Plastic film with layering control function and preparation method thereof

A technology of plastic film and peeling layer, which is applied in the field of communication materials, can solve the problems of peeling off the sheath layer, affecting the progress of the optical cable, and the cable core of the optical cable cannot be reused and wasted. Moisture-proof, neat end effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

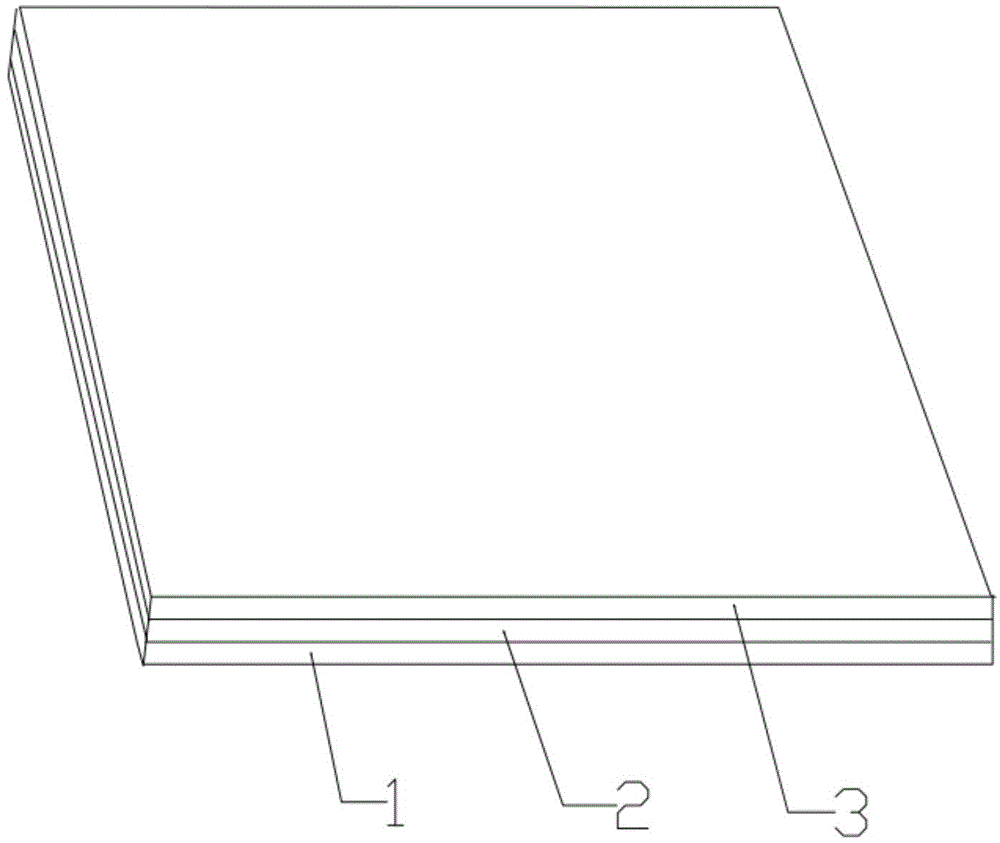

[0029]A controllable layered plastic film, comprising an adhesive layer, an easy-tear layer and a peeling layer, the thickness of the adhesive layer is 0.028mm, the thickness of the easy-tear layer is 0.008mm, and the thickness of the peeling layer is 0.040mm, and the weight ratio of each layer is: Adhesive layer: 30%, easy-tear layer: 30%, peeling layer: 40%, adhesive layer is made of ethylene-acrylic acid copolymer, easy-tear layer is made of the following raw materials by weight: vinyl acetate content of less than 5% Ethylene-vinyl acetate copolymer: 35%, ethylene-methacrylic acid ionomer: 45%, poly-1-butene: 18%, silica: 0.5%, beta-stearyl propionate: 0.2% , Phenyl triphosphite: 0.2%, N, N′-ethylene bisstearamide: 0.2%, 2,6-di-tert-butyl-4-methylphenol: 0.2%, oleic acid amide: 0.2%, phosphoric acid Triphenyl ester: 0.3%, Oleyl palmitamide: 0.2%, The release layer is made of the following raw materials in parts by weight: Ethylene-vinyl acetate copolymer with a vinyl acetat...

Embodiment 2

[0036] A controllable layered plastic film, comprising an adhesive layer, an easy-tear layer and a peeling layer, the thickness of the adhesive layer is 0.014mm, the thickness of the easy-tear layer is 0.012mm, and the thickness of the peeling layer is 0.016mm, and the weight ratio of each layer is: Adhesive layer: 35%, easy-tear layer: 25%, peeling layer: 35%, adhesive layer is made of ethylene-methacrylic acid copolymer with methacrylic acid content of 9%, easy-tear layer is made of the following raw materials in parts by weight Composition: Ethylene-vinyl acetate copolymer with 5-20% vinyl acetate content: 38%, Ethylene-methacrylic acid ionomer: 48%, Polybutene-1: 20%, Silica: 0.4%, β-stearyl propionate: 0.1%, phenyl triphosphite: 0.1%, N,N′-ethylene bisstearamide: 0.2%, 2,6-di-tert-butyl-4-methylphenol: 0.1%, Oleamide: 0.2%, Triphenyl Phosphate: 0.2%, Oleyl Palmitamide: 0.1%, The release layer is made of the following raw materials in parts by weight: Ethylene-vinyl acetat...

Embodiment 3

[0043] A controllable layered plastic film, comprising an adhesive layer, an easy-tear layer and a peeling layer, the thickness of the adhesive layer is 0.036mm, the thickness of the easy-tear layer is 0.024mm, and the thickness of the peeling layer is 0.025mm, and the weight ratio of each layer is: Adhesive layer: 40%, easy-tear layer: 15%, peeling layer: 45%, adhesive layer is made of ethylene-methacrylic acid copolymer with methacrylic acid content of 4%, easy-tear layer is made of the following raw materials in parts by weight Composition: ethylene-vinyl acetate copolymer with less than 5% vinyl acetate content: 36%, ethylene-methacrylic acid ionomer: 47%, polybutene-1: 18%, silica: 0.4%, beta -Stearyl propionate: 0.1%, phenyl triphosphite: 0.1%, N,N'-ethylene bisstearamide: 0.2%, 2,6-di-tert-butyl-4-methylphenol: 0.1 %, oleic acid amide: 0.2%, triphenyl phosphate: 0.1%, oleyl palmitamide: 0.1%, the release layer is made of the following raw materials in parts by weight: e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com