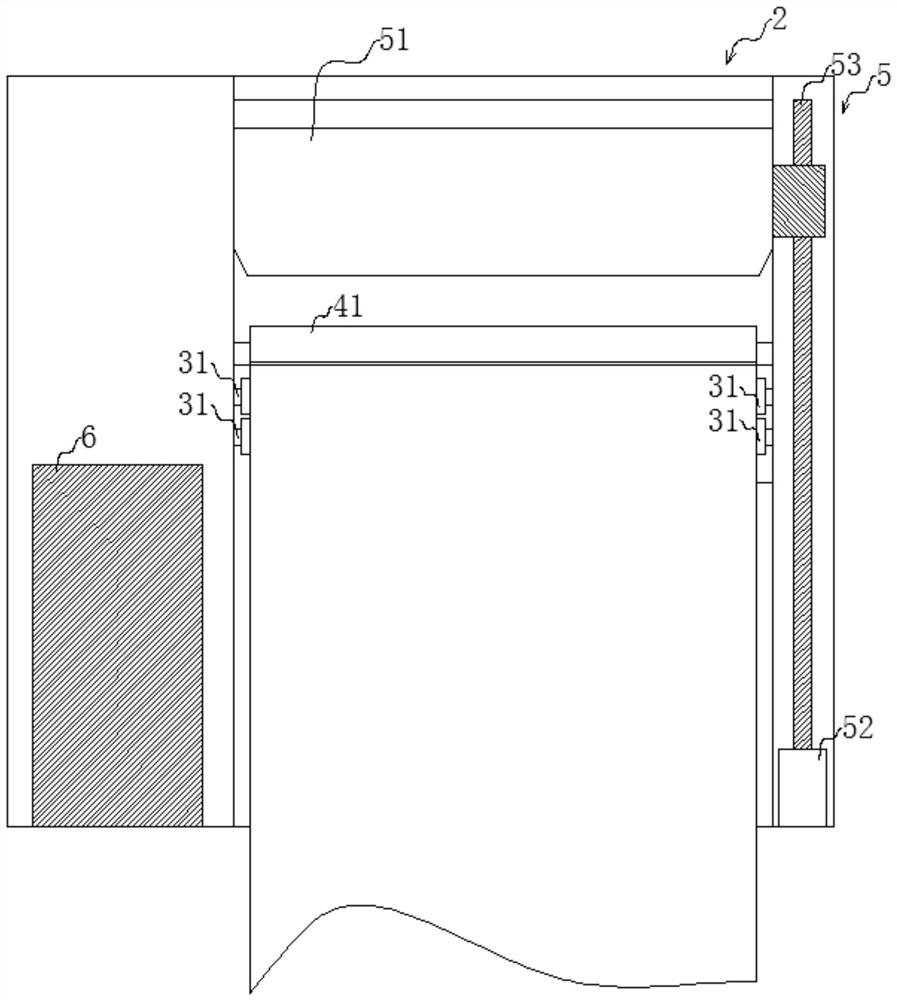

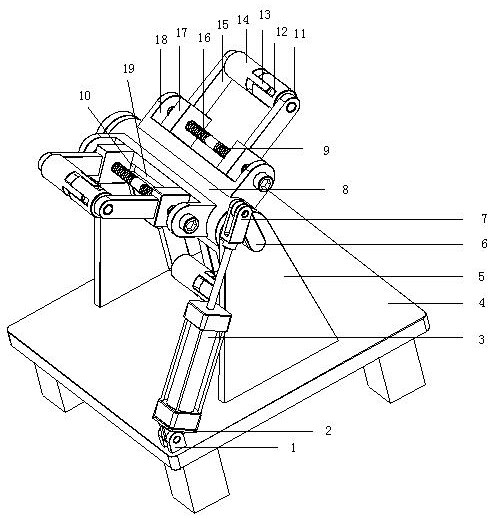

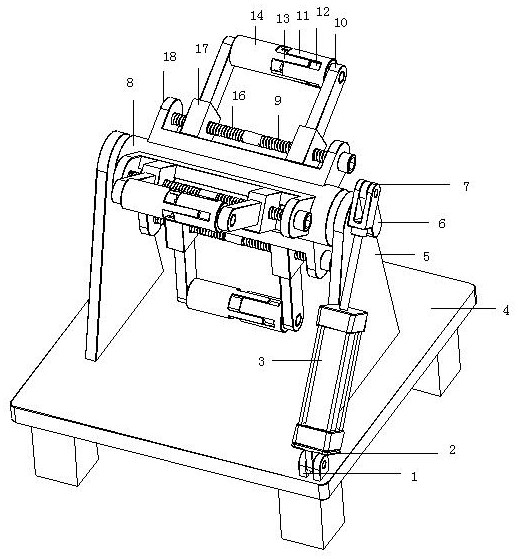

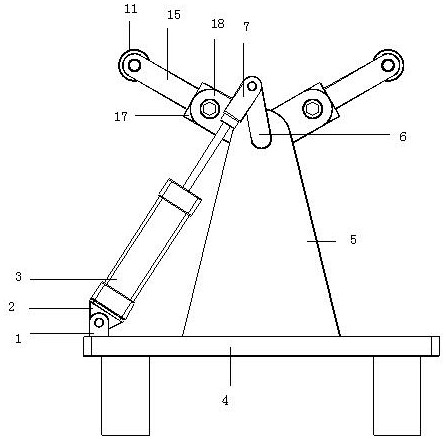

Ancient book image layout anti-wrinkle fixing frame based on character typefaces

InactiveCN109808331APlay the role of moisture-proofLess prone to wrinklingBookbinding pressesHydraulic cylinderFrame based

The invention relates to the technical field of fixing frames, and discloses an ancient book image layout anti-wrinkle fixing frame based on character typefaces. The fixing frame comprises a support;the upper surface of the support is fixedly connected with a table board; the bottom end of the interior of the table board is fixedly connected with a fan; an air outlet of the fan is provided with an electric heating wire inside the table board; one side of the table board is fixedly connected with a side board; one end of the side board is fixedly connected with a fixing board; the upper surface of the fixing board is fixedly connected with a supporting table; the upper surface of the supporting table is fixedly connected with a hydraulic cylinder; the output end of the hydraulic cylinder is fixedly connected with a hydraulic rod; one end of the hydraulic rod is fixedly connected with a connection rod; and one end of the connection rod is fixedly connected with a roller. The ancient book image layout anti-wrinkle fixing frame based on character typefaces is provided with the fan and the electric heating wire, the air outlet of the fan is provided with the electric heating wire inside the table board, wetted ancient books can be heated and dried through the electric heating wire, and the damp-proof function is achieved.

Owner:江苏文心古籍数字产业有限公司

A kind of flexible film folding colorful solar charger and its manufacturing process

ActiveCN106653908BLess prone to wrinklingPromote absorptionBatteries circuit arrangementsPhotovoltaicsEngineeringSolar charger

The invention discloses a flexible thin film folded dazzling solar charger and a fabrication process thereof, and relates to the field of a solar charger. The flexible thin film folded dazzling solar charger comprises an upper package dazzling cloth layer, a flexible thin film solar cell module layer and a lower package dazzling bottom layer, wherein the flexible thin film solar cell module layer is arranged between the upper package dazzling cloth layer and the lower package dazzling bottom layer by a package adhesive film, a plurality of U-shaped gaps are formed in both of two sides of the upper package dazzling cloth layer and the lower package dazzling bottom layer, the U-shaped gaps are arranged at positions where adjacent flexible thin film solar cell modules are connected, and a waist-shaped hole is formed between opposite U-shaped gaps and penetrates through the upper package dazzling cloth layer and the lower package dazzling bottom layer. By such a design, the flexible thin film folded dazzling solar charger has versatile functions, is attractive, is easy to fold and carry and is light in weight.

