A compact pipe-making device for concrete

A concrete and compact technology, which is applied in the field of compact pipe-making devices for concrete, can solve the problems of different accumulation of mold concrete, reduce construction efficiency, and reduce the quality of finished products, and achieve the effects of improving construction efficiency, improving the quality of finished products, and facilitating exhaust and leveling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

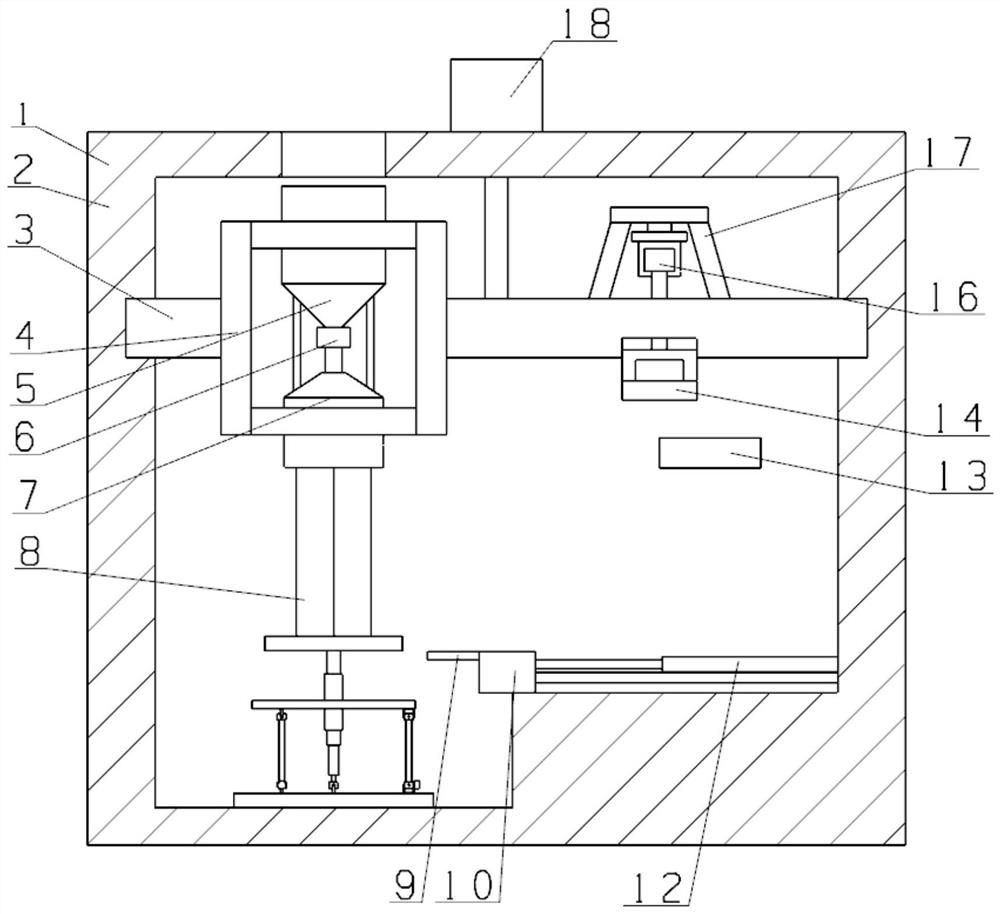

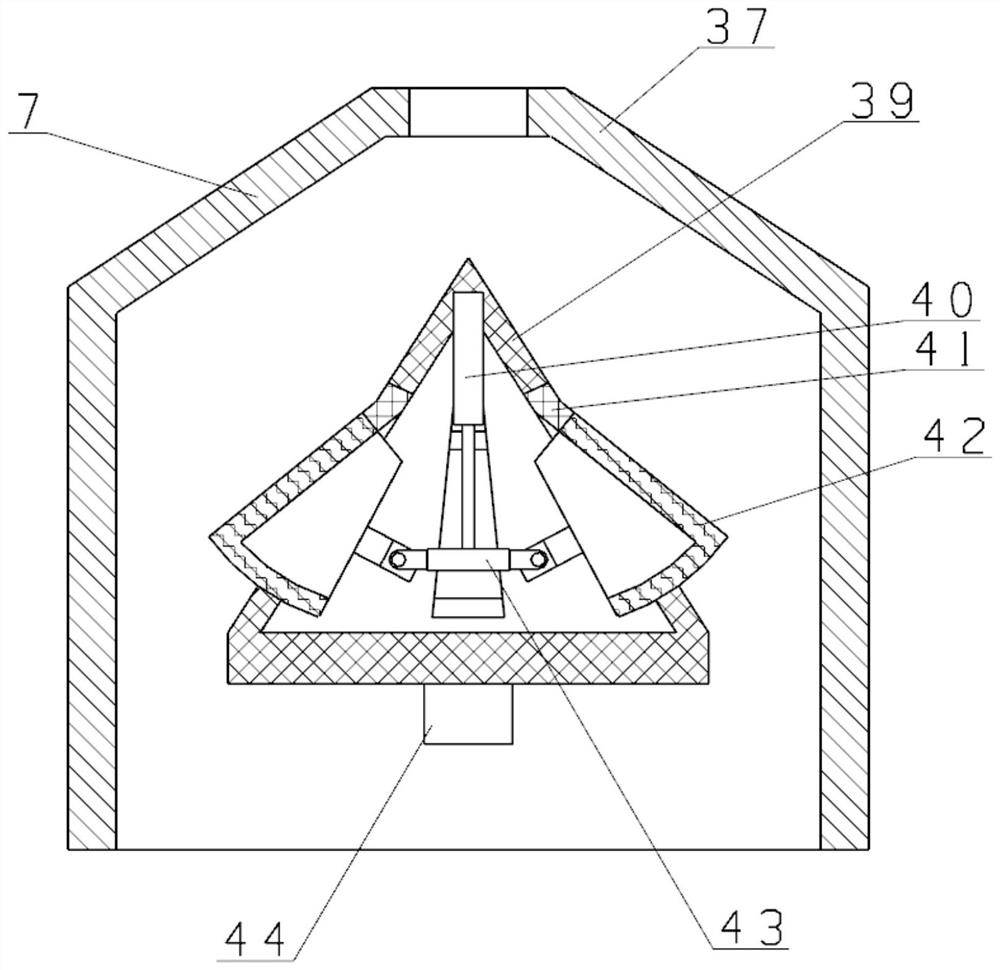

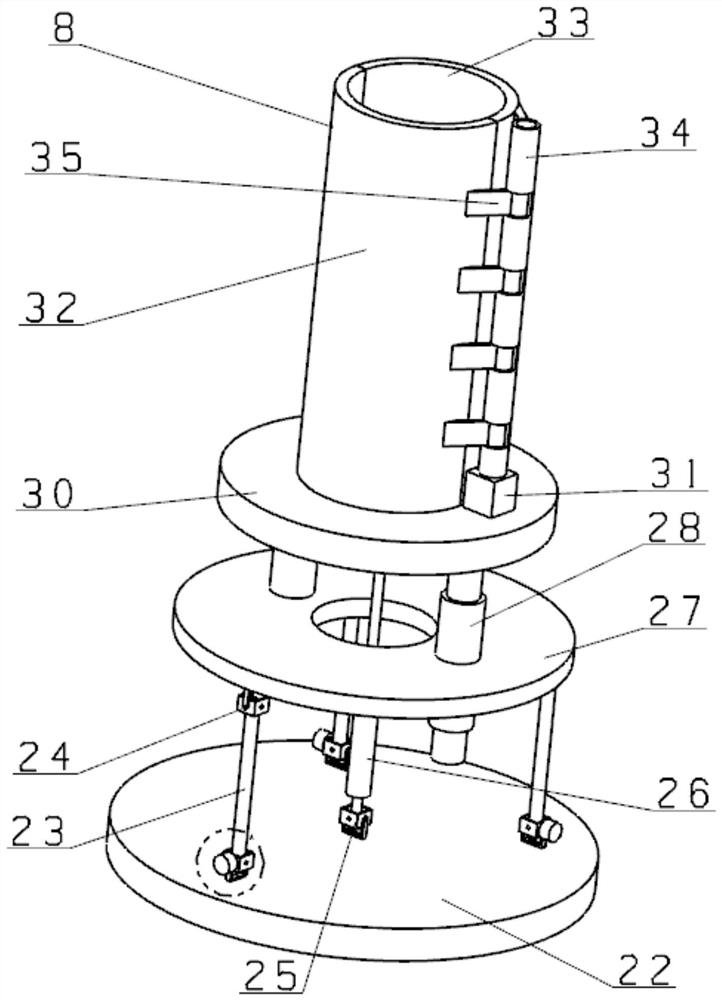

[0024] see Figure 1~Figure 7 As shown, a compact pipe-making device for concrete includes a pipe-making device 1, the pipe-making device 1 includes a frame body 2, a first motor 18 is arranged on the upper end surface of the frame body 2, and the output of the first motor 18 The shaft end is provided with a rotating plate 3, and the two ends of the rotating plate 3 are arranged in the frame body 2, and the rotating plate 3 is connected to the frame body 2 in rotation, and a square fixing frame 4 is fixedly installed on the rotating plate 3. The fixed frame 4 is provided with a material cylinder 5, the material cylinder 5 is connected with a control valve 6, and a feed pipe is arranged under the control valve 6, and the lower end of the feed pipe is fixedly connected with a speed control valve fixedly connected with the fixed frame 4. 7, the speed controller 7 includes an outer casing 37, a connecting plate 44 is connected inside the outer casing 37, an inner casing 39 is inst...

Embodiment 2

[0031] On the basis of embodiment one, refer to figure 1 , the lower right part of the frame body 2 is fixedly connected with a third electric push rod 12, a slider 10 is arranged on the third electric push rod 12, and a shovel plate 9 is fixedly installed on one side of the slider 10; The push rod 12 drives the slide block 10 so that the shovel plate 9 automatically takes out the formed concrete pipe, which saves manpower.

[0032]Working principle: In the process of use, through the setting of the feeding hopper 40, the outer shell 37, the connecting plate 44, the inner shell 39, the first electric push rod 40, the pushing block 43, the retaining plate 42, and the elastic reed 41 Cooperate with each other to block and control the falling concrete of the barrel 5. The higher the tilting angle of the baffle plate 42, the better the deceleration effect on the concrete. At the same time, the inner shell 39 can effectively divert and guide the concrete, and when the concrete flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com