A high-speed surface-mounted dual-rotor axial flux permanent magnet motor

A technology of axial flux and permanent magnet motors, applied in the direction of motors, magnetic circuits, electric components, etc., can solve the problems of large capacity of power electronic converters, poor heat dissipation performance of motors, high cogging torque, etc., and achieve superior heat dissipation performance , Improve the torque density, the effect of high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

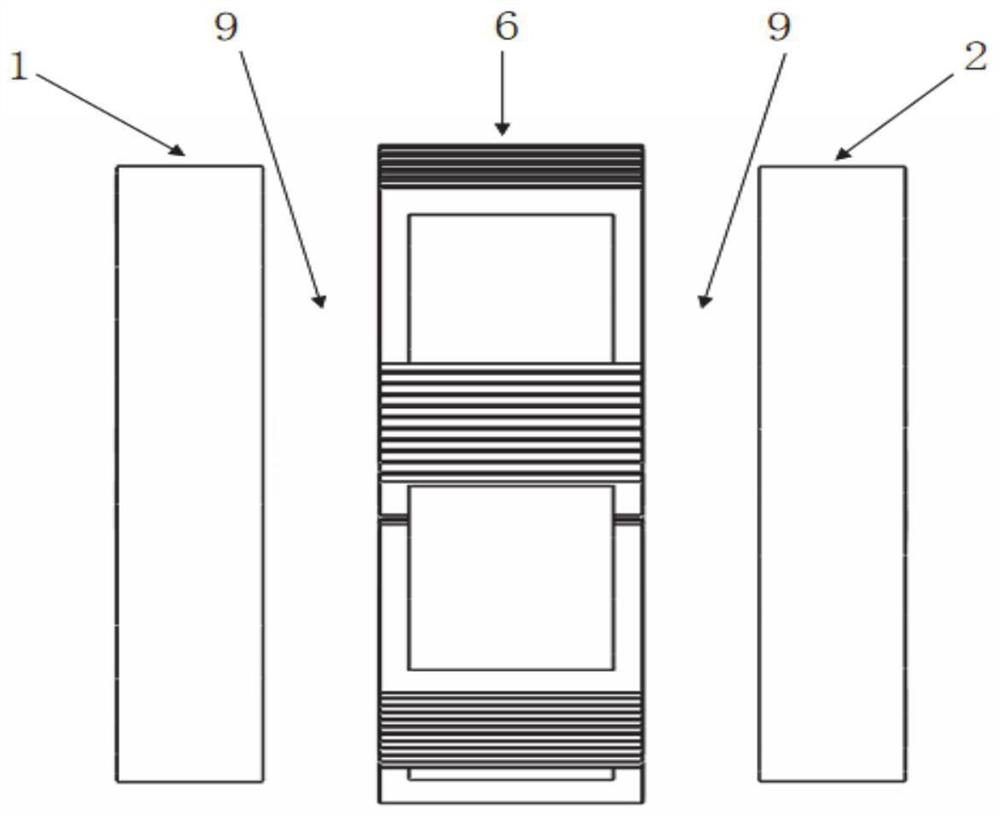

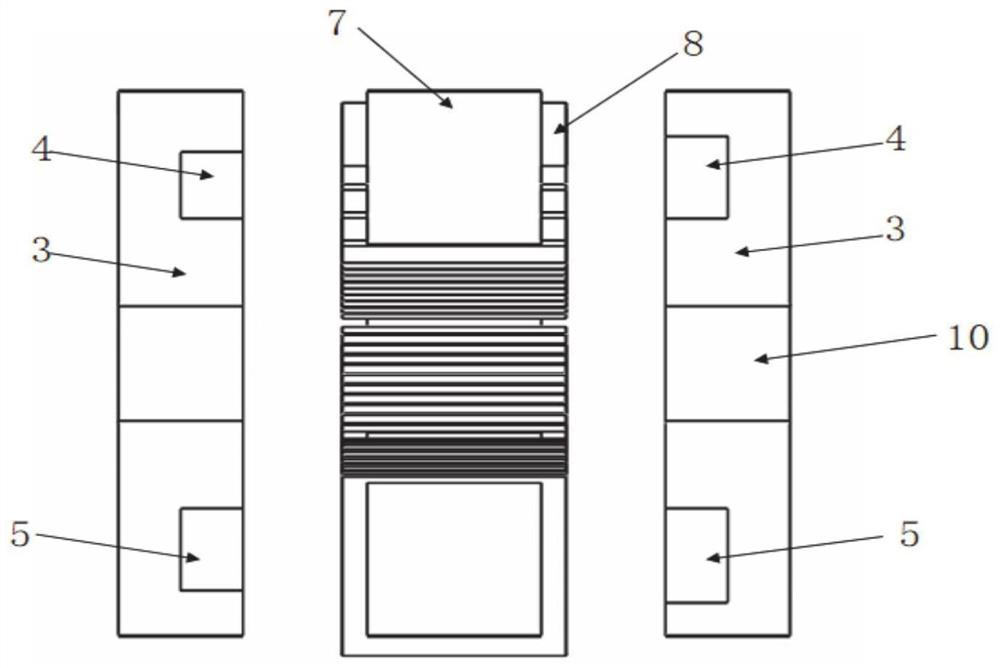

[0042] This embodiment discloses a high-speed surface-mounted double-rotor axial flux permanent magnet motor, which is mainly composed of a first rotor 1, a second rotor 2, a stator 6 and a shaft 10. The first rotor 1 and the second rotor 2 are