Patents

Literature

31results about How to "Neat ends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

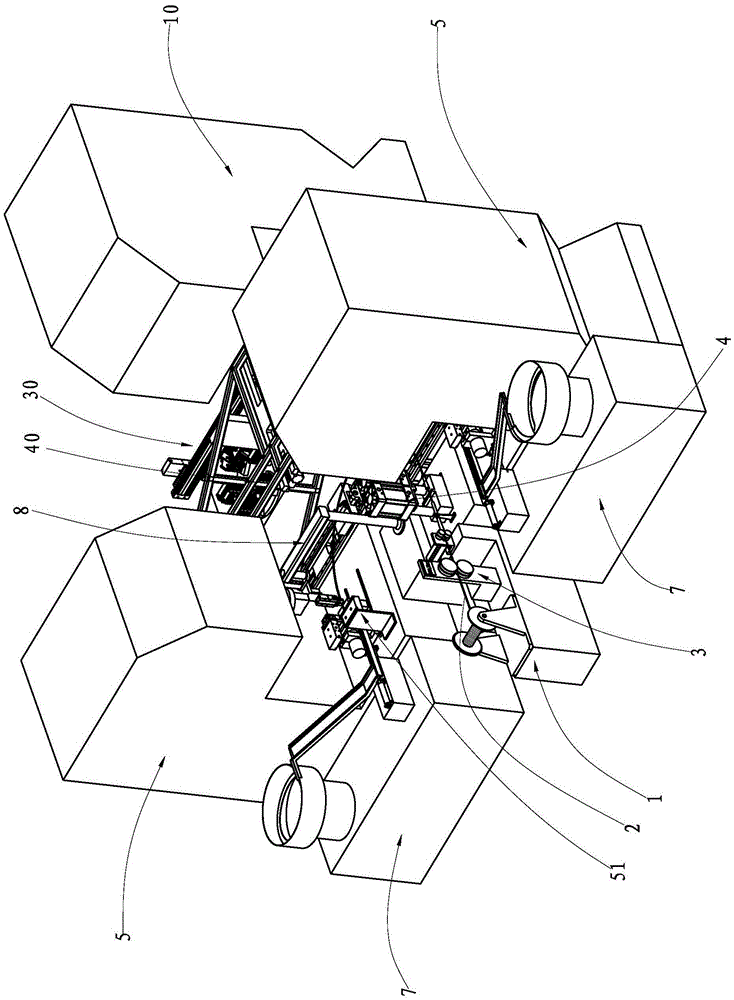

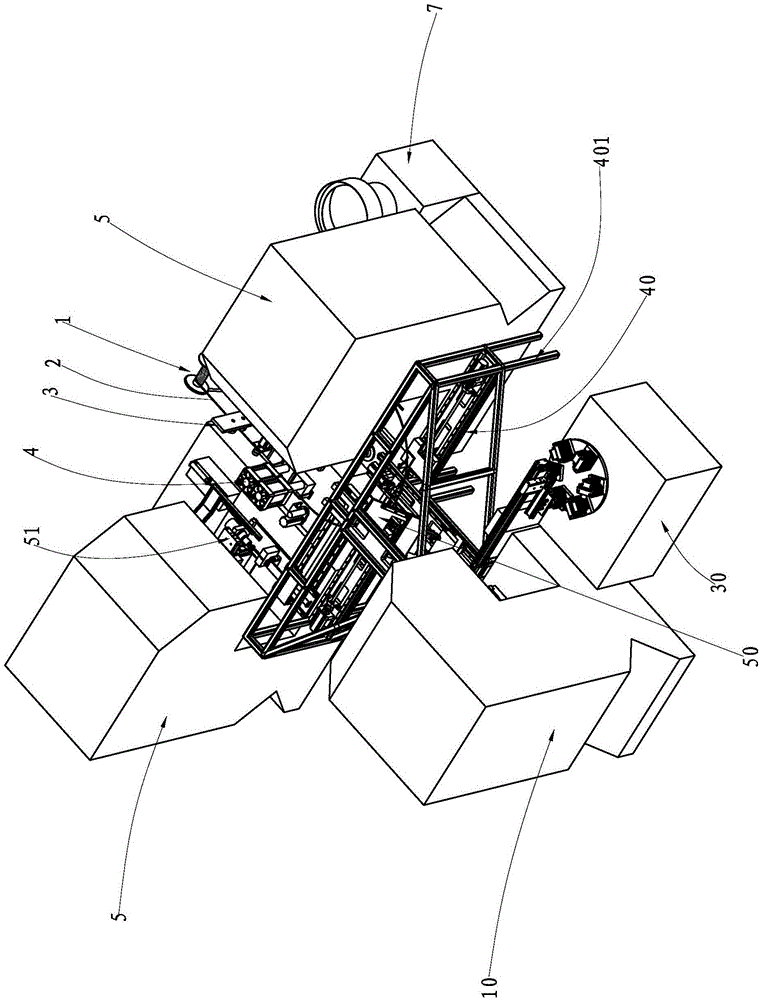

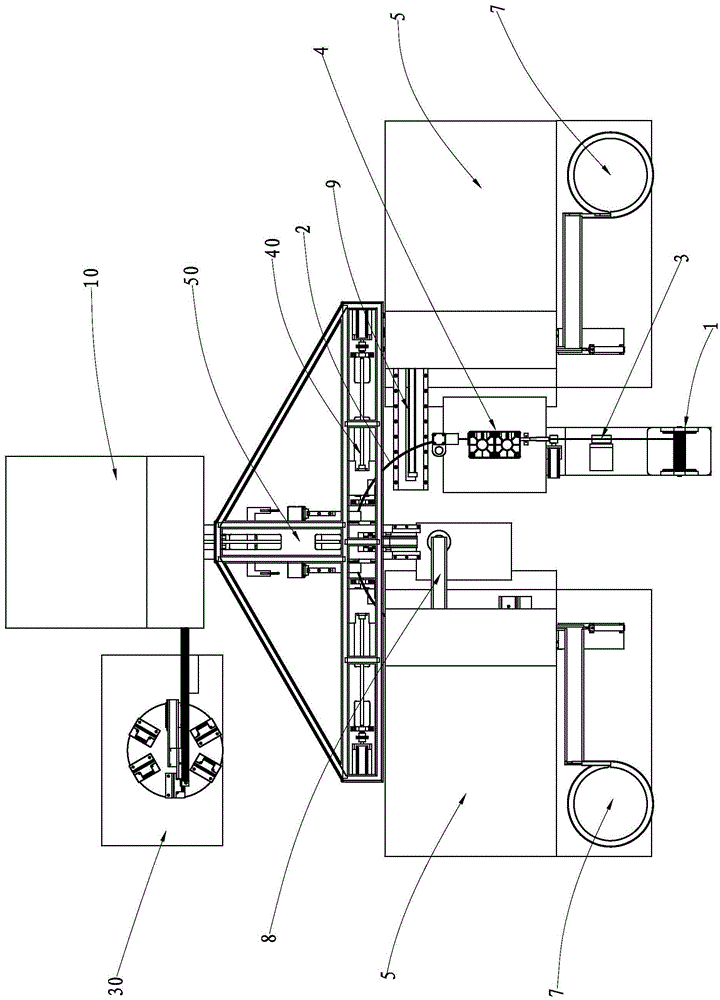

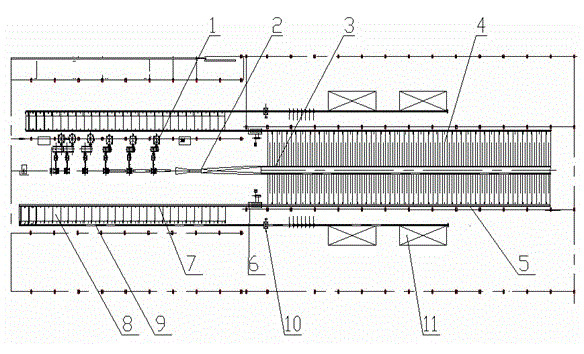

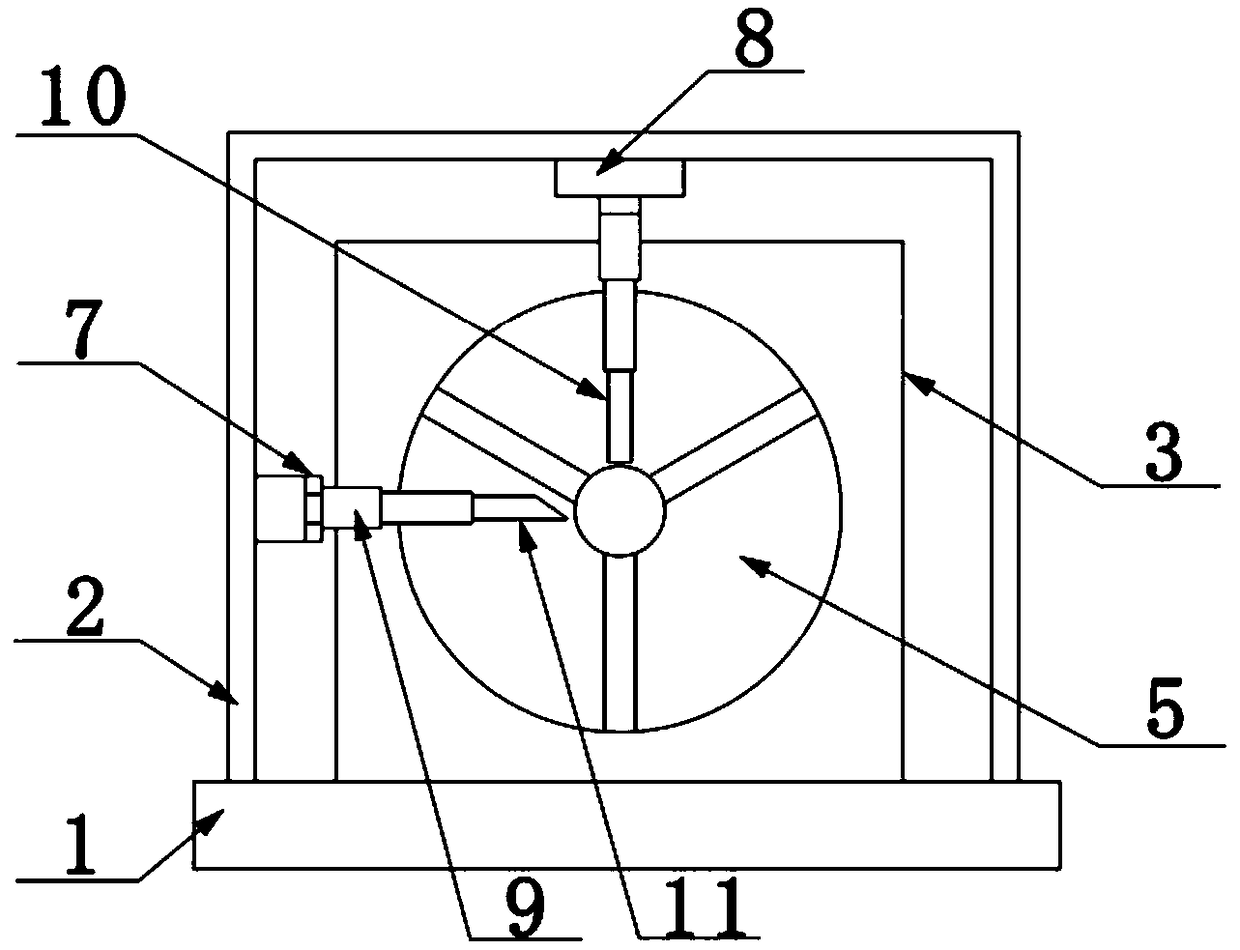

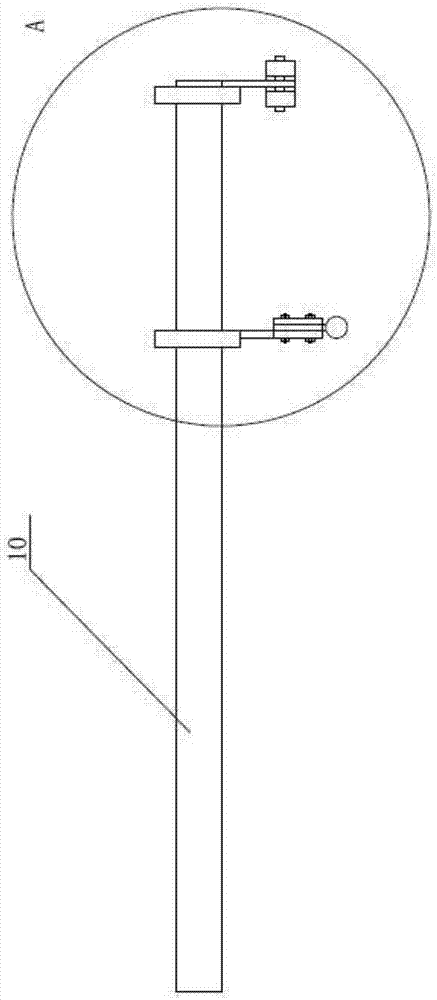

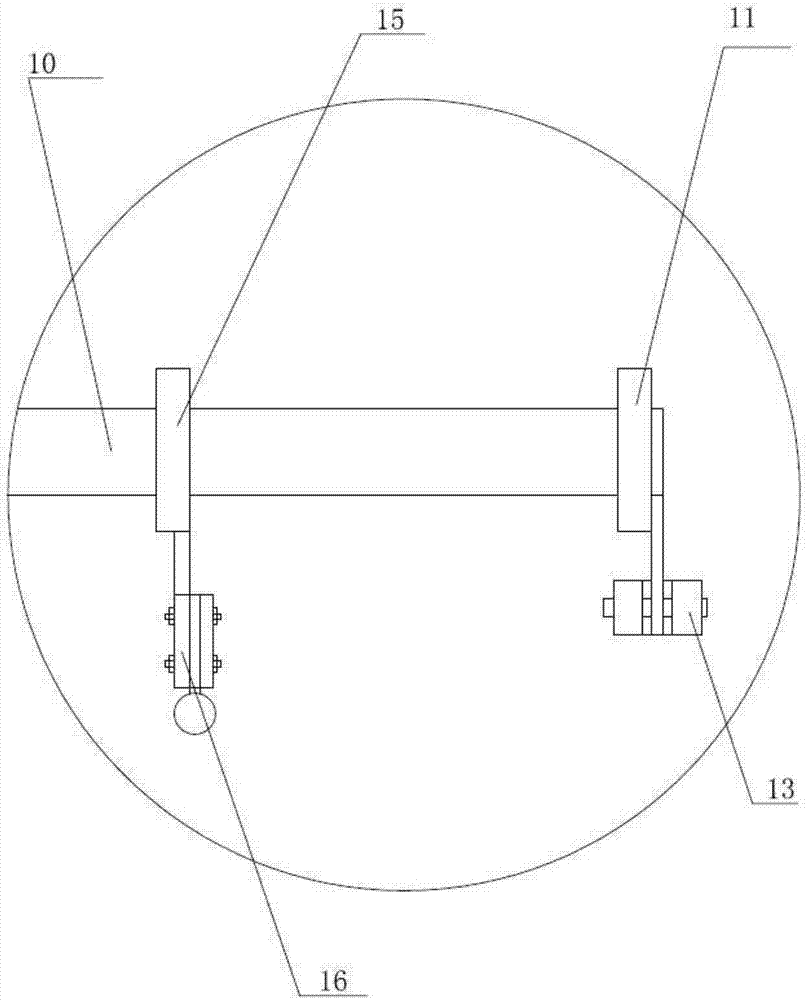

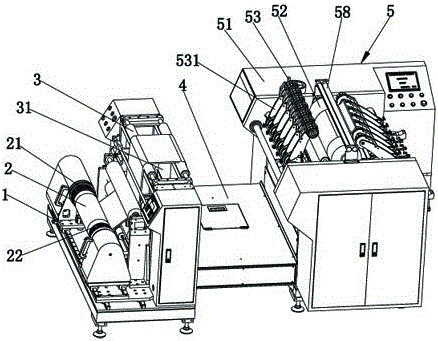

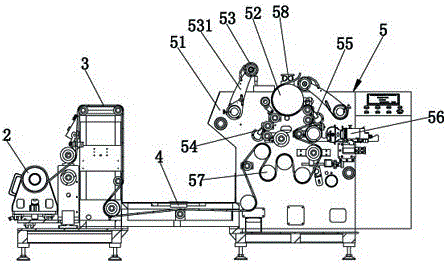

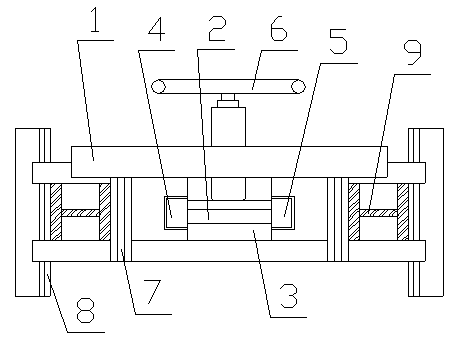

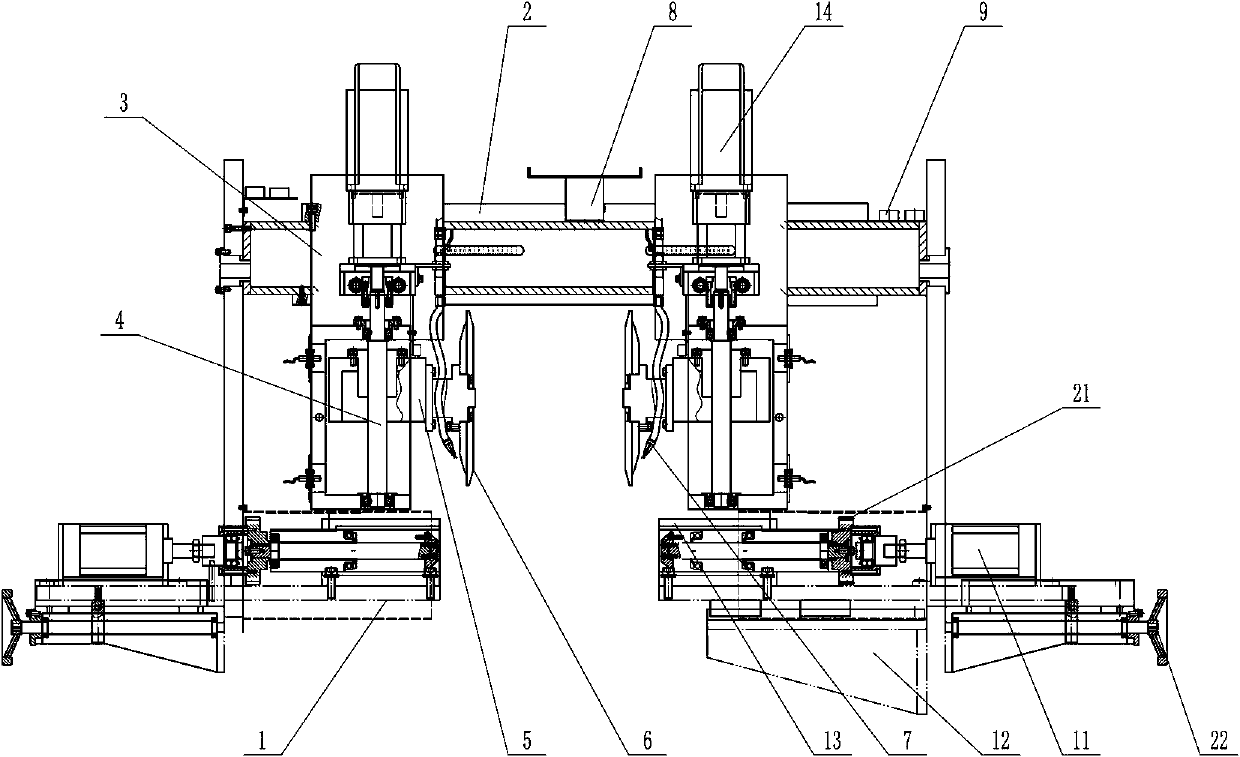

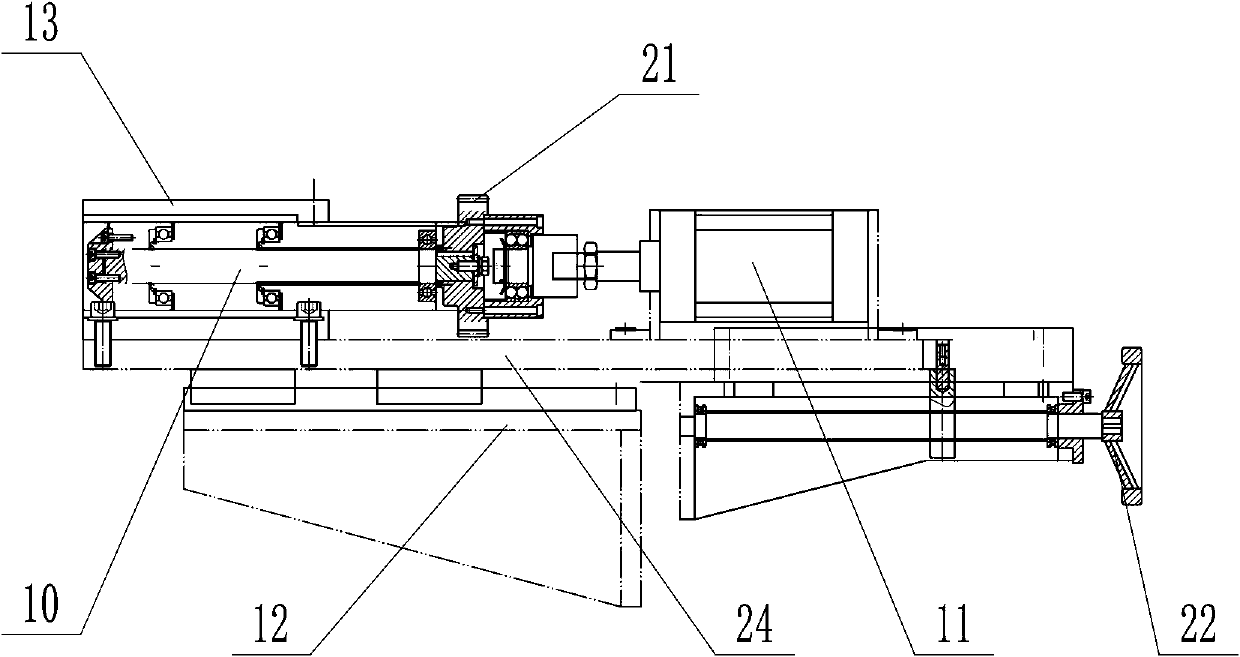

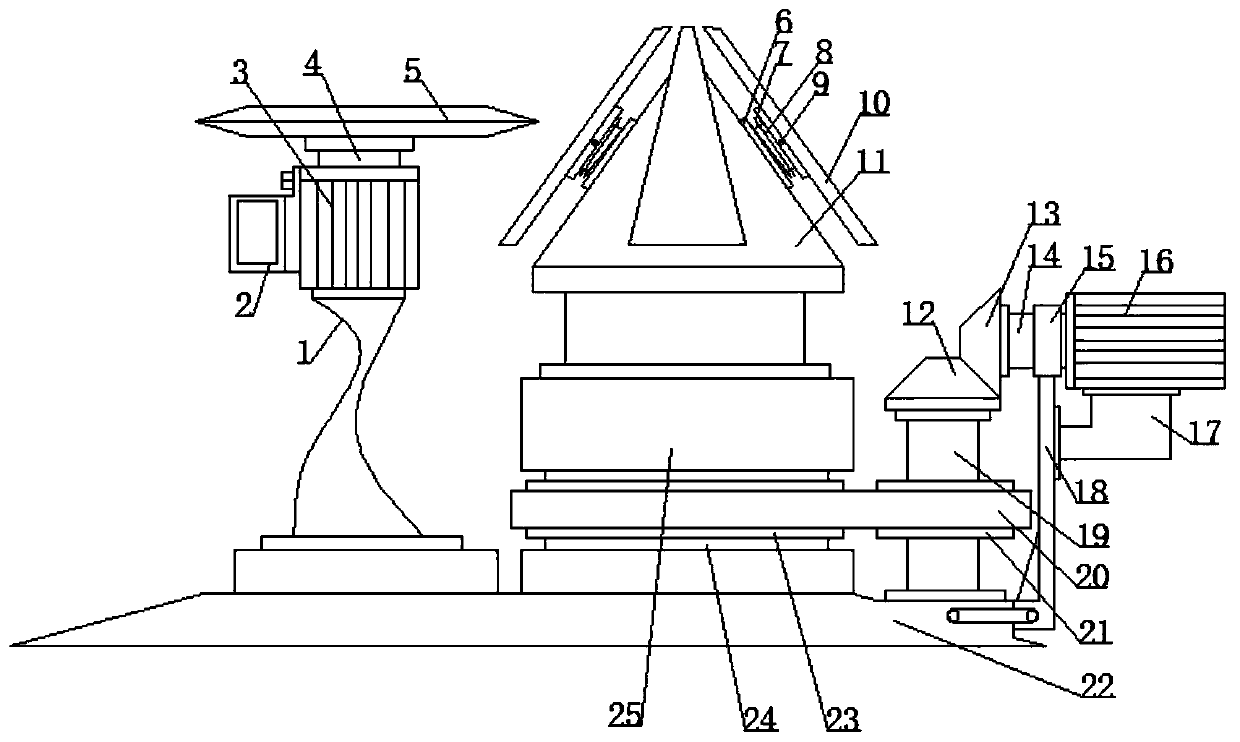

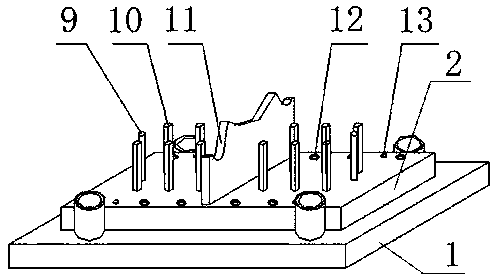

Steel rope processing equipment

ActiveCN105537430ARealize automated productionReduce labor costsMetal-working feeding devicesMetal working apparatusPunch pressButt joint

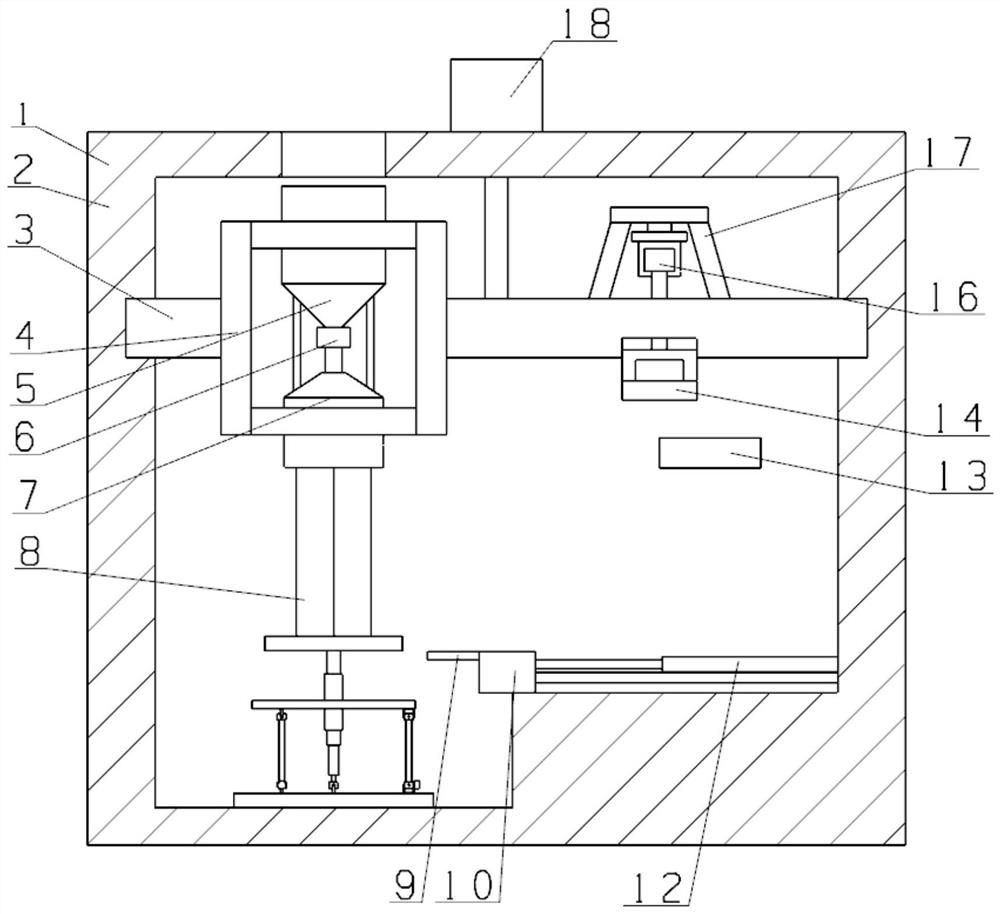

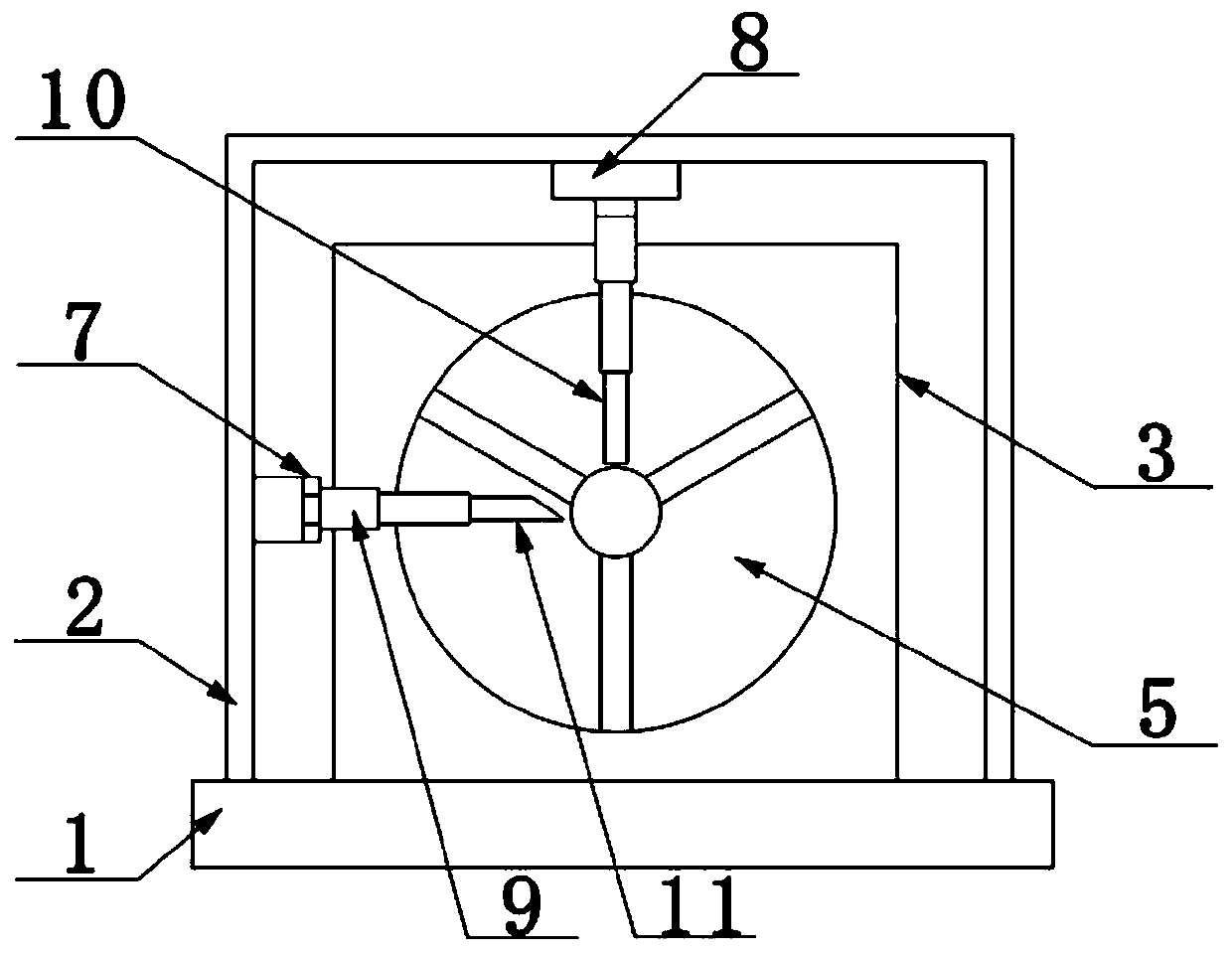

The invention discloses steel rope processing equipment. Firstly, a steel rope is automatically conveyed by a steel rope feeding device; the front end of the steel rope is clamped by a front-end clamping rotary mechanism, and is rotated to an end part processing punch so as to be in butt joint and riveted with a screw; then, the steel rope is straightened by a steel rope length computing auxiliary mechanism, the length of the steel rope is computed by a counter, the steel rope feeding device and the steel rope length computing auxiliary mechanism stop when the length of the steel rope reaches designed length, and a steel rope cut-off device correspondingly cuts off the steel rope; the tail end of the steel rope is clamped by a tail-end clamping translation mechanism, and is moved to a processing punch on the other end part for being in butt joint and riveted with the screw; the middle part of the steel rope is clamped by a middle butt-joint mechanism, and is moved to a connecting plate processing punch so as to be in butt joint and riveted with a connecting plate, so that the finished product processing is completed; and in the whole processing process, only one person is required to operate and control, so that automatic production is realized, labor cost is reduced, the production efficiency is improved and the yield is increased, and therefore, the steel rope processing equipment is suitable for large-scale processing production.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

