Square tube manufacturing equipment capable of achieving continuous forming through deformation

A technology of manufacturing equipment and deformation, applied in the direction of mechanical processing/deformation, metal processing, etc., can solve the problems of limited production efficiency of spiral square paper tubes, the production efficiency of square paper tubes needs to be further improved, and many limiting factors, etc., to achieve improvement Transfer efficiency, low processing difficulty, saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

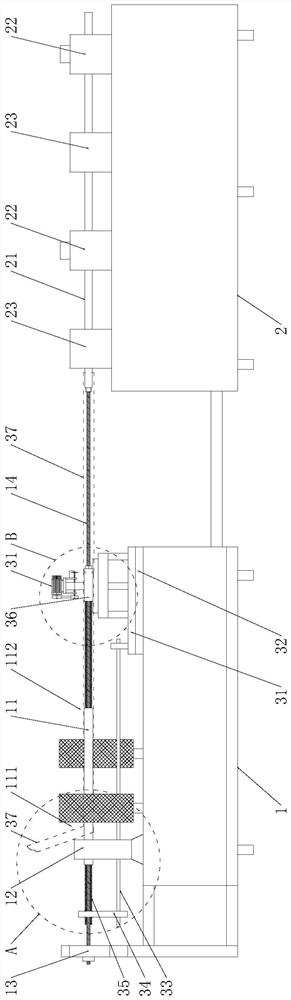

[0059] figure 1 It shows a continuous forming square tube manufacturing equipment through deformation in a preferred embodiment of the present invention, including a circular paper tube manufacturing equipment 1 and a square paper tube manufacturing equipment 2 .

