Patents

Literature

450results about How to "Avoid rigid contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

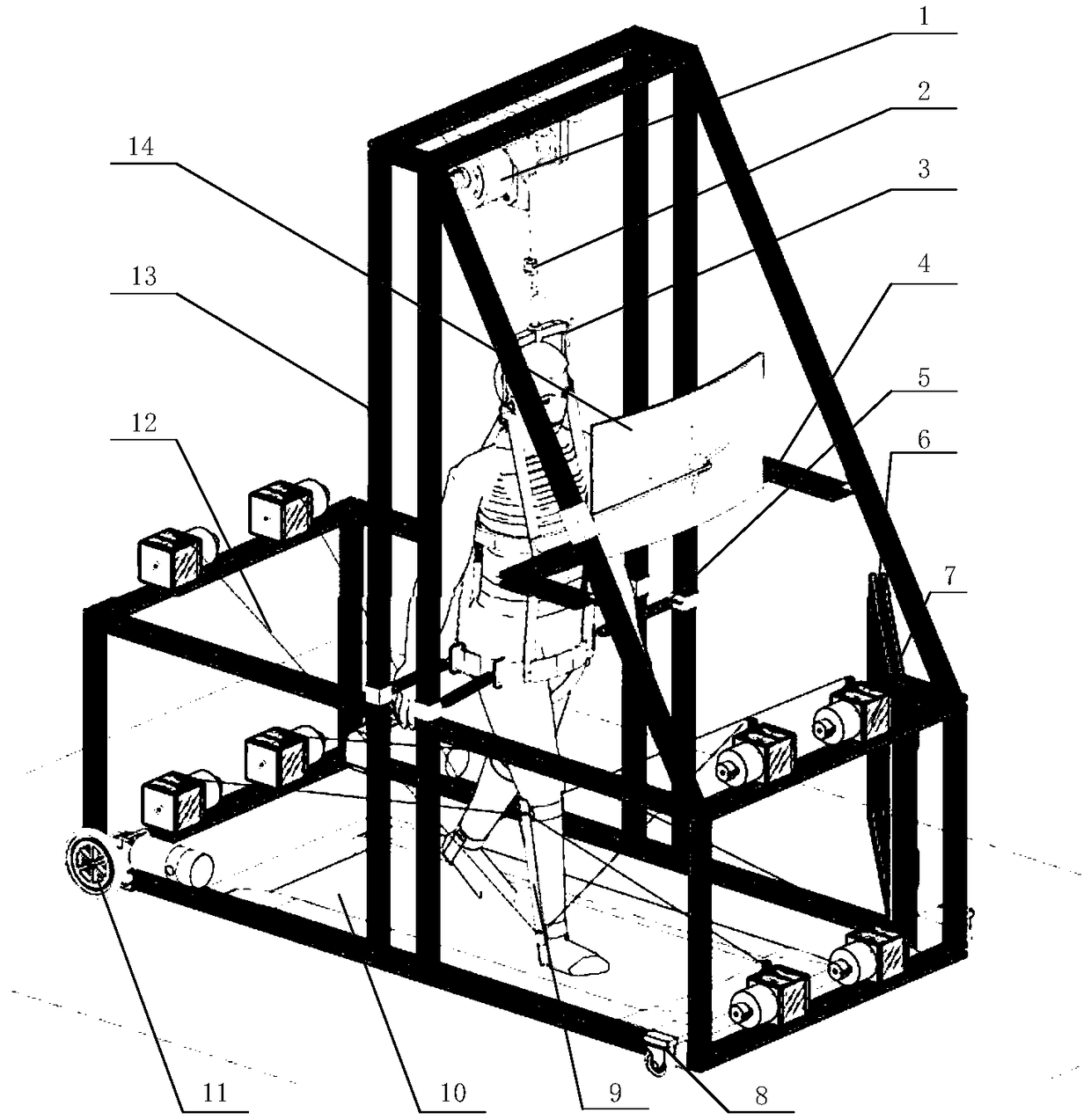

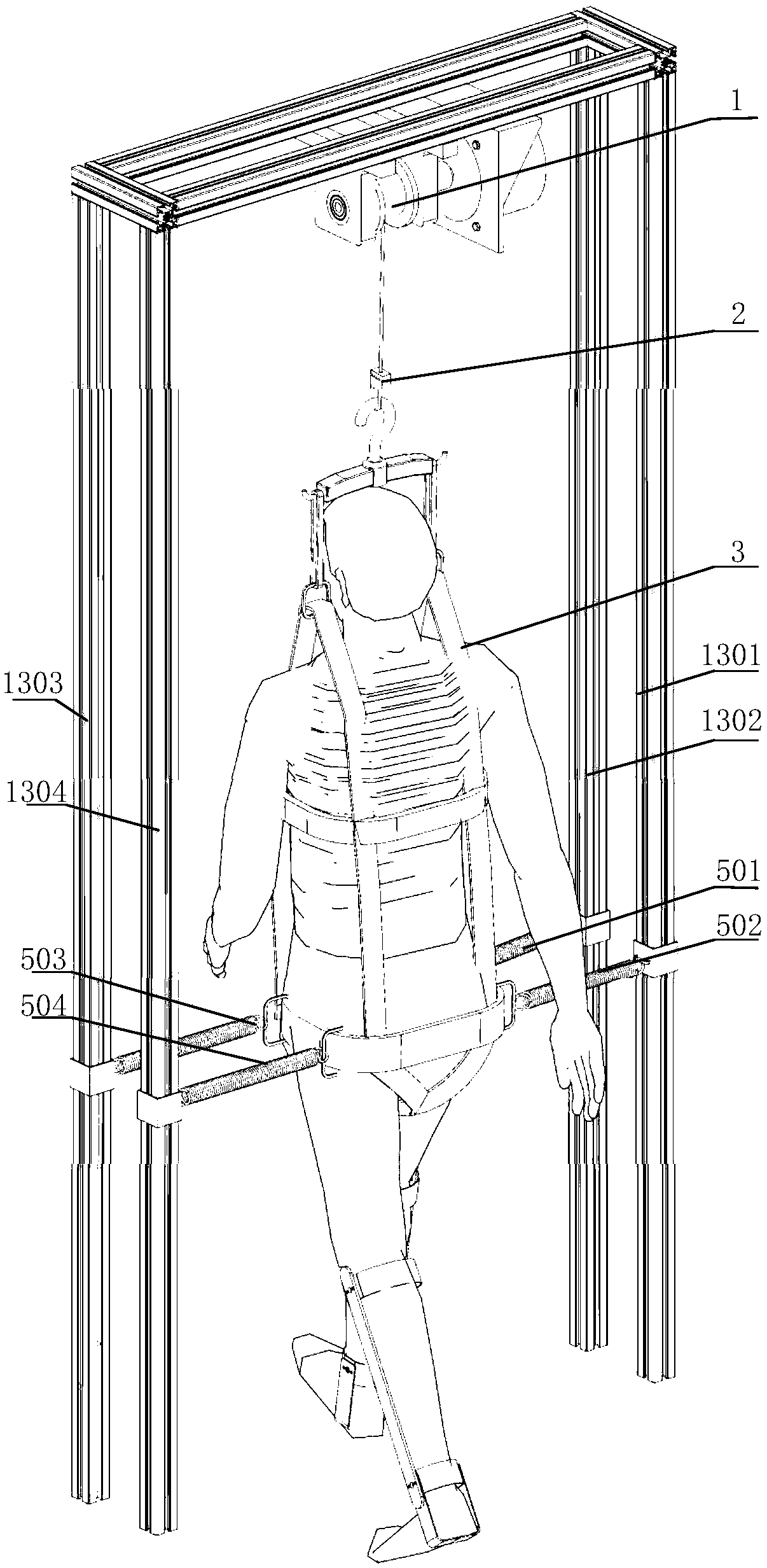

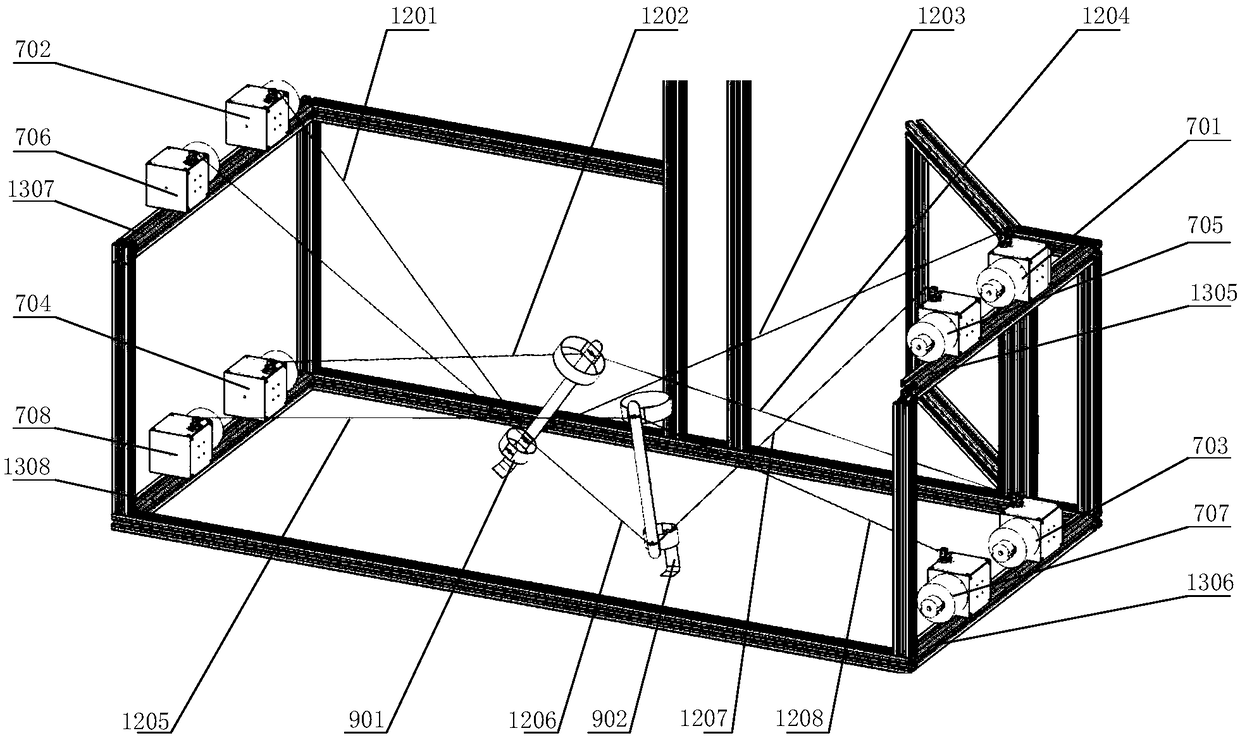

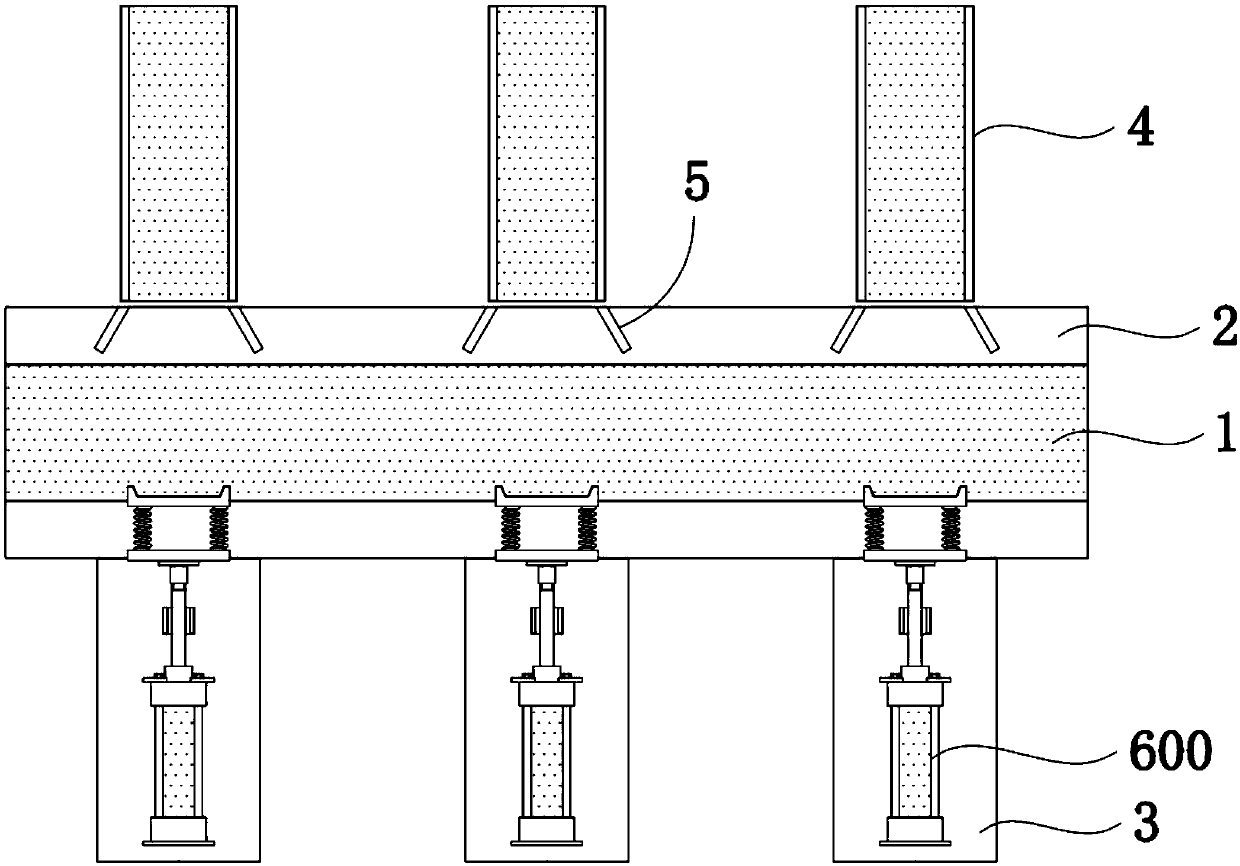

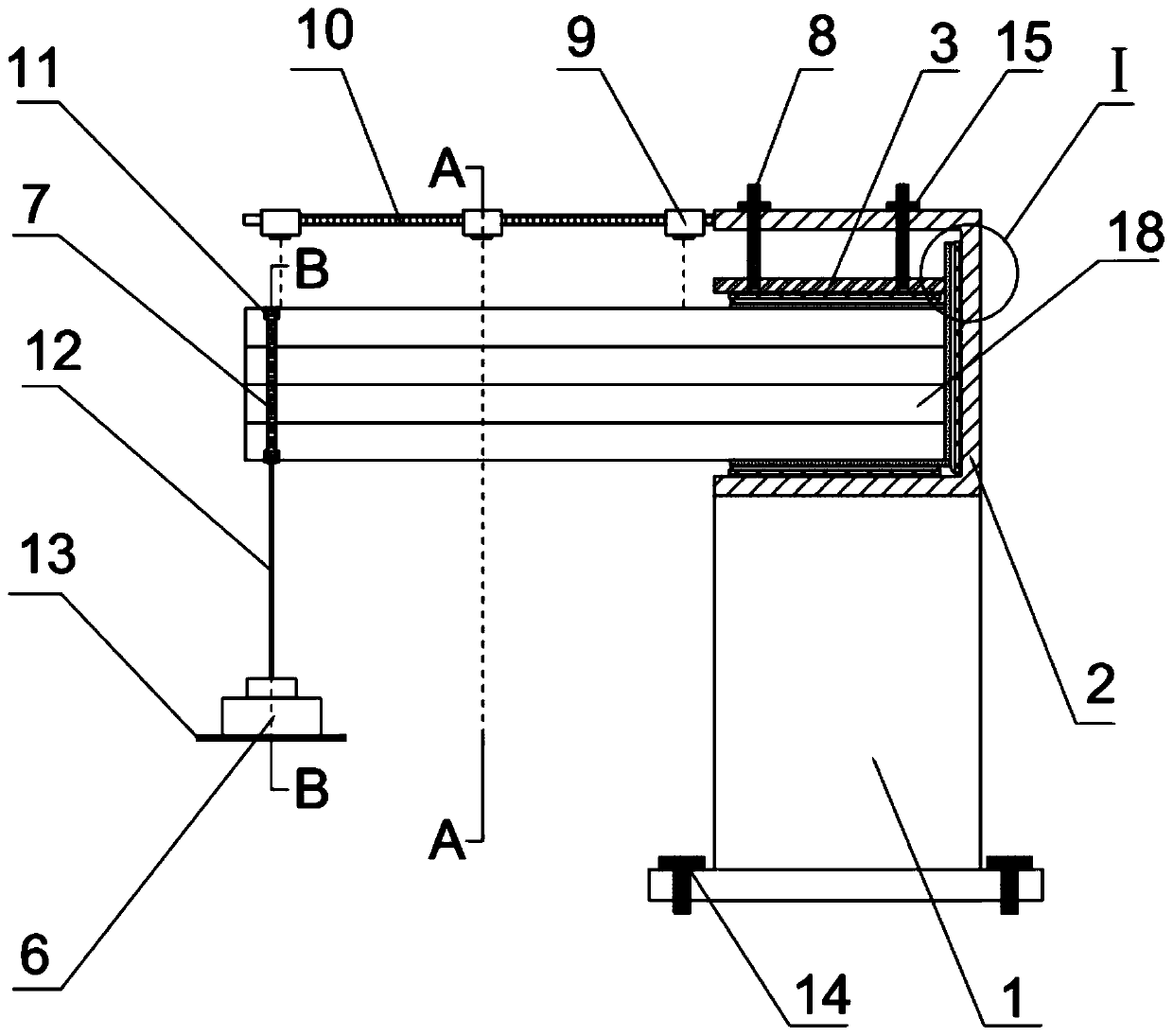

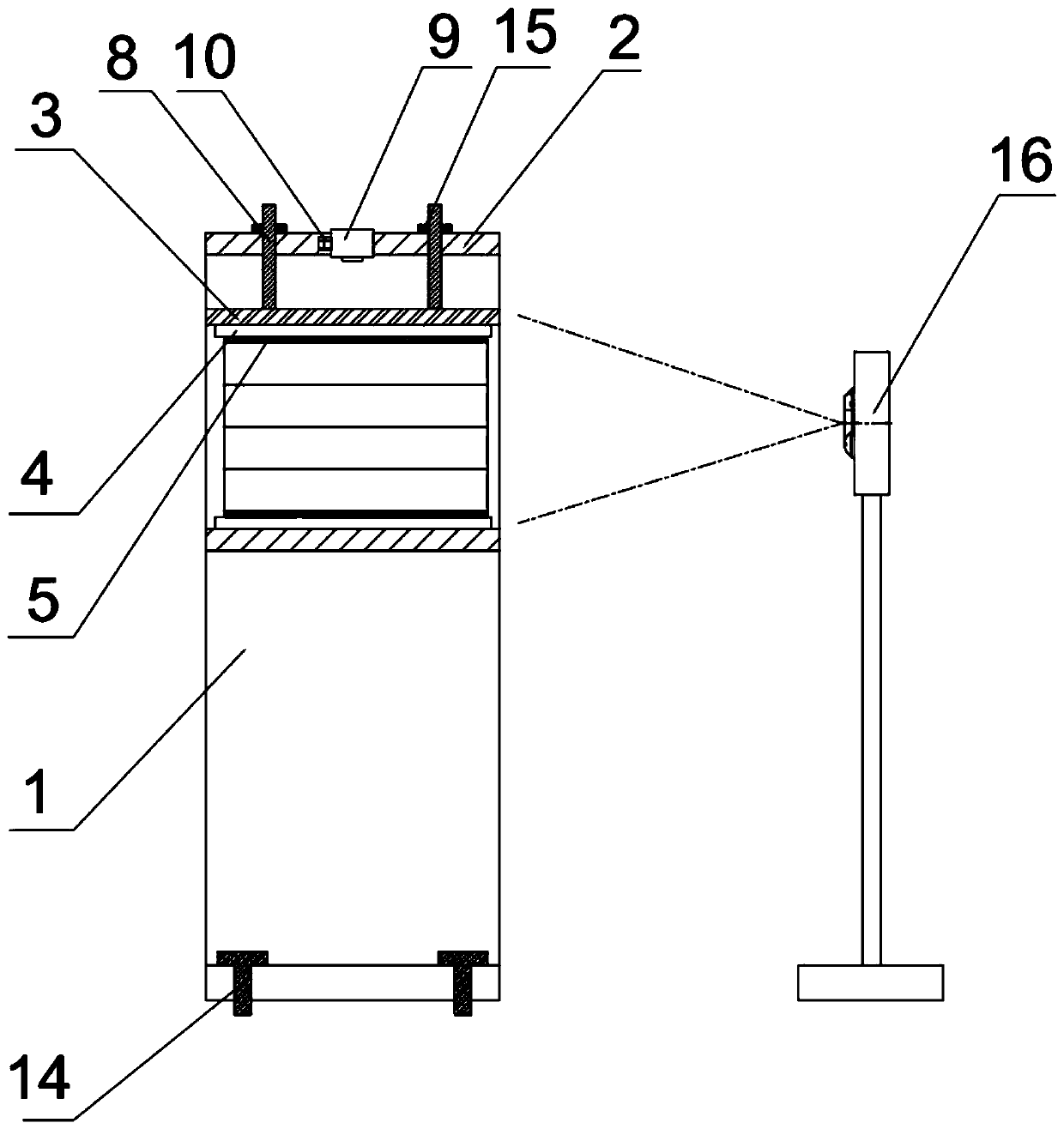

Movable parallel wire driven lower limb rehabilitation robot and implementation method thereof

ActiveCN108606907AEnsure safetyAchieve coordinated movementChiropractic devicesWalking aidsDrive wheelEngineering