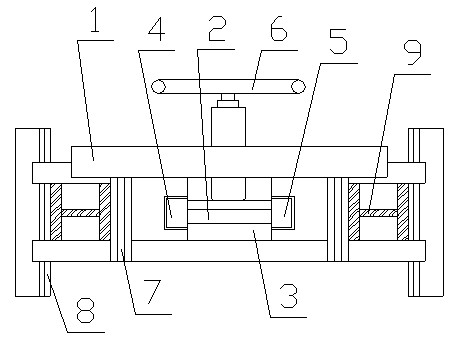

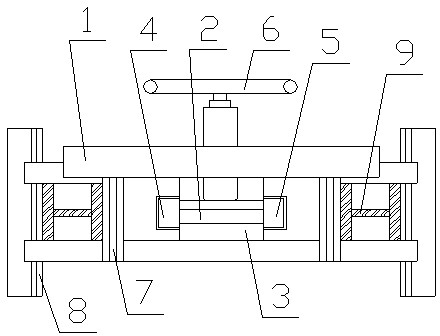

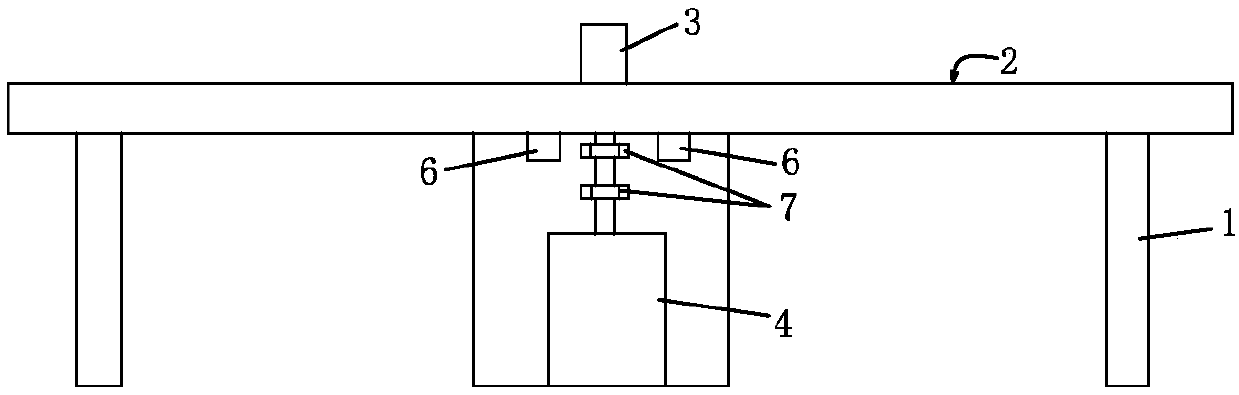

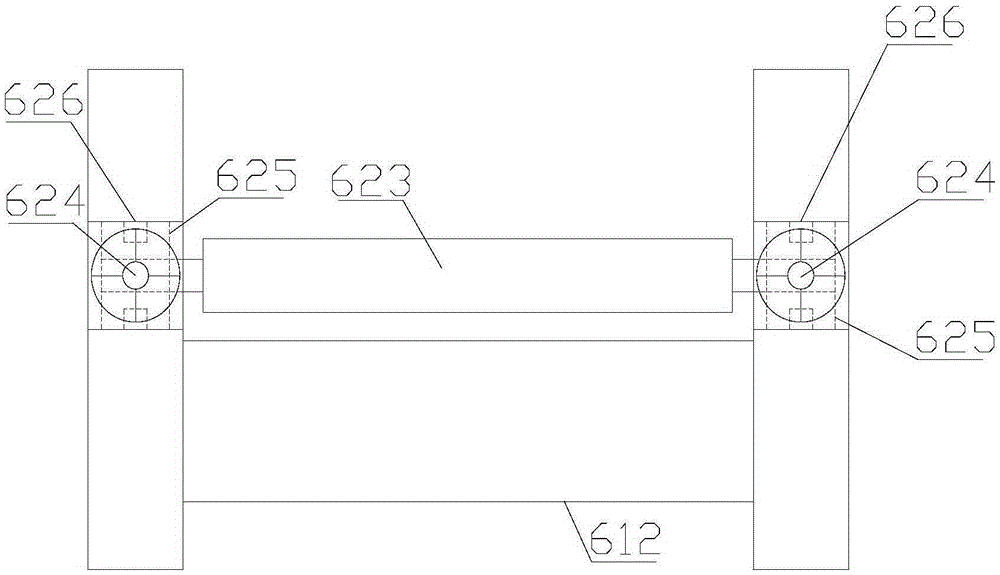

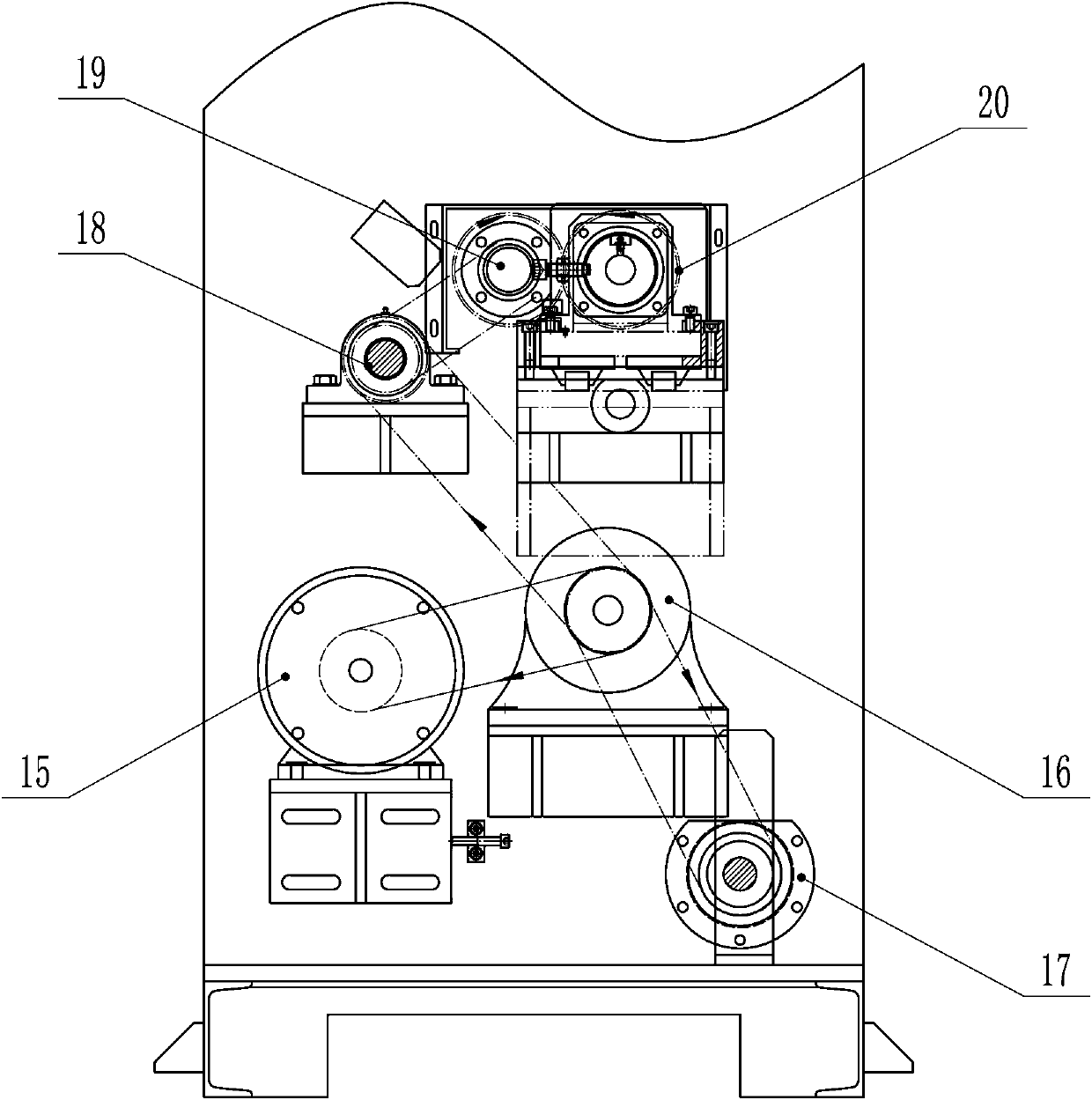

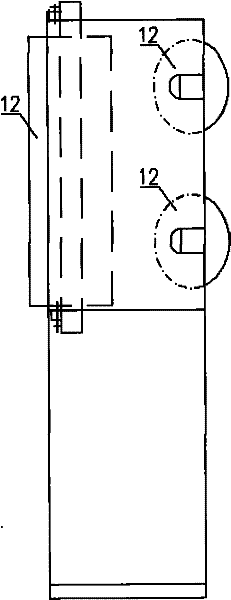

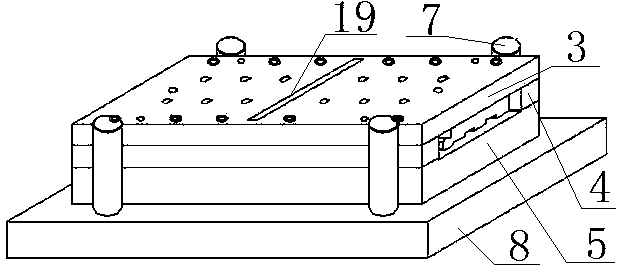

Rolling mill guide mechanism

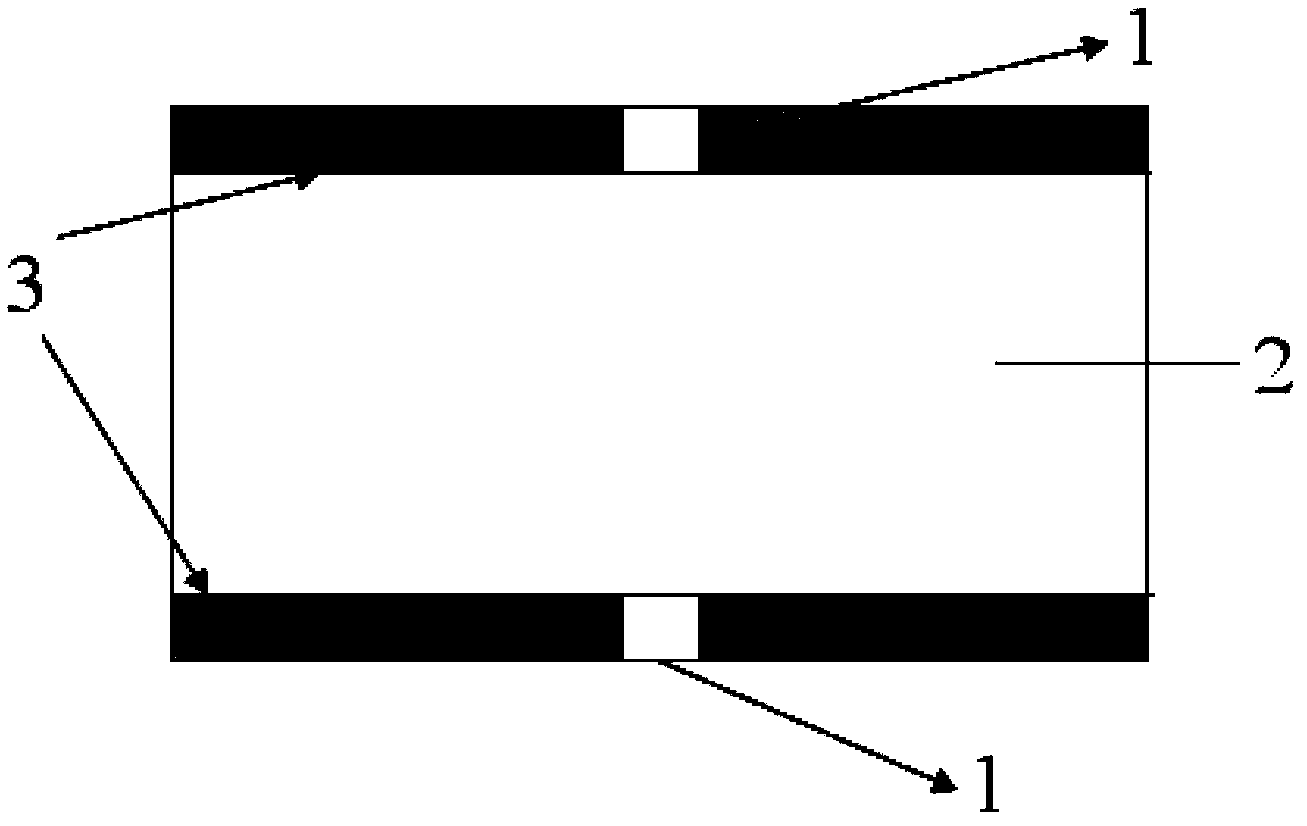

ActiveCN102513380AAvoid bouncing up and down situationsThe case of bouncing up and down will notGuiding/positioning/aligning arrangementsEngineeringSteel belt

The invention relates to a rolling mill guide mechanism with the advantages that the combined fixation mode is adopted, the material position guide can be realized, the finished product rate of materials can be greatly improved, the waste of strip heads and strip tails of the materials is also reduced, and a large number of raw materials are saved. The rolling mill guide mechanism comprises a machine frame, wherein an upper clamping plate and a lower clamping plate are arranged between an upper cross beam and a lower cross beam of the machine frame, a left guide device and a right guide device are arranged at two sides of the upper clamping and the lower clamping plate, the upper cross beam of the machine is provided with a vertical position guide regulator, in addition, a regulating rod arranged at the bottom of the vertical position guide regulator passes through the upper cross beam to be connected with the upper clamping plate, and parts of the upper clamping plate and the lower clamping plate connected with the left guide device and the right guide device are provided with locking plates. The rolling mill guide mechanism has the advantages that 1, a position guide mechanism is applicable to the position guide of materials with different thicknesses, and in addition, the condition of vertical material jumping caused by the shaking generated during the rolling mill operation is avoided; and 2, the position guide mechanism is adopted, the tail parts of finished steel strips and the head parts of non-rolled materials are ensured to pass through a rolling mill for rolling, and the waste of raw materials is reduced.

Owner:浙江富日进精密金属股份有限公司

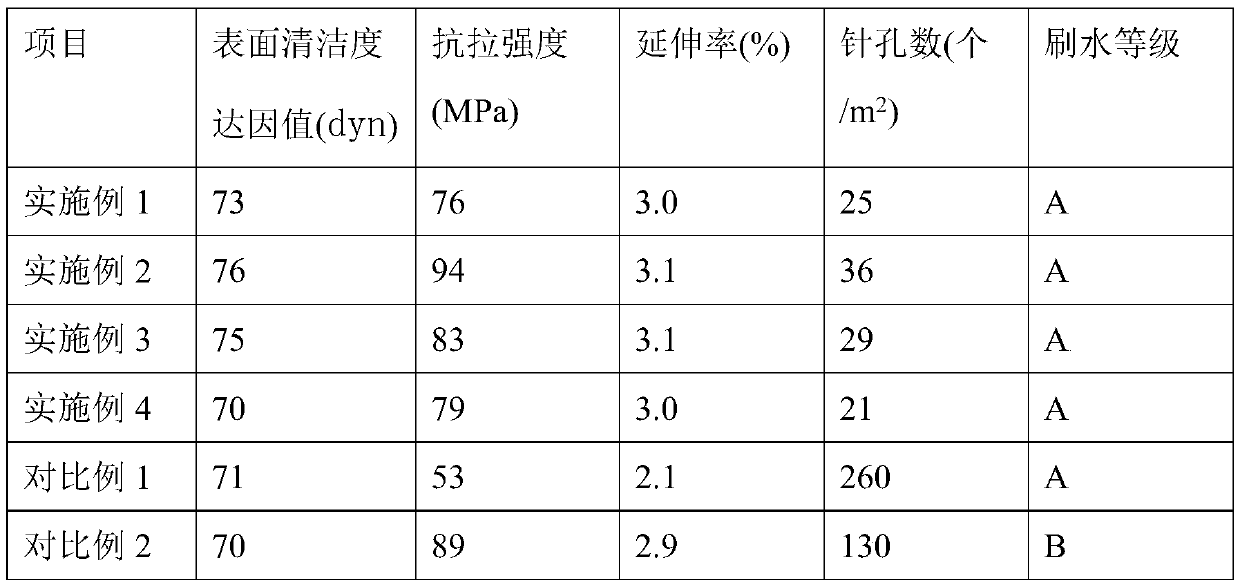

Rare earth aluminum-manganese alloy sterilization foil for fresh steaming brick of pet food package and production technology thereof

PendingCN111589861ANeat endsThickness deviation range is smallRollsMetal rolling arrangementsManganeseAlloy

The invention discloses rare earth aluminum-manganese alloy sterilization foil for a fresh steaming brick of a pet food package. The foil comprises the following raw materials of, by mass percentage,less than or equal to 0.3% of Si, less than or equal to 0.6% of Fe, 0.12-0.18% of Cu, 1.1-1.4% of Mn, 0.10-0.25% of La, less than or equal to 0.01% of Mg, less than or equal to 0.03% of Zn, less thanor equal to 0.05% of Ti, less than or equal to 0.01% of P, less than or equal to 0.03% of Li, and the balance Al. The foil is obtained through cast-rolled coil production, rolling in a cold rolling mill, a foil rolling process, a finished product cutting process, a finished product annealing process and an inspection and packaging process. The rare earth aluminum-manganese alloy sterilization foilfor the fresh steaming brick of the pet food package has the advantages of uniform structure, flatness, no wave, consistent foil surface color and high heat resistance, heat conduction, flexibility,corrosion resistance and air tightness of the aluminum foil completely meet the requirements of the sterilization aluminum foil for the fresh steaming brick of the pet food package.

Owner:JIANGSU ZHONGJI LAMINATION MATERIALS

Finishing method for straightening small and medium-sized angle steel double-line long ruler

The invention discloses a finishing method for straightening a small and medium-sized angle double-line long ruler. The finishing method is characterized in that two finishing lines are simultaneously arranged at the back of a continuous and finishing mill, and finished angle steel can simultaneously enter the two finishing lines; a bifurcation roller bed is arranged before the finished angle steel is delivered; the finished angle steel firstly enters a cooling bed for cooling; after being cooled, the finished angle steel enters a straightening machine for straightening; after being straightened, the finished angle steel enters a pay cooling bed for aggregating and grouping; then, the finished angle steel is exported for shearing; after being sheared, the finished angle steel is exported for classification packing and bundling; and finally, the finished angle steel is calculated for storing. By the finishing method, the finished angle steel is straightened and then sheared without being dredged, thereby saving labor and time and greatly simplifying the distribution of the whole finishing lines.

Owner:安徽中杭股份有限公司

Machining technique for equal-height sleeve

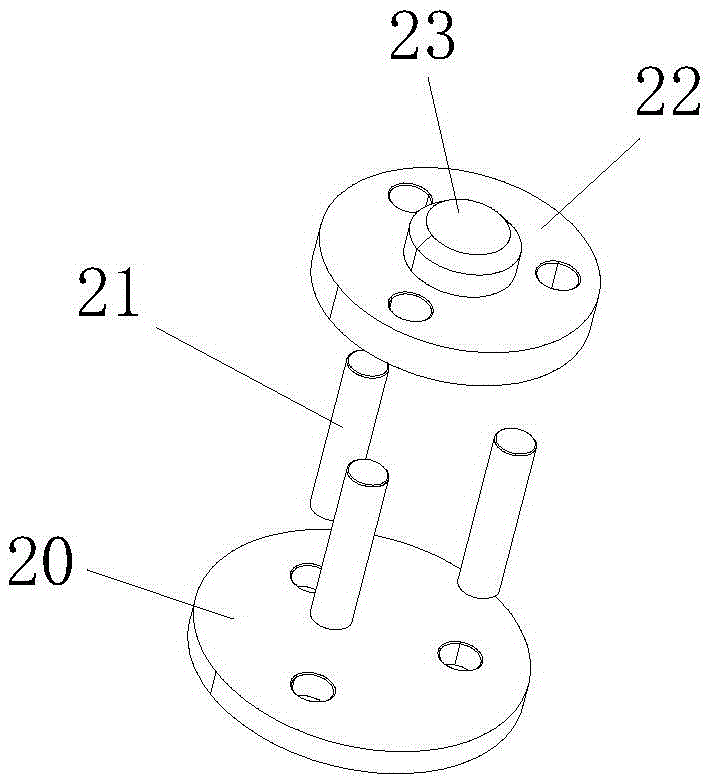

The invention discloses a machining technique for an equal-height sleeve. The machining technique for the equal-height sleeve comprises the following steps that 1, a fixing base is prepared and pluralities of threaded holes are formed in the upper end face of the fixing base; 2, one end of a column-shaped material is fixed and marked as a surface A, and the other end is subjected to the grinding treatment and marked as a surface B; 3, a first receding groove and a second receding groove are formed in the surface A and the surface B of the column-shaped material respectively, and a receding hole is formed to make the first receding groove to communicated with the second receding groove; 4, a bolt penetrates into the receding hole of the column-shaped material so as to fix the column-shapedmaterial on the fixing seat; 5, one-cutter grinding on the surfaces A of a plurality of the column-shaped materials is carried out; 6, pluralities of the column-shaped materials are reversely locked,and one-cutter grinding is then carried out on the surfaces B; and 7, a through hole in the axial direction is formed in the column-shaped material which is ground at the two ends, the through hole covers the original first receding groove, the receding hole and the second receding groove, and the equal-height sleeve is thus obtained. By means of the one-cutter grinding, end parts of a plurality of equal-height sleeves can be guaranteed to be flush after being machined so as to reduce the tolerance among the matched equal-height sleeves.

Owner:浙江优端精密电子科技有限公司

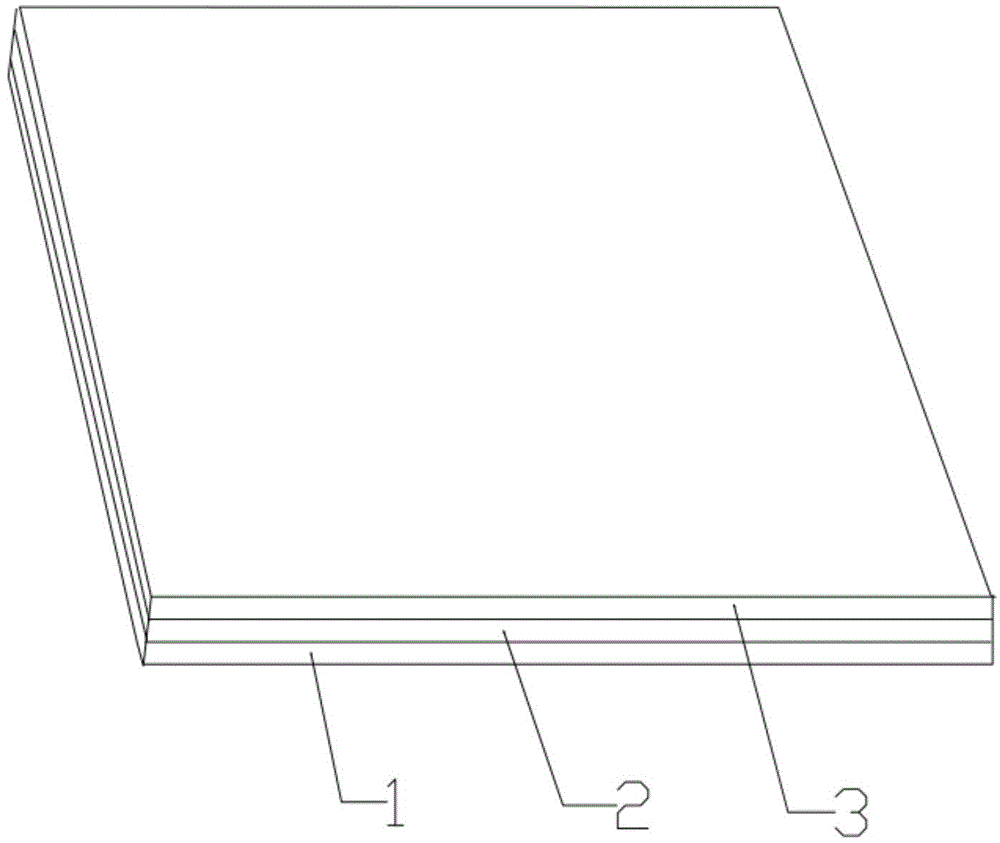

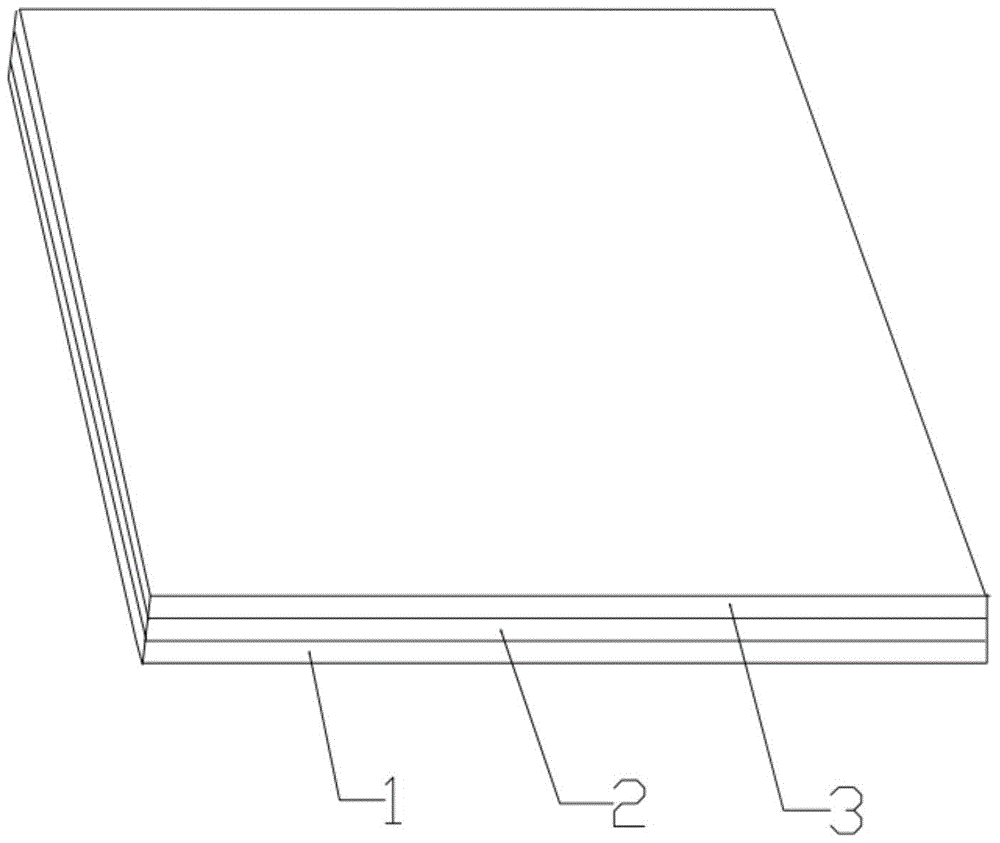

Plastic film with layering control function and preparation method thereof

ActiveCN104890333ASpeed upInaccessibleSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention relates to a plastic film with a layering control function and a preparation method thereof. The plastic film comprises a bonding layer, an easy-to-tear layer and a stripping layer, wherein the bonding layer is prepared from ethylene-acrylic acid copolymer or ethylene-methacrylic acid copolymer; the easy-to-tear layer is prepared from a blend formed by mixing ethylene-vinyl acetate copolymer, ethylene-methacrylic acid ionic polymer, poly-1-butene, silicon dioxide, beta-propionic acid octade, triphenyl phosphite, N,N'-ethylenebisoctadecanamide, 2,6-Di-tert-butyl-4-methylphenol, oleamide, triphenyl phosphate and oleyl palmitamide according to a certain weight ratio; the stripping layer is prepared from a blend formed by mixing ethylene-vinyl acetate copolymer, low-density polyethylene and a linear low-density polyethylene resin material according to a certain weight ratio. The plastic film with the layering control function ensures that an external sheath layer of an optical cable or an electric cable can be disengaged from the bonding layer and also ensures that a metal-plastic composite belt is free of moisture invasion.