Owner:夏颖

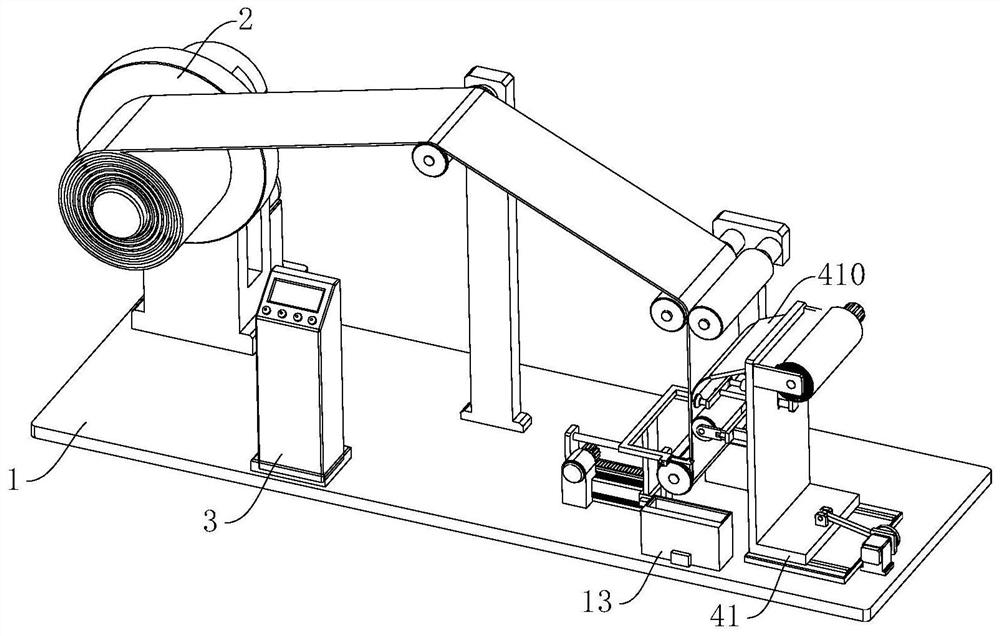

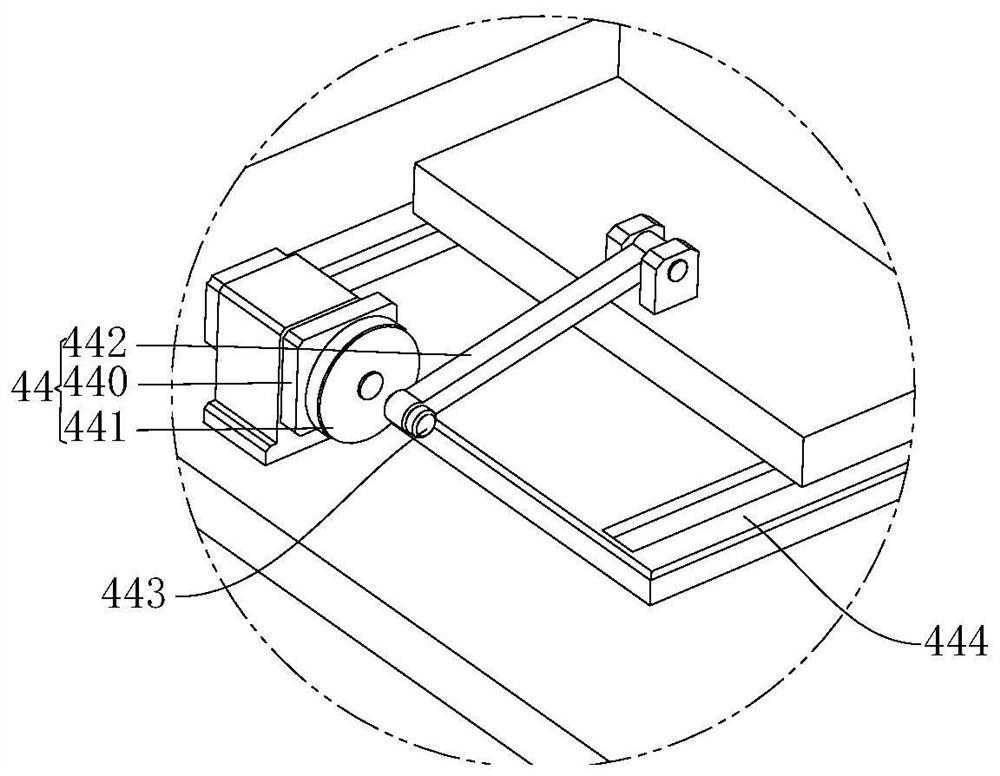

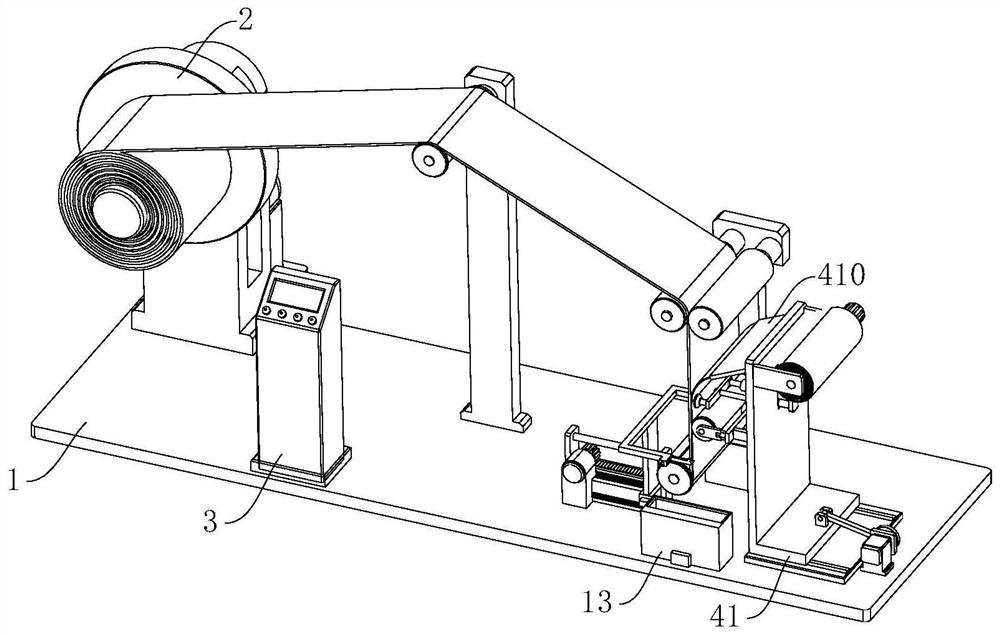

Cigarette tinfoil positioning, trimming and cutting device

PendingCN113799194ACompact structureImprove segmentation accuracyMetal working apparatusElectrical connectionControl cell

The invention relates to a cigarette tinfoil positioning, trimming and cutting device. The device comprises supporting frames, a cutting machine body, conveying assemblies, positioning assemblies, a cutting assembly and a control unit; the supporting frames are arranged on one side of the cutting machine body at intervals, the conveying assemblies and the positioning assemblies are arranged at the top of the cutting machine body, the positioning assemblies are arranged on the two sides of the conveying assemblies, and the control unit is arranged in the cutting machine body and is electrically connected to the conveying assemblies, the positioning assemblies and the cutting assembly. The device is compact in structure, jamming caused by the wrinkling phenomenon of the tinfoil does not occur easily, meanwhile, the tension of the tinfoil is kept, the cutting precision is improved, the interior of the device is of a detachable structure, and later maintenance is facilitated.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