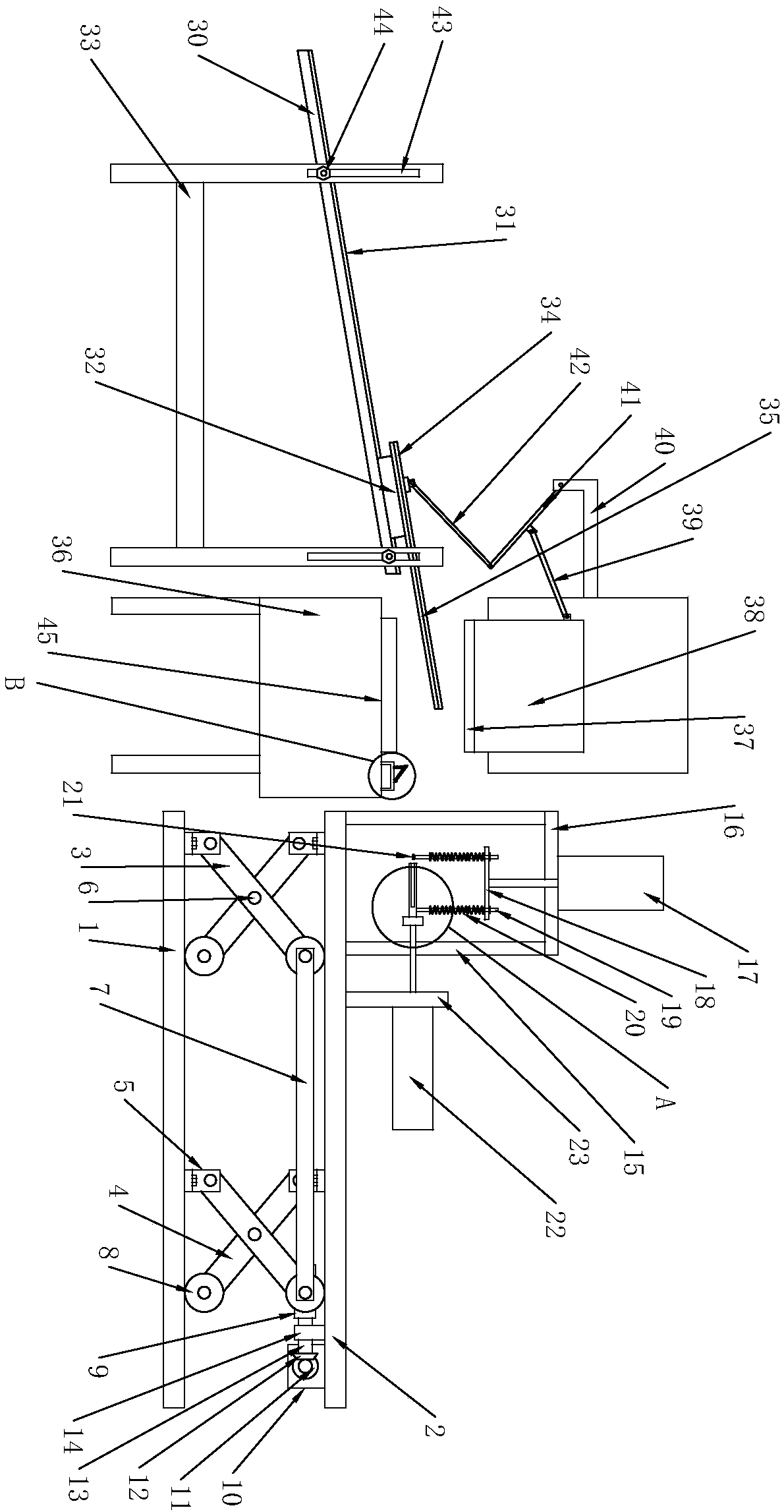

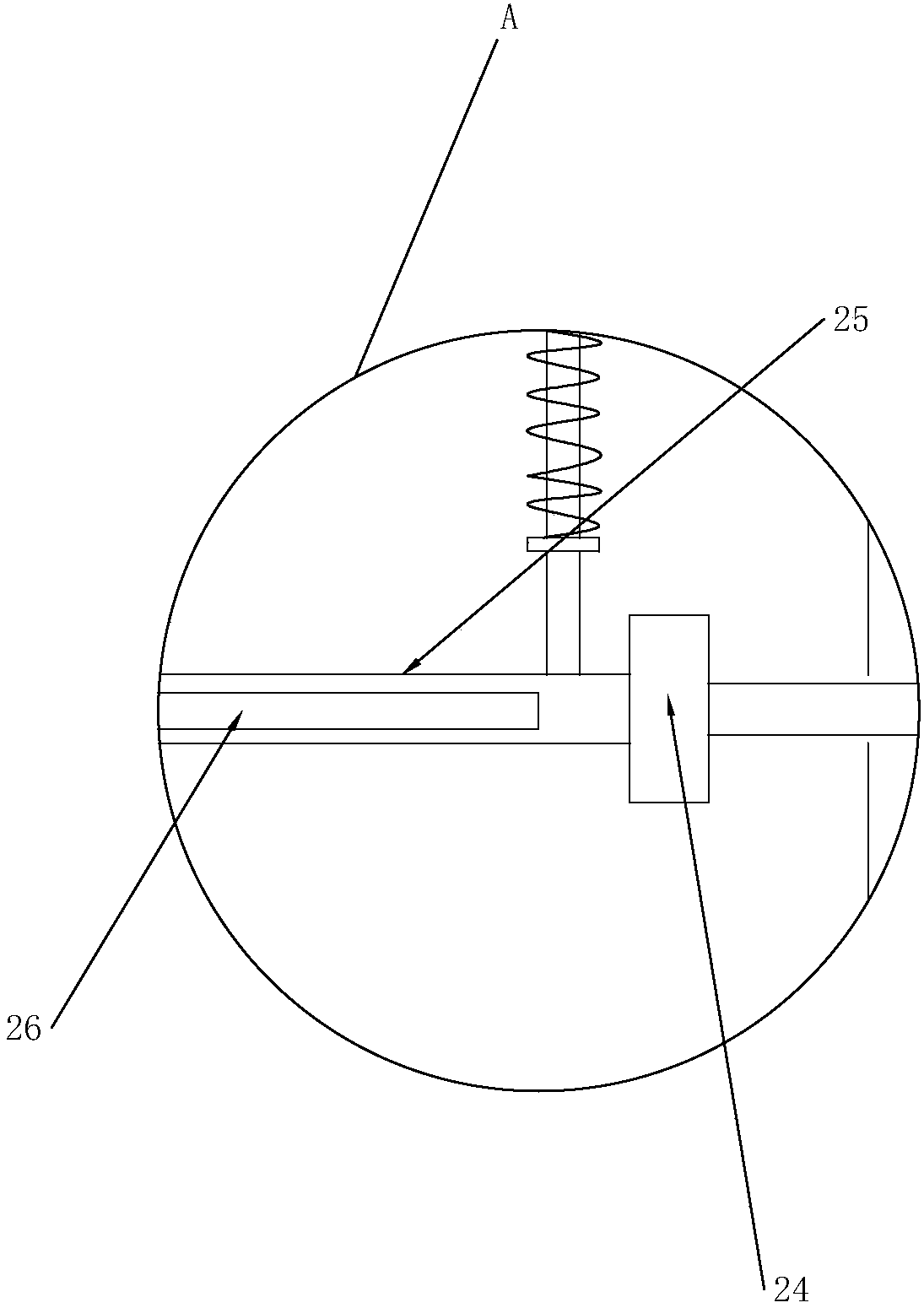

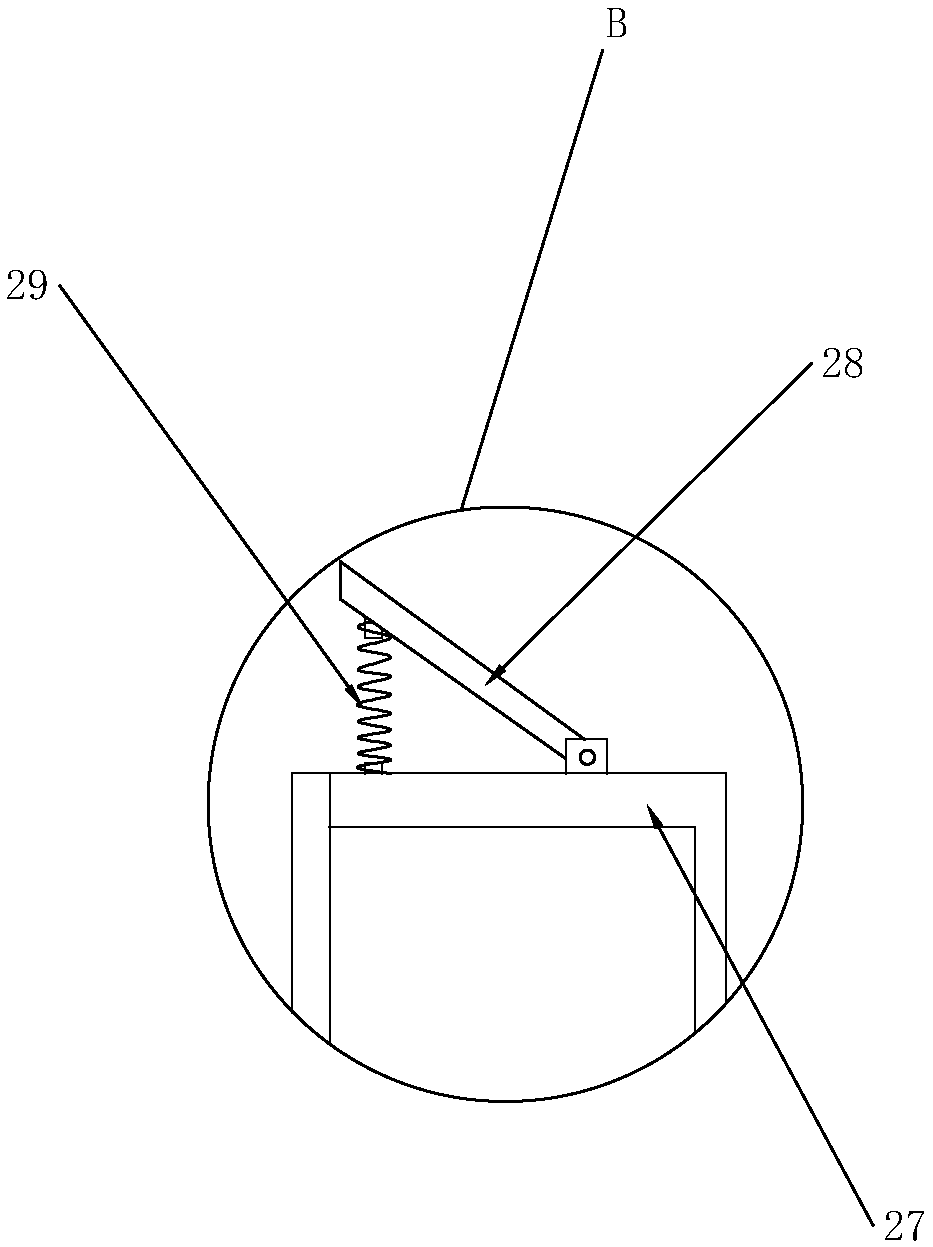

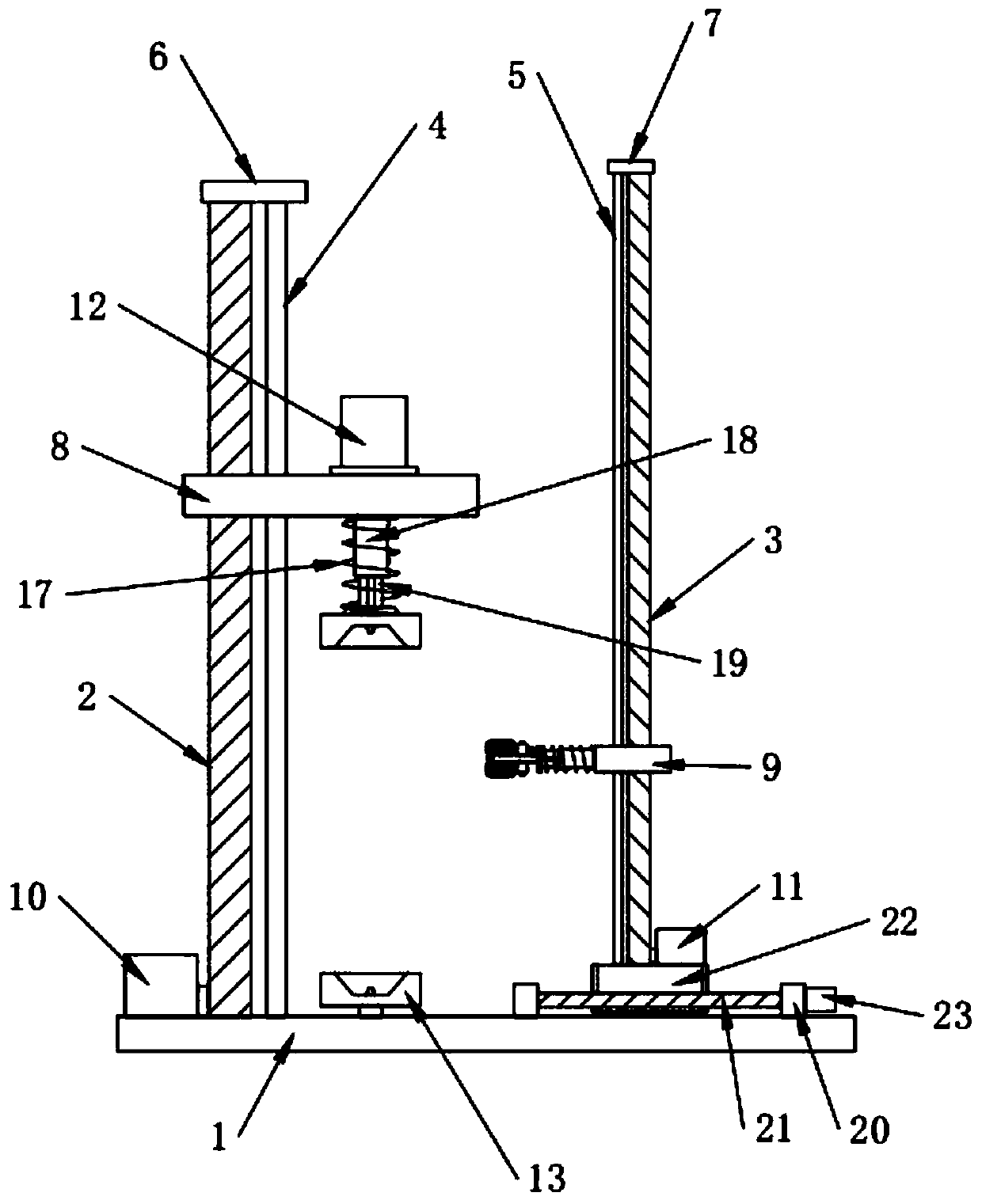

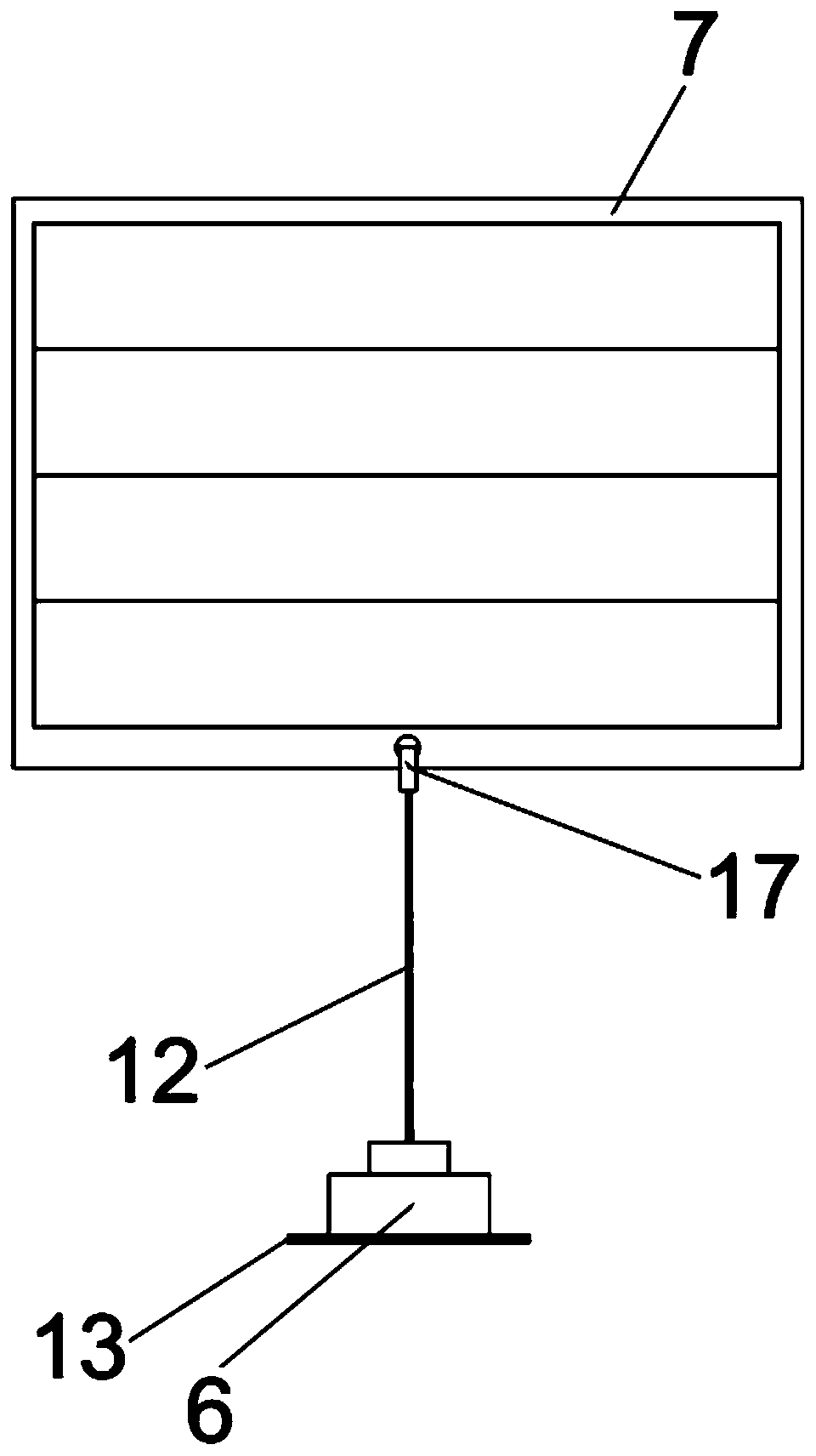

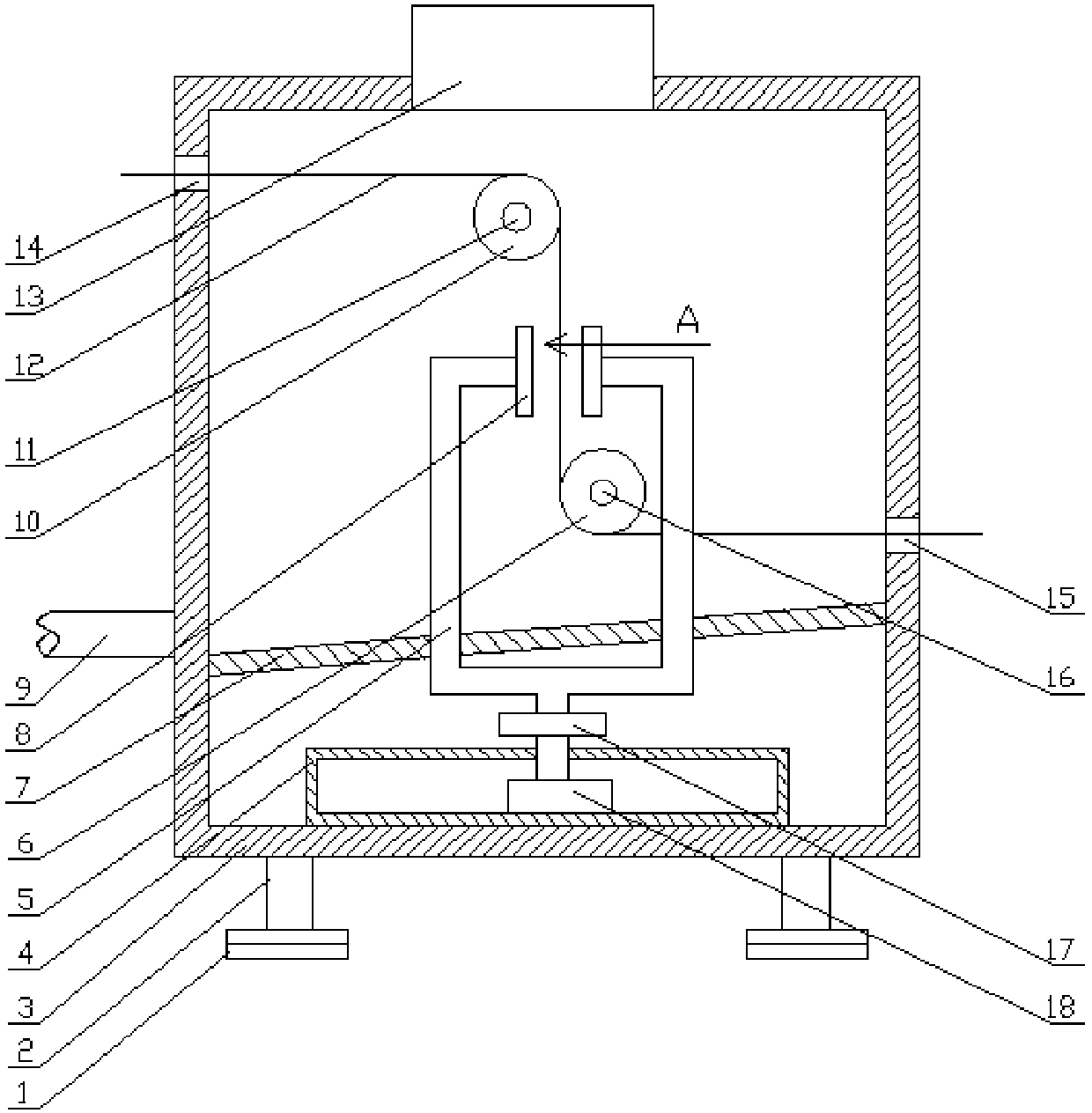

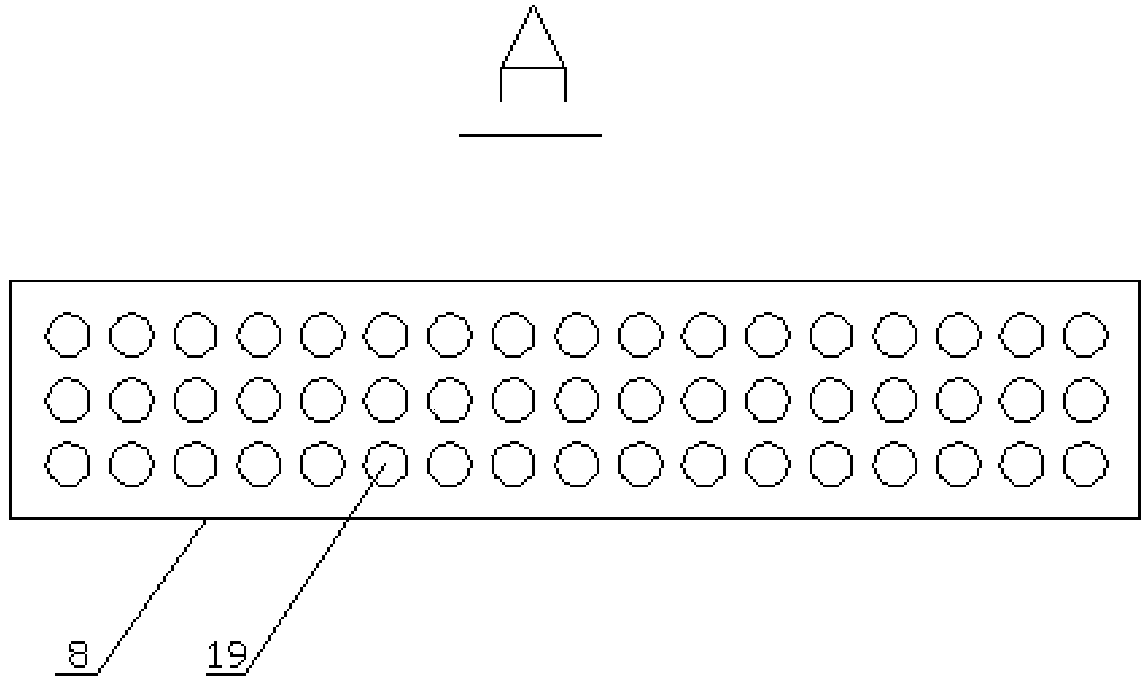

The invention relates to a movable parallel wire driven lower limb rehabilitation robot and an implementation method thereof. The robot comprises a suspension weight reducing unit, a tension sensor, safety straps, a safety handrail, a spring, a door fence, wire driving units, universal driven wheels, a leg wearing device, a treadmill, rear driving wheels, wires, a supporting frame and a liquid crystal display screen. The whole robot is of a truss structure formed by the supporting frame, and the suspension weight reducing unit on the upper portion is connected with the safety straps through the wires; the movement of the waist of a patient is constrained through four groups of springs between four vertical beams on the left and on the right and between the safety straps; the liquid crystalscreen is arranged above the safety handrail on the front portion of the robot; the patient and a wheelchair enter and go out through the left door fence; four cross beams at corresponding positionsof an affected limb sagittal plane on each side are provided with the four wire driving units; the affected limb is driven for rehabilitation training by pulling the leg wearing device through the wires; the universal driven wheels are installed on the front portion of the bottom of the robot, and the rear driving wheels are arranged on the rear portion of the robot. The robot can achieve gait training and walking training in passive, power-assisted and active modes.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

