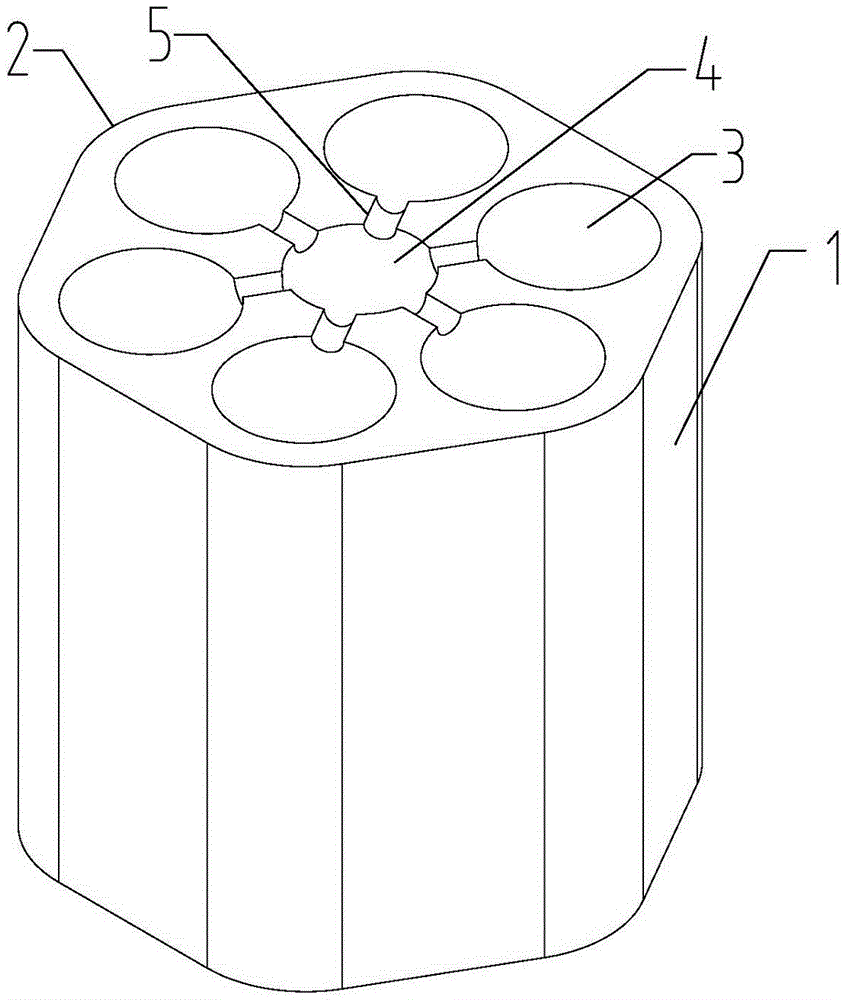

Lattice brick for blast furnace hot blast stove

A checkered brick and hot blast stove technology, applied in the field of kilns, can solve the problems of uneven airflow temperature, pressure, flow rate, checkered brick cracking and damage, fire well wall collapse, etc., so as to reduce cracking or interlayer slip, side and The end face is regular and the effect of stress concentration is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