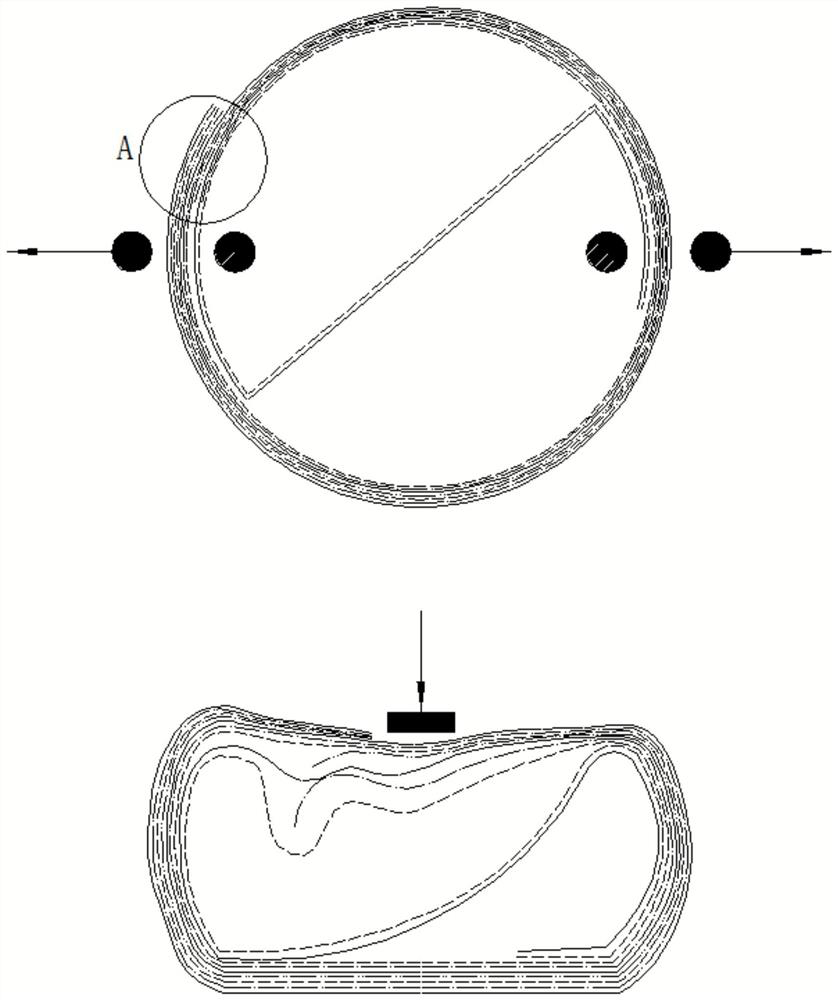

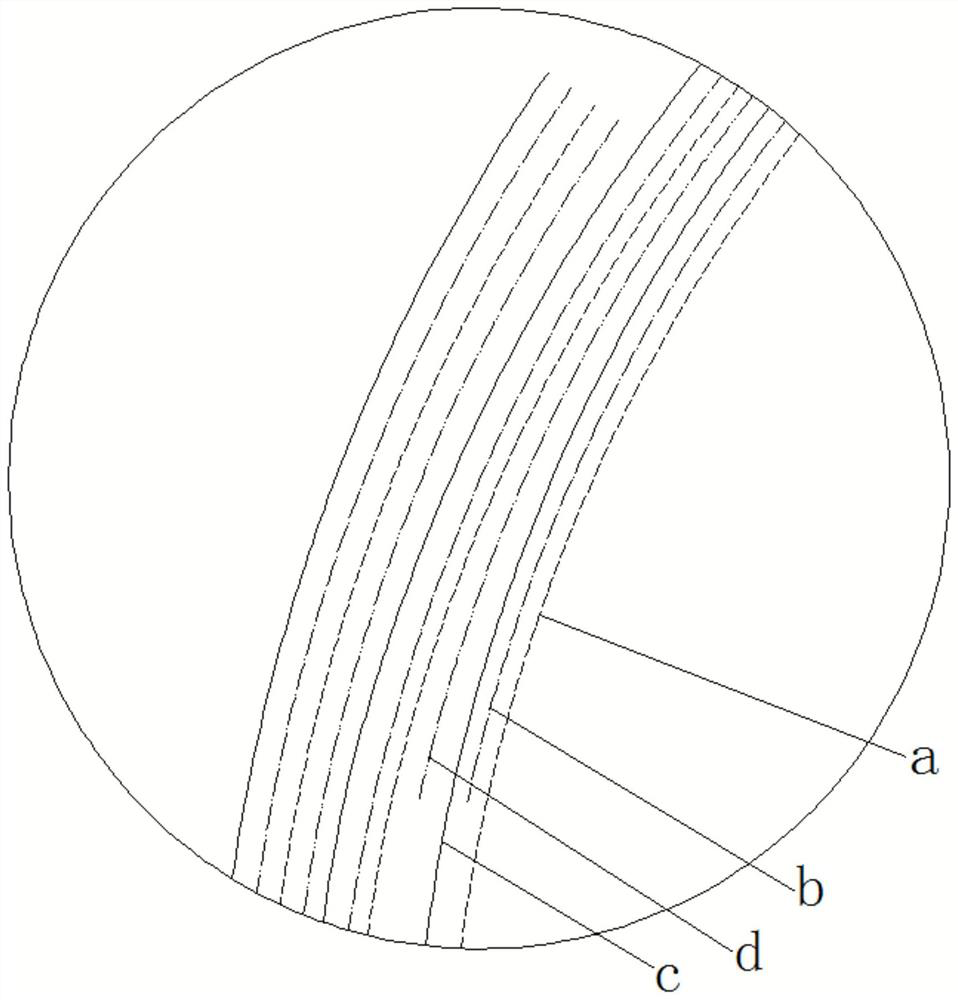

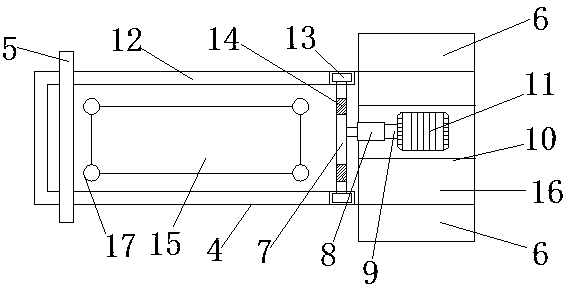

Large-variable-diameter thin-wall pipe composite forming device

PendingCN109877220ASave manpower and material resourcesImprove forming efficiencyDrive shaftLarge deformation

The invention relates to a large-variable-diameter thin-wall pipe composite forming device. According to the technical problem to be solved, the large-variable-diameter thin-wall pipe composite forming device can achieve large-variable-ratio formation, and is high in production efficiency. The large-variable-diameter thin-wall pipe composite forming device comprises a rack, a first motor, a transmission device, a transmission shaft, a first clamping device, a first push-pull device, a connecting disc and a second clamping device. The first motor is fixedly installed on the bottom of the rack.The output end of the first motor is connected with the transmission device. The output end of the transmission device is connected with the transmission shaft. The other end of the transmission shaftis fixedly connected with the first clamping device. The first push-pull device is fixedly installed on the top of the rack. The output end of the first push-pull device is connected with the connecting disc. The connecting disc is fixedly connected with the second clamping device. The large-variable-diameter thin-wall pipe composite forming device achieves the effects that thin-wall pipe large-deformation-ratio deformation is convenient and the production efficiency is high. By means of reasonable device layout, the device is simple in structure, and easy and efficient to operate.

Owner:JIANGXI UNIV OF SCI & TECH

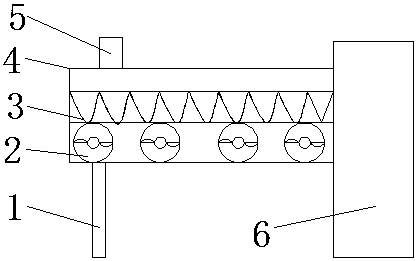

Regular winding device for fire hose

The invention discloses a regular winding device for a fire hose. The regular winding device comprises a base, a vertical plate, a rotating shaft and a mounting part. Multiple winding roller assemblies are arranged on the mounting part. Each winding roller assembly comprises a mounting arm, a first rotating roller and a second rotating roller, and the first rotating rollers and the second rotatingrollers are coaxial and are used for jointly winding the fire hose. The distance between two mounting arms is adjusted by an adjusting unit, so that the axial distances between the first rotating rollers and the second rotating rollers are adjusted to adapt to fire hoses with different widths. The regular winding device for the fire hose has the beneficial effects that the first rotating rollersand the second rotating rollers on the winding roller assemblies are used for jointly winding the fire hose, meanwhile, the multiple winding roller assemblies can rotate in the axial direction of therotating shaft through rotation of the rotating shaft, and therefore the winding roller assemblies in the idle state can be conveniently rotated to the proper position, and the fire hose can be conveniently wound on the winding roller assemblies.

Owner:湖南润华新材料有限公司

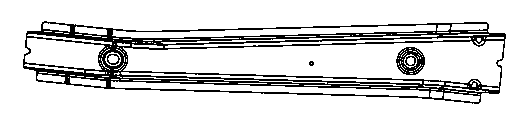

Square tube manufacturing equipment capable of achieving continuous forming through deformation

PendingCN114393885AQuality improvementLess prone to wrinklingMechanical working/deformationMetal working apparatusMechanical engineeringIndustrial engineering

The invention discloses square tube manufacturing equipment capable of achieving continuous forming through deformation. The square tube manufacturing equipment comprises round paper tube manufacturing equipment and square paper tube manufacturing equipment. The circular paper tube manufacturing equipment is provided with a circular tube inner mold, and the circular tube inner mold is used for forming a circular paper tube. The discharging end of the round pipe inner mold is closer to the square paper pipe manufacturing equipment than the feeding end of the round pipe inner mold, and the feeding end of the round pipe inner mold is used for winding slitting paper. The square paper tube manufacturing equipment is provided with a square tube inner mold, and the square tube inner mold is used for forming a square paper tube. The end, close to the circular paper tube manufacturing equipment, of the square tube inner mold is connected with the discharging end of the circular tube inner mold so that a circular paper tube formed on the circular tube inner mold can be conveyed to the square tube inner mold. The production efficiency of the square paper tube can be further improved.

Owner:GUANGZHOU HAIFANG TECH CO LTD

Preparation method of high-adhesion strength sticky rice adhesive used for paper lantern

InactiveCN107815269AIncrease initial viscosityReduced aestheticsNon-macromolecular adhesive additivesStarch adhesivesAdhesiveMixed materials

The invention discloses a preparation method of high-adhesion strength sticky rice adhesive used for a paper lantern. The preparation method comprises the following steps: uniformly stirring glutinousrice flour, phosphated distarch phosphate and water, adding polyoxyethylene xylitol anhydride monostearate and borax, heating and stirring to obtain a mixed material; and adding modified cotton linters, white emulsion, a defoaming agent, glycerin and a bactericide to the mixed material and uniformly mixing to obtain the high-adhesion strength sticky rice adhesive used for a paper lantern. The modified cotton linters are prepared by adopting the following process: uniformly mixing cotton linters, sepiolite and acetone, adding epoxidized soybean oil and uniformly stirring, adding lignin sulfonic acid calcium, water and sorbitol, heating and stirring to obtain the modified linters.