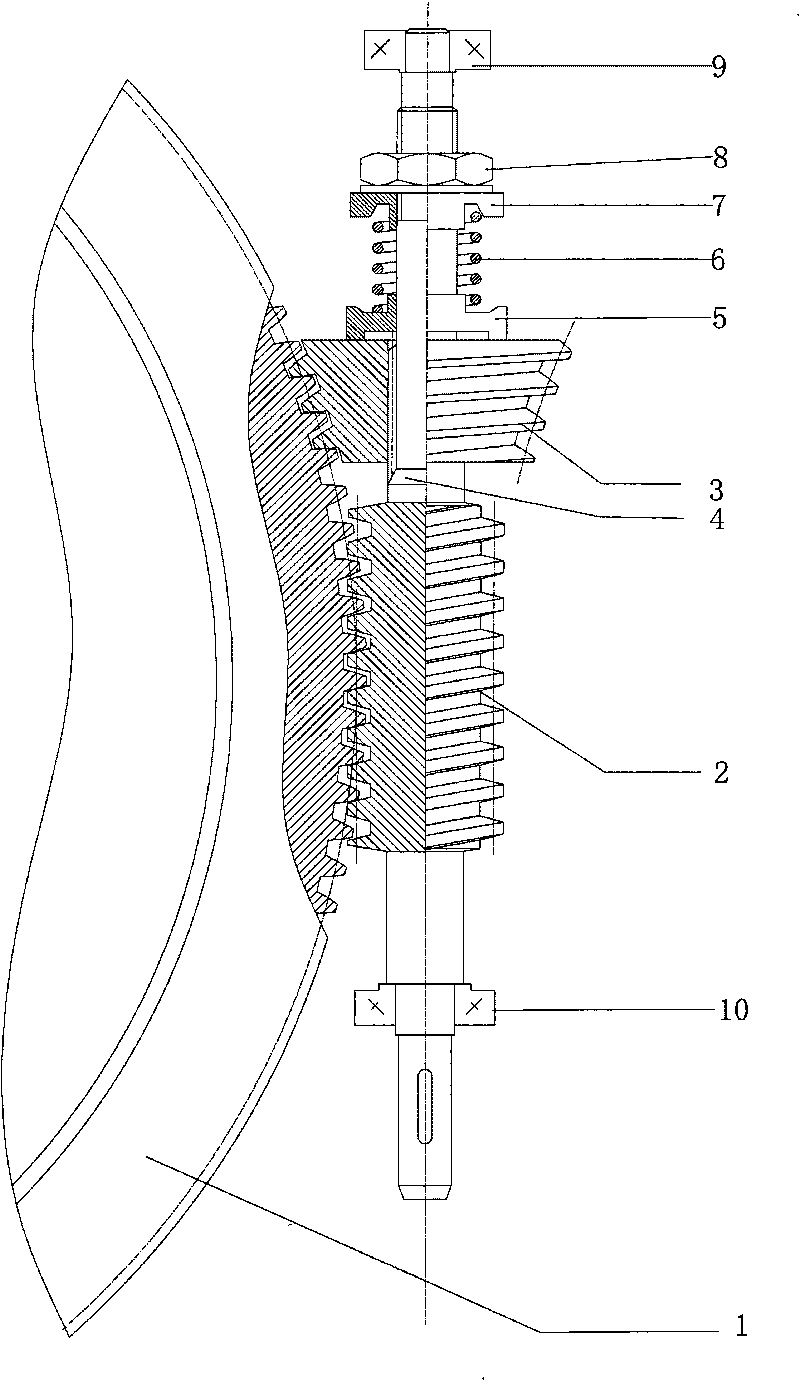

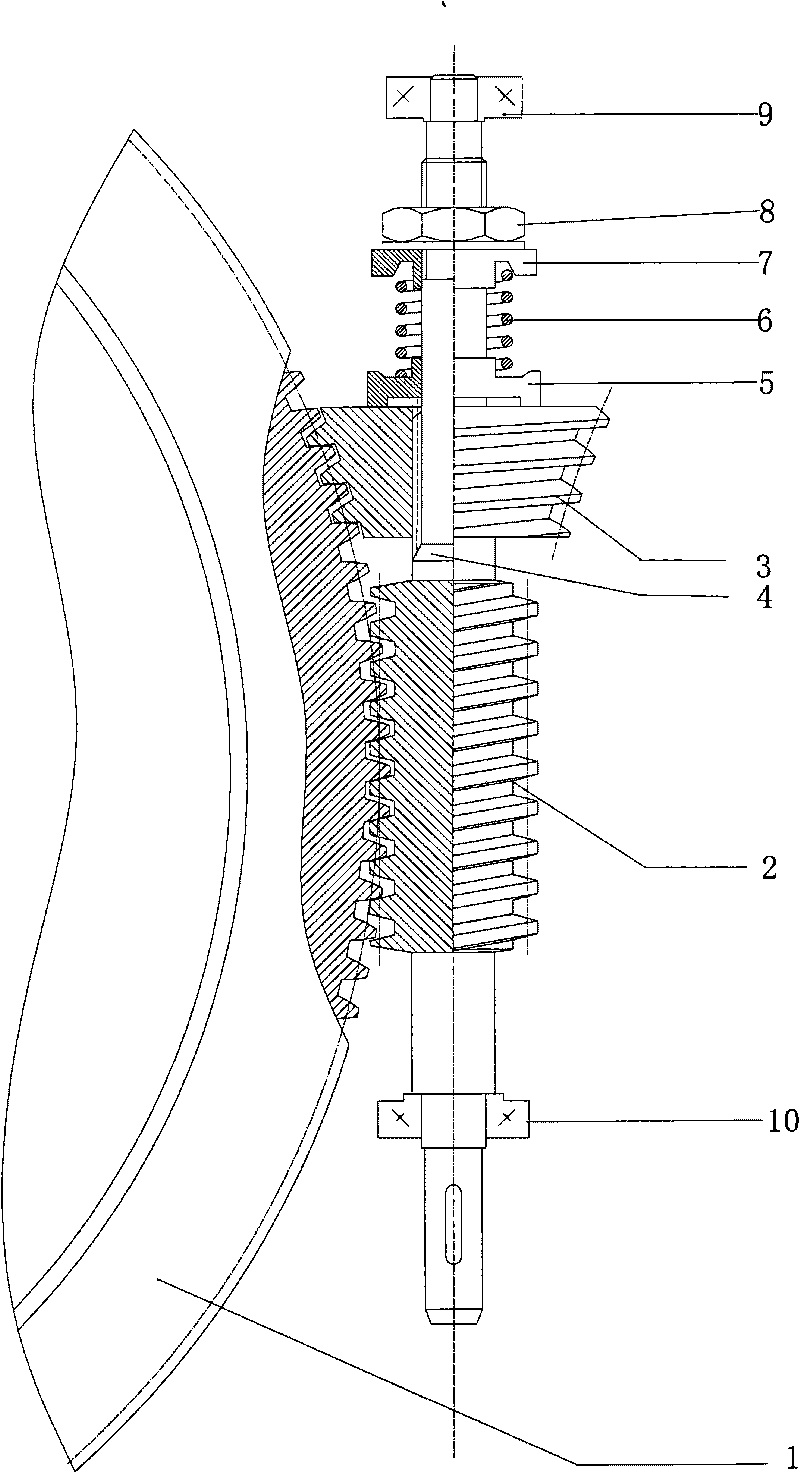

Worm gear-worm pair backlash eliminating device adopting enveloping worm

InactiveCN101705987ACompact structureReduce volumePortable liftingGearing elementsLow noiseEngineering

The invention relates to a worm gear-worm pair backlash eliminating device adopting an enveloping worm, which mainly consists of a worm gear, a cylindrical worm, the enveloping worm, an elastic pre-tightening device and a bearing. The cylindrical worm and the enveloping worm play the main force scale division role and the resistance role respectively, and the two worms are coaxially mounted and carry out the regulation and impose the pre-tightening force on a resistance worm in the axial direction through the elastic pre-tightening device. The pre-tightening device consists of a regulating nut, two spring positioning sleeves and a pre-tightening spring, regulates and pre-tightens the resistance worm in the axial direction through the regulating nut. The elastic pre-tightening device can be one of a spring device, a hydraulic device or a pneumatic device. The resistance enveloping worm and the main force worm are coaxially mounted in the worm gear-worm pair backlash eliminating device, and the axial regulation and the pre-tightening are carried out on the resistance worm through the elastic pre-tightening device, thereby providing the more stable, high-efficient and low-noise transmission and simultaneously having the advantages of compact structure, light weight, low cost and the like. The worm gear-worm pair backlash eliminating device is applied in a transmission mechanism of a rotary workbench of a machine tool and can provide better backlash eliminating effect in comparison with a single worm gear-single worm mechanism or a double-worm gear-worm mechanism.