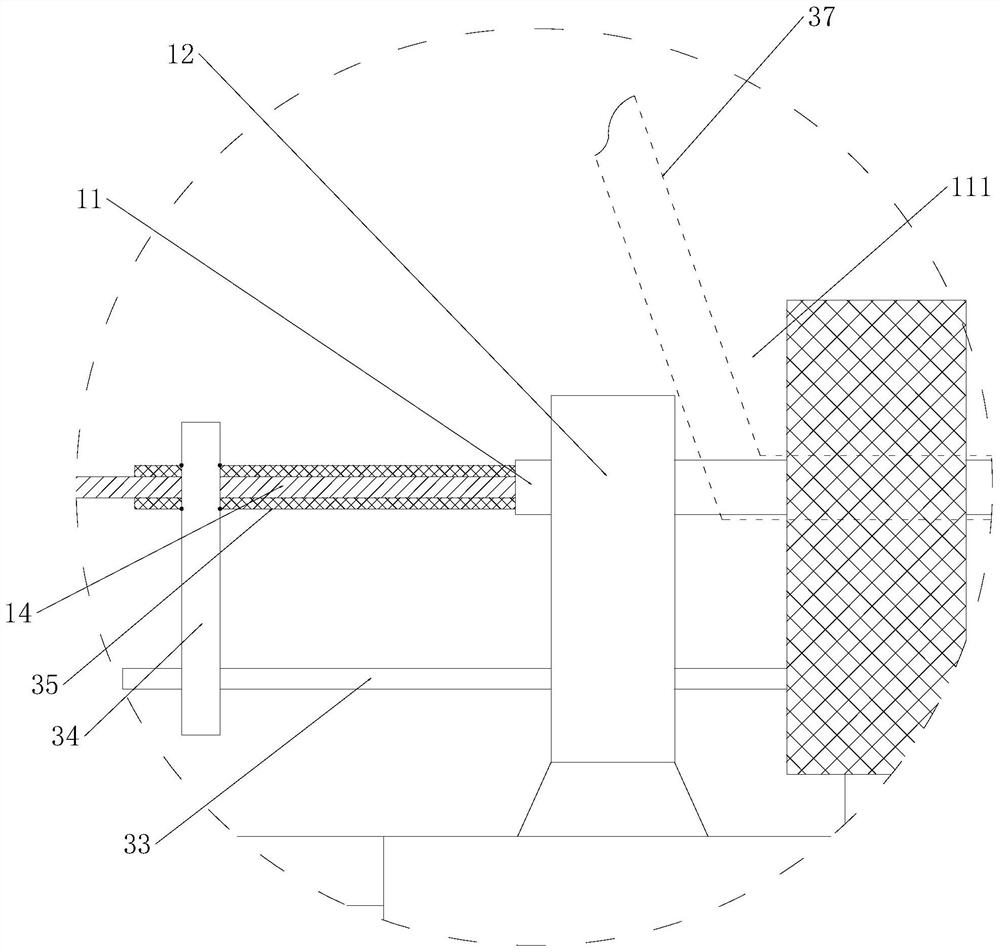

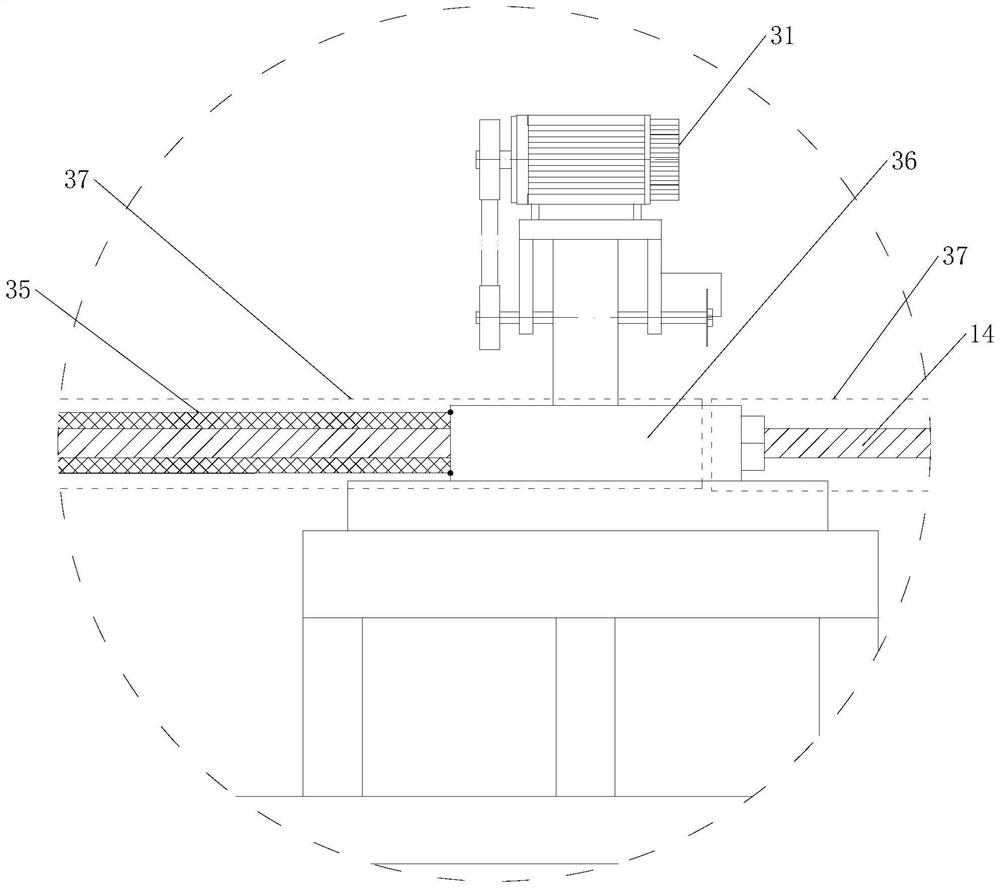

[0060] see figure 1 and figure 2 , The circular paper tube manufacturing equipment 1 has a circular tube inner mold 11, and the circular tube inner mold 11 is used for forming a circular paper tube. The blanking end 112 of the circular tube inner mold is closer to the square paper tube manufacturing equipment 2 than the feeding end 111 of the circular tube inner mold, and the feeding end 111 of the circular tube inner mold is used for winding the slitting paper (the slitting paper is figure 2 Workpieces in 37). Driven by the circular paper tube manufacturing equipment 1, the workpiece 37 moves along the axial direction of the circular tube inner mold 11, and spirally winds around the circumferential direction o...

no. 2 example

[0082] Figure 17 and Figure 18 It shows a structural schematic diagram of the left and right rolling mechanism and the up and down rolling mechanism of a continuous forming square tube manufacturing equipment according to the second embodiment of the present invention. It differs from the first embodiment in that it is controlled by electric means, so as to be applicable to workpieces 37 of different sizes. details as follows:

[0083] Preferably, the square paper tube manufacturing equipment 2 is provided with a left and right rolling mechanism 22 and an up and down rolling mechanism 23, and a left and right rolling mechanism 22 (see Figure 17 ) for rolling the opposite sides of the circular paper tube in the horizontal direction until the flat structure, the upper and lower rolling mechanism 23 (see Figure 18 ) for rolling the opposite sides of the circular paper tube in the direction of gravity until a flat structure.

[0084] see Figure 17 , the left and right ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com