Owner:望江县红和木业灯饰有限公司

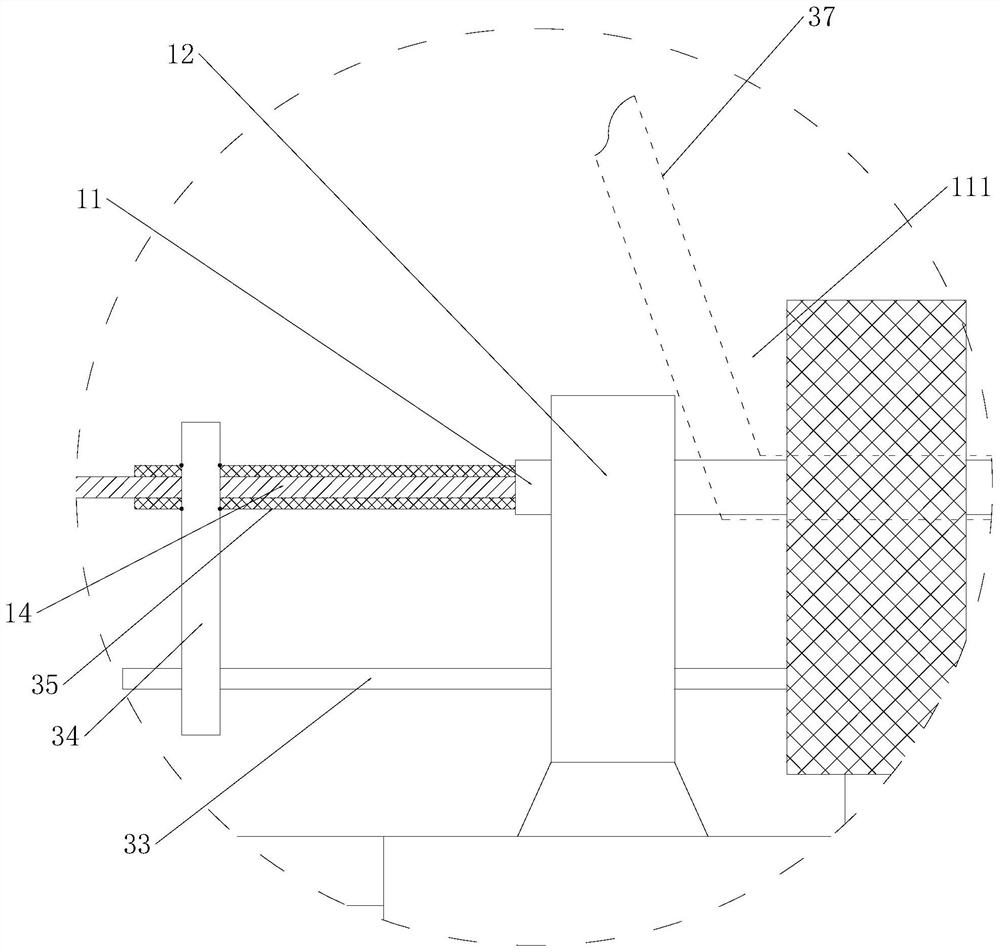

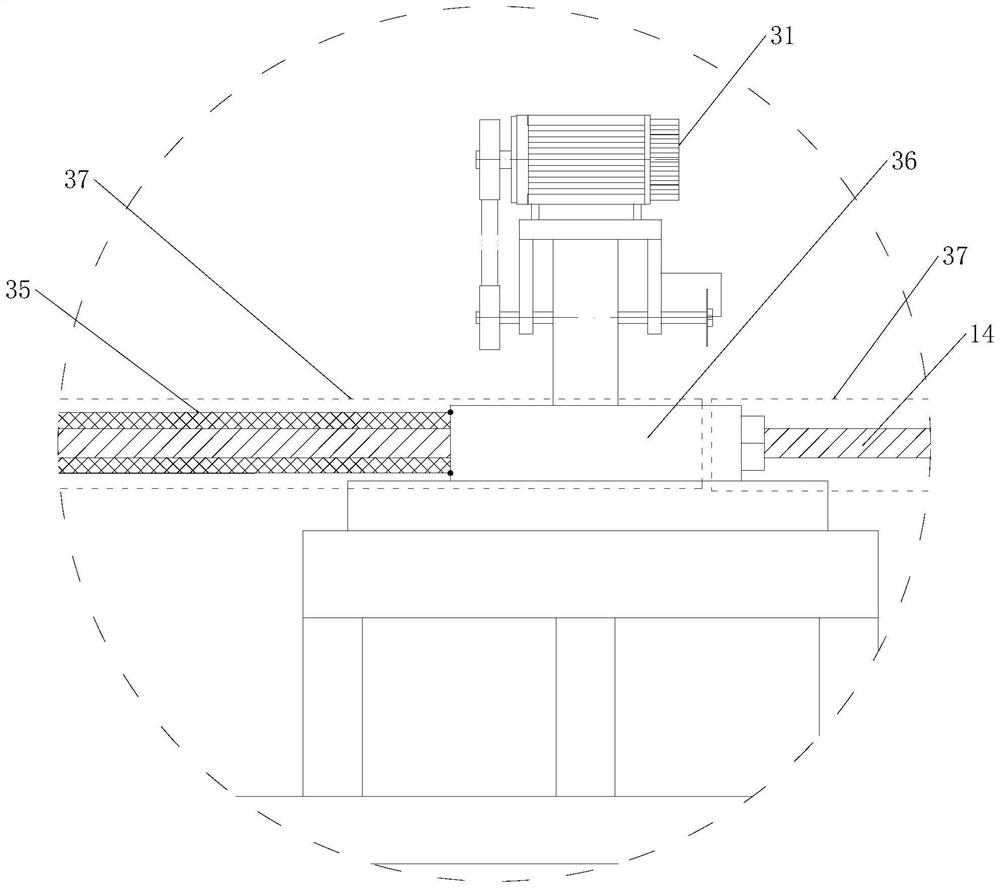

Method for exfoliation and transfer of GaN-on-Si epitaxial layer

ActiveCN103985664BLess prone to wrinklingAvoid breakingSemiconductor/solid-state device manufacturingThin membraneGallium nitride

The invention relates to a method for peeling and transferring silicon-based gallium nitride epitaxial layer, which comprises the following steps: 1) cleaning the silicon-based gallium nitride epitaxial wafer and the surface of the temporary carrier with hydrochloric acid, then rinsing with deionized water, and then putting the 2) Spin-coat photoresist on the front side, and paste the silicon-based GaN epitaxial wafer on the temporary carrier through the photoresist; 3) Configure the etching solution for etching the silicon substrate; 4) Bond the The final wafer is placed in an etching solution for etching; 5) Spin-coat BCB on the exposed GaN-on-Si epitaxial layer; 6) After natural cooling, the GaN-on-Si epitaxial layer on the temporary carrier and the target The front side of the substrate is bonded at a temperature of 250 degrees Celsius; 7) Remove the temporary carrier. Advantages: the method of the present invention can completely transfer the gallium nitride epitaxial layer film on the silicon-based gallium nitride epitaxial wafer to the required substrate, the process is simple, the yield is high, and the gallium nitride epitaxial layer will not damaged.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