Owner:CHONGQING UNIV

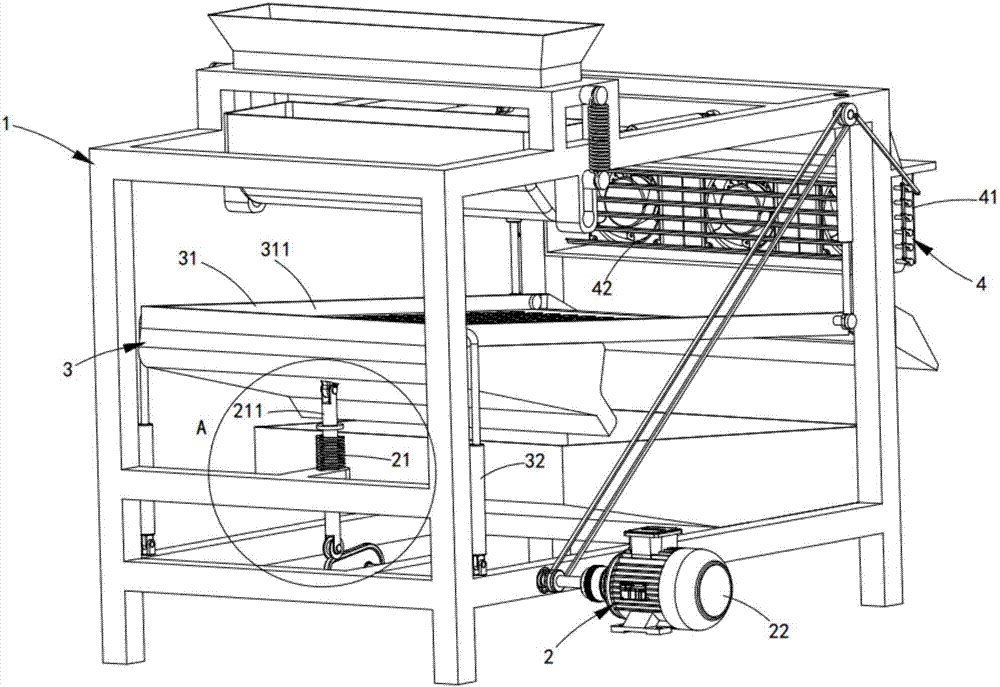

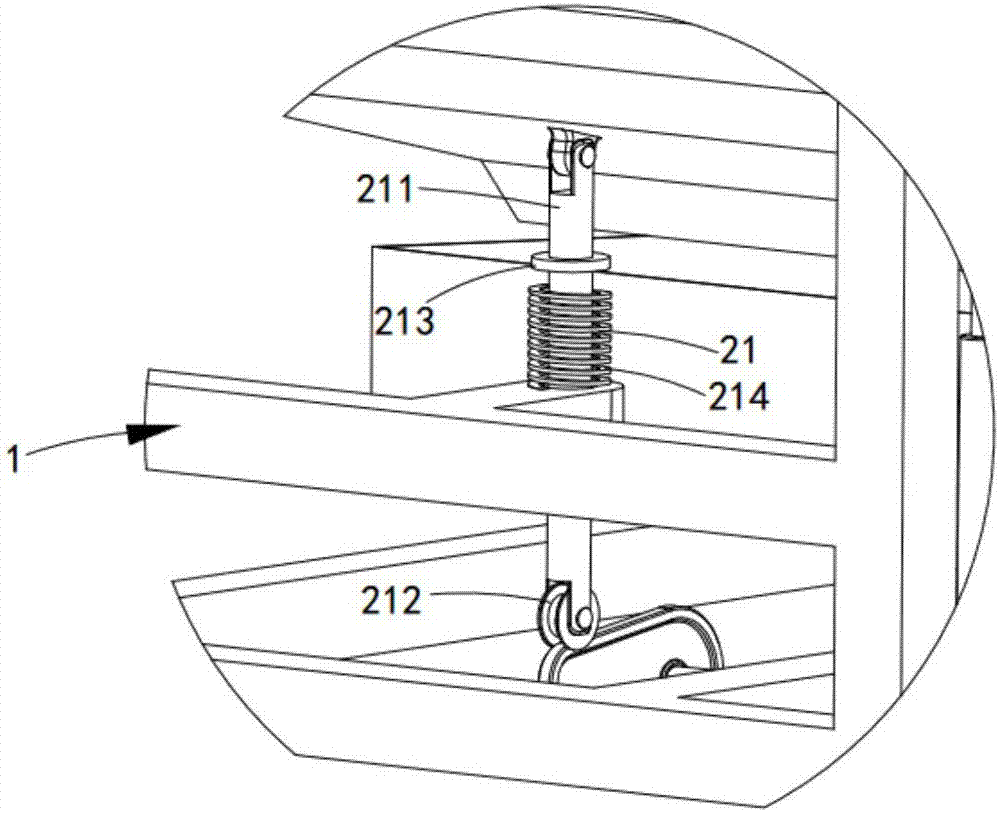

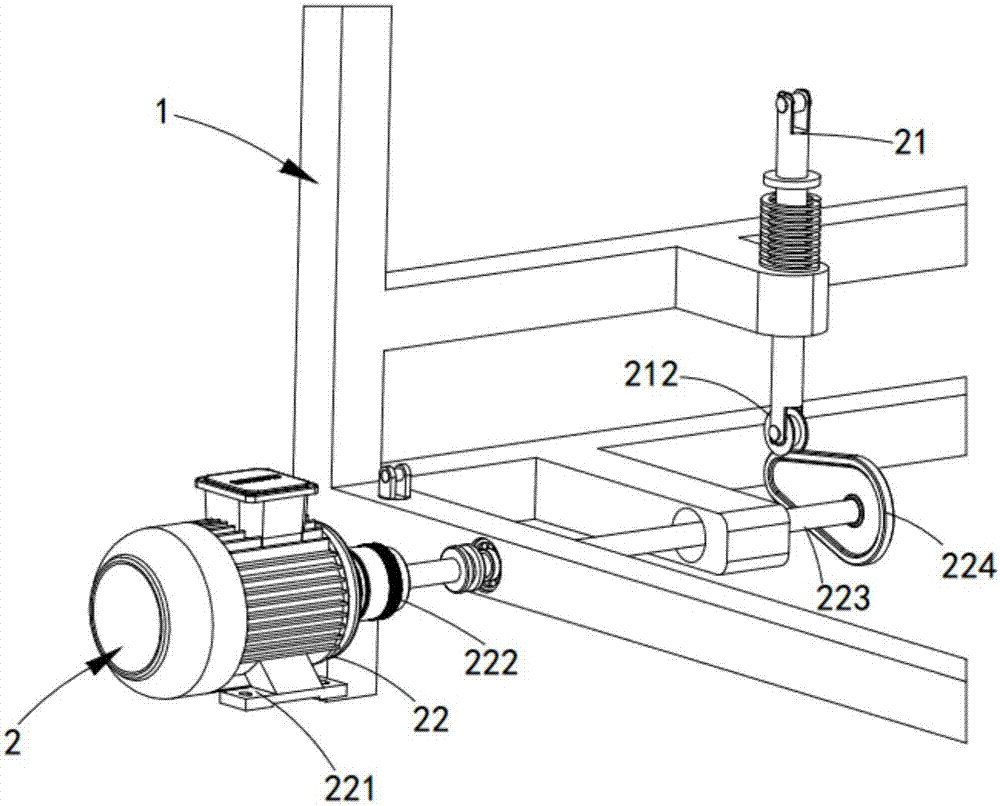

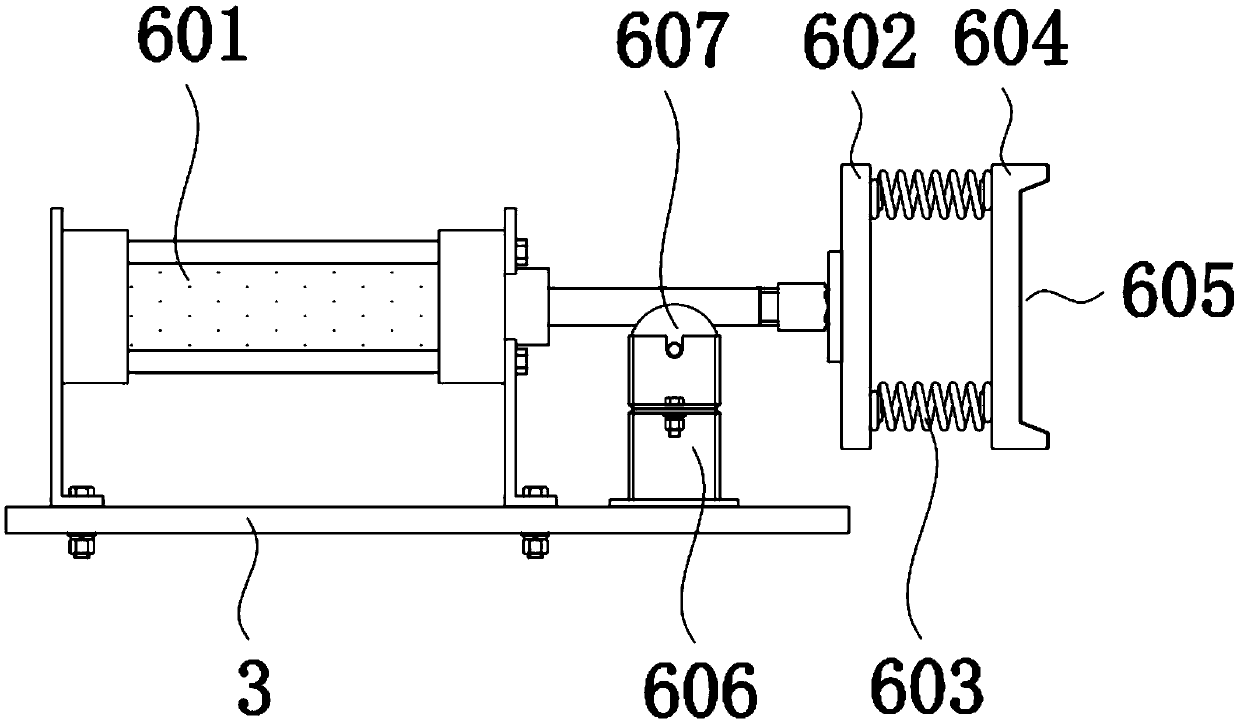

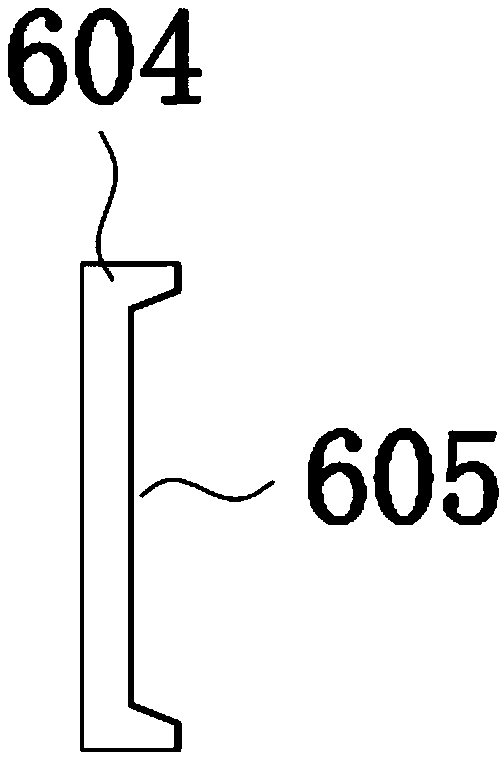

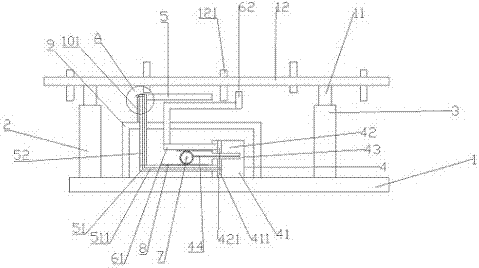

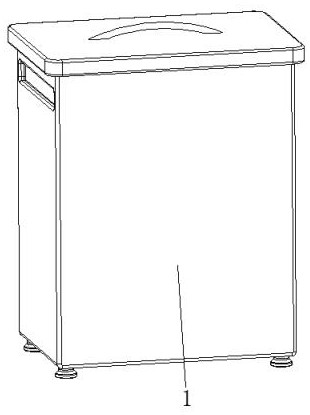

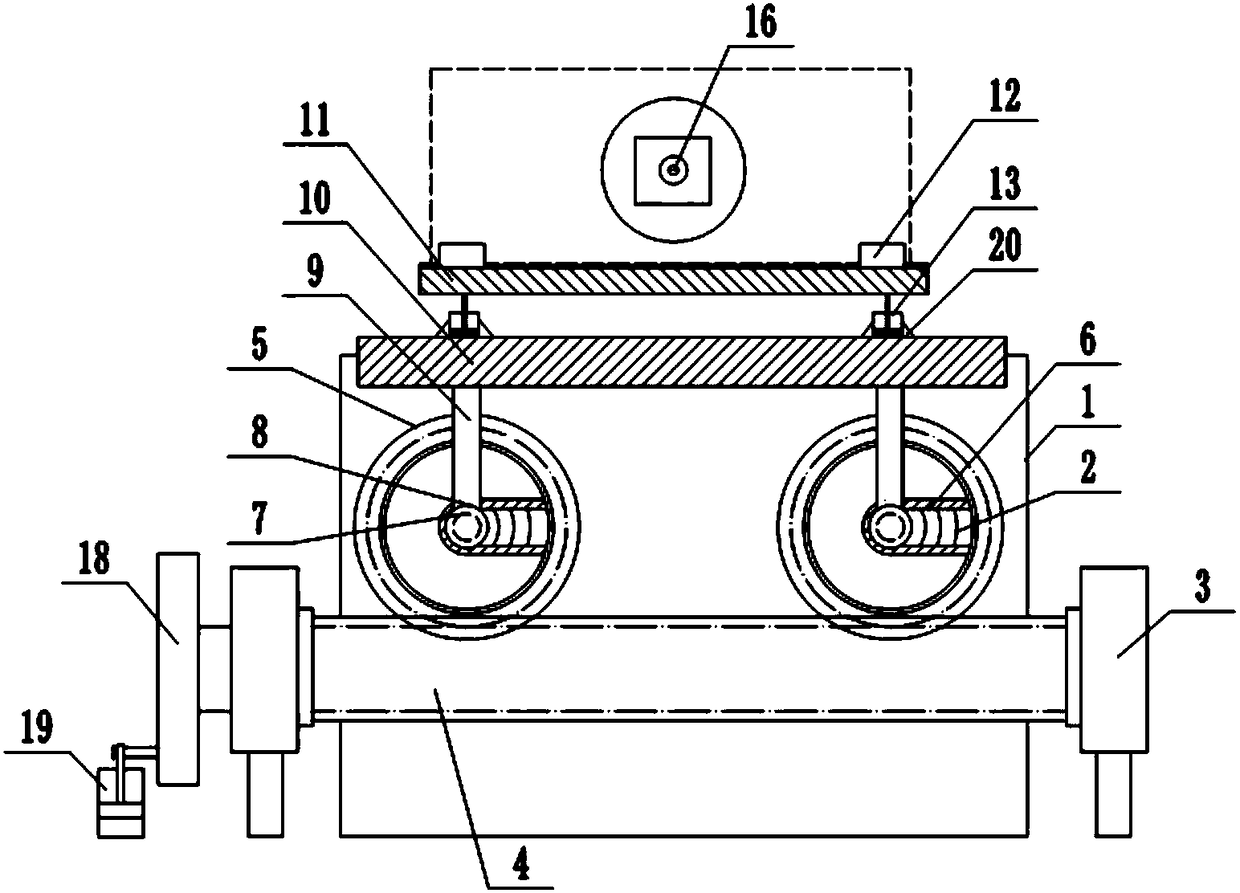

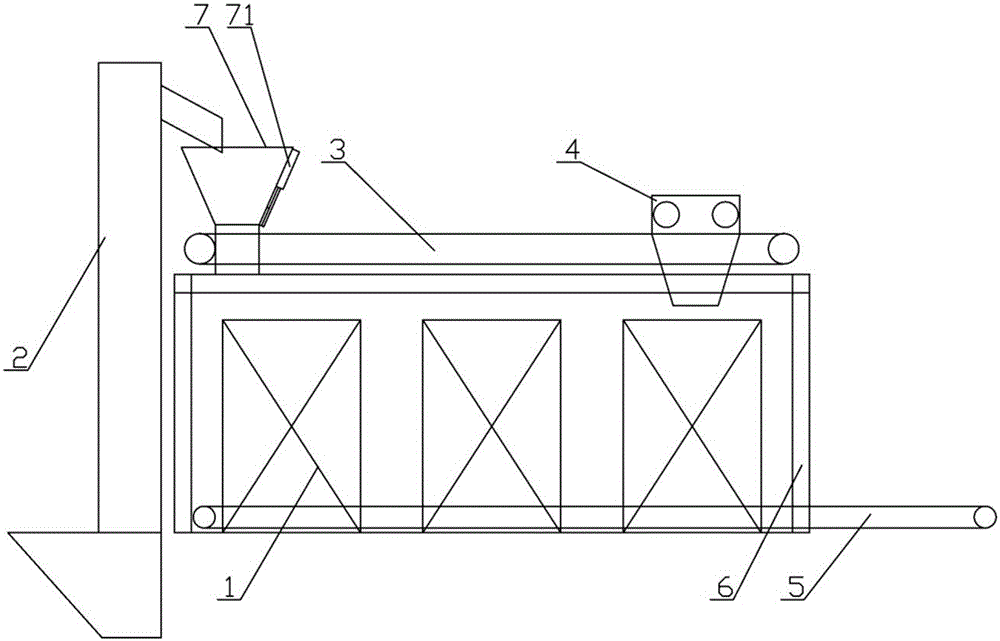

Small-size oscillation grain dehuller

InactiveCN106862081AImprove efficiencyAvoid rigid contactSievingGas current separationEngineeringImpurity

The invention discloses a small oscillating grain hulling machine, which comprises a frame, an oscillating mechanism, a screening mechanism and an air outlet mechanism. The air outlet component and the damper component drive the vibration component to run through the driving component. After the vibration component pushes the screening net in the screening component to a high place, the screening net drops rapidly by gravity, throws the grain on the screening net into the air, and is removed by the wind component. Light impurities such as chaff in the grain, and then the grain is returned to the screening net, and the granular impurities in the grain are screened and removed by the screening net. Repeat this process to completely remove the chaff impurities and granular impurities in the grain, and improve the screening efficiency.