mirror-symmetrically installed on both sides of the stator 6 along the rotating shaft 10, and there are air gaps 9 of the same axial length between the stator 6 and the two rotors.

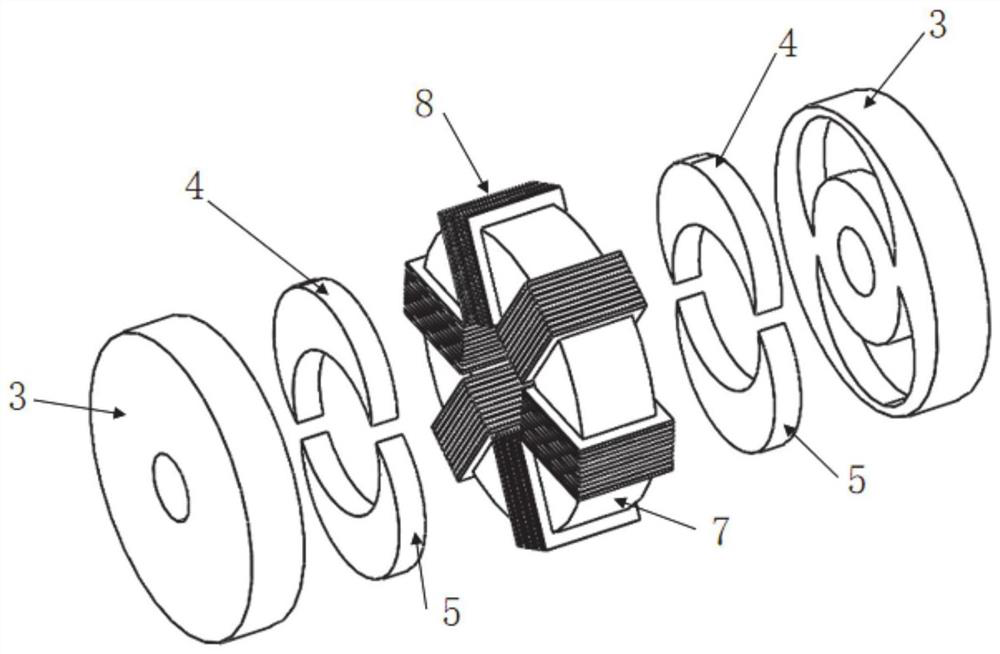

[0043] The first rotor 1 and the second rotor 2 have the same specifications, and are composed of a rotor core 3 and two permanent magnets. The rotor core 3 is disc-shaped, and the two permanent magnets are symmetrically distributed around the rotating shaft and have opposite polarities. One is the N pole 4 of the permanent magnet, and the other is the S pole 5 of the permanent magnet. The permanent magnet N pole 4 and the permanent magnet S pole 5 have the same specification, both are crescent-shaped, and are embedded on the surface of the rotor core 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com