Owner:烟台万泰通信科技有限公司

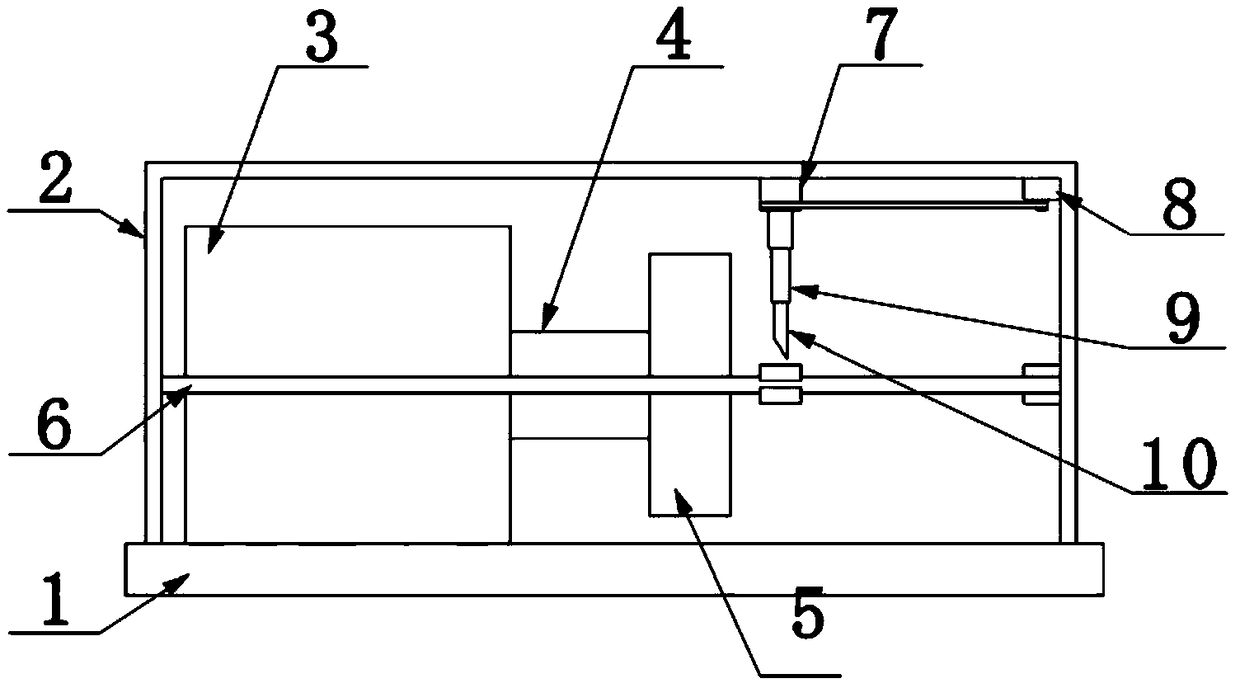

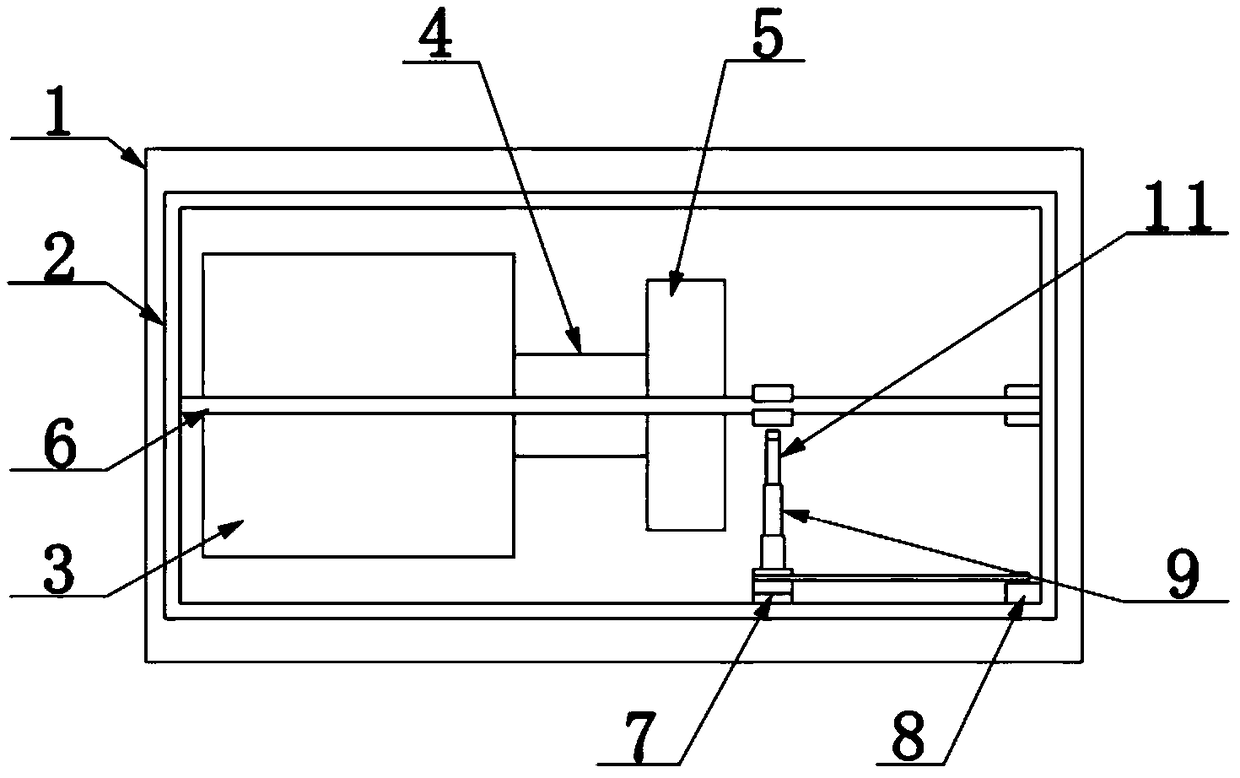

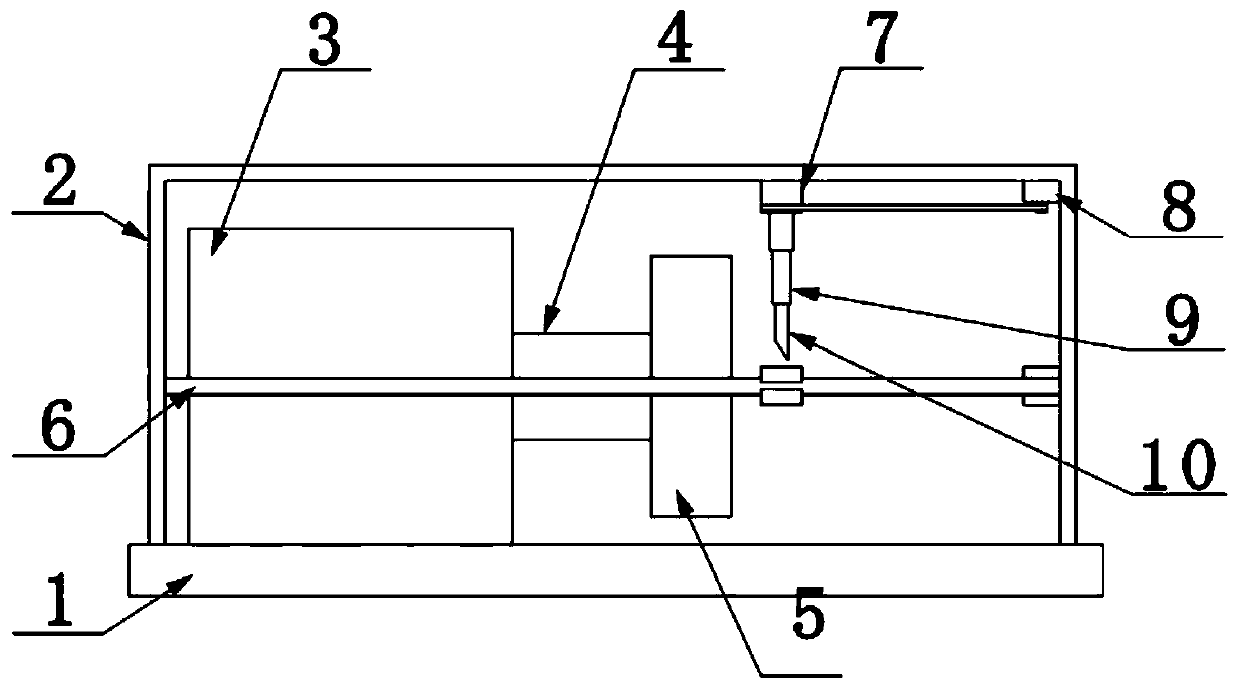

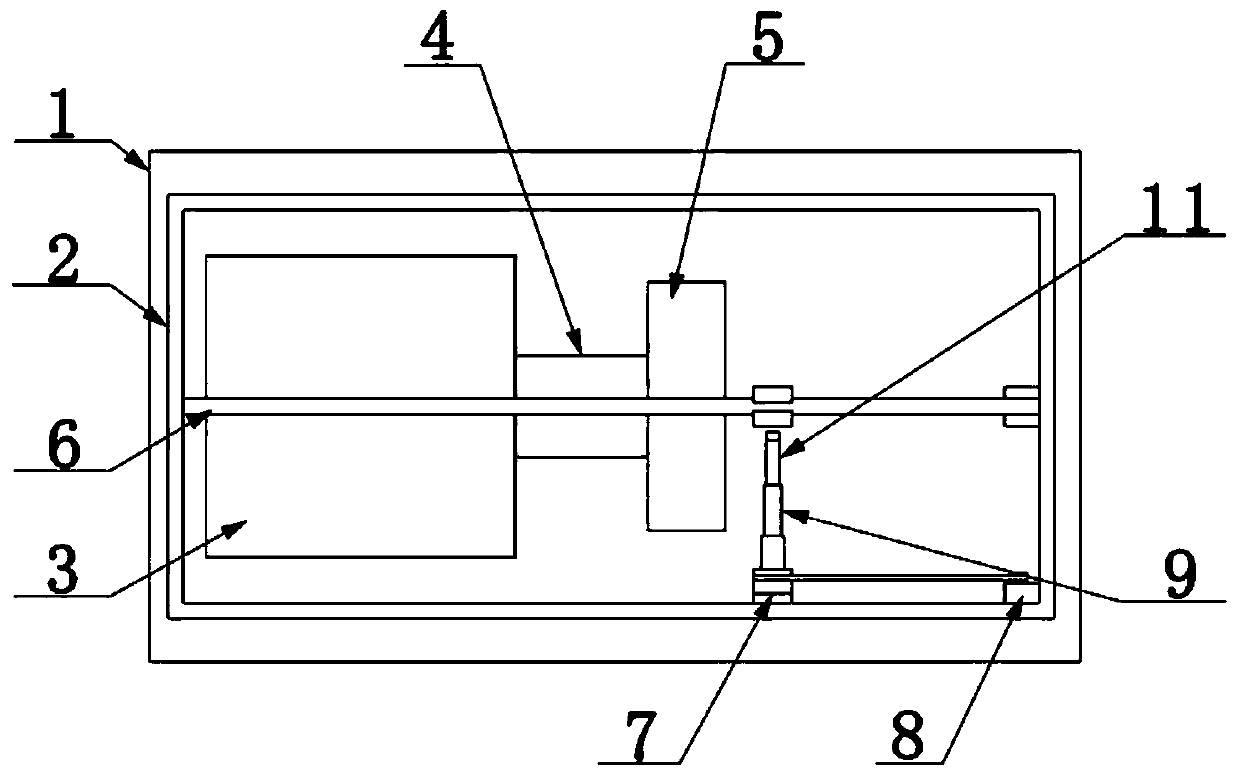

Rigid coaxial cable stripping device and cable stripping technology

ActiveCN109119945ADiameter size limitAvoid Cutting Difficult QuestionsLine/current collector detailsApparatus for removing/armouring cablesCoaxial cableMachine tool

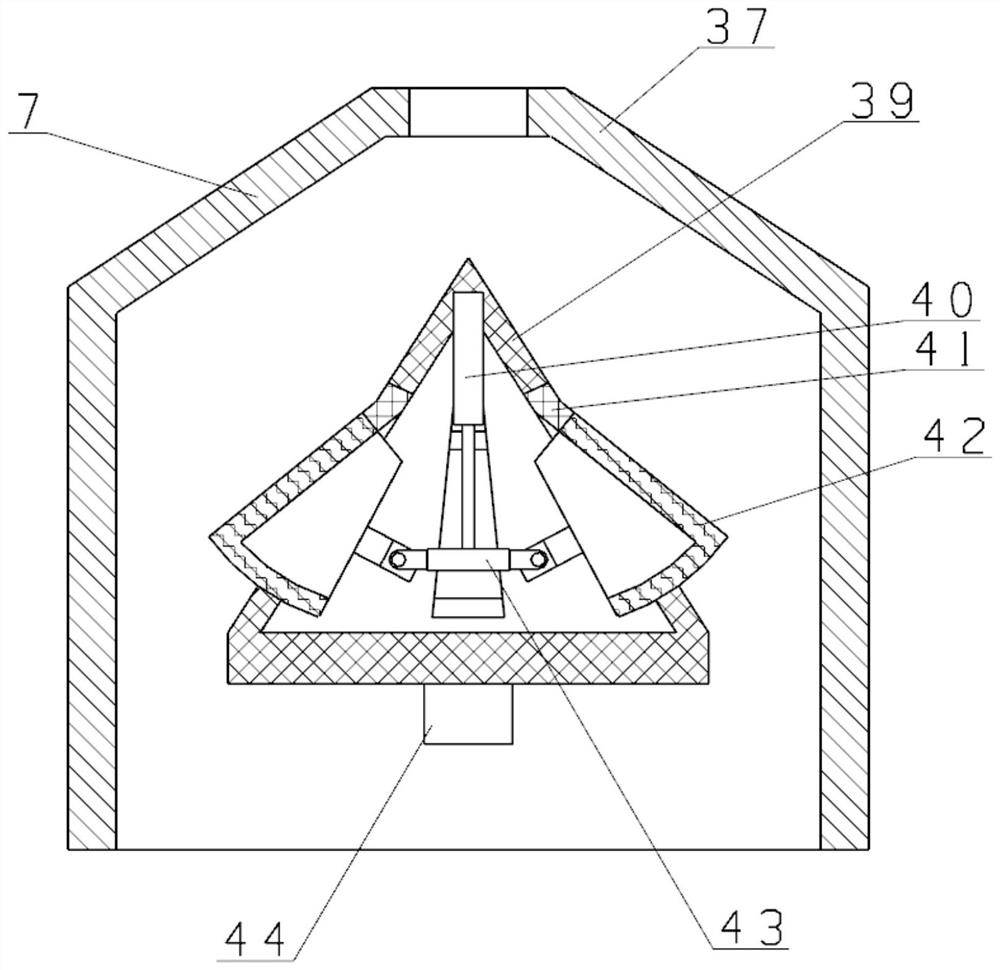

The present invention discloses a rigid coaxial cable stripping device and a cable stripping technology. The device comprises a pedestal, the pedestal is provided with a cable stripping machine tool,the main shaft end portion of the cable stripping machine tool is provided with a chuck, the upper portion of the pedestal is provided with a frame, the top portion and the side portion of the frame are provided with two guide rails in the main shaft direction of the cable stripping machine tool, the two guide rails are both respectively provided with sliding blocks, the sliding blocks are connected with a belt of a stepping motor at the end portions of the guide rails, the inner sides of the sliding blocks are fixedly connected with electric push rods, the end portions of the electric push rods are provided with a cable wiring knife and a cut-off knife, the knife surface of the cable wiring knife is parallel to the main shaft of the cable stripping machine tool, and the knife surface of the cut-off knife is perpendicular to the main shaft of the cable stripping machine tool. The cable stripping technology employs the rigid coaxial cable stripping device to perform stripping for a metal outer layer and a medium inner layer of the rigid coaxial cable so as to achieve the connection demand. The rigid coaxial cable stripping device and the matched cable stripping technology can effectively solve the problems that the knife is serious in wearing and the production efficiency is low when a current automatic cable stripping machine is employed for cable stripping and the qualified rate is low after cable stripping.

Owner:SICHUAN HUAFENG ENTERPRISE GRP +1

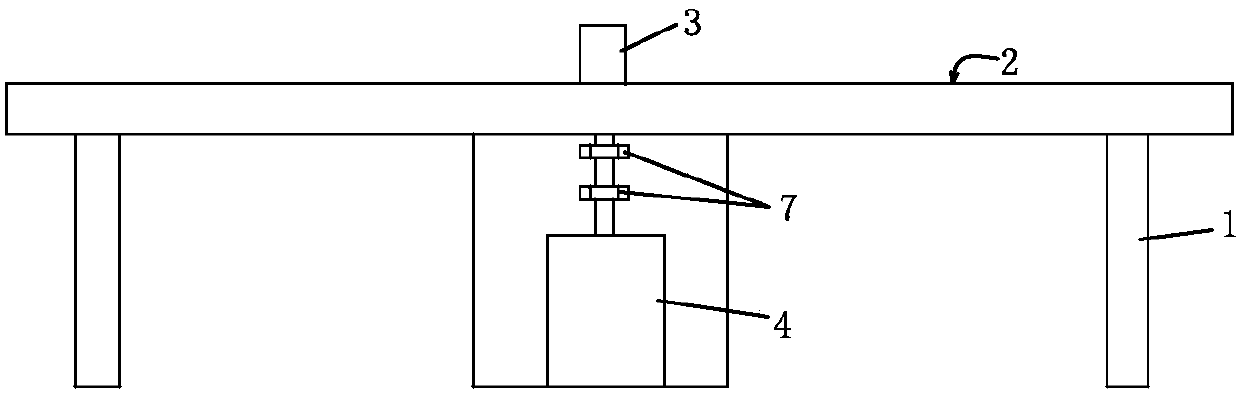

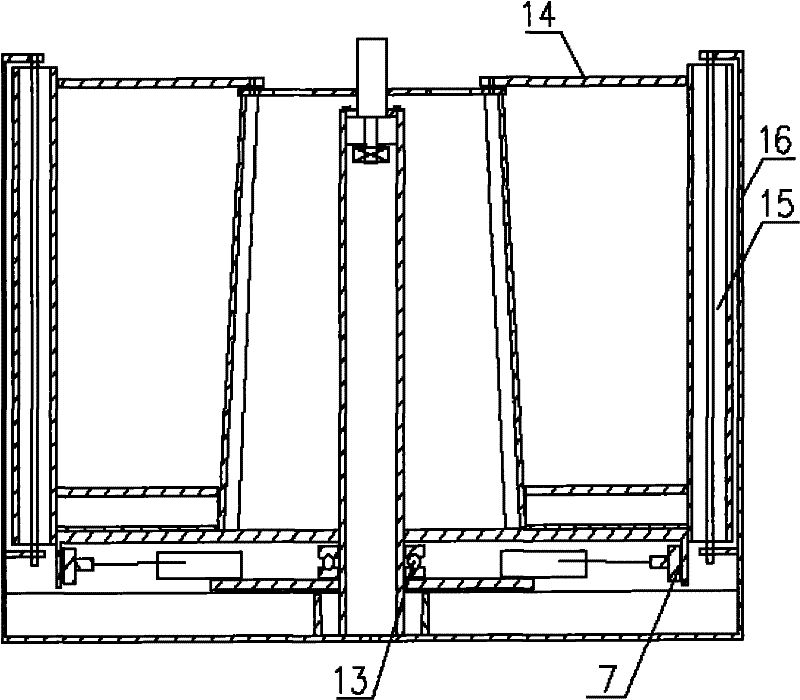

Unwinding and winding device and use method thereof

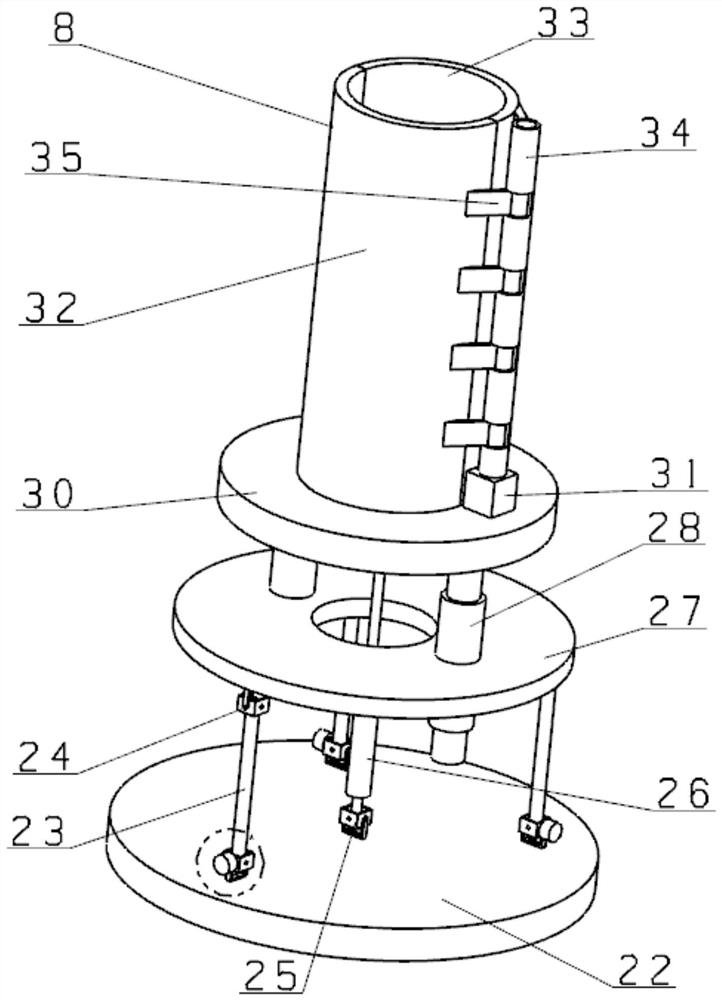

The invention discloses an unwinding and winding device and a use method thereof. The unwinding and winding device comprises a winding platform mounted on a support. A gas-expansion shaft is rotationally mounted on the winding platform. The lower end of the gas-expansion shaft is connected with a driving shaft of a driving motor through a transmission device. In a deflated state, the diameter of the gas-expansion shaft is smaller than the diameter of a reel which is used for winding veneers, and after being inflated, the gas-expansion shaft can clamp the reel from the inner side and drive thereel and a winding shaft to rotate synchronously. The winding platform is provided with at least two ejecting blocks symmetrically arranged along the gas-expansion shaft, the ejecting blocks are arranged on the winding platform in a lifting mode, and the lower ends of the ejecting blocks are connected with telescopic rods of driving cylinders. The winding process in the last production stage of veneers is achieved through cooperation of a pressing plate and the gas-expansion shaft, so that obtained veneer rolls are orderly in end face; and moreover, wound veneer rolls can be scattered and thentidied again.

Owner:德清德沃装饰材料有限公司

Technology for hot-melting edge cutting and splitting of mesh yarns, and device of same

The invention relates to a technology for hot-melting edge cutting and splitting of mesh yarns, and a device of the same. According to the invention, the structure is simple and use is convenient; through the technology provided by the invention, automatic edge cutting and splitting of the mesh yarns can be carried out during unreeling; and a hot-melting cutter is used for the edge cutting and splitting, so former problems that fine filaments can be easily drawn out on mesh yarn edges and reeling off can take place easily after cold-cutter edge cutting and splitting can be avoided. The equipment adopts a friction rolling manner as well, so no fold and scratch will appear, end faces are orderly and the rolling surface has proper hardness during collection of a mesh yarn rolling material with a known width. In this way, the product rejection rate is greatly reduced; product quality is improved; and production progress is accelerated.