Owner:奥林精密机械科技(长兴)有限公司

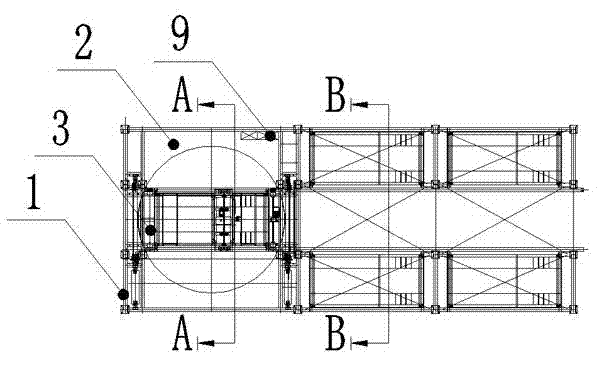

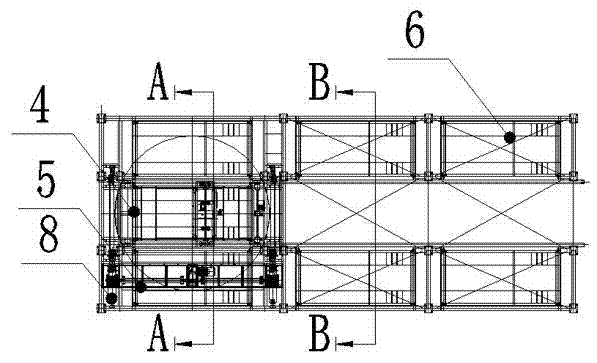

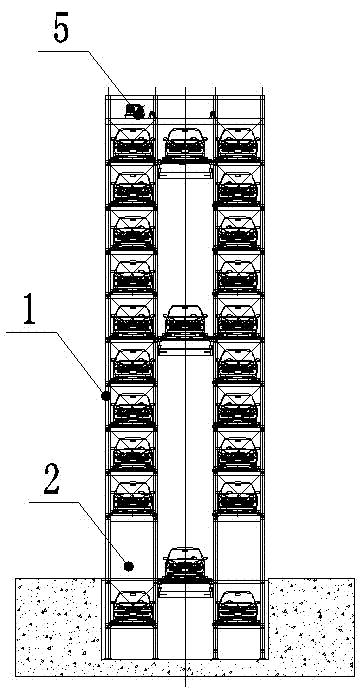

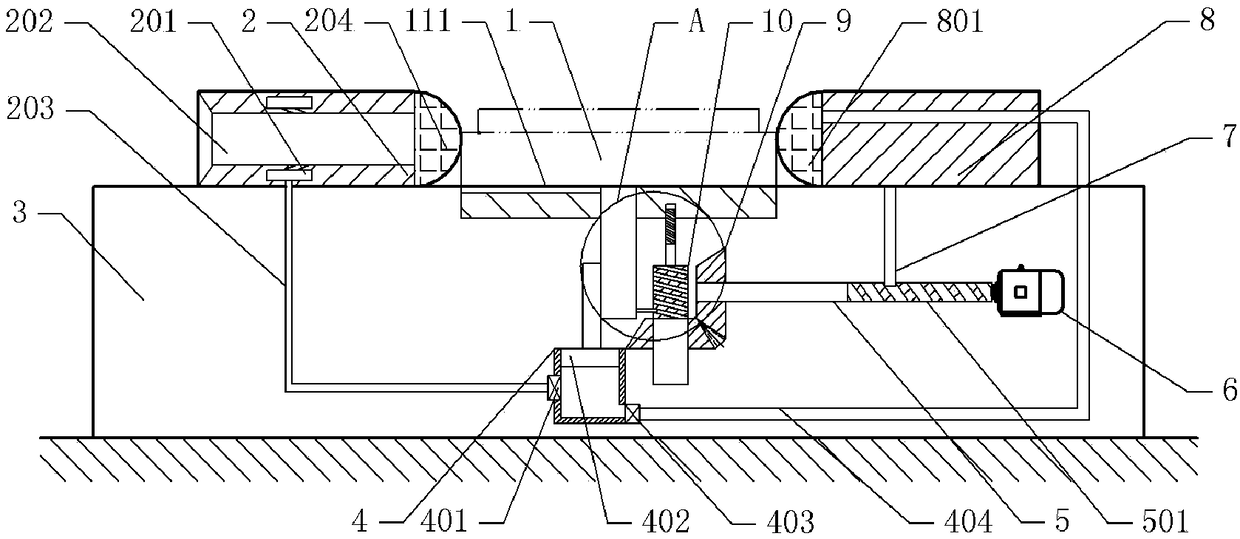

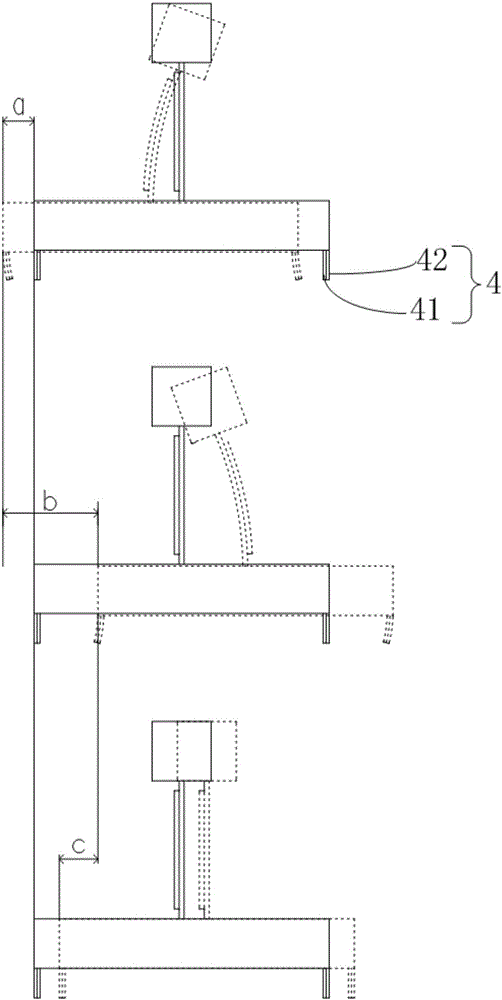

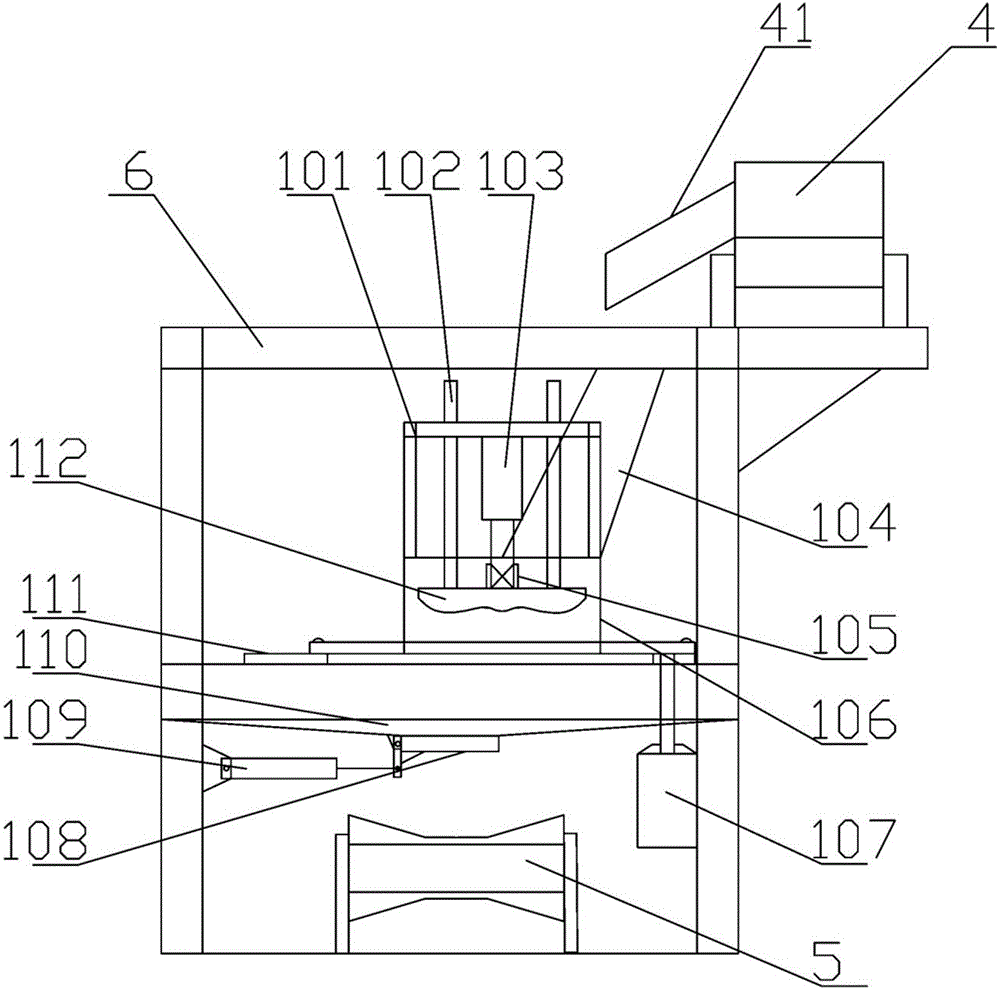

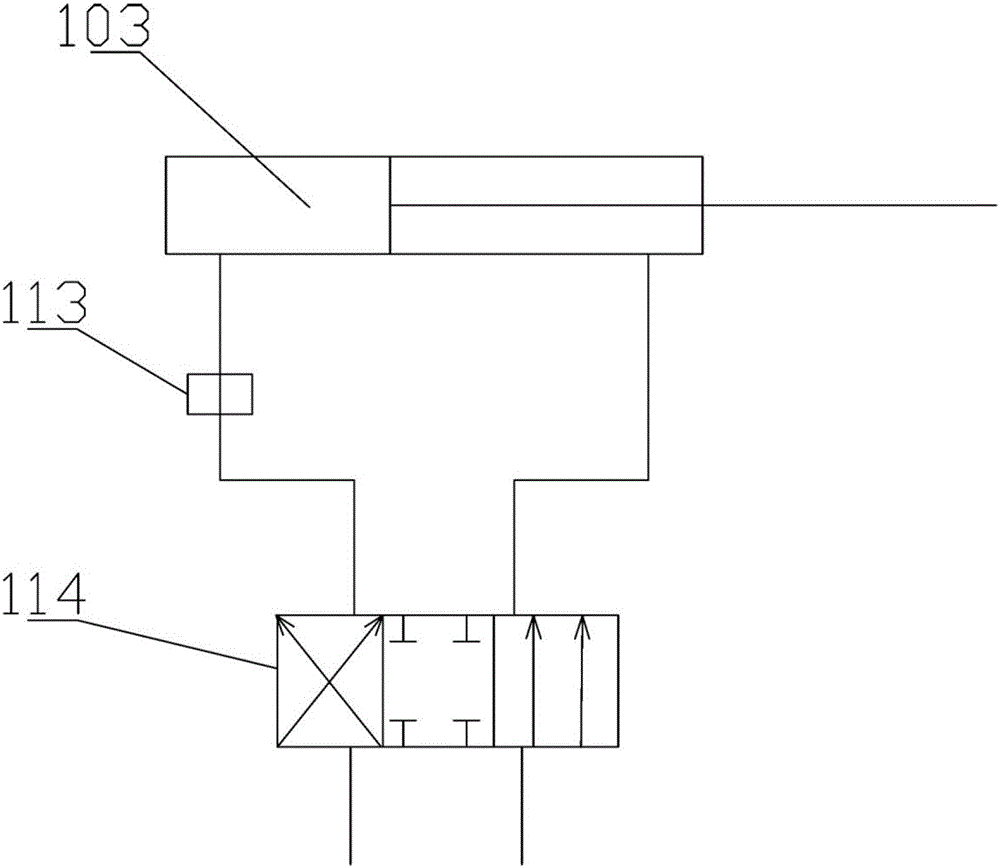

Plate-type longitudinal mechanical parking device of chain transmission rotating middle lifting machine

ActiveCN103669942AIncrease the lengthMeet the maximum use requirementsParkingsChain linkSteel structures

The invention discloses a plate-type longitudinal mechanical parking device of a chain transmission rotating middle lifting machine. The lifting machine is arranged on the top of a steel structure frame and the steel structure frame is composed of a plurality of parking floors and roadways, wherein the parking floors are arranged on the two sides of the roadways, a plurality of parking positions of the parking floors are longitudinally arranged to form a plate-type longitudinal structure, and vehicle-carrying plates on the parking positions can transversely and correspondingly move along parking guide rails on the parking positions respectively. Fixed guide rails for longitudinal moving of carriers are arranged in the roadways of the parking floors respectively. The lifting machine is provided with a rotary device provided with moving guide rails, the carriers are arranged on the moving guide rails, and storage and taking exchange mechanisms are arranged on the carriers. A lifting well communicated with the bottom floor and the top floor is arranged on the end portions of the roadways, the lifting machine is arranged in the lifting well, the lifting machine and an access opening are located on the end portions of the roadways without occupying the parking positions, transverse moving motion from the access opening to the roadways is reduced, and the vehicle storage and taking time is short; because the lifting machine is provided with the rotary device itself, the purpose that a stored vehicle can enter the access opening and leave the access opening with the head of the vehicle facing the access opening can be achieved.

