Energy-saving power generation device for ship

A technology for energy-saving power generation and ships, applied to electromechanical devices, wind power generation, engines, etc., to achieve good deceleration effect, simple structure, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

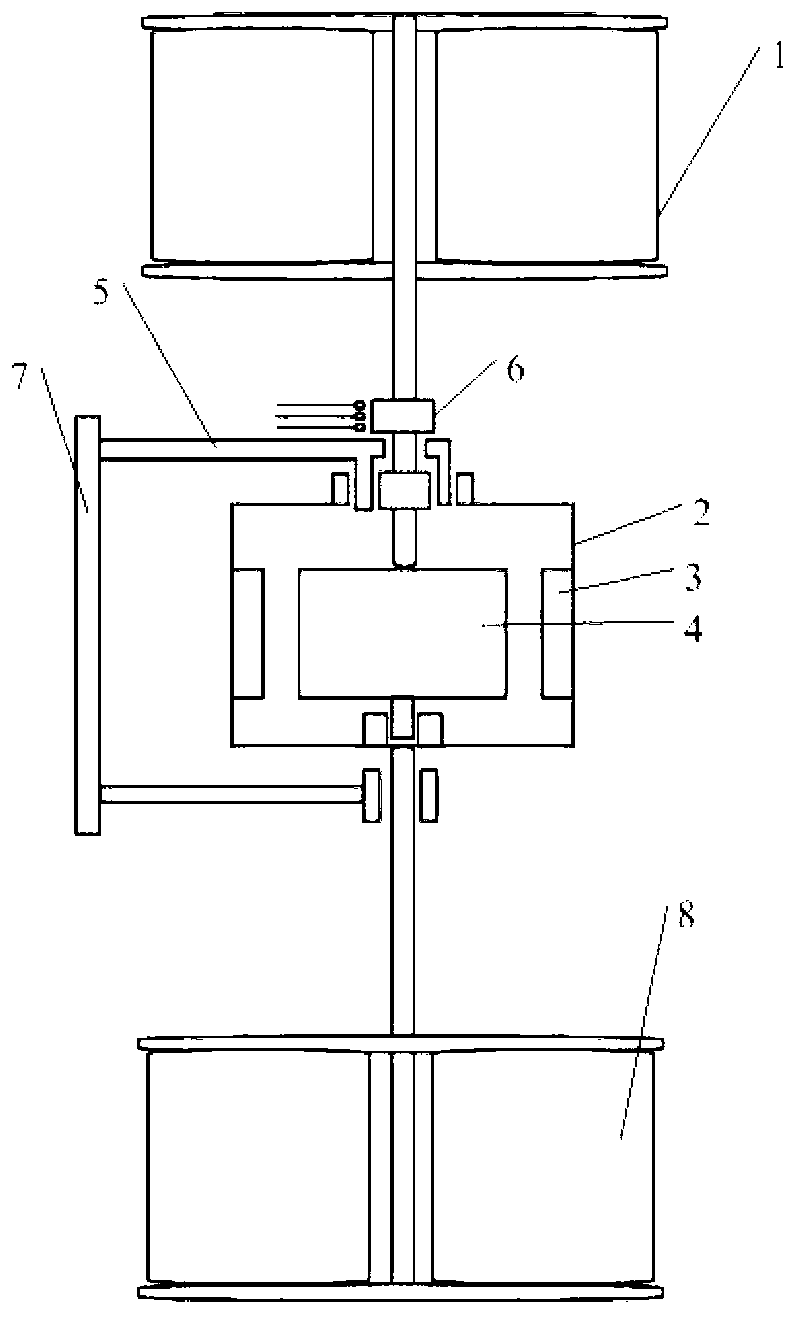

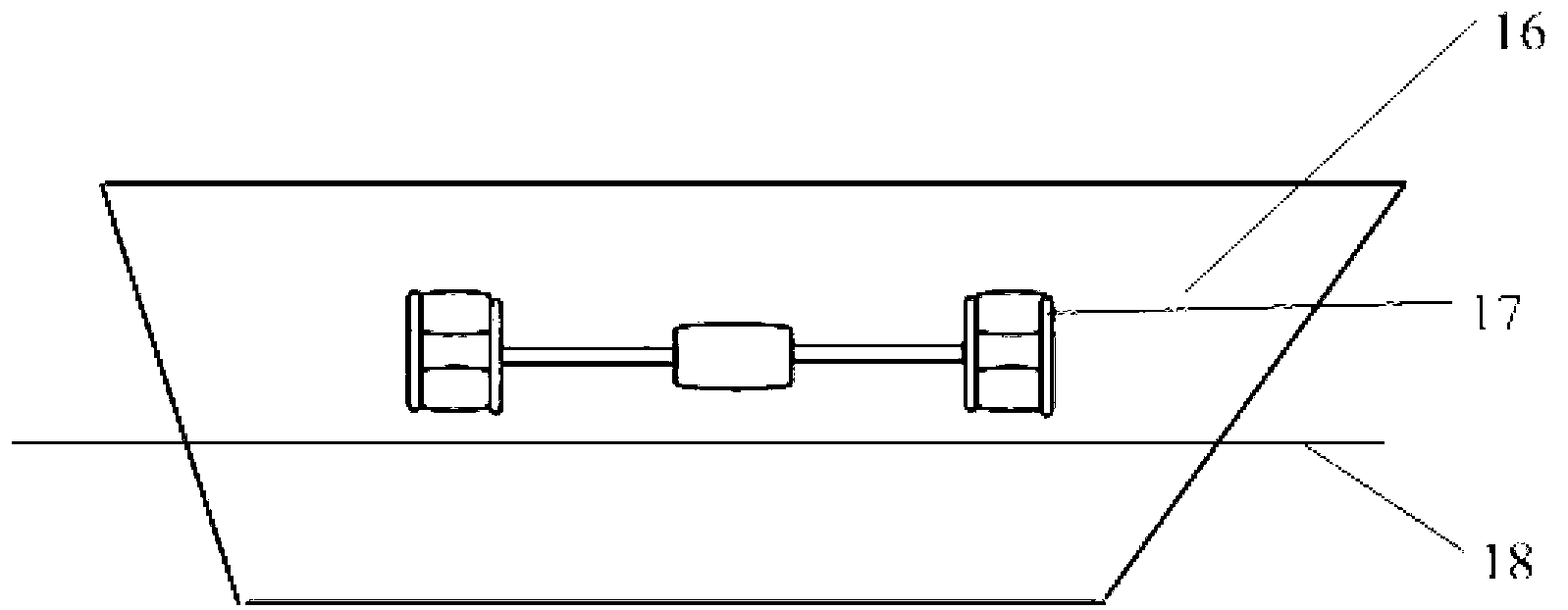

[0024] Specific implementation mode 1: see figure 1 , 3 4. This design mainly uses the structural characteristics of the dual-rotor generator, fully combines the advantages of wind power generation and water current power generation, and is mainly used when the ship is decelerating and stationary according to the characteristics of the ship when it is sailing. This generator can be installed in such image 3 , 4 In the shipboard position shown, when the ship sails normally, power generation is not required at this time, and the additional resistance brought by the power generation device to the ship's navigation needs to be minimized. When the power generation device is not working, the control mechanism controls the rotation of the turntable 7 so that the power generation device is in the image 3 In the position shown, the power generation device is in a horizontal state, the water turbine is out of the water, and the wind turbine and water turbine in the form of a vertic...