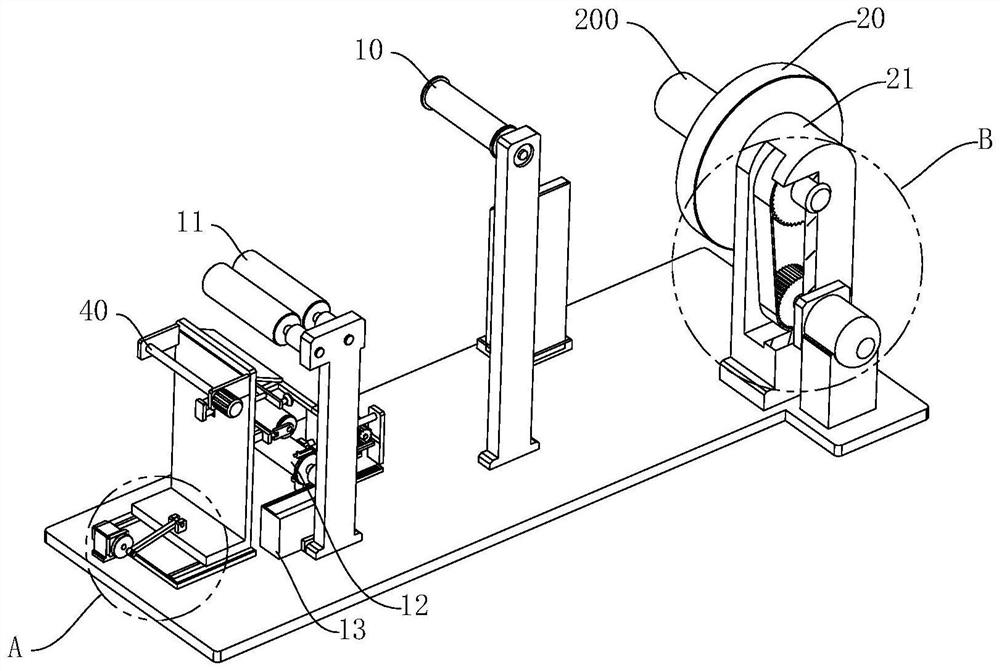

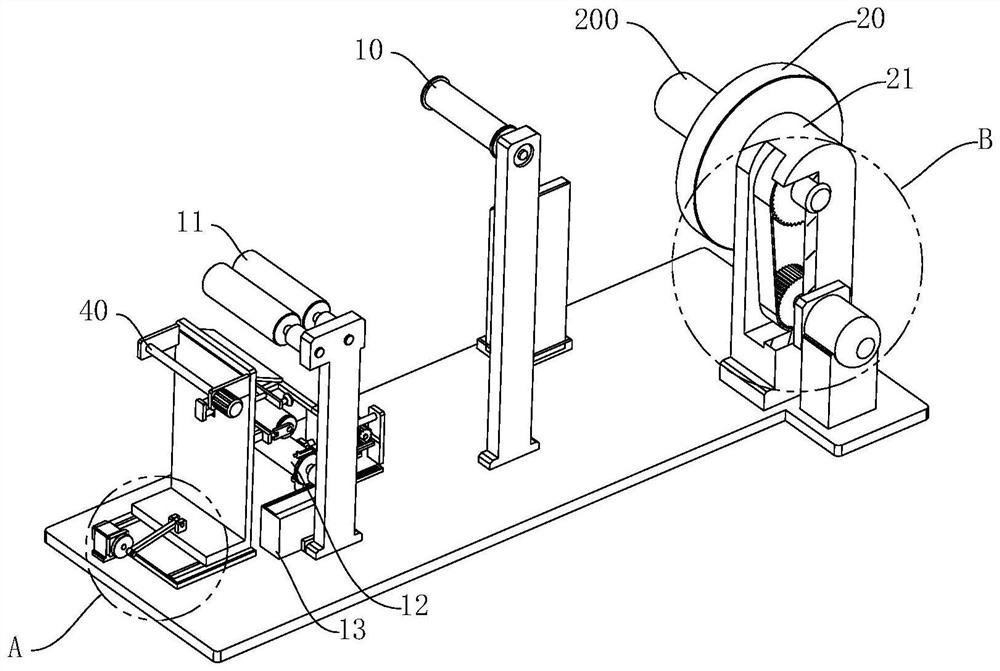

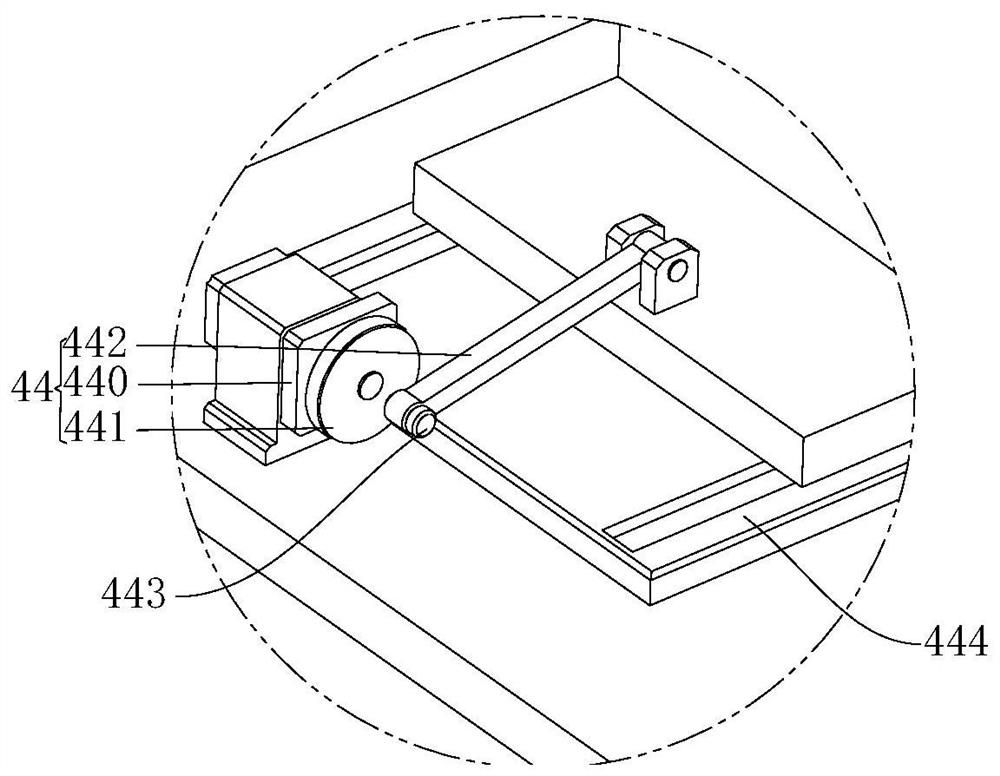

A protective paper attaching device capable of automatically adapting to the width of the steel strip

ActiveCN111573341BIncrease flexibilityPracticalMetal working apparatusArticle deliverySlide plateSteel belt

The invention relates to the technical field of steel strip processing, in particular to a protective paper attaching device capable of automatically adapting the width of the steel strip, including a base and an unwinding mechanism, the unwinding mechanism including a turntable, a support column and a drive assembly, and a controller , an attachment mechanism and a cutting mechanism, the attachment mechanism is arranged on the top of the base to attach the protective paper to the surface of the steel strip, the attachment mechanism includes a set of rollers, a slide plate, a pressing assembly, a flattening assembly and a traction assembly, the said The cutting mechanism is set on the side of the attaching mechanism to cut the leftover material on the surface of the steel strip. The cutting mechanism includes a support frame, a pushing component and two cutters, a pressing component, a flattening component, a traction component, a pushing component and a controller They are all electrically connected. The protective paper attaching device and working method that can automatically adapt to the width of the steel strip of the present invention can cut the leftovers of the protective paper for steel strips of different widths, and at the same time has its own pressing function to ensure The protective paper adheres effectively and avoids creasing.

Owner:湖南中先智能科技有限公司

A working method and components of a protective paper attachment device capable of automatically adapting to the width of a steel strip

The invention relates to the technical field of steel strip processing, in particular to a protective paper attaching device capable of automatically adapting the width of the steel strip, including a base and an unwinding mechanism, the unwinding mechanism including a turntable, a support column and a drive assembly, and a controller , an attachment mechanism and a cutting mechanism, the attachment mechanism is arranged on the top of the base to attach the protective paper to the surface of the steel strip, the attachment mechanism includes a set of rollers, a slide plate, a pressing assembly, a flattening assembly and a traction assembly, the said The cutting mechanism is set on the side of the attaching mechanism to cut the leftover material on the surface of the steel strip. The cutting mechanism includes a support frame, a pushing component and two cutters, a pressing component, a flattening component, a traction component, a pushing component and a controller They are all electrically connected. The protective paper attaching device and working method that can automatically adapt to the width of the steel strip of the present invention can cut the leftovers of the protective paper for steel strips of different widths, and at the same time has its own pressing function to ensure The protective paper adheres effectively and avoids creasing.