Owner:SHANDONG TIANCHEN INTELLIGENT PARKING EQUIPMENT CO LTD

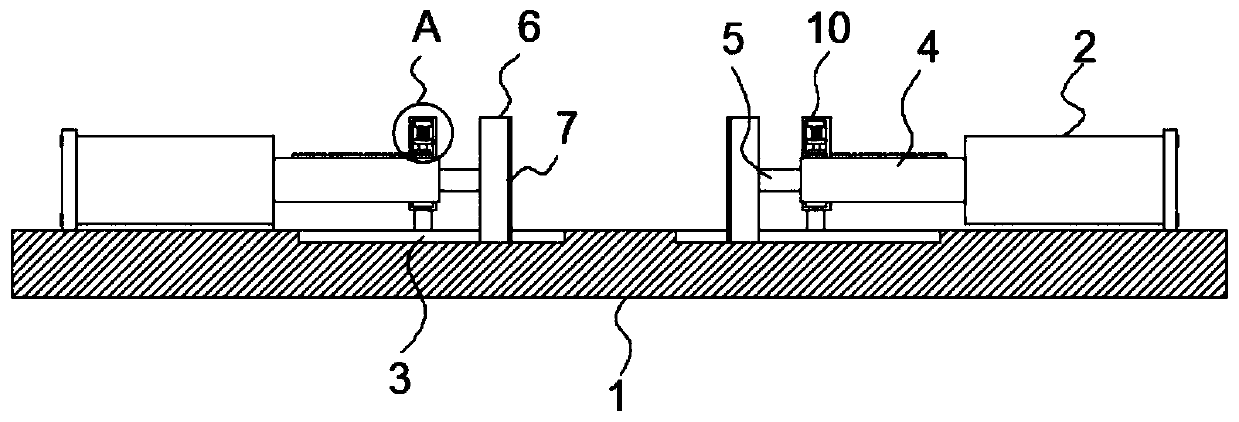

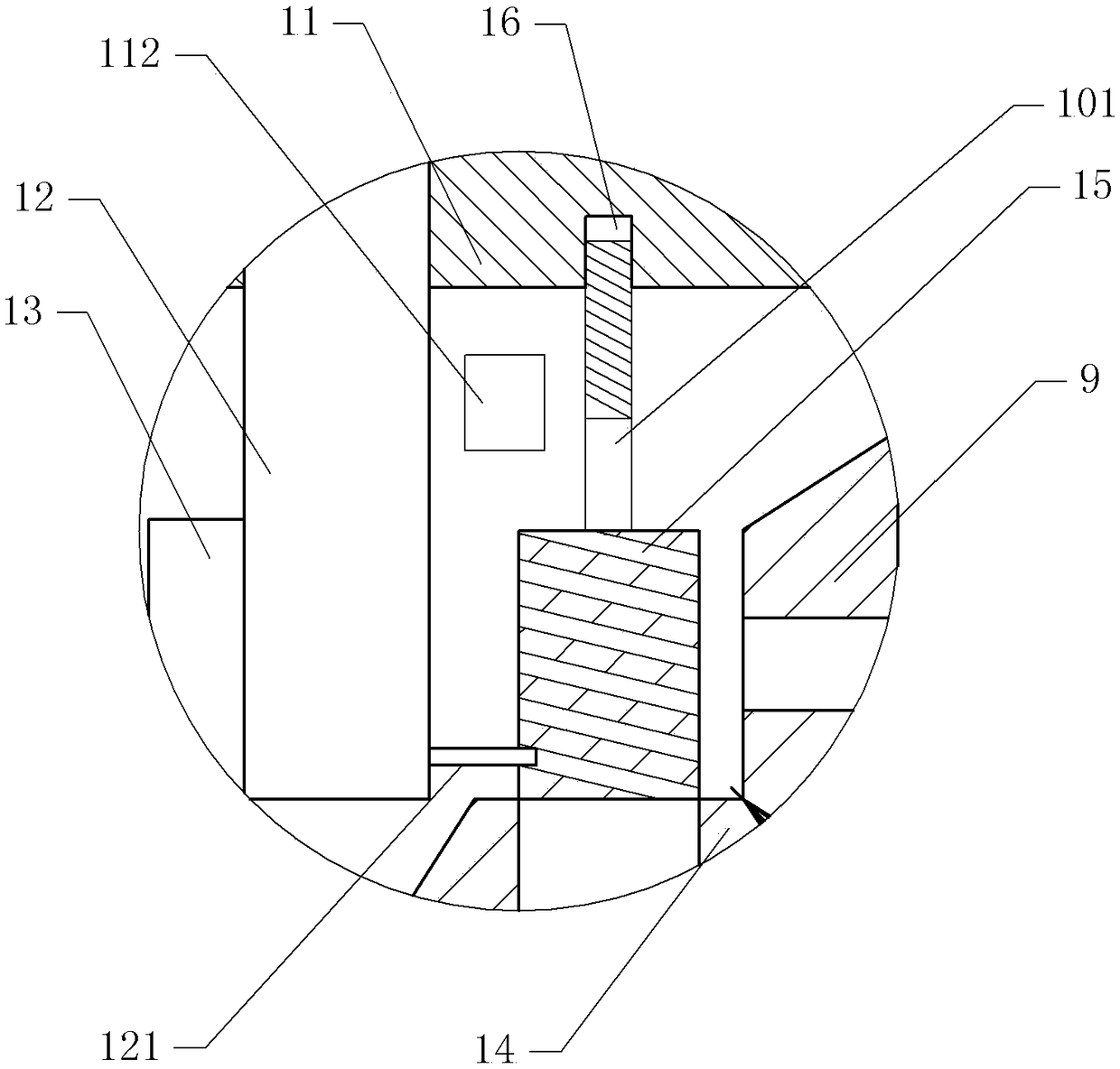

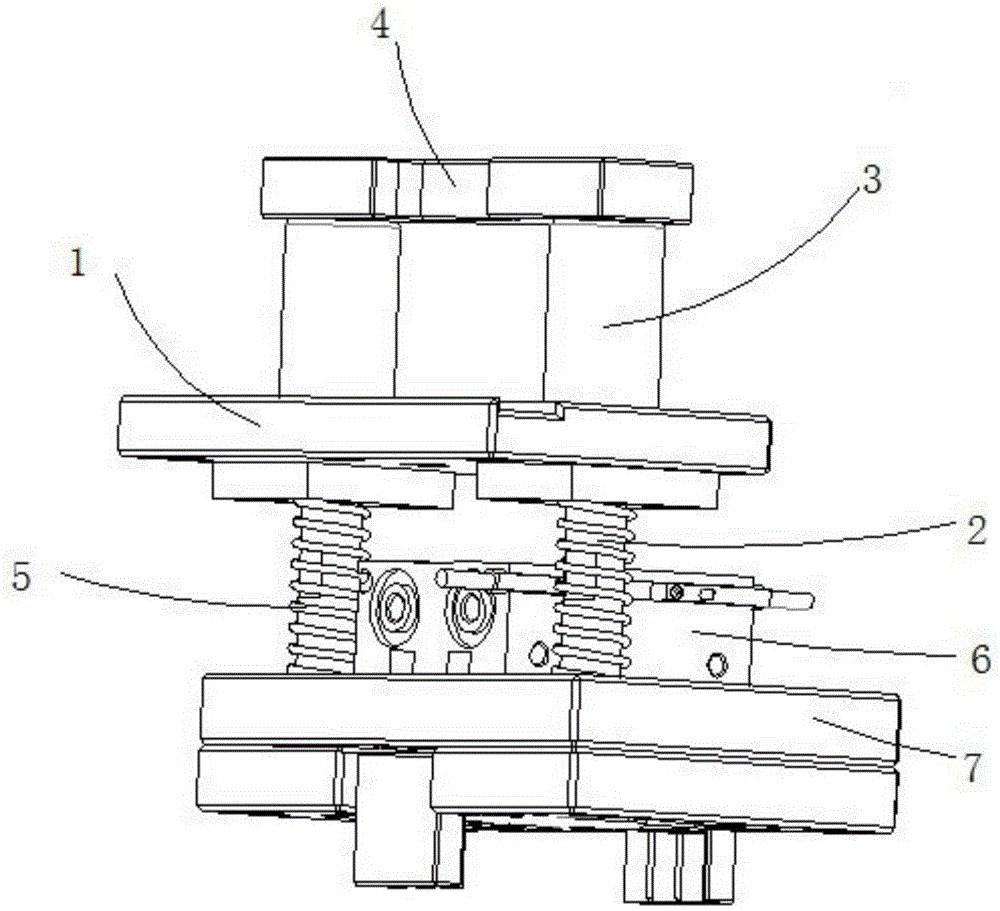

Machining fixture locking device

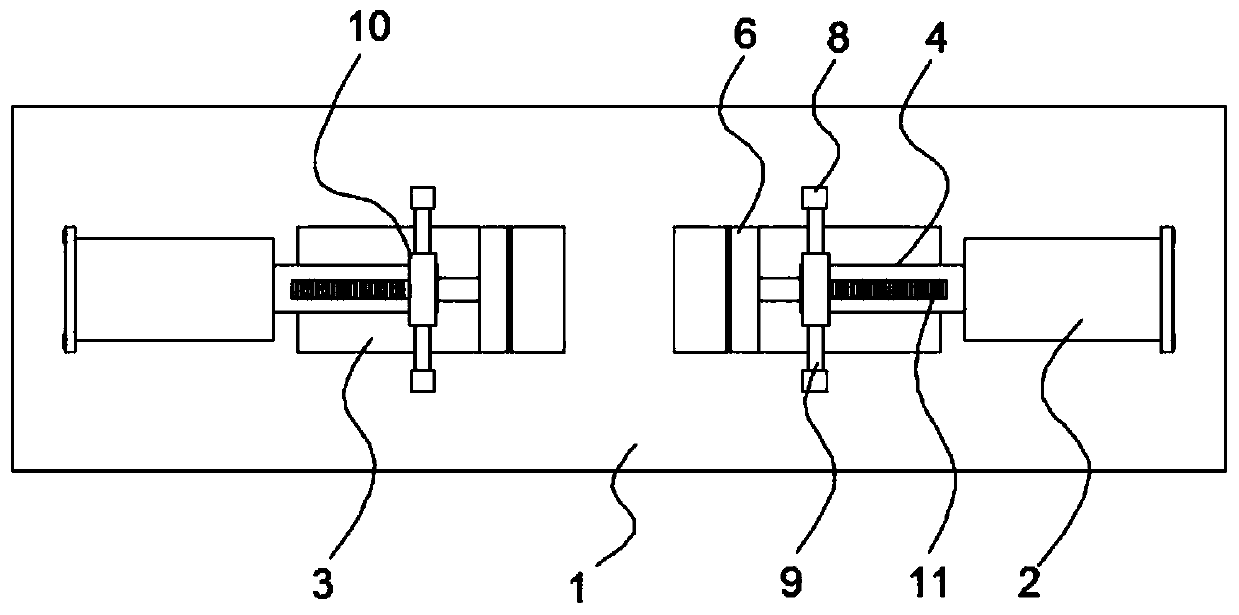

The invention discloses a machining fixture locking device. The machining fixture locking device comprises a base plate; two extension cylinders are symmetrically and fixedly mounted on the base plate; piston rods are arranged on the two extension cylinders, and are fixedly connected with tooth plates; buffer cavities are formed in the piston rods; piston blocks are slidingly connected into the buffer cavities; moving rods are fixedly connected to one sides of the piston blocks; the ends, far from the piston blocks, of the moving rods are fixedly connected with clamping plates; the other sidesof the piston blocks are fixedly connected with second springs; and the ends, far from the piston blocks, of the second springs are fixedly connected to the side walls of the buffer cavities. Tooth blocks adaptively slide up, and meanwhile, drive first springs to compress; and under the elastic effect of the first springs, the tooth blocks are engaged with the tooth plates again, and meanwhile, end surfaces B abut against the tooth plates to prevent retreating of the tooth plates, so that the locking effect on the piston rods is achieved, and the influence on the clamping effect of the pistonrods by instable air pressure of the extension cylinders is prevented.

Owner:浙江零捷网络科技有限公司

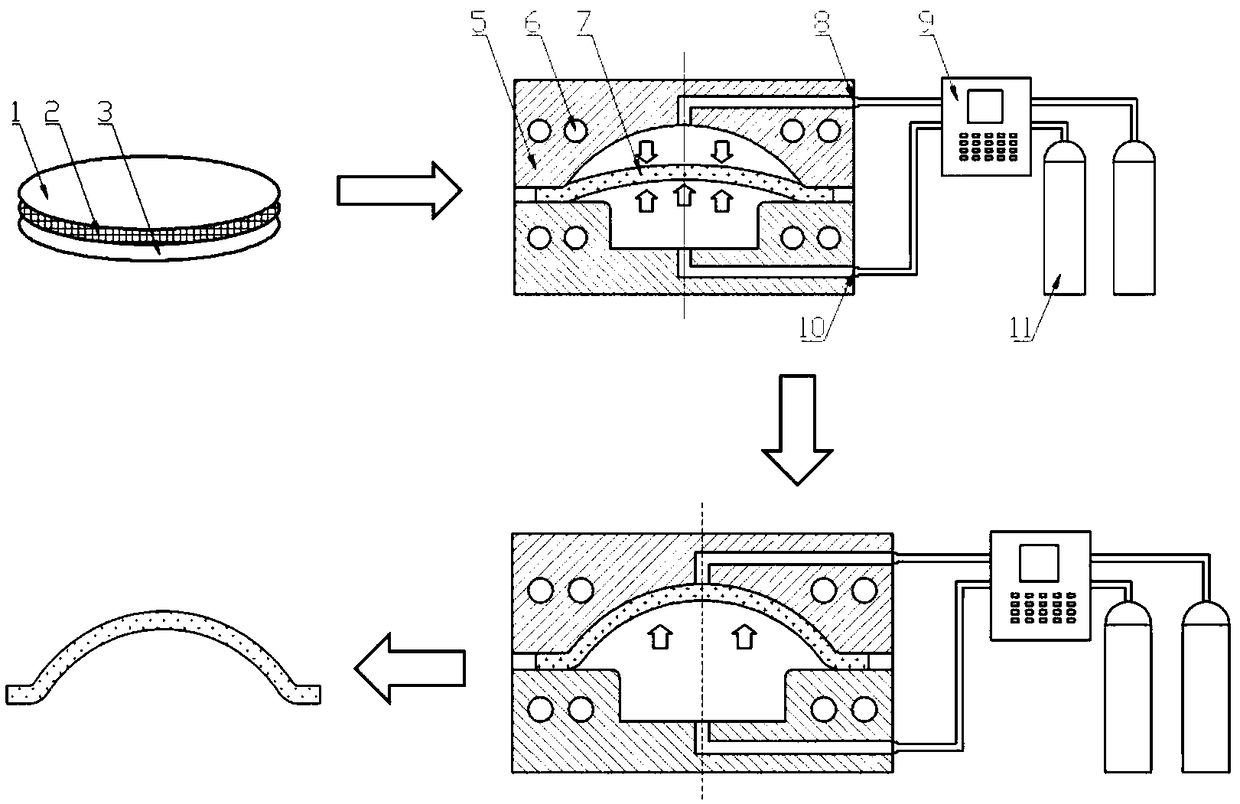

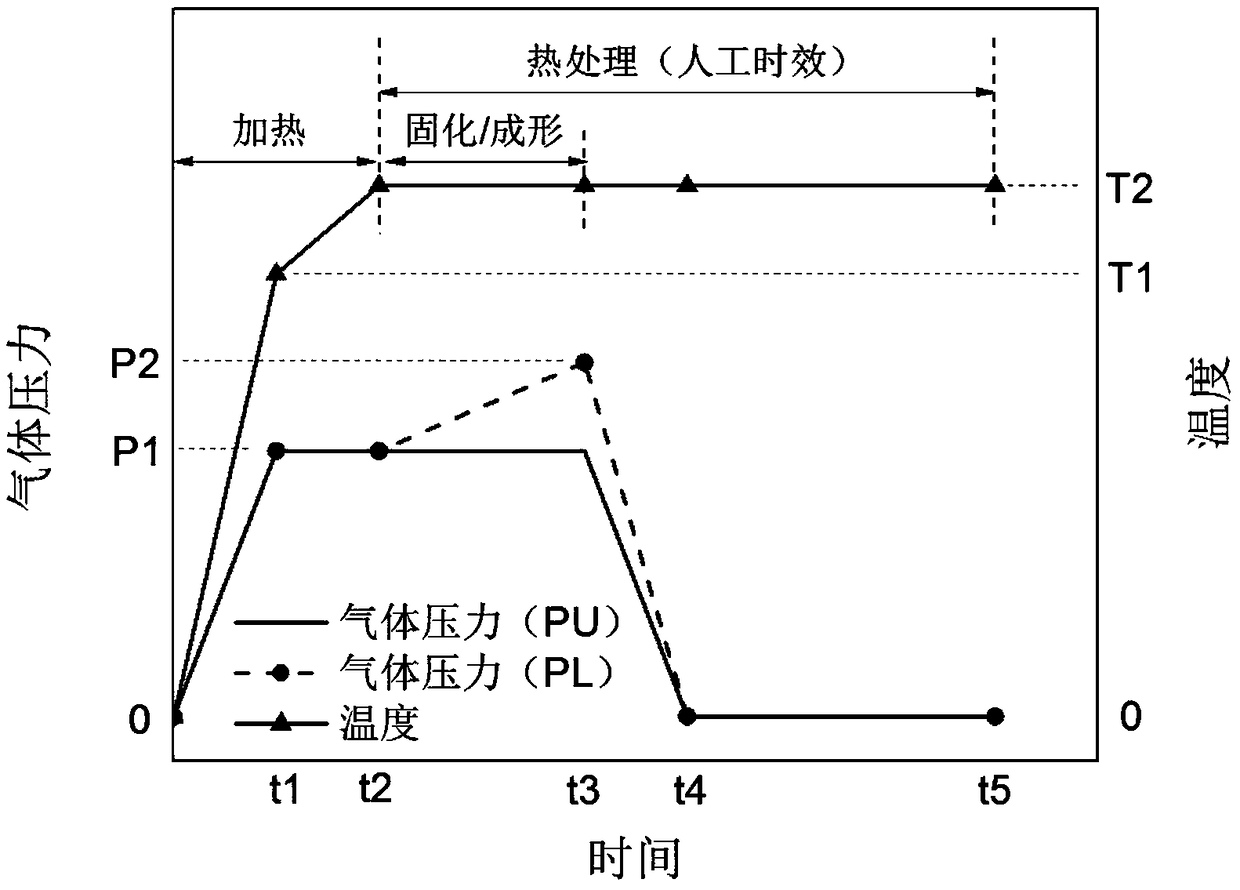

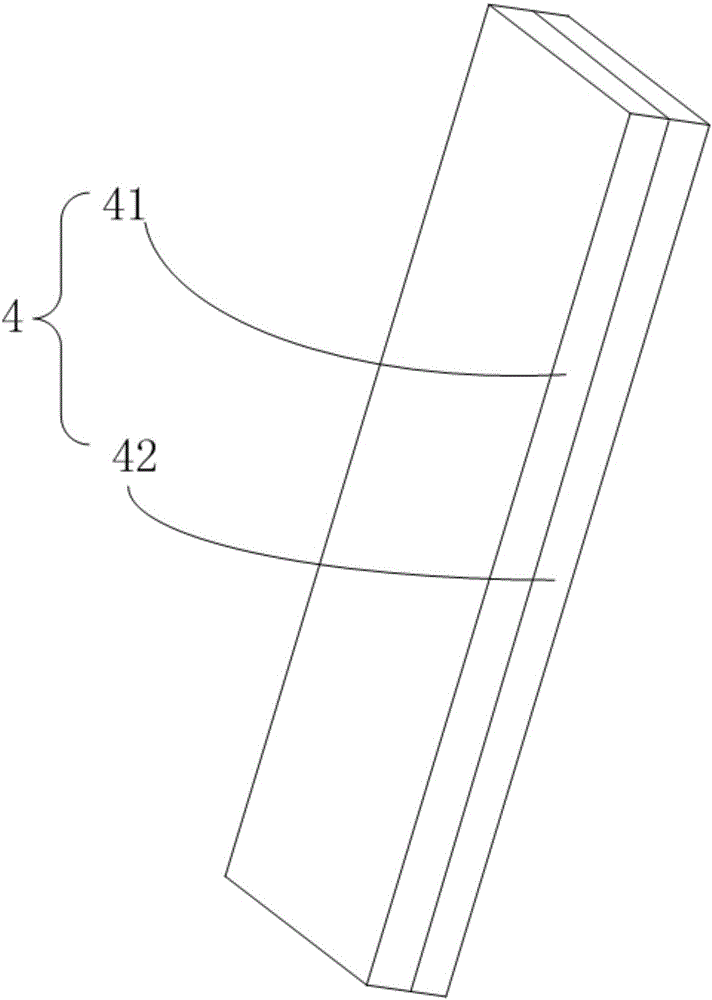

Solidification/forming/heat treatment integrated preparation method of carbon fiber metal laminate curved surface piece

ActiveCN109334164AIncreased shear strengthImprove plasticitySynthetic resin layered productsLaminationCarbon fibersFiber metal laminate