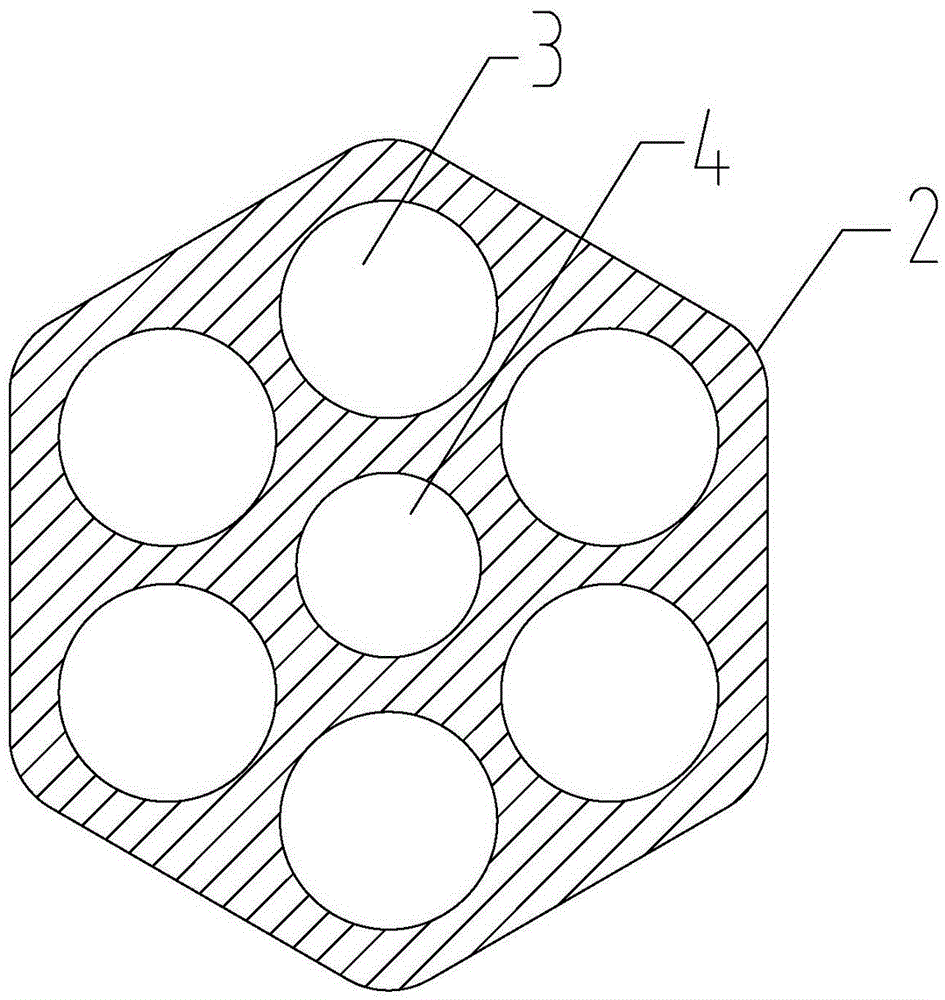

Embodiment 1

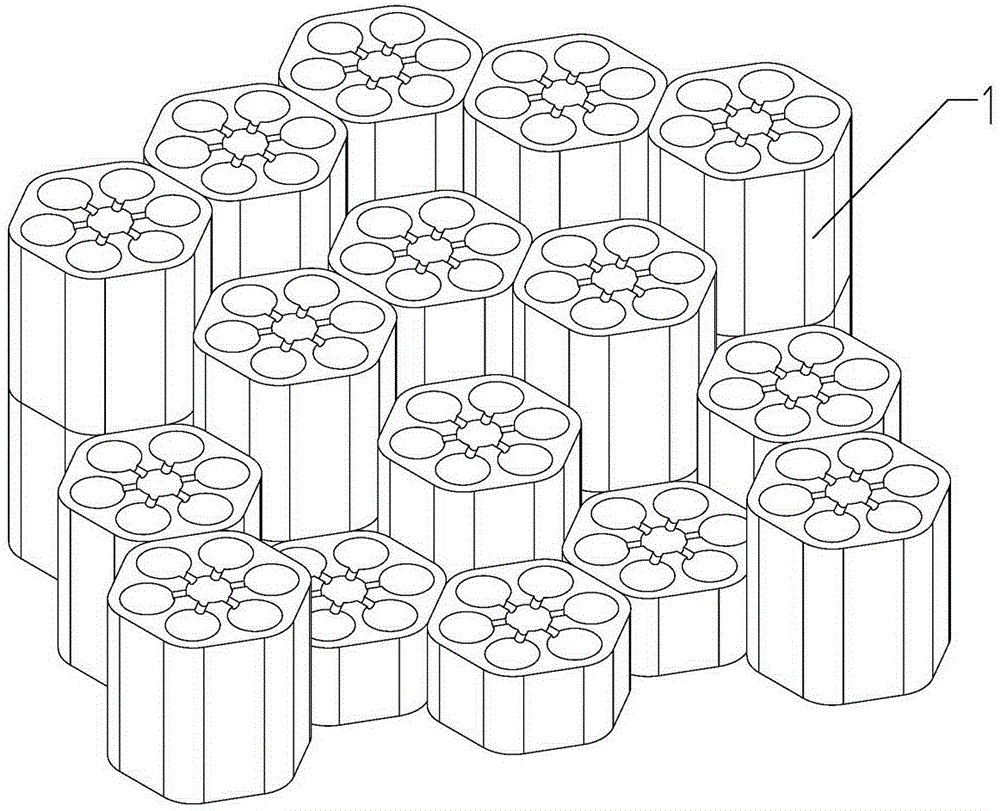

[0017] Embodiment 1: In the staggered-layer circular paving method of the present invention, the checker brick is made of magnesia siliceous olivine, and its composition is 2MgO SiO 2 content of 96%, the radius of the transition arc of prism 1 is 12mm, and the vertical distance between the opposite sides of the hexagon is 230mm. Two kinds of checker bricks are used for masonry, one is the end face distance and each side The whole height brick is 230mm in height, and the other is the half-height brick with the distance between the end face and the height of each side being 115mm. At the center of the circle, half-height bricks are paved on each side, full-height bricks are paved on the outer ring side of the half-height bricks, and half-height bricks are paved on the outer ring of the full-height bricks, and the paving is repeated in turn until it reaches the hot blast furnace wall , using conventional technology to fill the gaps between the checker bricks and the hot blast sto...

Embodiment 2

[0018] Embodiment two: the staggered layer in-line paving method of the present invention, the material of checker brick is magnesia siliceous olivine, and its composition 2MgO·SiO 2 The content is 96%. The full-height brick with the distance between the end face and the height of each side is 230mm. After cutting, it is processed into an adjusted brick whose height and the height of each side are half the height of the full-height brick. The center of the circular section of the furnace and the straight line that divides the hot blast stove fire well wall into two symmetrical parts are the reference line. A full-height brick is laid from the hot blast furnace wall as the starting brick, and then a row of full-height bricks is laid in sequence along the reference line until the hot blast The wall of the furnace well is used as the reference row, and then a row of adjustment bricks is paved on both sides of it, and then the whole height bricks are paved respectively, and the pav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com