Owner:江西浙丰工贸有限公司

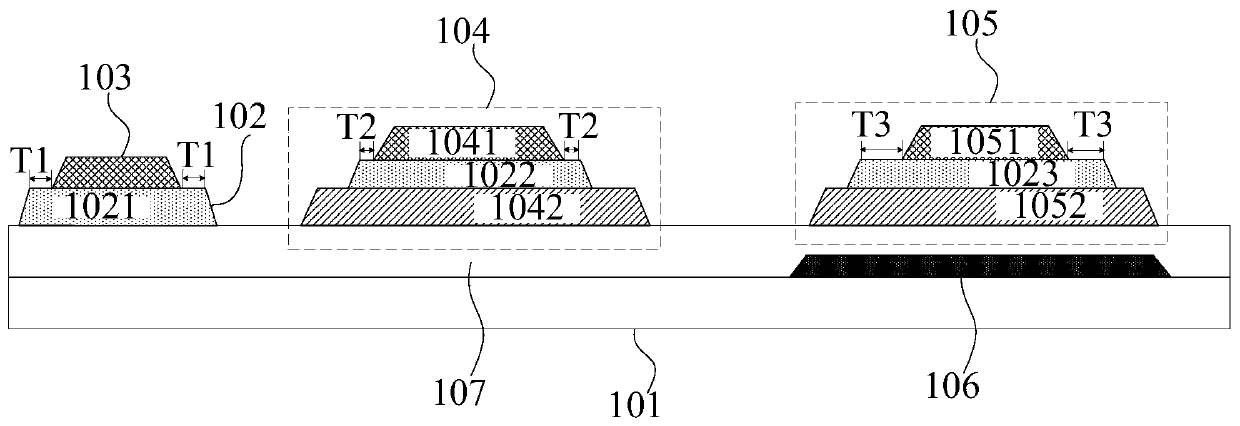

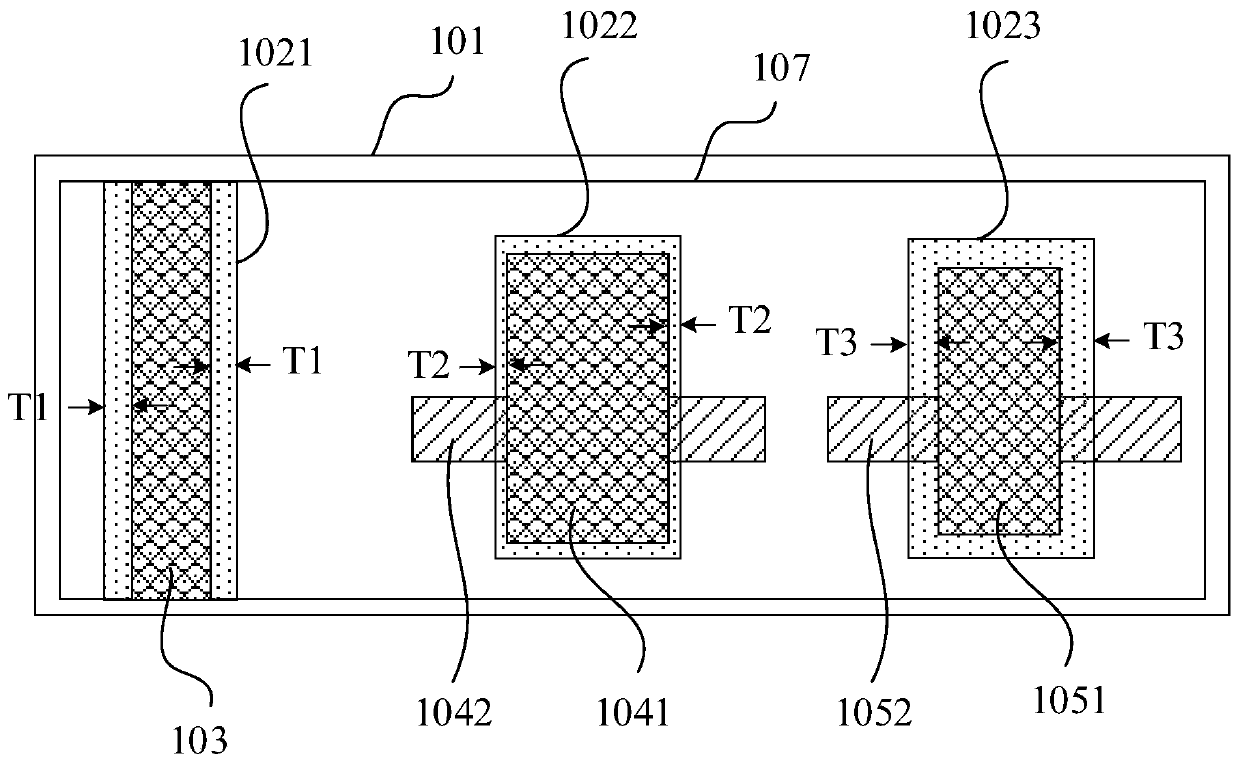

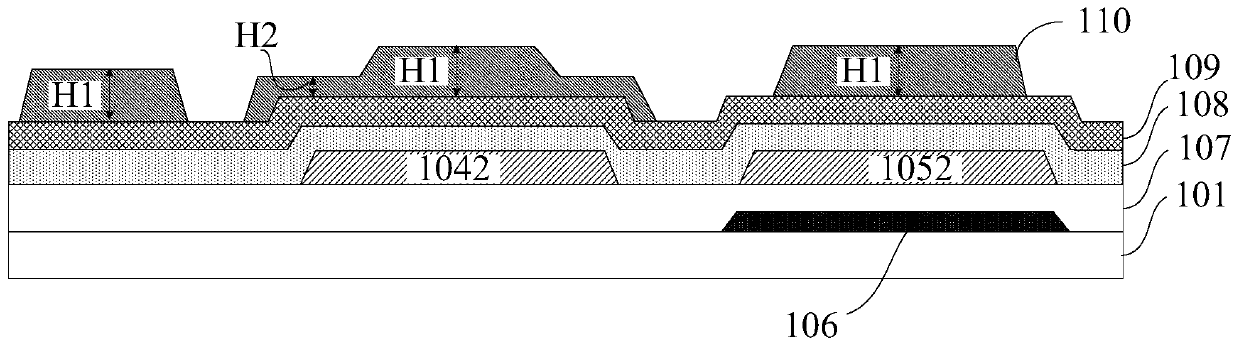

Array substrate, manufacturing method thereof and display device

ActiveCN111312724AChange structurePoor improvementSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an array substrate, a manufacturing method thereof and a display device. The array substrate comprises a gate insulating layer, a gate line and a switching transistor which arelocated on a substrate, the gate insulating layer comprises a first part covering the gate line and a second part covering a gate of the switching transistor; a first distance is formed between an edge of the first part and an edge of the gate line; the first distance is greater than a second distance between an edge of the second part and a gate edge of the switching transistor; equivalently, the GI tail of the gate insulating layer in a switching transistor region is not changed; the GI tail in a gate line region is increased; a subsequent interlayer dielectric layer continuously completestwo climbing processes; due to the fact that the distance between an edge of the gate insulating layer and the edge of the gate line is large, the interlayer dielectric layer is not prone to wrinkles,a subsequent source-drain metal layer cannot be thinned or sharp due to the wrinkles, the DGS defect can be well overcome, meanwhile, the structure of the switching transistor is not changed, it is guaranteed that no newly-added defect exists, and the product yield is increased.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