Owner:JIANGYIN WEIKANG TEXTILE CO LTD

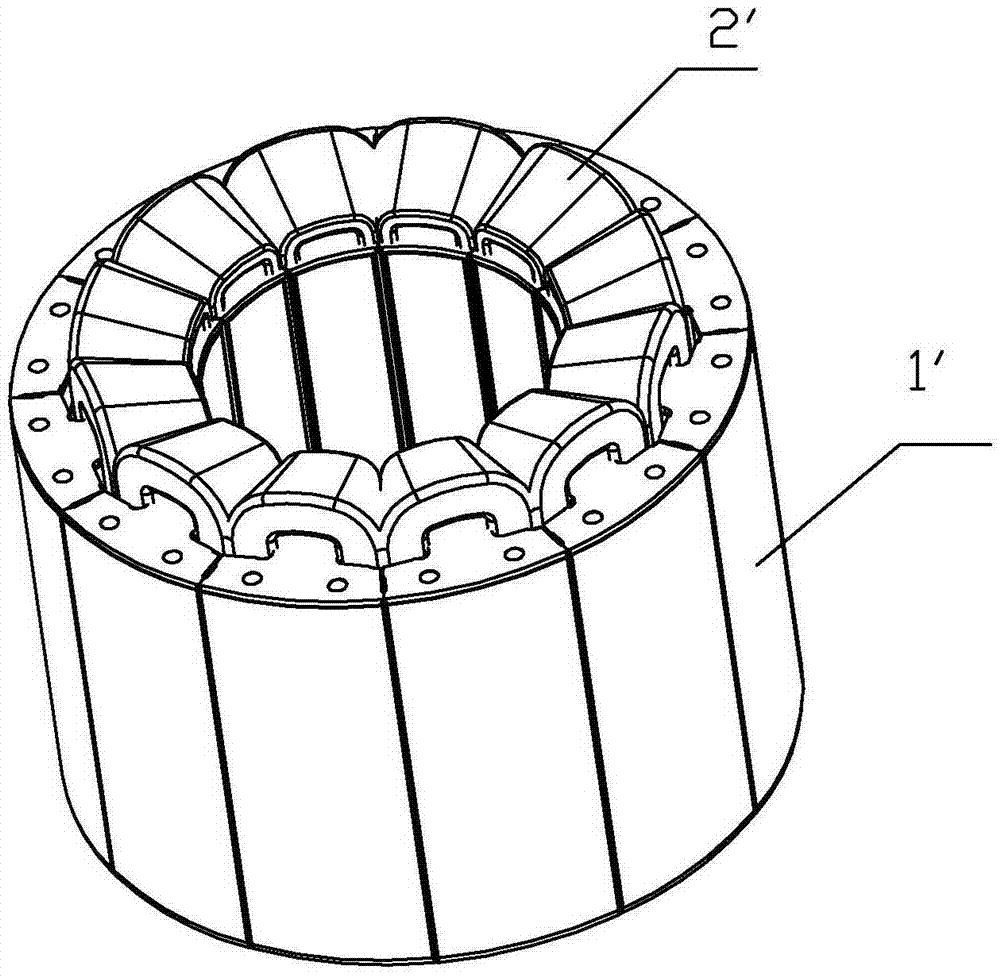

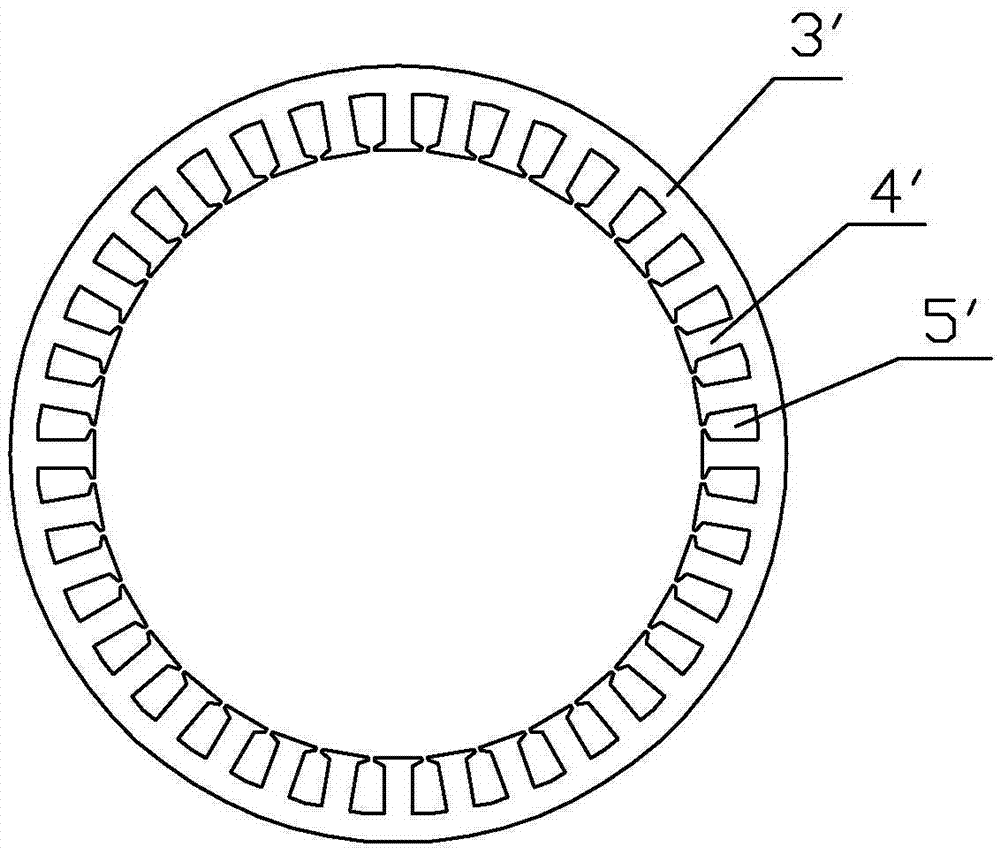

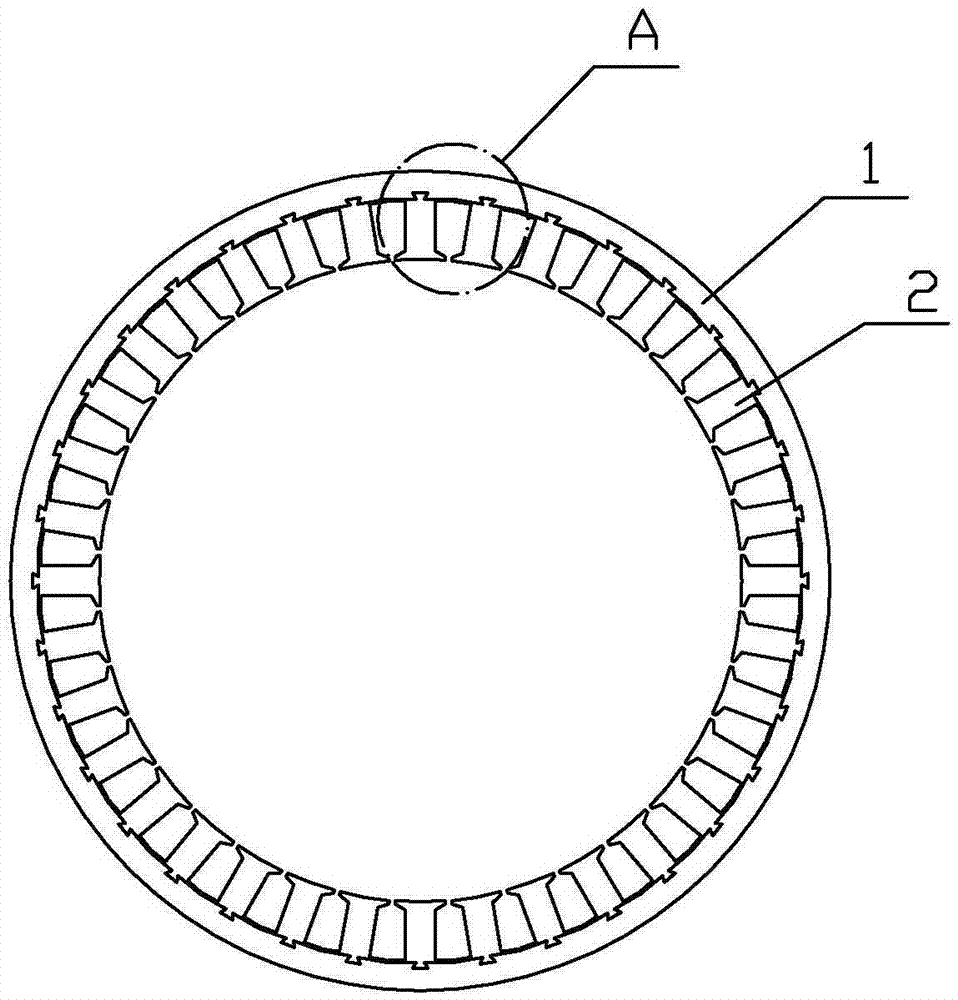

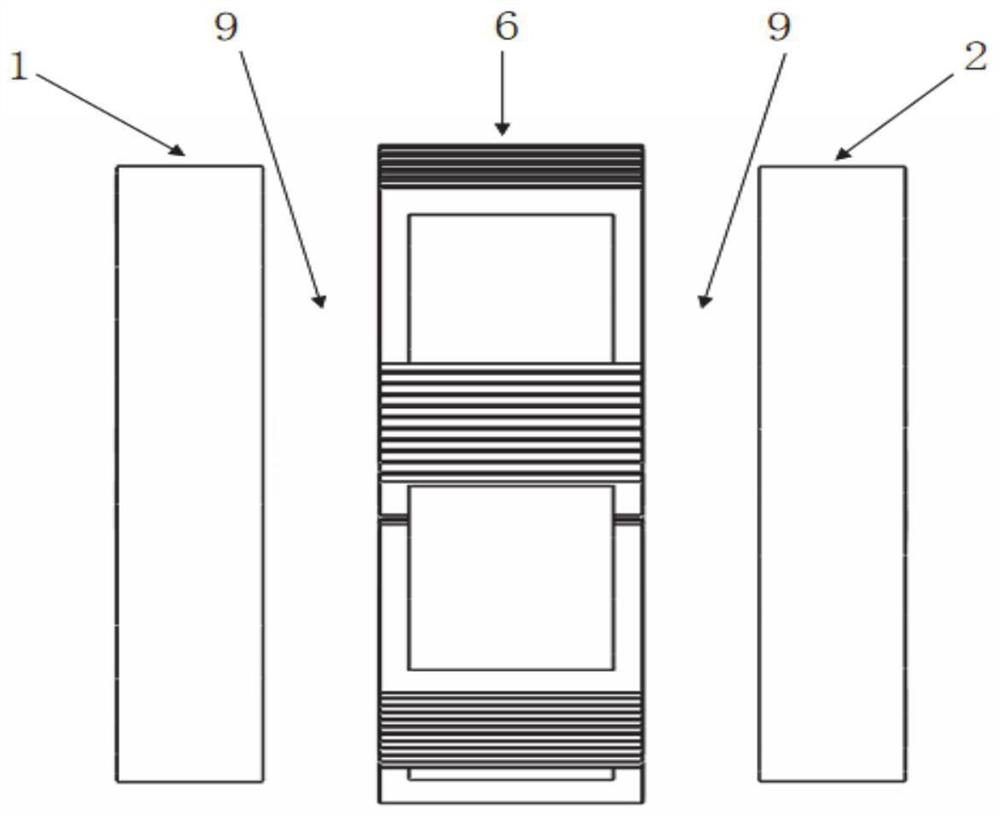

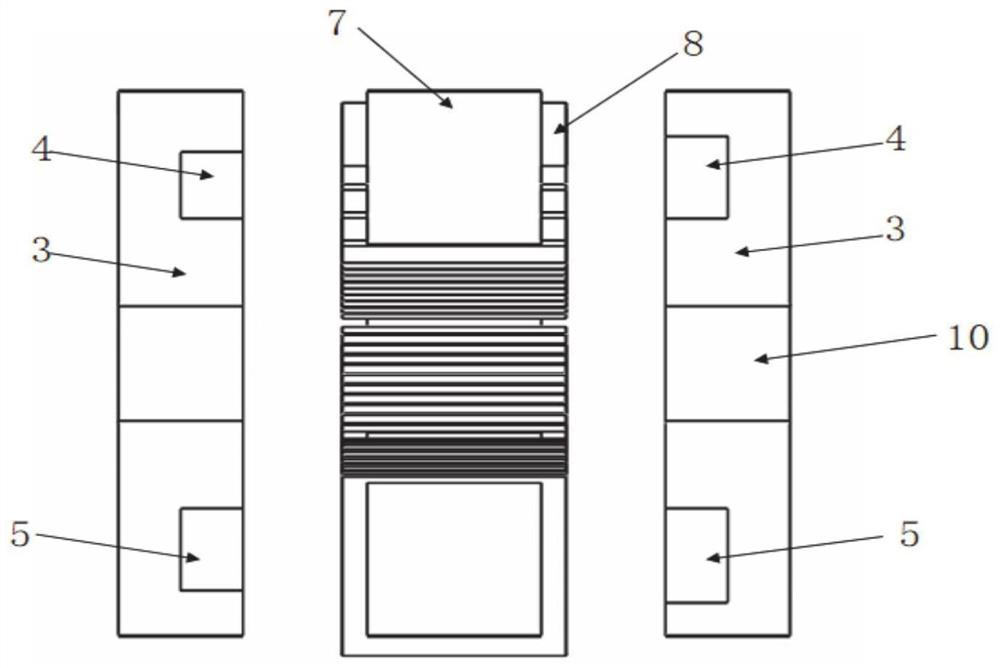

Large-diameter motor stator structure and mounting method thereof

InactiveCN105449880AImprove performanceImprove unityMagnetic circuit stationary partsManufacturing dynamo-electric machinesWinding machineInsulation layer

The invention relates to a large-diameter motor stator structure and a mounting method thereof. The stator structure comprises a yoke body, a plurality of tooth bodies connected with the yoke body, and an enameled wire windings winding around the tooth bodies. A plurality of clamp grooves are formed in the inner side surface of the yoke body; the rear sides of the tooth bodies are provided with clamp heads matching the clamp grooves; and the tooth bodies are clamped into the clamp grooves by the clamp heads and are connected with the yoke body. A blocking shoulder is arranged at each of the two sides of the rear sides of the tooth bodies; a blocking plate is arranged at each of the two sides of the front sides of the tooth bodies; winding slots are formed between the blocking shoulders and the blocking plates; and enameled wire windings wind around the winding slots. In addition, the mounting method includes: an enameled wire winding winds around each tooth body by a winding machine; the tooth bodies wound with the enameled wire windings are embedded into the inner side surface of the yoke body one by one; the clamp heads of the clamp bodies and the clamp grooves of the yoke body are clamped; and the multiple tooth bodies are distributed uniformly along the periphery of the yoke body. According to the invention, winding of the enameled wire windings becomes convenient; the windings are arranged in order; the winding becomes compact; the end part is small; the groove filling rate is high; the utilization rate of the enameled wire winding is high; the coil insulation layer is not easy to damage; and the reliability is improved.

Owner:杭州桢正机器人科技有限公司

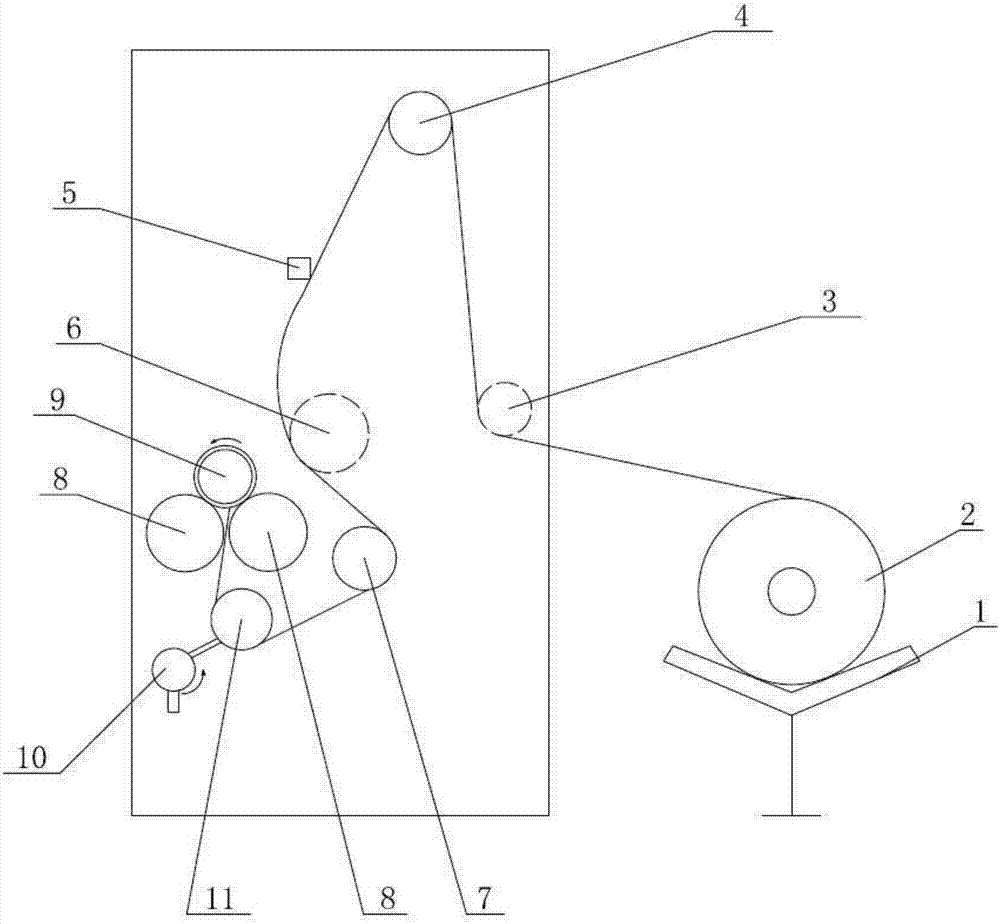

Li-ion battery separator slitting machine

The invention discloses a Li-ion battery separator slitting machine. The Li-ion battery separator slitting machine comprises an edge correcting platform mechanism, wherein a pneumatic shaft unwinding mechanism is arranged at the upper end of the edge correcting platform mechanism; the upper end at the right side of the pneumatic shaft unwinding mechanism is provided with a flaw detecting platform; the lower end at the right side of the flaw detecting platform is provided with a transition mechanism; the right end of the transition mechanism is provided with a winding mechanism; the winding mechanism comprises a winding rack; the upper end of the winding rack is provided with a winding main roller; the left side and the right side of the winding main roller are provided with differential slip ring locking devices; the winding main roller is provided with a separator back cutting-up mechanism and a separator front cutting-up mechanism; the lower end of the separator back cutting-up mechanism and the lower end of the separator front cutting-up mechanism are each provided with a roller main transmission mechanism; and the right side of the separator front cutting-up mechanism is provided with a circular knife hobbing device. The Li-ion battery separator slitting machine can achieve zero-tension unwinding, stable separator winding and regular end surfaces, and can eliminate wrinkle stripes on the surface of the separator, so that the slit and unwound separator is more flat in surface, and different needs of clients can be met, and therefore, the Li-ion battery separator slitting machine can be widely applied in the lithium battery industry.