specific Embodiment approach 2

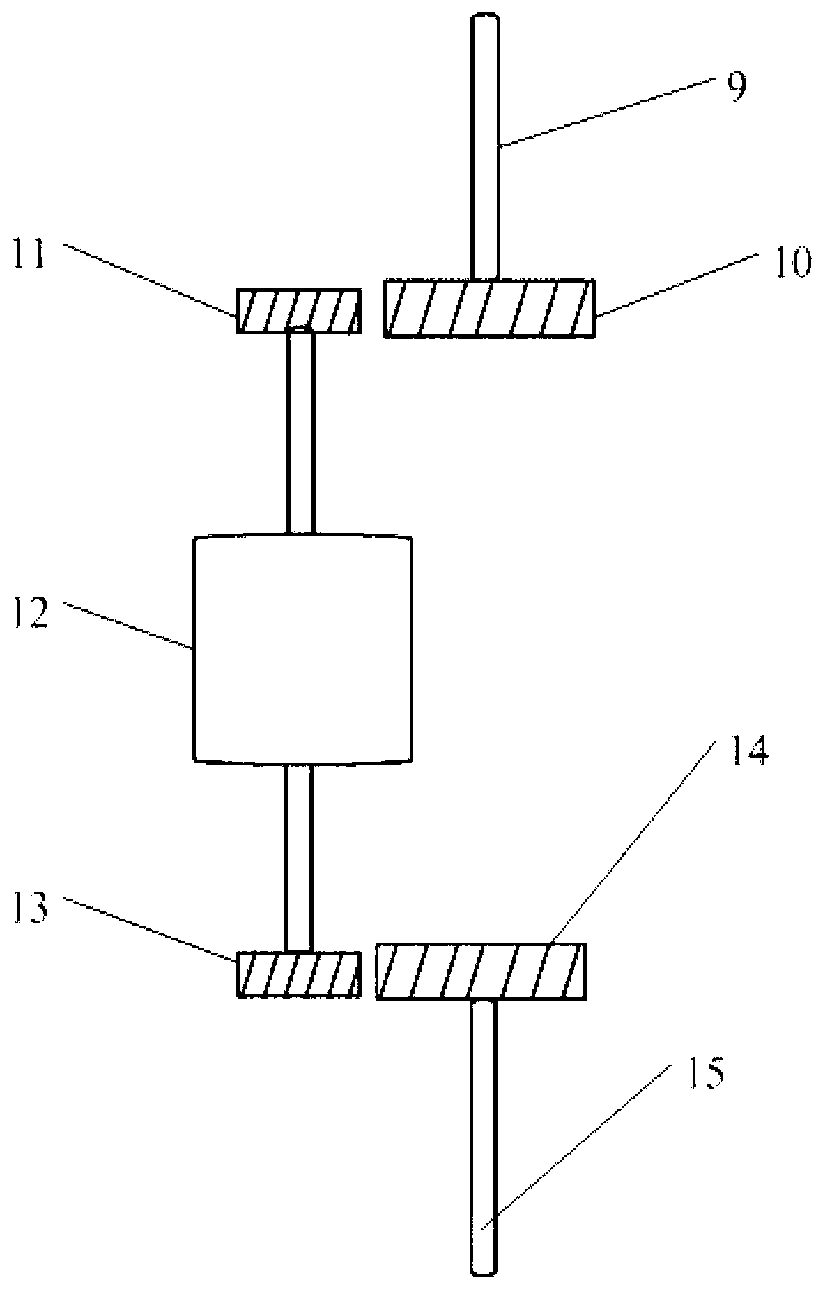

[0025] Specific implementation mode 2: see figure 1 , 2, 3, 4, the installation method of the power generation device is the same as that of the scheme 1. On the basis of the implementation mode 1, implementation mode 2 adds such as between the wind turbine and the generator and between the water turbine and the generator. figure 2 The gear speed increaser shown. figure 2 Middle 9 is the rotating shaft of the wind turbine, and 15 is the rotating shaft of the water turbine. Since the rotating speed of the wind turbine and the water turbine is relatively slow during work, the figure 2 The effect of the middle gear 10, the gear 11, the gear 13 and the gear 14 increases the rotating speed of the input generator 12. The generator obtains a higher rotating speed, the volume of the generator can be further reduced, and the output power can also be increased.

specific Embodiment approach 3

[0026] Specific embodiment 3: the power generation device in embodiment 1 and embodiment 2 all is to work under the ship deceleration or berthing state, in order to reduce the resistance of power generation device to ship navigation when ship sails normally, power generation device will not work. The situation during the ship's navigation is very complicated, and situations such as insufficient power supply of the power system may occur. The power generation device in the present invention can also be used as a conventional power generation device in the normal navigation of the ship. As long as the power generation device is fixed in the vertical direction through the control device when the ship is sailing normally, the power generation device can continuously supply power to the ship's power grid through the converter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com