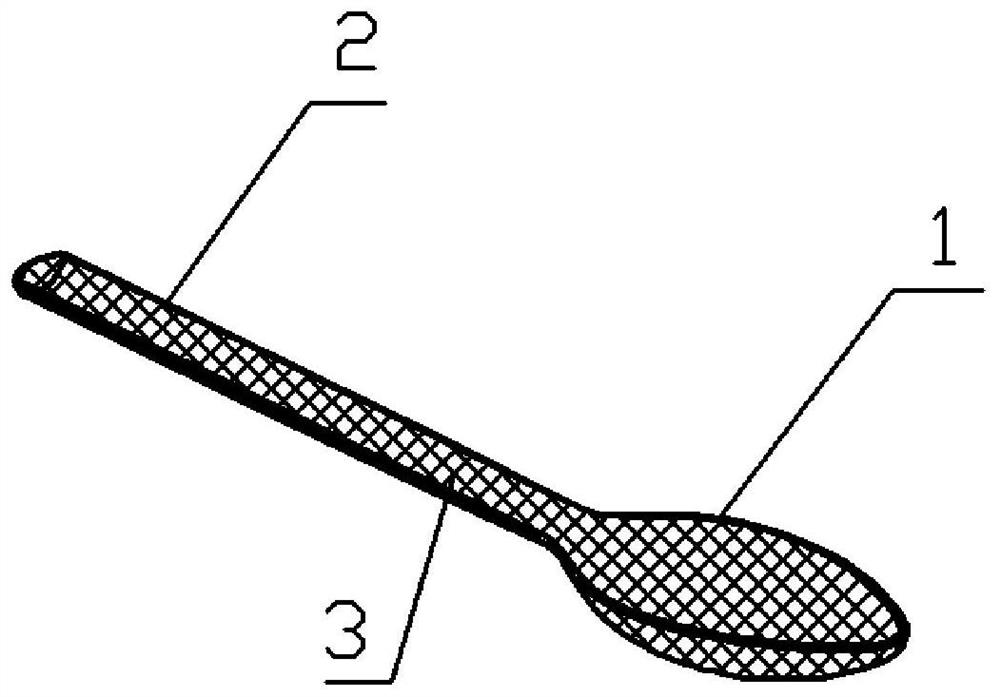

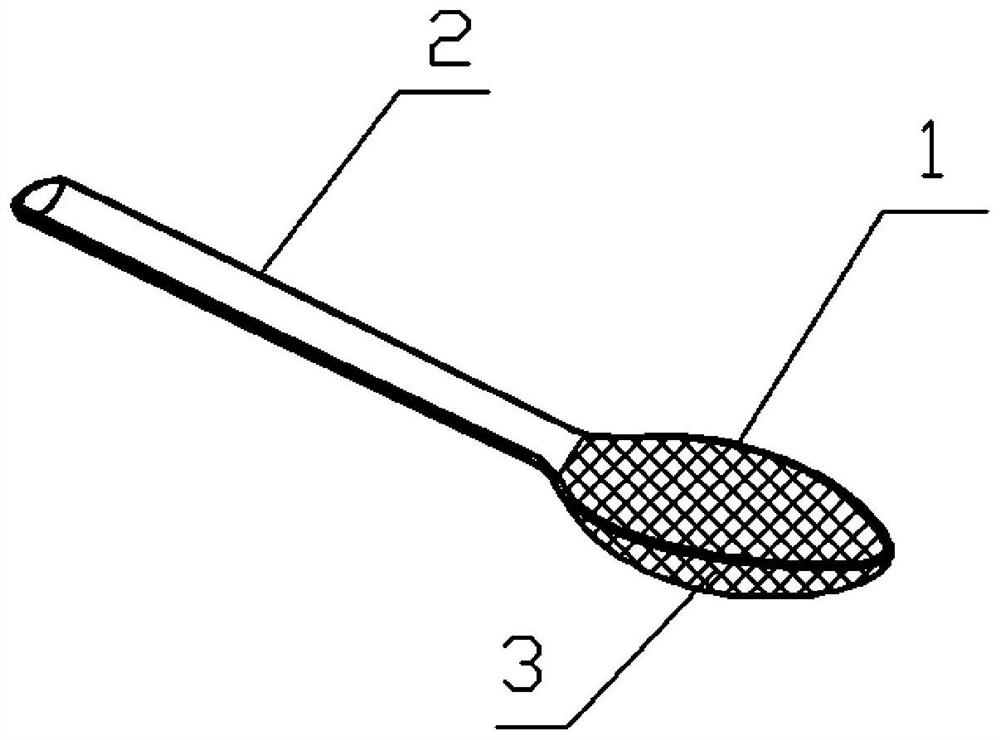

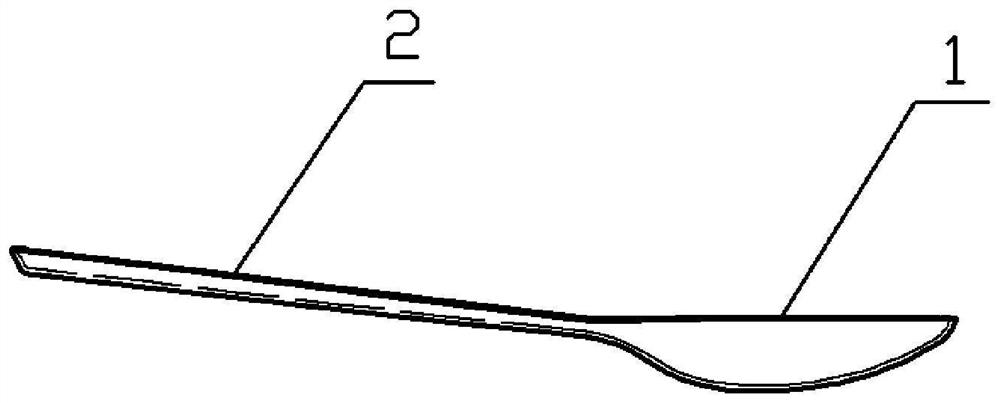

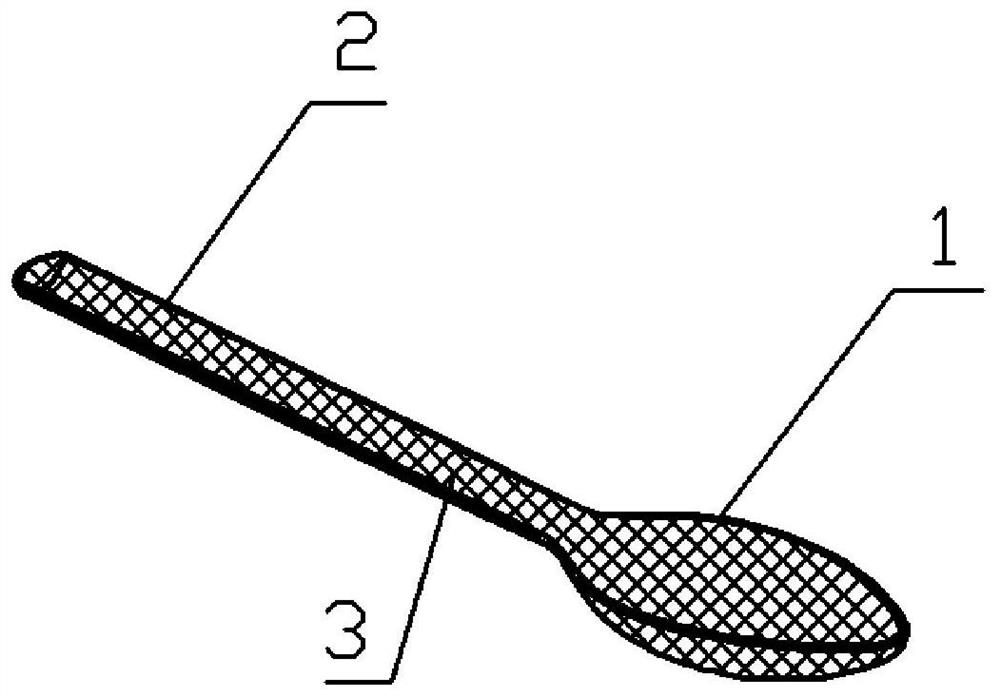

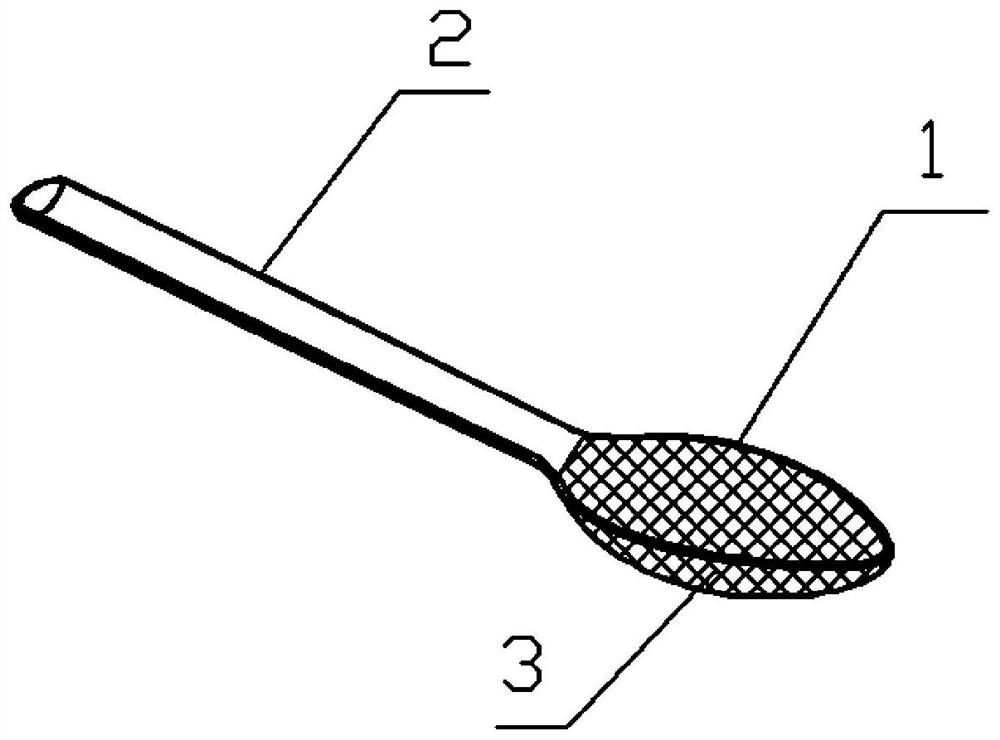

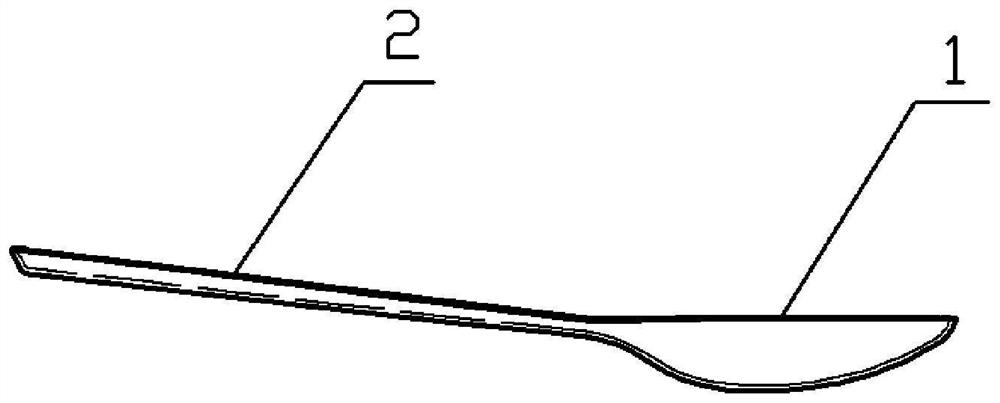

Disposable paper tableware

PendingCN113142949AImprove aestheticsComfortable to useMetal working apparatusMetal-working hand toolsMechanical engineeringIndustrial engineering