Owner:DONGGUAN CITY KAIJIN MACHINERY & ELECTRONICS CO LTD

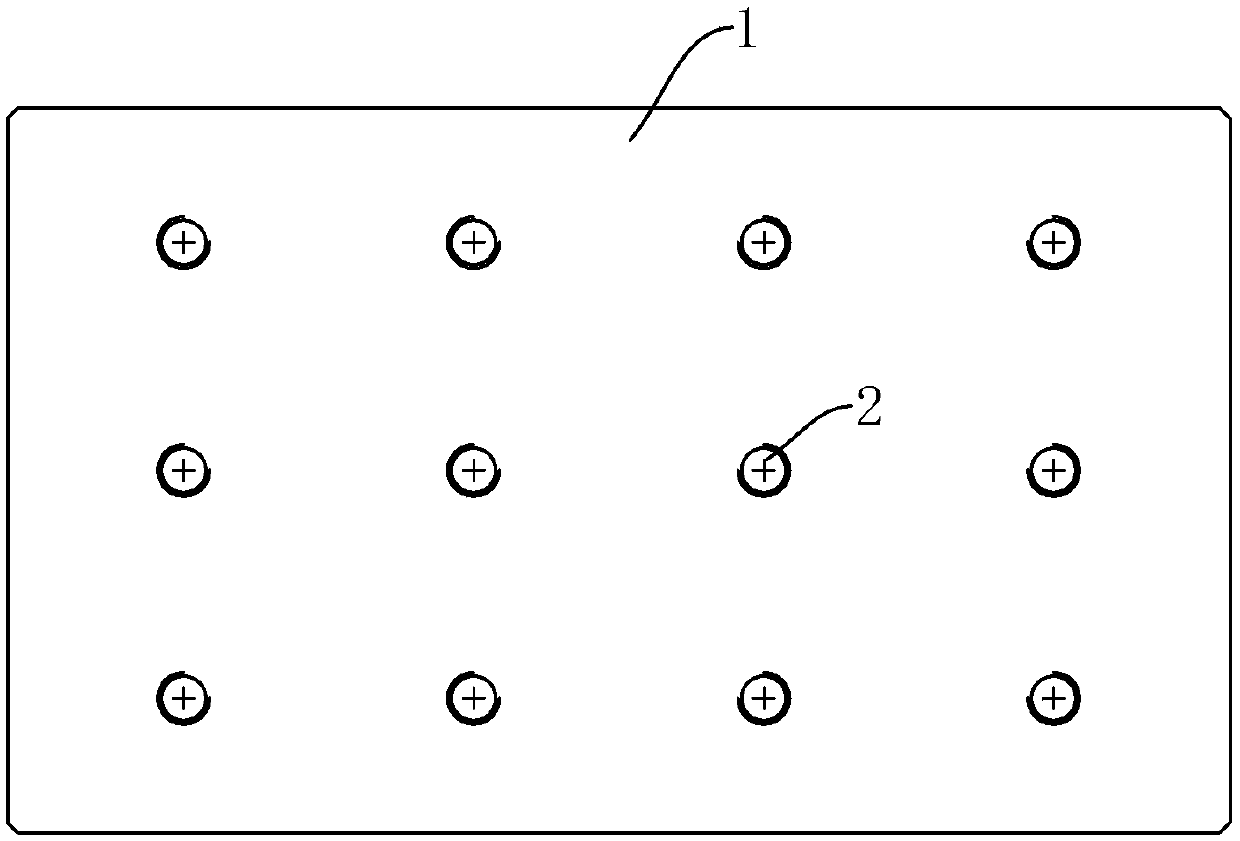

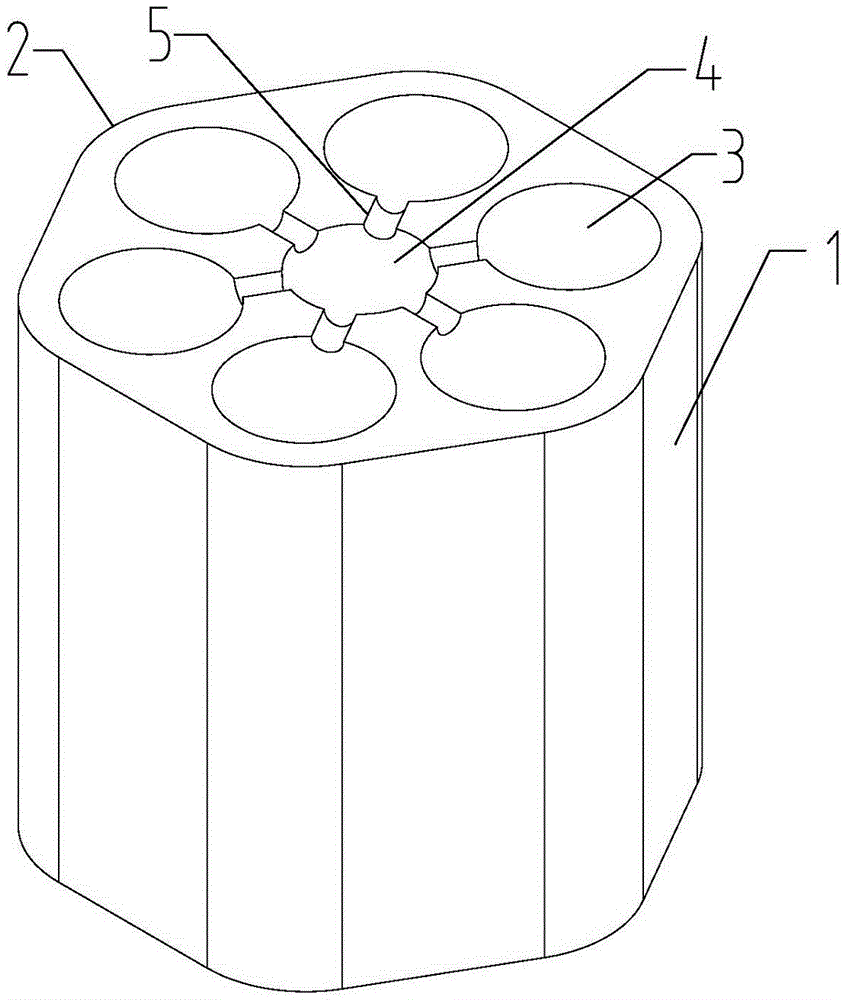

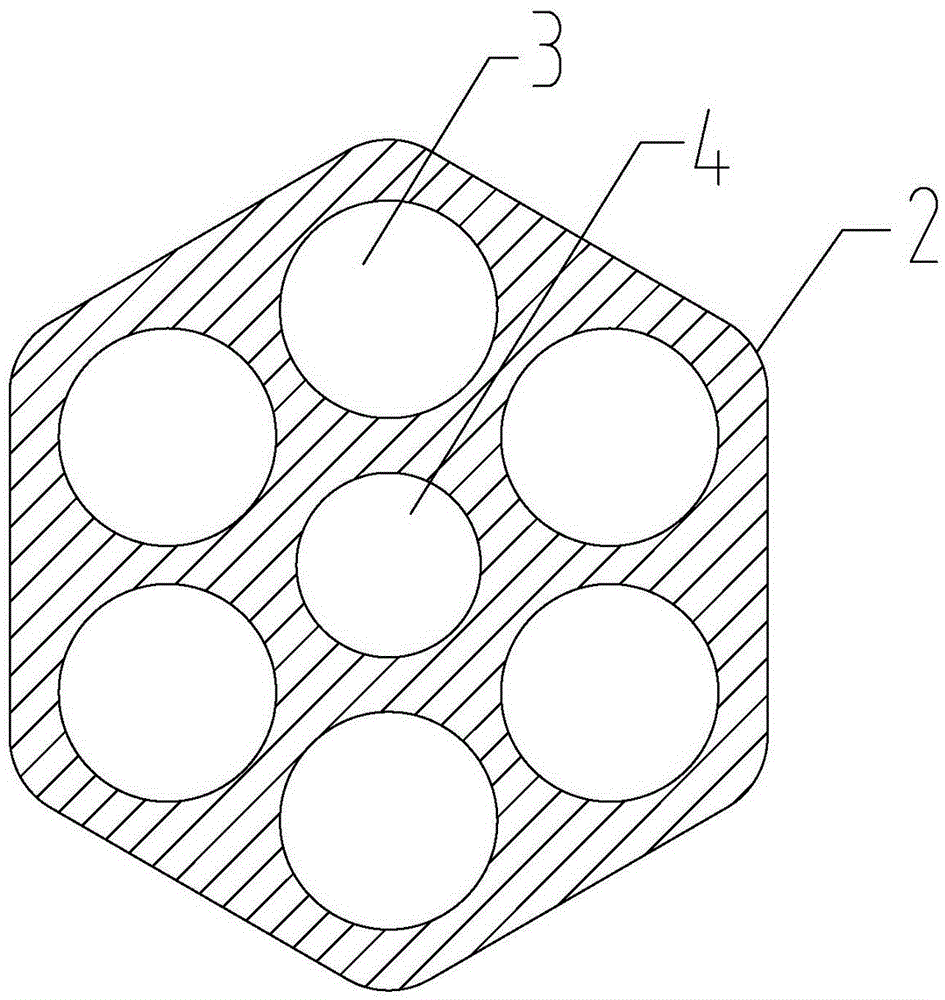

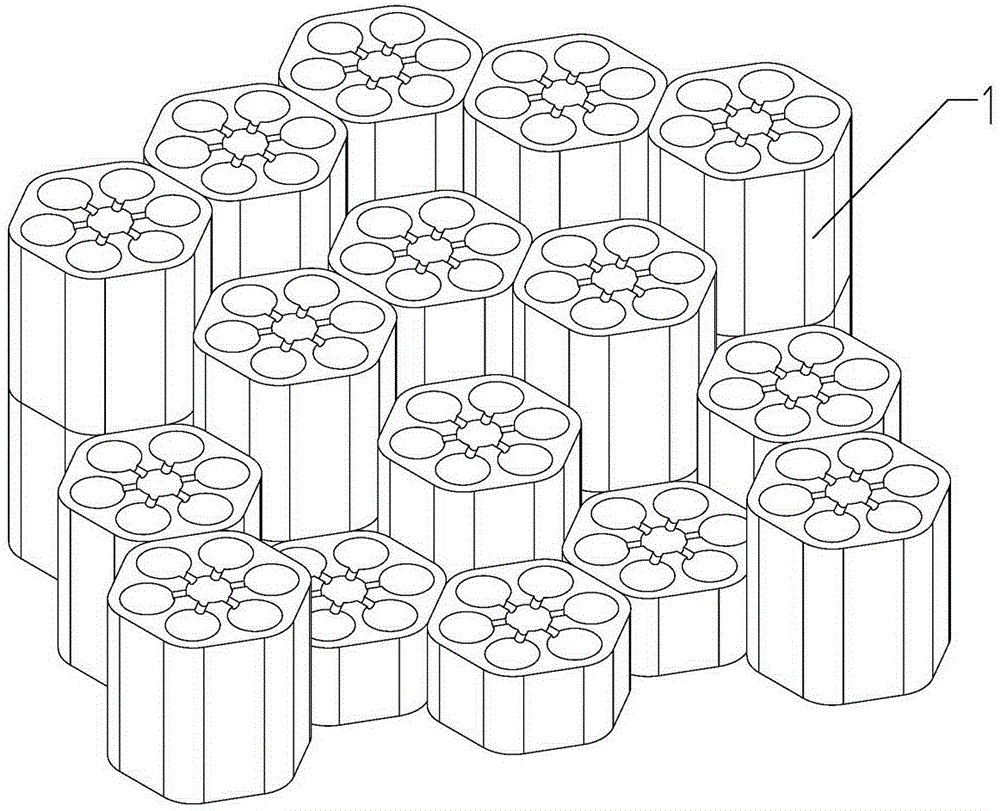

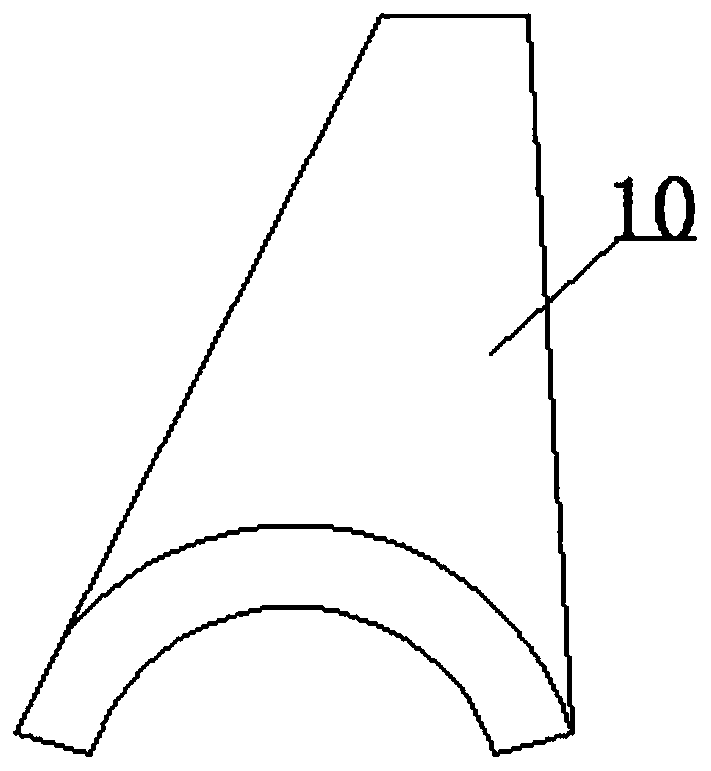

Lattice brick for blast furnace hot blast stove

InactiveCN105603143AReduce crackingReduce slippage between layersBrick-hot blast stovesStress concentrationBrick

The invention relates to a lattice brick for a blast furnace hot blast stove. The lattice brick is of a regular hexagonal prism shape in appearance, the vertical distances between two opposite side planes are 230+ / -3mm, an intersected ridge between every two adjacent side planes of the prism is a transition circular arc surface tangent with the side plane, and diameters of side through holes are not smaller than the diameter of a central through hole; and six grooves penetrating through the central through hole and the side through holes are formed in each of the upper and the lower end surfaces of the prism, and the radiuses of the cross sections of the grooves are smaller than 7% of the diameter of the central through hole. The lattice brick has the advantages that the hole pattern is simple, and the structure is compact; furthermore, the stress concentration does not easily occur in the lattice brick, and the side surfaces and the end surfaces are regular and can be applicable to mutual staggered stacking; and the lattice brick is significant for reducing the fracture or interlayer slippage of the lattice brick caused by the stress concentration, prolonging the service life of the hot blast stove and improving the air supply quality of the hot blast stove.

Owner:ZHENGZHOU UNIV

A roll-forming device of a non-woven fabric dyeing production line

ActiveCN103818759BPrevent springbackAvoid position changesWebs handlingProduction lineNonwoven fabric

The invention discloses a coiling device for a non-woven fabric dying production line. The coiling device comprises a frame body, a coiling shaft, guiding grooves, baffles, bolts, a transmission mechanism, a misalignment prevention mechanism, a crimple prevention mechanism, a rebound prevention mechanism and a tensioning mechanism. The tensioning mechanism, the rebound prevention mechanism, the crimple prevention mechanism, the misalignment prevention mechanism and the transmission mechanism are sequentially installed on the frame body from front to rear. The front portion and the rear portion of the frame body are provided with the guiding grooves, the two ends of the coiling shaft can be connected with the guiding grooves in a sliding mode, the baffles are arranged on the guiding grooves, and the bolts are arranged on the baffles. Compared with the prior art, coiling of non-woven fabric can be good, compactness is good, two end faces are neat, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are guaranteed, rebound of the cut non-woven fabric under the action of tensioning force is avoided, time can be saved, working efficiency is improved, slippage in transmission can also be avoided, and the transmission rate is guaranteed.

Owner:FENGJIE DONGYANG BUILDING MATERIALS CO LTD

Rolling mill guide mechanism

ActiveCN102513380BAvoid bouncing up and down situationsThe case of bouncing up and down will notGuiding/positioning/aligning arrangementsEngineeringSteel belt

The invention relates to a rolling mill guide mechanism with the advantages that the combined fixation mode is adopted, the material position guide can be realized, the finished product rate of materials can be greatly improved, the waste of strip heads and strip tails of the materials is also reduced, and a large number of raw materials are saved. The rolling mill guide mechanism comprises a machine frame, wherein an upper clamping plate and a lower clamping plate are arranged between an upper cross beam and a lower cross beam of the machine frame, a left guide device and a right guide device are arranged at two sides of the upper clamping and the lower clamping plate, the upper cross beam of the machine is provided with a vertical position guide regulator, in addition, a regulating rod arranged at the bottom of the vertical position guide regulator passes through the upper cross beam to be connected with the upper clamping plate, and parts of the upper clamping plate and the lower clamping plate connected with the left guide device and the right guide device are provided with locking plates. The rolling mill guide mechanism has the advantages that 1, a position guide mechanism is applicable to the position guide of materials with different thicknesses, and in addition, the condition of vertical material jumping caused by the shaking generated during the rolling mill operation is avoided; and 2, the position guide mechanism is adopted, the tail parts of finished steel strips and the head parts of non-rolled materials are ensured to pass through a rolling mill for rolling, and the waste of raw materials is reduced.

Owner:浙江富日进精密金属股份有限公司

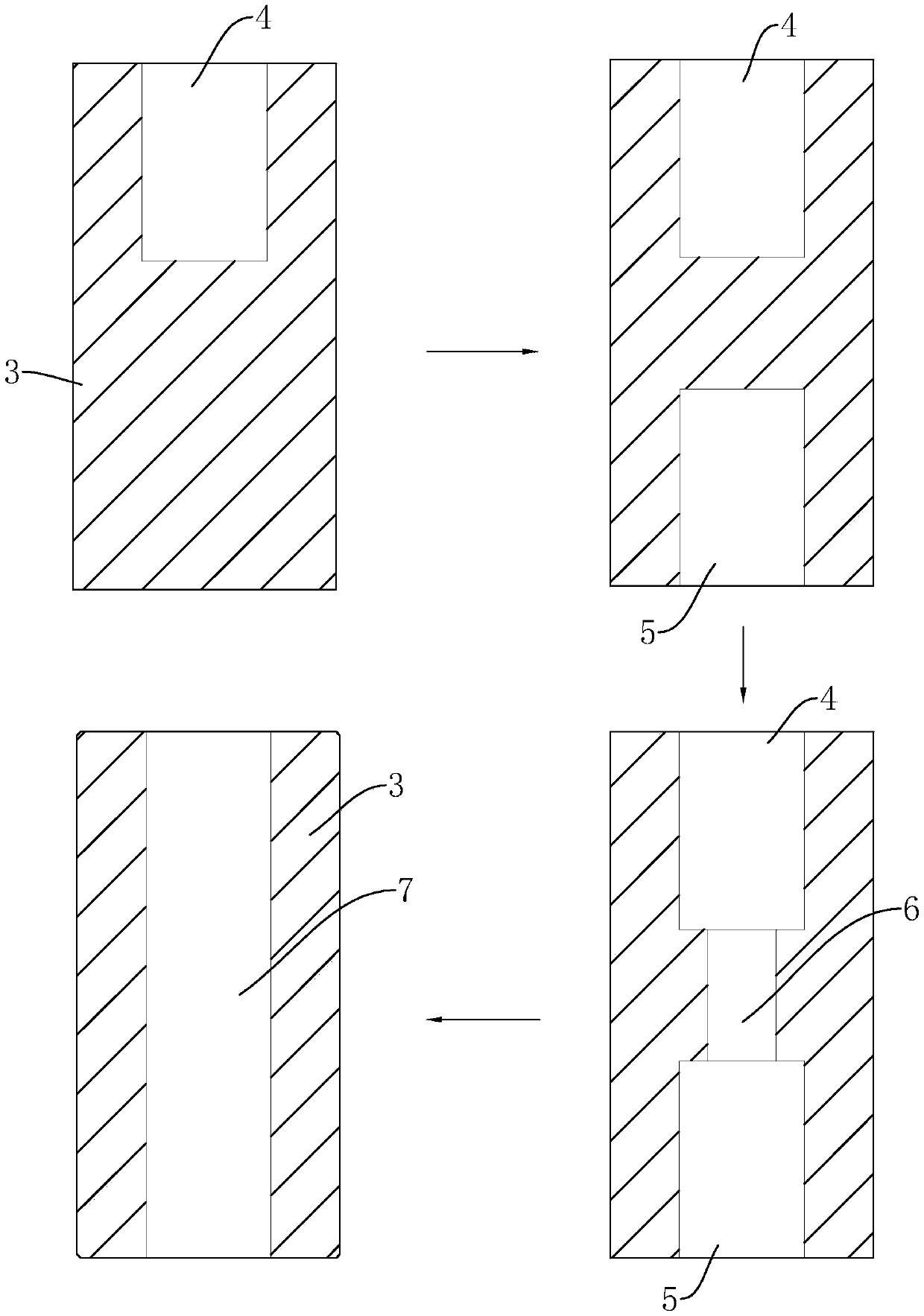

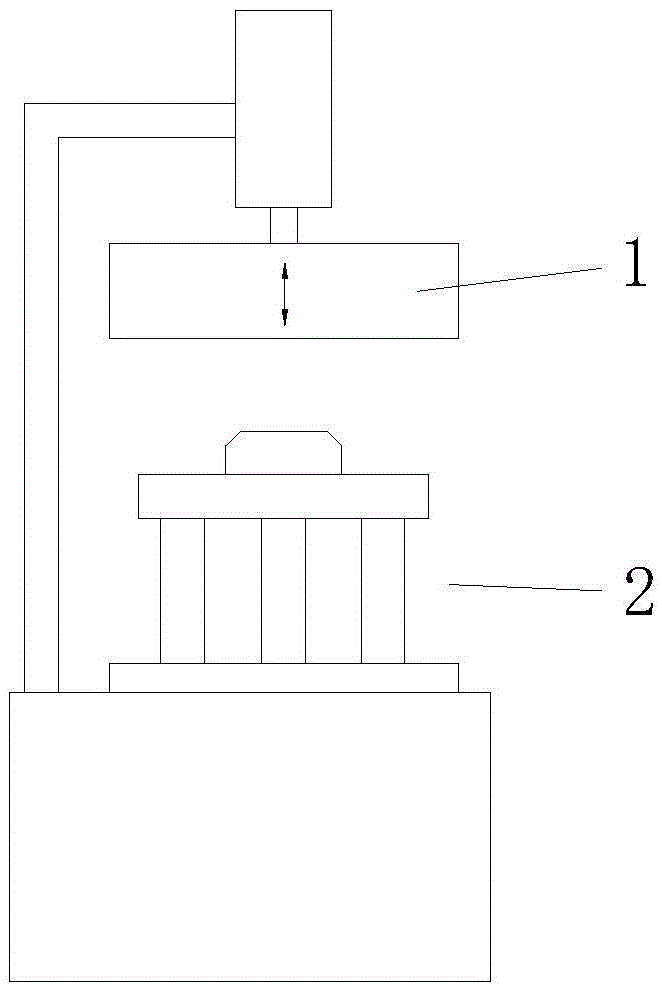

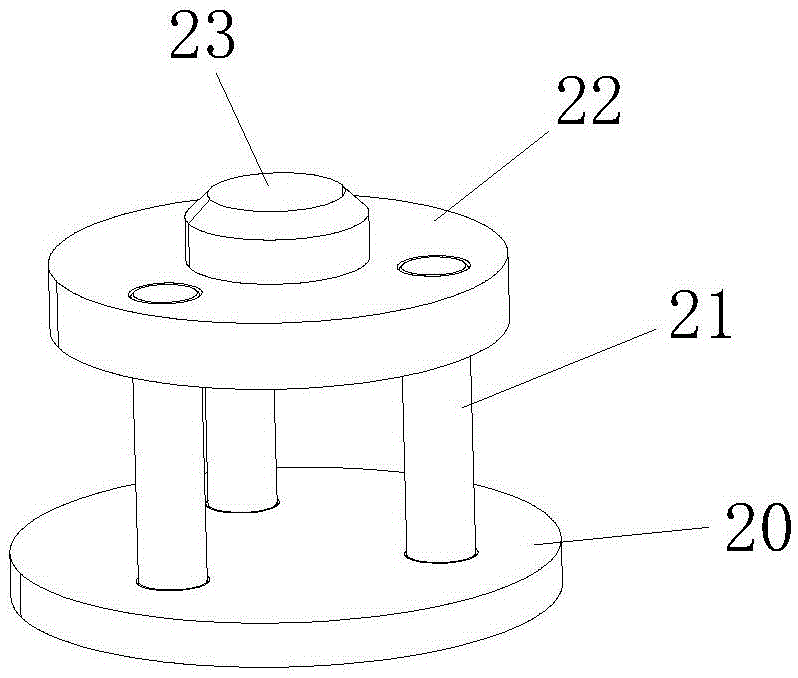

A method and special equipment for edge sealing of tubular parts

The invention discloses a method and special equipment for sealing an edge of a tubular workpiece. The method comprises the following steps: firstly placing the tubular workpiece at the inner side of a cylindrical die; turning up and fixing one end, to be subjected to edge sealing, of the tubular workpiece; enabling the tubular workpiece to cling to one end part of the die; and pressing the end part of the die by an ultrasonic wave die pressing head, thereby accomplishing the fusion-welding edge sealing of a notch at the same time of forming the tubular workpiece by die cutting. The special equipment for sealing the edge of the tubular workpiece comprises a fixed die and the ultrasonic wave die pressing head, wherein the fixed die comprises a base and a cutting tool, and the cutting tool is arranged on the base via a connecting rod and is provided with a cylindrical die cutting edge. The tubular workpiece is manufactured in an ultrasonic wave die cutting mode, fusion-welding edge sealing is performed on the end part of the tubular workpiece at the same time of die cutting, the end part of the tubular workpiece is neat without burr, and the defects that the edge of the end part of the work workpiece is not neat enough and burr is formed easily in the prior art are overcome.

