Automatic speed reducing device for rotating shaft

A rotating shaft, automatic technology, applied in the direction of brake types, drum brakes, brake actuators, etc., can solve the problems of personal injury, lack of protective devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

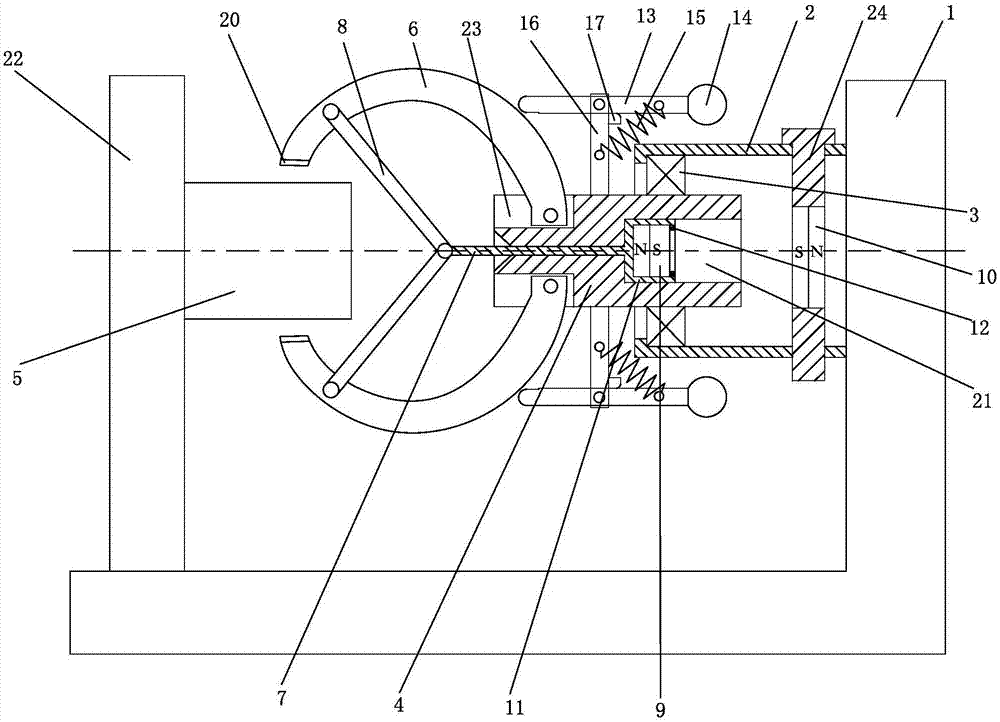

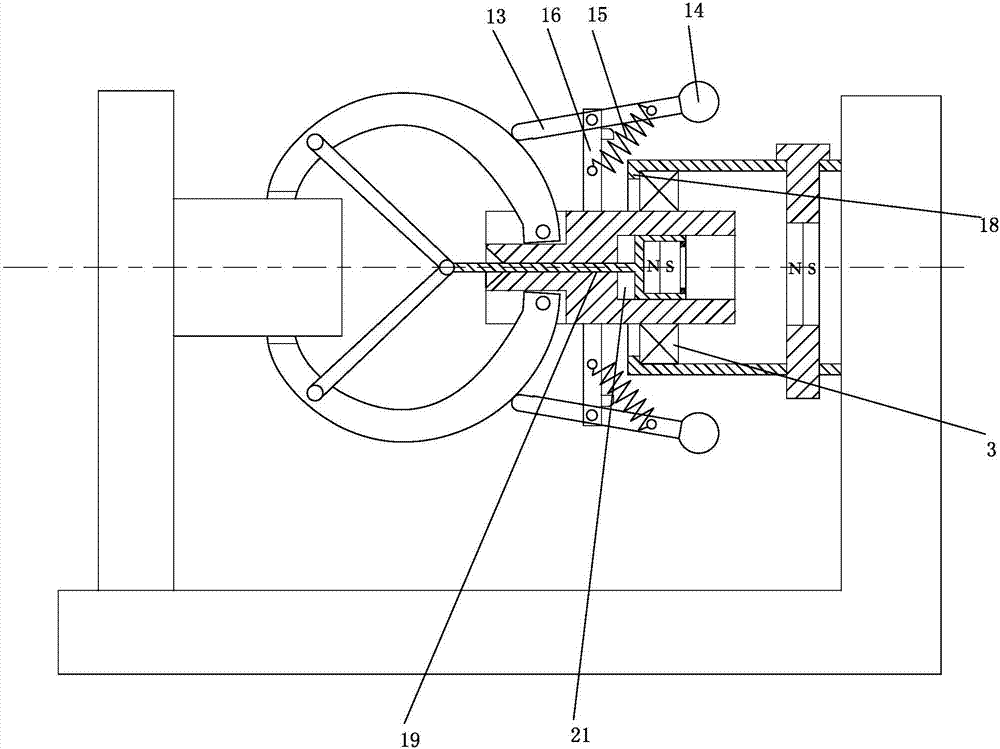

[0014] The present invention will be further described below with reference to the drawings and specific embodiments.

[0015] As shown in the figure, the device for automatic deceleration of a rotating shaft of the present invention includes a base 1, which can be connected with an electric tool 22, a guide sleeve 2 is provided on the base 1, and the guide sleeve 2 is rotatably connected through a bearing 3. Cylinder 4, a plurality of claws 6 are connected to the end of the cylinder 4 to rotate towards the shaft 5, the rotation shaft 5 is the output end of the electric tool 22, and the claws 6 are evenly distributed around the axis of the cylinder 4; the cylinder 4 is slidingly connected There is a pull rod 7, one end of the pull rod 7 close to the rotating shaft 5 is provided with a connecting rod 8 for driving a plurality of claws 6 to rotate synchronously, a first magnet 9 is provided on the end of the pull rod 7 away from the rotating shaft 5, and an end of the guide sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com