The invention relates to the field of tableware, and discloses disposable paper tableware, which comprises a paper handheld part and a containing part, and is characterized in that the edge of the containing part is a concave arc, a plurality of embossed dents are arranged on the surface of the containing part, and the embossed dents extend to the edge of the containing part. The possibility is provided for the effective flowing of the paper surface material of the containing part, the redundant paper surface material flows to the outside of the embossed dents, and finally corresponding embossed patterns are formed, so that the tableware is not easy to wrinkle, and linear creases protruding out of the surface of the tableware are not generated. In this way, the tableware is high in attractiveness, diners can use the tableware more comfortably due to the fact that linear folds protruding out of the surface do not exist, and meanwhile the strength of the disposable paper tableware is enhanced.

Owner:NINGBO YARRA PAPER PROD CO LTD

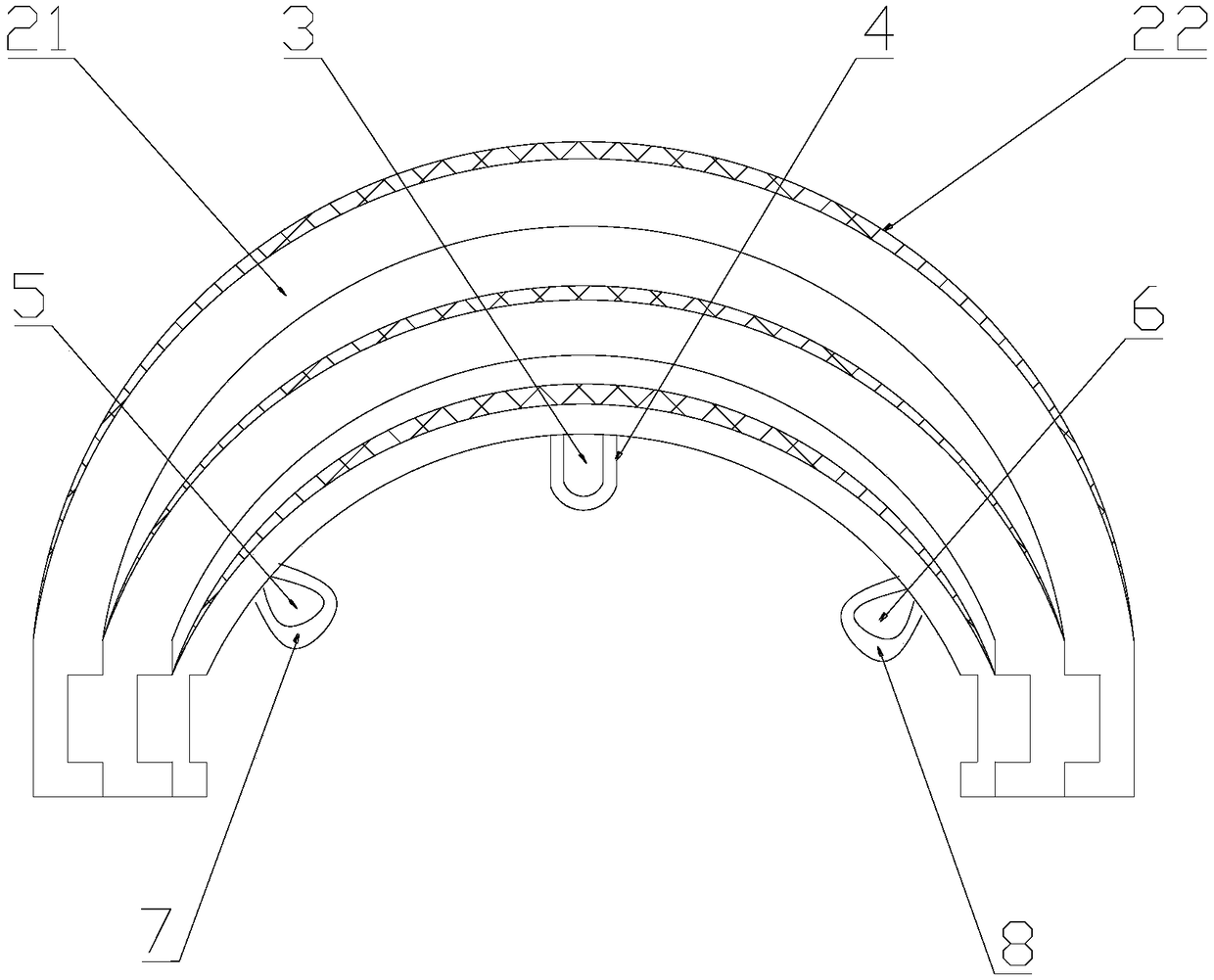

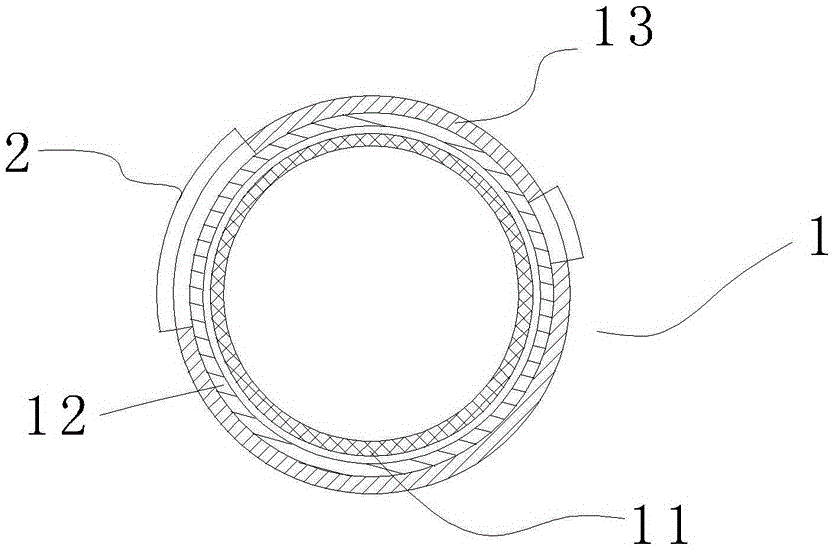

A transparent roller for laser embossing and a laser embossing device

ActiveCN103722917BImprove surface accuracyImprove heat resistancePattern printingStampingElectric machineryLaser patterning

The invention discloses a transparent roller for laser imprinting. The transparent roller comprises a roller body, a roller hub and a roller shaft. The roller body comprises a quartz glass transparent roller and a plastic transparent roller which is arranged on the quartz glass transparent roller in a sleeved mode and is not in contact with the quartz glass transparent roller. The quartz glass transparent roller and the plastic transparent roller are driven in a synchronous mode through a servo motor. The transparent roller is provided with at least one mother set with an engraved laser pattern. The transparent roller further comprises a shading layer which is arranged above the plastic transparent roller. A light transmitting pattern of the shading layer is matched with the laser pattern of the mother set. Correspondingly, the invention discloses a laser imprinting device used for the transparent roller. Point-to-point location special set pattern imprinting transferring can be achieved, the fringing phenomenon of four sides of a transferred pattern is removed, imprinting transferring pattern accuracy is improved, and pattern surface quality is improved.

Owner:广东依明机械科技有限公司

Disposable paper tableware production process

ActiveCN113147100AEasy to operateLow cost of adaptationMechanical working/deformationProcess engineeringIndustrial engineering

The invention relates to the field of tableware, and discloses a disposable paper tableware production process. The disposable paper tableware production process comprises the step of stamping forming, and is characterized in that (a), a paper blank is placed in a forming space of a stamping die, the part of the stamping die, which corresponds to a tableware containing part, is a containing part forming surface, a cavity formed by enclosing the containing part forming surface is in a concave shape, and embossed protrusions are arranged on the containing part forming surface and extend to the edge of the containing part forming surface; and (b), the stamping die fully contacts with the paper blank to form a formed product. The disposable paper tableware production process is technically improved on the basis of the stamping forming process, the operation is simple, and a production line does not need to be greatly improved. The processed tableware is free of wrinkles and high in attractiveness, diners can use the tableware more comfortably due to the fact that linear creases protruding out of the surface do not exist, and meanwhile, the strength of the disposable paper tableware is enhanced.

Owner:NINGBO YARRA PAPER PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com