Owner:深圳德睿康科技有限公司

Winding and unwinding device and using method thereof

The invention discloses a winding and unwinding device and a using method thereof. The winding and unwinding device comprises a winding platform mounted on brackets, an air swelling shaft is rotatablymounted on the winding platform, and the lower end of the air swelling shaft is connected by a driving shaft of a driving motor through a transmission device; and under the deflating state, the shaftdiameter of the air swelling shaft is less than the diameter of a winding drum used for winding wood veneer, after the air swelling shaft is inflated, the winding drum can be clamped from the inner side, and the winding drum and a winding shaft are driven to rotate synchronously. According to the winding and unwinding device and the using method thereof, the winding process of the final stage ofwood veneer production is achieved through cooperation of a pressing plate and the air swelling shaft, so that the end surface of an obtained wood veneer reel is neat, and the winding and unwinding device and the using method thereof can be used for rearranging the scattered and wound wood veneer reel.

Owner:德清德沃装饰材料有限公司

Automatic conveying and trimming device for plastic film roll

The invention relates to an automatic conveying and trimming device for a plastic film roll. The device comprises clamping devices used for clamping a paper tube, a cutting device arranged above the clamping device, and a conveying device arranged between the clamping devices and used for conveying the film roll. The clamping devices comprise top shafts symmetrically arranged on the two sides of the conveying device and driving devices arranged behind the top shafts for driving the top shafts to advance or retreat; the positions of the top shafts correspond to the center of the paper tube, anddriven gears are arranged on the top shafts and driven by a transmission device to rotate. The paper tube is clamped by the clamping devices, the position of a blade is adjusted by a position adjusting device to achieve the cutting effect on the film roll, and the end face of the film roll is kept tidy. The top shafts can carry out self rotation while advancing or retreating, can drive the papertube to rotate together when clamping the paper tube, and are matched with a cutter to carry out proper position adjustment in the whole process, so that the automatic trimming work of the film roll is completed.

Owner:XINLE HUABAO PLASTIC MACHINERY

Regular winding device for fire hose

The invention discloses a regular winding device for a fire hose. The regular winding device comprises a base, a vertical plate, a rotating shaft and a mounting part. Multiple winding roller assemblies are arranged on the mounting part. Each winding roller assembly comprises a mounting arm, a first rotating roller and a second rotating roller, and the first rotating rollers and the second rotatingrollers are coaxial and are used for jointly winding the fire hose. The distance between two mounting arms is adjusted by an adjusting unit, so that the axial distances between the first rotating rollers and the second rotating rollers are adjusted to adapt to fire hoses with different widths. The regular winding device for the fire hose has the beneficial effects that the first rotating rollersand the second rotating rollers on the winding roller assemblies are used for jointly winding the fire hose, meanwhile, the multiple winding roller assemblies can rotate in the axial direction of therotating shaft through rotation of the rotating shaft, and therefore the winding roller assemblies in the idle state can be conveniently rotated to the proper position, and the fire hose can be conveniently wound on the winding roller assemblies.

Owner:湖南润华新材料有限公司

Deckle edge pulp-scraping separating device

InactiveCN103669081AGuarantee the appearance qualityReduce or avoid jammed edgesMachine wet endState of artPaper sheet

The invention relates to a deckle edge pulp-scraping separating device. A blanket operation portion arranged on a paper-making technology section carries out edge cutting processing on a paper web running in the technology section. The device comprises two pulp-scraping wheels which are arranged on a transmission side and an operation side respectively, the contact portions between the pulp-scraping wheels and a blanket of the blanket operation portion are arranged at the positions of squirt cutting lines of cut edges of the paper web, the surfaces of the pulp-scraping wheels are in contact with the blanket, a roller is driven to move through the blanket operation portion, edges, on the blanket, of the paper web are transferred to the pulp-scraping wheels, and the edges of the paper web are cut through the pulp-scraping wheels. Compared with the prior art, the device can obviously reduce steam consumption, reduces the problem that paper pulp is stuck to the roller, improves appearance quality of primary rolling of the paper web rolled by a paper machine, and reduces or avoids the phenomena that during secondary rolling, end faces clamp paper edges and the paper is scrambled.

Owner:上海东冠纸业有限公司

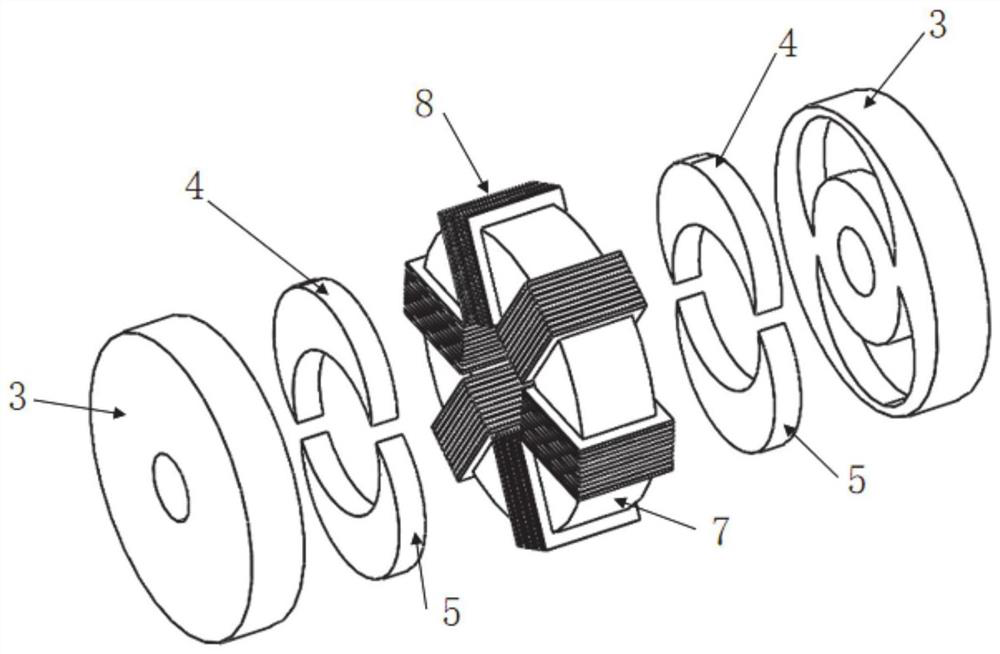

A high-speed surface-mounted dual-rotor axial flux permanent magnet motor

ActiveCN111641307BIncreased torque densityImprove cooling effectElectric machinesMagnetic circuit stationary partsEngineeringHigh torque

Owner:SHANDONG UNIV

Method for controlling rolling of underfeed winder based on mechanical CAD model

InactiveCN101923334BReduce hardware costsReduce data volumeProgramme controlComputer controlEngineeringPressure controlled ventilation

Owner:上海大华总线电气技术有限公司

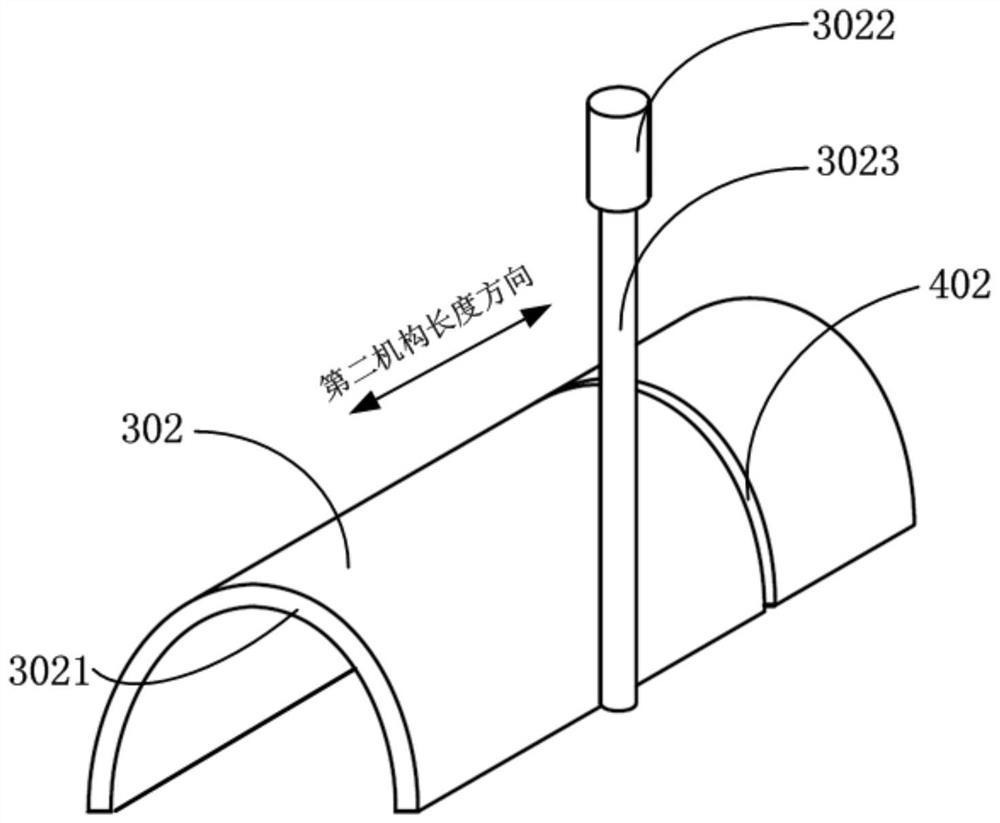

A compact pipe-making device for concrete

ActiveCN112847769BImprove deceleration effectEffective Diversion OrientationAuxillary shaping apparatusClassical mechanicsElectric machinery

The present invention relates to the technical field of concrete molding devices, in particular to a compact pipe-making device for concrete, which includes a pipe-making device. The output shaft end of the output shaft is provided with a rotating plate, and the two ends of the rotating plate are arranged in the frame body, and the rotating plate is connected with the frame body in rotation, and a square fixing frame is fixedly installed on the rotating plate, and a barrel , the barrel is connected with a control valve, a feeding pipe is arranged under the control valve, a speed controller fixedly connected with a fixed frame is fixedly connected to the lower end of the feeding pipe, the speed controller includes an outer shell, and the A shock tube device is installed under the outer casing; the device has a high degree of automation, which facilitates smooth exhaust, improves construction efficiency, and improves the quality of finished products.

Owner:杭州钱龙实业有限公司

Steel pipe cutting device

InactiveCN111570900ANeat cutting sectionNeat endsTube shearing machinesShearing machine accessoriesSteel tubeElectric machinery

The invention aims to disclose a steel pipe cutting device which solves the problem that a cutting knife is severely abraded by means of an existing cutting mode. The steel pipe cutting device comprises a base. A connecting belt is tied on the left side of the upper surface of the base. The upper end of the connecting belt is fixedly connected with a first motor. The side face of the first motor is fixedly provided with a handle. The upper side of the first motor is provided with a first rotating shaft. A cutting disc is fixedly installed at the upper end of the first rotating shaft. A supporting rod is fixedly installed on the right side face of the base. A sleeve ring is welded to the top end of the supporting rod. A second rotating shaft is sleeved with the sleeve ring. A second motor is installed at the right end of the second rotating shaft. A support is fixedly installed between the second motor and the supporting rod. Under the driving of the second motor, a push plate can be used for grinding the inner wall of a steel pipe, then the steel pipe can be easily cut, the cutting disc is protected, and meanwhile a cut end face is neater.

Owner:曹爱保

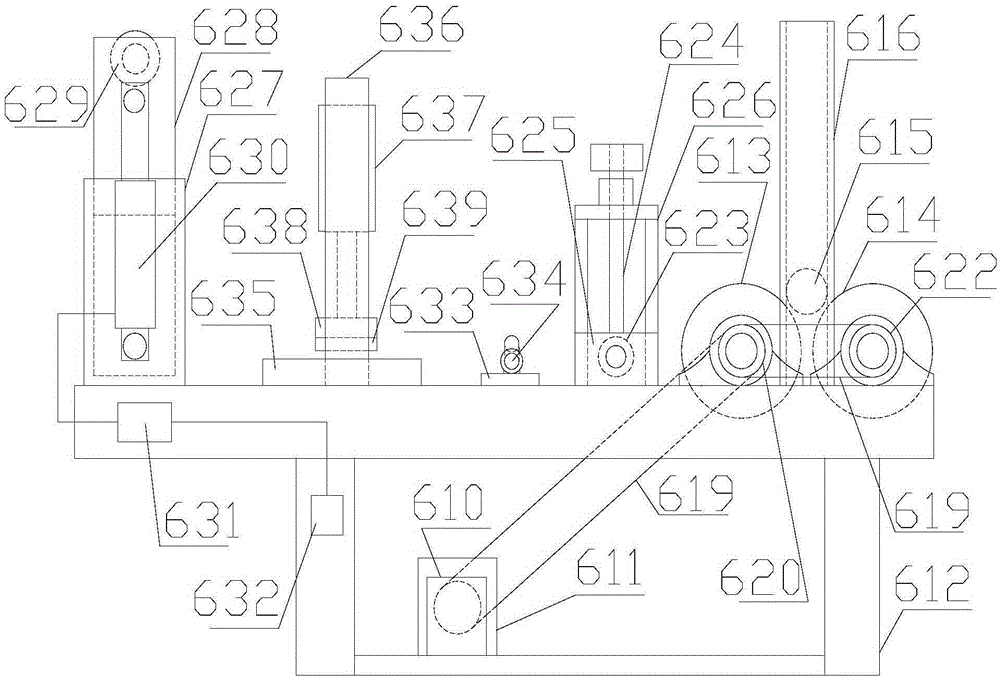

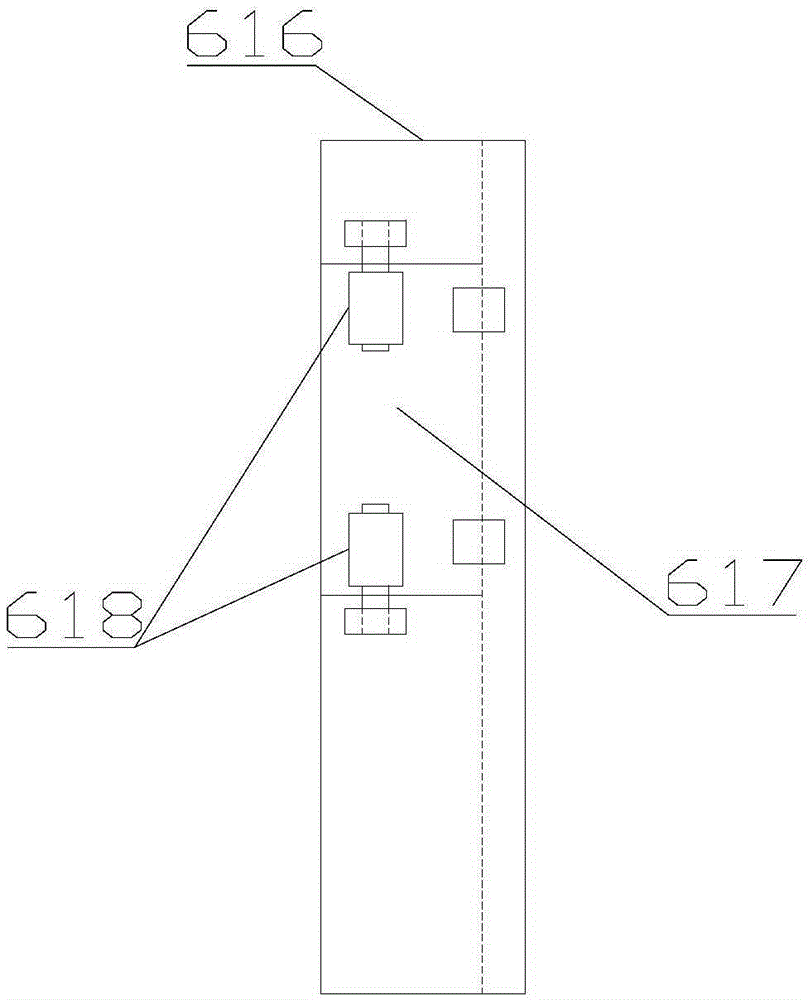

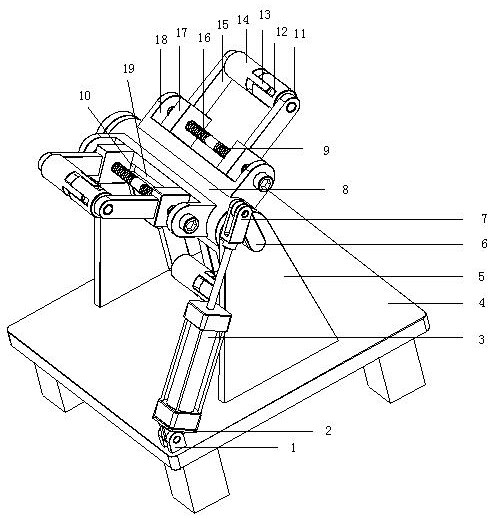

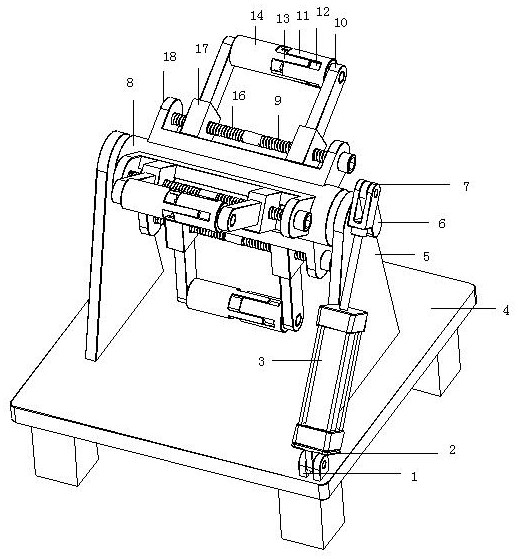

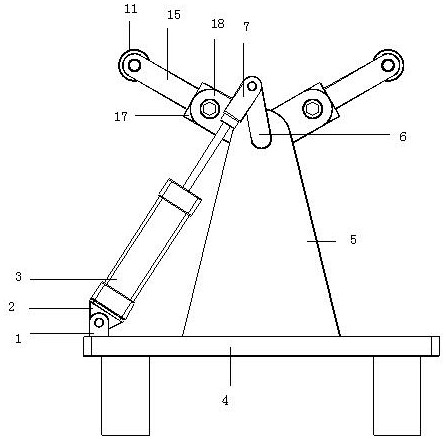

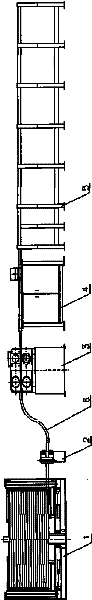

Fully automatic anchor cable blanking machine

ActiveCN101700586BExact lengthNeat endsMetal sawing devicesMetal sawing accessoriesControl systemElectrical control

Owner:兖矿能源集团股份有限公司

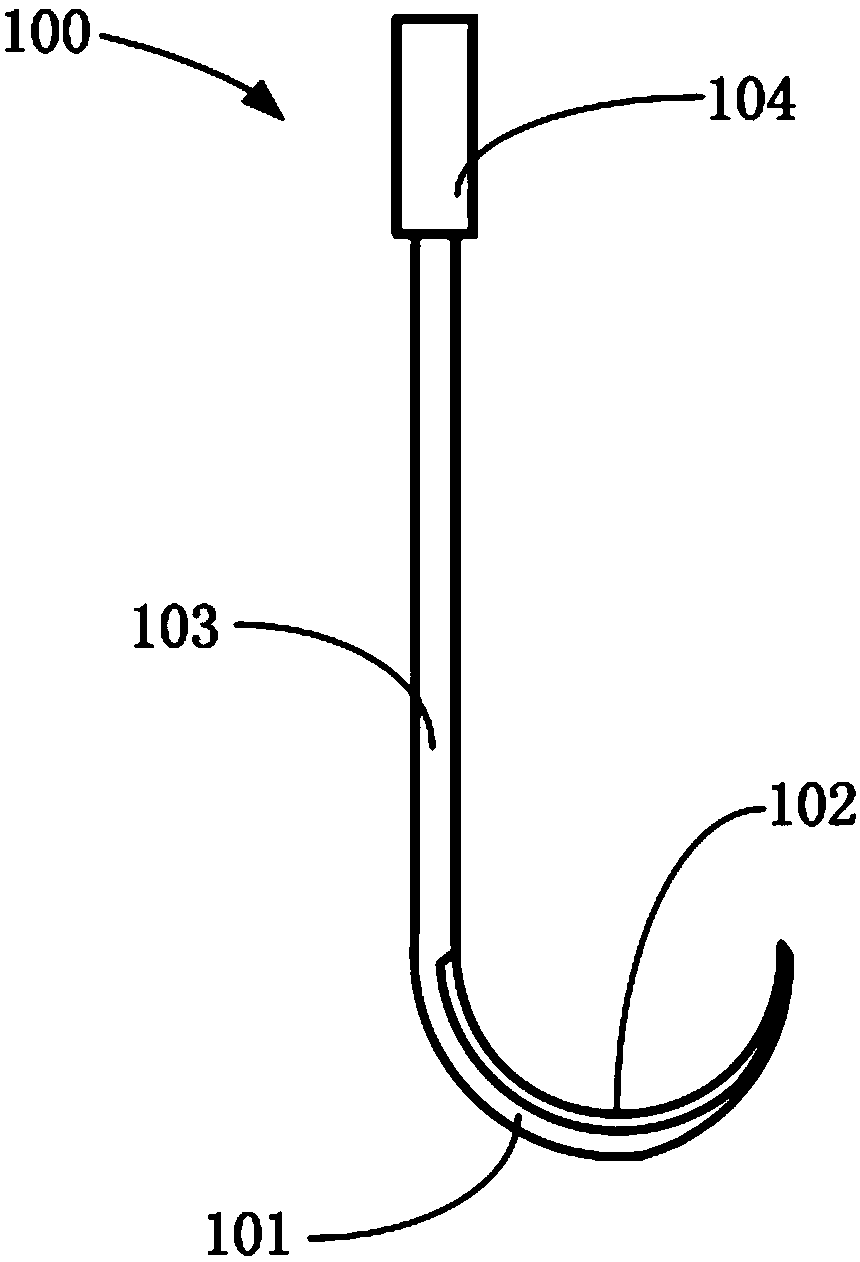

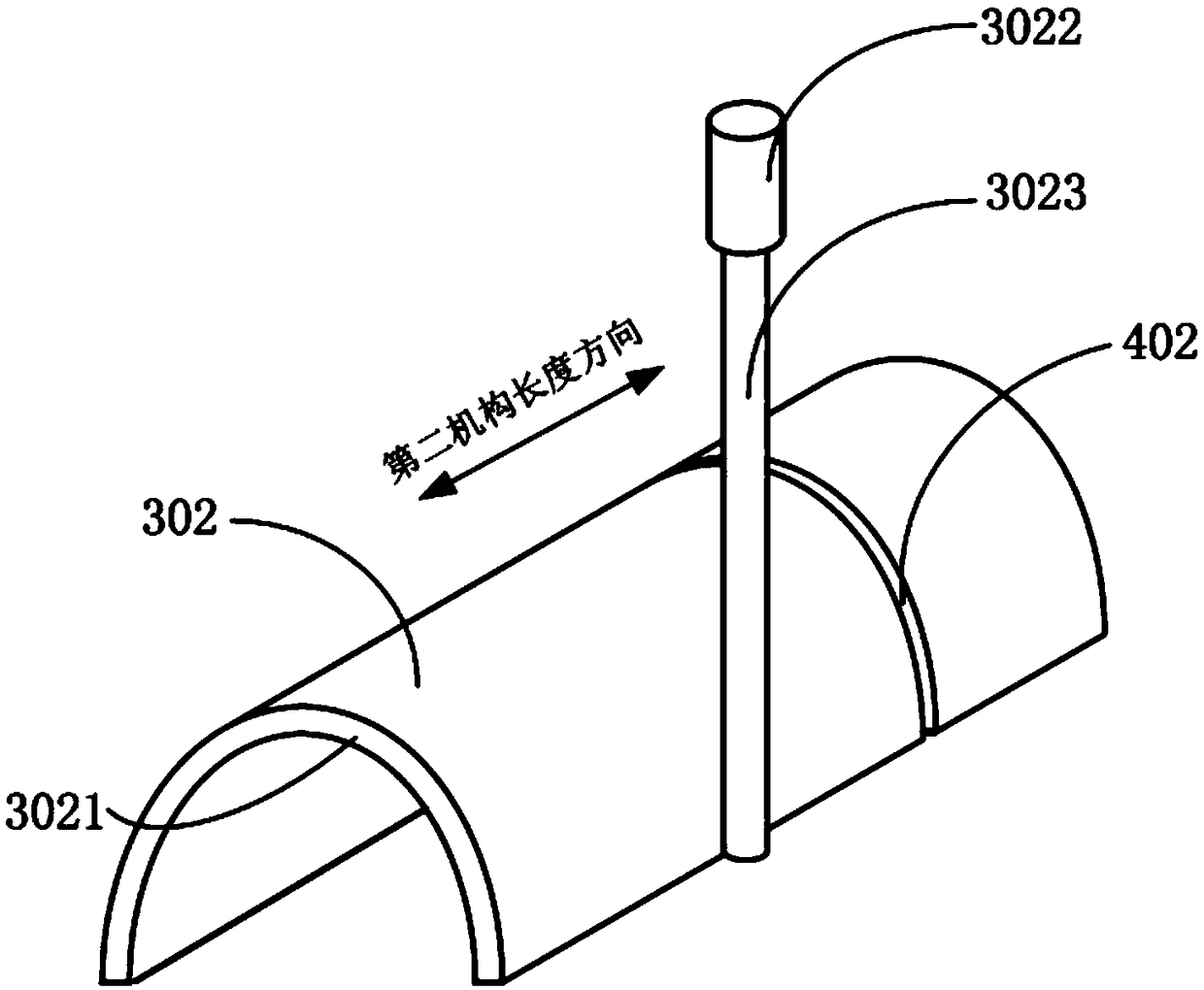

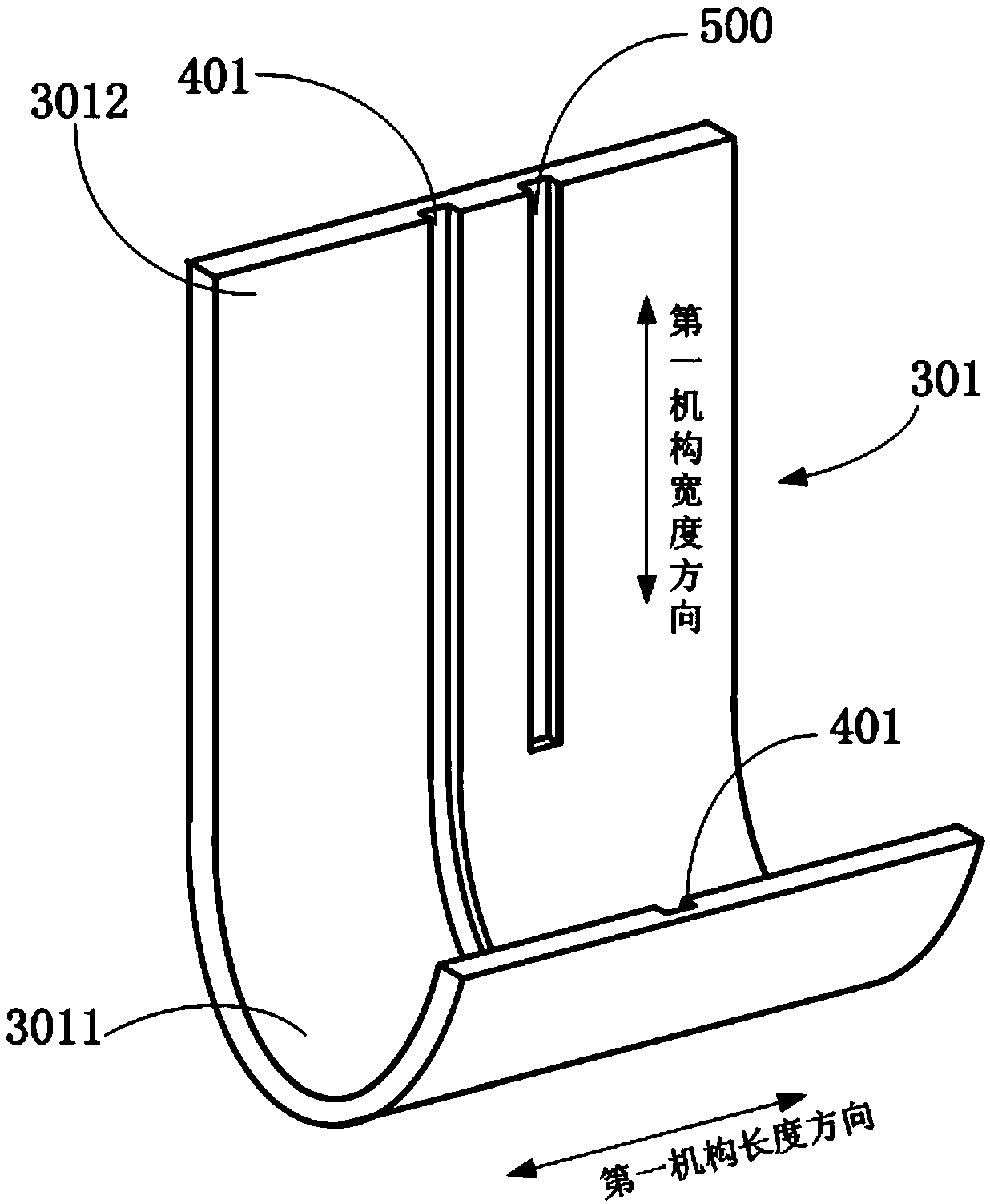

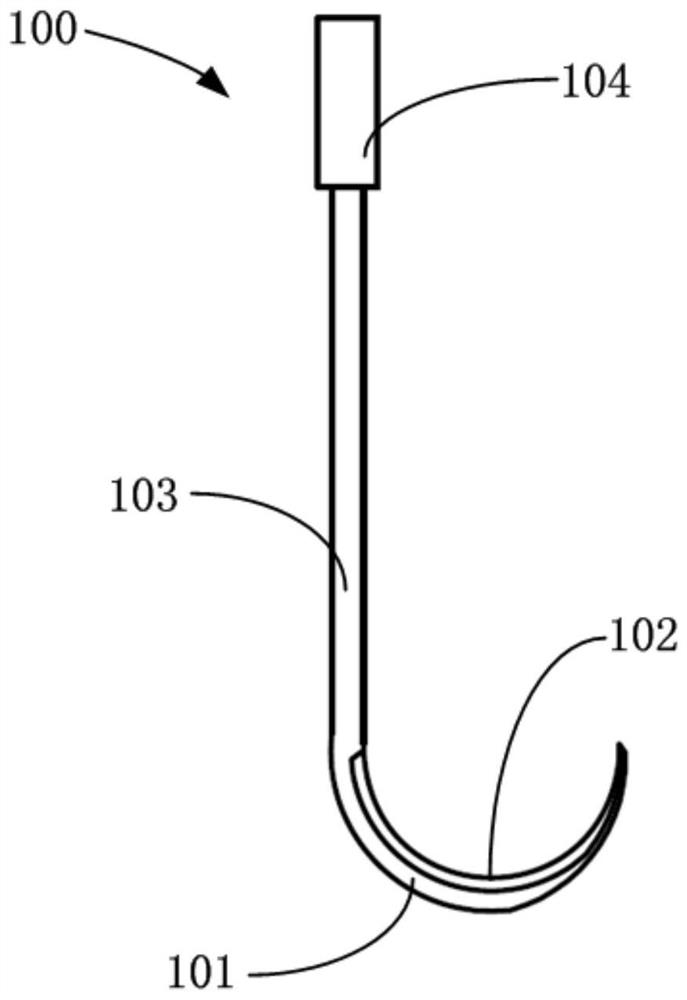

Medical spinal cord cutting device

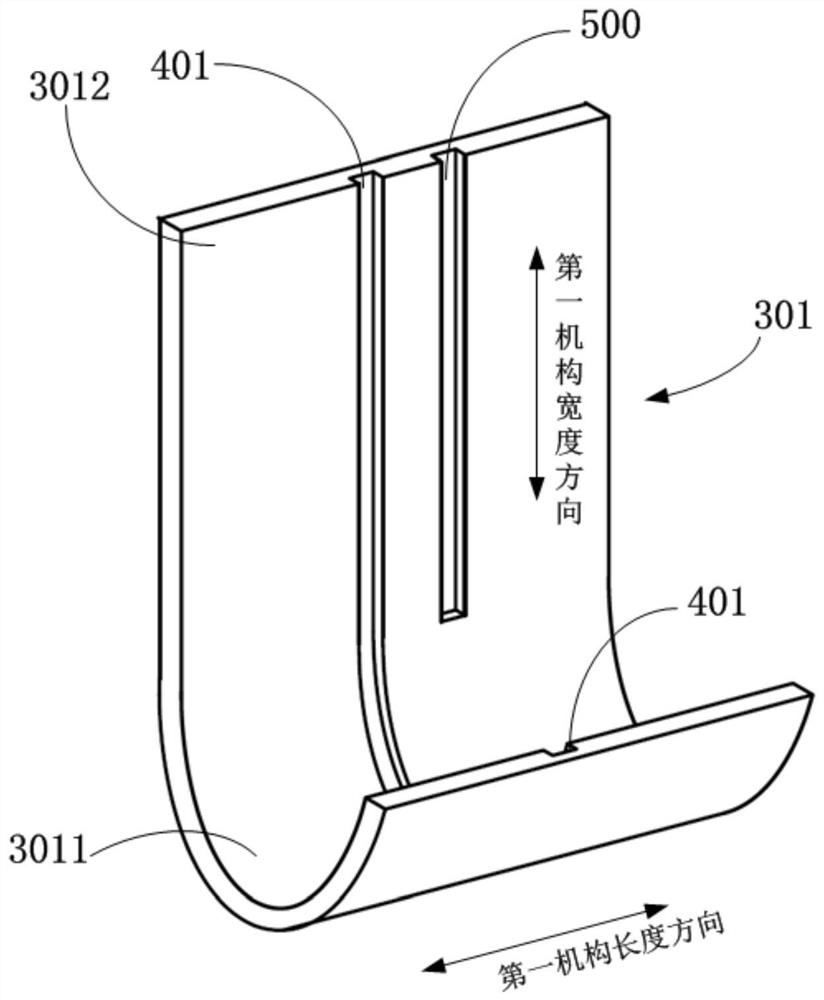

The invention provides a medical spinal cord cutting device, which relates to a medical spinal cord processing device. The medical spinal cord cutting device comprises a scalpel formed with a C-shapedknife arm, the knife edge of the scalpel is formed at the recess of the knife arm and arranged along the arc of the knife arm, and the side wall of the spinal cord is arranged in the recess of the knife arm; And a holding mechanism including a first mechanism formed with a first recess; A second mechanism formed with a second recess, the second mechanism selectively engaging or disengaging with the first mechanism so that the first recess is engaged with the second recess to form a hole, and the spinal cord and the knife arm are retained in the hole; And a guide portion formed in the first mechanism and / or the second mechanism, wherein the scalpel is disposed in the guide portion, and the guide portion is used for guiding the knife arm to be disengaged from the holding portion from the lateral direction of the spinal cord to cut the spinal cord. The spinal cord was transected and the end face was very neat, which provided a very favorable guarantee for the follow-up spinal cord end fusion effect and recovery of spinal cord injury.

Owner:任晓平

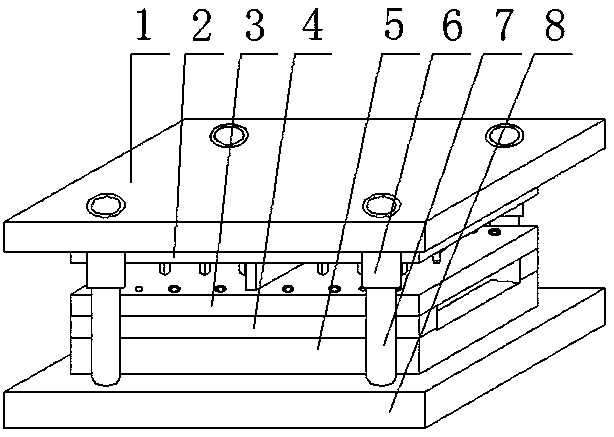

A compound die for punching and cutting

ActiveCN105537413BCompact structureReduce processing stepsShaping toolsPerforating toolsPunchingCurve shape

Owner:黄友华

Rigid coaxial cable stripping device and stripping process

ActiveCN109119945BDiameter size limitAvoid Cutting Difficult QuestionsLine/current collector detailsApparatus for removing/armouring cablesCoaxial cableElectric machinery

Owner:SICHUAN HUAFENG ENTERPRISE GRP +1

Airbag type constant-pressure tension platform

InactiveCN103861890AMake up for tension fluctuationsConsistent tightnessAirbag deploymentTension control

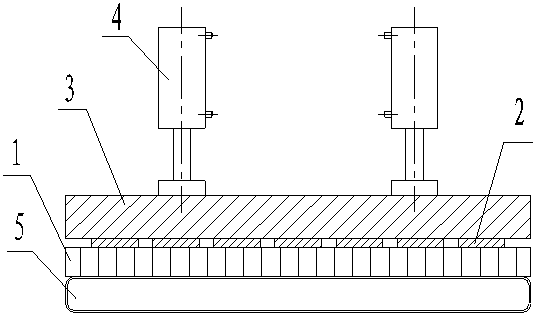

The invention discloses an airbag type constant-pressure tension platform, which belongs to the field of steel rolling machinery. The objective of the invention is to overcome the problem of nonuniform tension caused by tension establishment with pressure of upper and lower plates in the process of curling after slitting of sheet metal in the prior art. The airbag type constant-pressure tension platform is mainly composed of an upper pressing plate, a lower pressing plate and screwdown cylinders, wherein the screwdown cylinders apply pressure onto the upper pressing plate to tightly press a plurality of plate belts between the upper pressing plate and the lower pressing plate, so tension is established in the curling process of the plate belts. The airbag type constant-pressure tension platform is characterized in that an airbag is arranged below the lower pressing plate, and the lower pressing plate is formed by a plurality of sheets of piano type structures which are arrayed in parallel. According to the airbag type constant-pressure tension platform disclosed by the invention, tension adjustment and tension control become simple because of the designs of an airbag type structure and the piano type lower pressing plate, and the pressing force is uniform, so tension fluctuation caused by abnormal plate shapes and uneven thickness of strips can be compensated; and the tension of each strip tends to be consistent in the curling process, so the tightness degree of each coil of the strip is consistent, end faces of the strips are ordered, and defects of staggered layers and the like are reduced.

Owner:武钢集团有限公司

A kind of medical spinal cord cutting device

The invention provides a medical spinal cord cutting device and relates to a medical spinal cord processing device. The medical spinal cord cutting device includes: a scalpel with a C-shaped knife arm, the blade of the scalpel is formed in the depression of the knife arm and arranged along the arc of the knife arm, and the side wall of the spinal cord is placed on the knife arm. In the depression; and the holding mechanism includes a first mechanism, which is formed with a first depression; a second mechanism, which is formed with a second depression, and the second mechanism can be selectively engaged with or separated from the first mechanism, so that the first A concave part is fastened with the second concave part to form a hole-shaped part, the spinal cord and the knife arm are kept in the hole-shaped part; and the guide part is formed in the first mechanism or / and the second mechanism, and the scalpel is placed in the guide part, The guide part is used to guide the knife arm to separate from the foramen in the transverse direction of the spinal cord, so as to cut off the spinal cord. The end surface of the transected spinal cord is very neat, thus providing a very favorable guarantee for the subsequent fusion effect of the end of the spinal cord and the recovery of the spinal cord injury.

Owner:任晓平

A kind of controllable layered plastic film and its preparation method

ActiveCN104890333BSpeed upInaccessibleSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention relates to a plastic film with a layering control function and a preparation method thereof. The plastic film comprises a bonding layer, an easy-to-tear layer and a stripping layer, wherein the bonding layer is prepared from ethylene-acrylic acid copolymer or ethylene-methacrylic acid copolymer; the easy-to-tear layer is prepared from a blend formed by mixing ethylene-vinyl acetate copolymer, ethylene-methacrylic acid ionic polymer, poly-1-butene, silicon dioxide, beta-propionic acid octade, triphenyl phosphite, N,N'-ethylenebisoctadecanamide, 2,6-Di-tert-butyl-4-methylphenol, oleamide, triphenyl phosphate and oleyl palmitamide according to a certain weight ratio; the stripping layer is prepared from a blend formed by mixing ethylene-vinyl acetate copolymer, low-density polyethylene and a linear low-density polyethylene resin material according to a certain weight ratio. The plastic film with the layering control function ensures that an external sheath layer of an optical cable or an electric cable can be disengaged from the bonding layer and also ensures that a metal-plastic composite belt is free of moisture invasion.

Owner:烟台万泰通信科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com