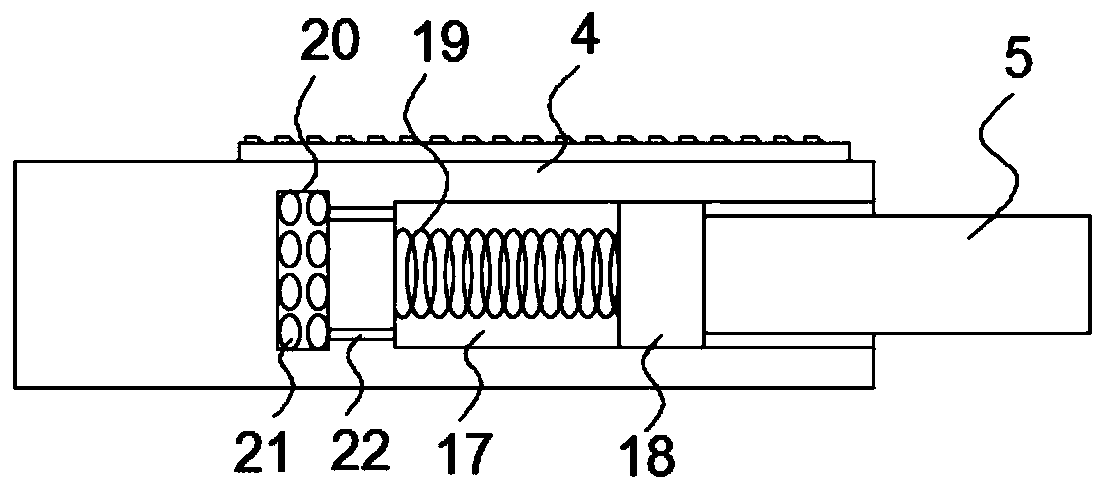

The invention provides a solidification / forming / heat treatment integrated preparation method of a carbon fiber metal laminate curved surface piece, and belongs to the technical field of multi-layer plate preparation and forming. According to the method, carbon fiber resin composite materials and solid solution-state aluminum alloy plates are alternately laminated to obtain a non-solidified fiber metal laminate; and the non-solidified fiber metal laminate undergoes heating, double-side pressing, heat preservation, solidification, forming and aging treatment to obtain the carbon fiber metal laminate. By adopting the process, the solidification / forming / heat treatment process of the fiber metal laminate can be integrated to significantly improve the processing efficiency; under the action of normal stress, the shear strength between the fiber layers and the aluminum alloy layers is higher and the plasticity of the aluminum alloy plates is better; and double-side gas pressure forming is adopted, so that the rigid contact of molds is avoided and the surface quality of components is better.

Owner:WUHAN UNIV OF TECH

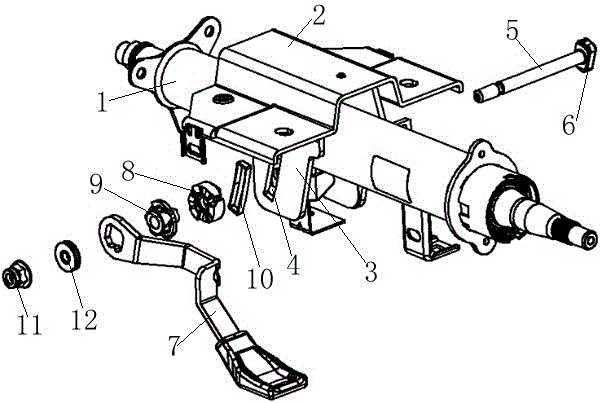

Angle adjusting mechanism of steering tubular column

The invention relates to an angle adjusting mechanism of a steering tubular column. The angle adjusting mechanism comprises the steering tubular column, an adjusting bracket and an adjusting rod, wherein a bracket is fixedly connected onto the steering tubular column; a through hole is formed in the bracket; the adjusting bracket is provided with two side plates; first strip-shaped holes are formed in the two side plates; the bracket is located between the two side plates; the adjusting rod penetrates through the through hole and the two first strip-shaped holes; a locking structure is arranged on the adjusting rod; each first strip-shaped hole is provided with an elastic lining; each elastic lining is provided with a second strip-shaped hole; one end of each second strip-shaped hole in the length direction is a large-width end, and the other end of each second strip-shaped hole is a small-width end; the width of each second strip-shaped hole is gradually reduced from the large-width end to the small-width end; the adjusting rod penetrates through the two second strip-shaped holes; and the diameter of the adjusting rod is greater than the width of the small-width end of each second strip-shaped hole. With the adoption of the angle adjusting mechanism of the steering tubular column, an abrasion problem caused by the fact that the steering tubular column is adjusted can be solved, and noises caused by the fact that the steering tubular column is adjusted can also be reduced, so that the reliability and the comfort are improved when the steering tubular column is adjusted.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Dynamic allocation logistics conveying auxiliary device

The invention relates to the technical field of logistics conveying, in particular to a dynamic allocation logistics conveying auxiliary device. The dynamic allocation logistics conveying auxiliary device comprises a main conveying belt and a plurality of assistant conveying belts, an obliquely arranged oblique plane is arranged on one side of the main conveying belt, and the assistant conveying belts are arranged at the bottommost end of the oblique plane; and U-shaped grooves are formed in the sides, close to the main conveying belt, of pushing plates, protection cushions are arranged in theU-shaped grooves in a covering mode, rotary supporting frames are further installed on main supporting platforms, and supporting rollers are installed at the top ends of the rotary supporting framesand located under piston rods of air cylinders. According to the dynamic allocation logistics conveying auxiliary device, movement of materials from the main conveying belt to the assistant conveyingbelts is realized, springs are designed, the dynamic allocation logistics conveying auxiliary device has a good buffering effect, the pushing plates are prevented from being in rigidity contact with the materials, the supporting rollers play good supporting action on the piston rods of the air cylinders, and the service life of the piston rods is prolonged; and a plurality of sets of height detecting and material pushing integrated structures are arranged corresponding to the assistant conveying belts, the multiple sets of the height detecting and material pushing integrated structures can work synchronously, and the working efficiency is high.

Owner:陈章银

Boiler waste heat collection and utilization device

InactiveCN107990773ALess economic valueAvoid rigid contactRecuperative heat exchangersCorrosion preventionWater columnMagnet

The invention provides a boiler waste heat collection and utilization device, which relates to the technical field of boilers. The boiler waste heat collection and utilization device comprises a smokebox, wherein a water column pipe is fixedly arranged in the smokebox through a fixing block; two ends of the water column pipe penetrate through the top part of an inner wall of the smokebox and extend to the top part of the smokebox so as to communicate with a water inlet and a water outlet pipe; an air inlet pipe communicates to a position, close to the left side, of the bottom part of the smokebox; an air outlet pipe communicates to a position, close to the top part, of the right side of the smokebox; and a side box is fixedly arranged on a side wall of the smokebox. According to the boilerwaste heat collection and utilization device, a motor controls a turbine to move up and down on an outer surface of a screw rod, a mutual attraction force of an external magnet and an internal magnetdrives a clearing block to move up and down on an outer surface of the water column pipe, and a friction block slides up and down on the outer surface of the water column pipe so as to scrape dust onthe outer surface of the water column pipe, so that the occurrence of the phenomenon that increasing smoke dust accumulated on the outer surface of the water column pipe so as to cause the reducing of heat exchange efficiency and the relatively reducing of an economic value of a waste heat system is avoided.

Owner:佘峰

Full-automatic system for stamping sheet metal

PendingCN108356160AEasy to installGuaranteed stabilityMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a full-automatic system for stamping sheet metal, and relates to the technical field of sheet metal stamping. The full-automatic system comprises a base, a supporting plate, amounting frame, a material conveying plate and a punching machine body; the base and the supporting plate are arranged horizontally up and down correspondingly, two groups of supporting frames are arranged in parallel in a lifting space, and each group of supporting frames comprises two lifting frames arranged in parallel, wherein each lifting frame comprises a first supporting rod and a second supporting rod; the supporting plate is further provided with a clamping mechanism in a sliding mode up and down, a feeding mechanism is horizontally arranged on one side of the clamping mechanism in asliding mode, and the punching machine body is positioned at the limit position where the feeding mechanism advances; a material returning mechanism is arranged on a supporting platform, in a punchingarea, of the punching machine body; and the material conveying plate is obliquely arranged on the mounting frame. The full-automatic system realizes the technical effects of integrating of feeding, punching and discharging and saving labor force.

Owner:青岛创高世纪信息科技有限公司

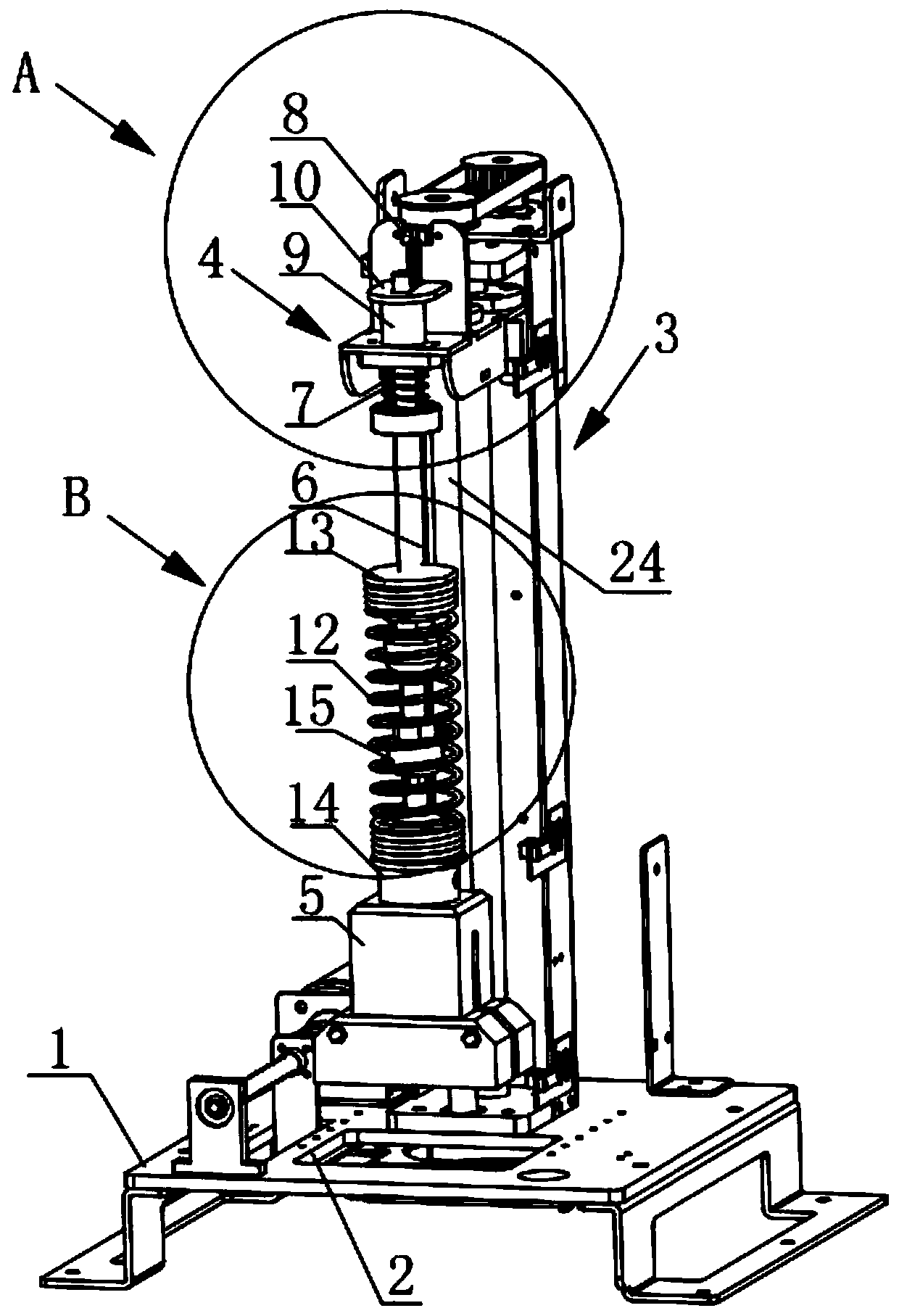

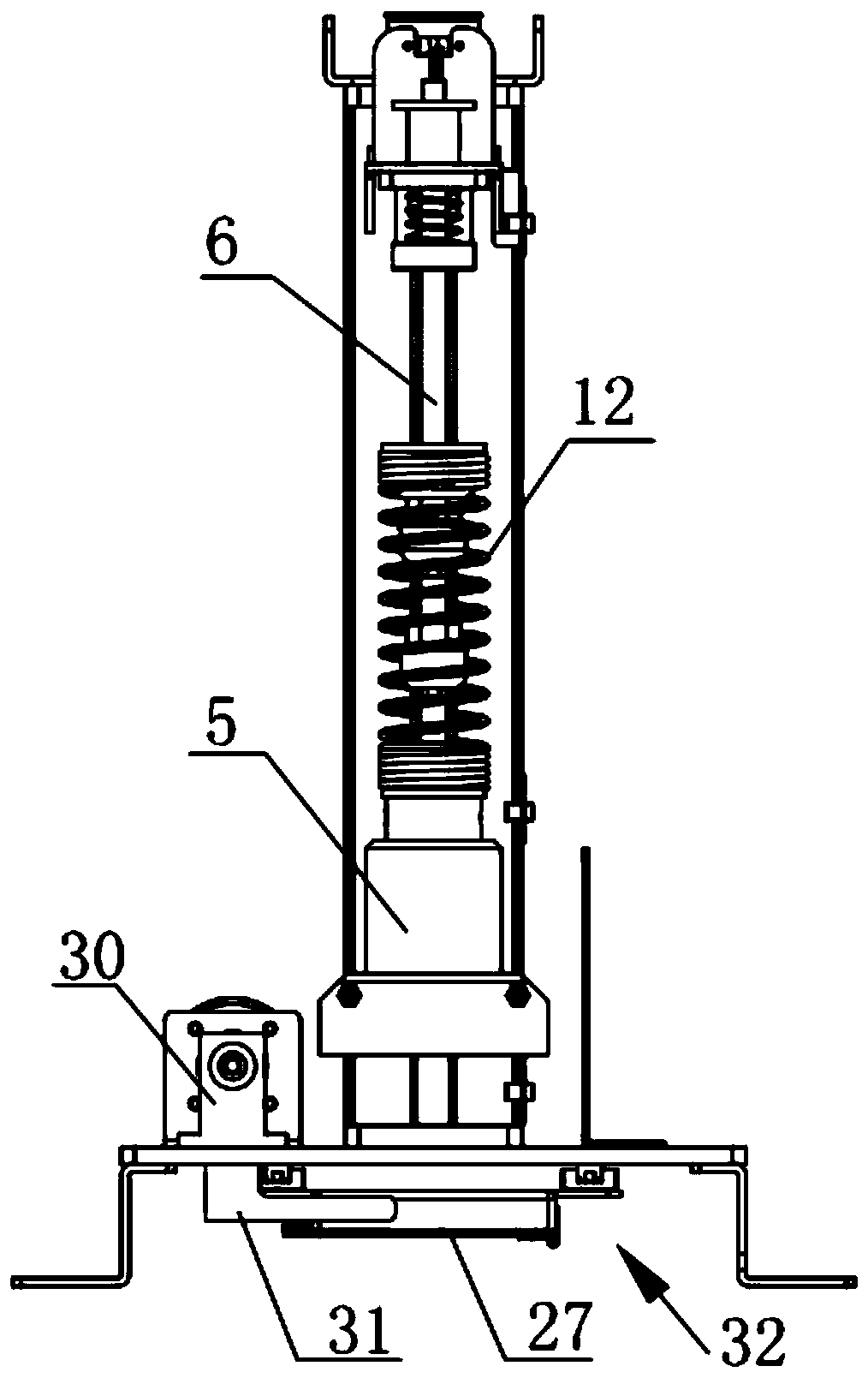

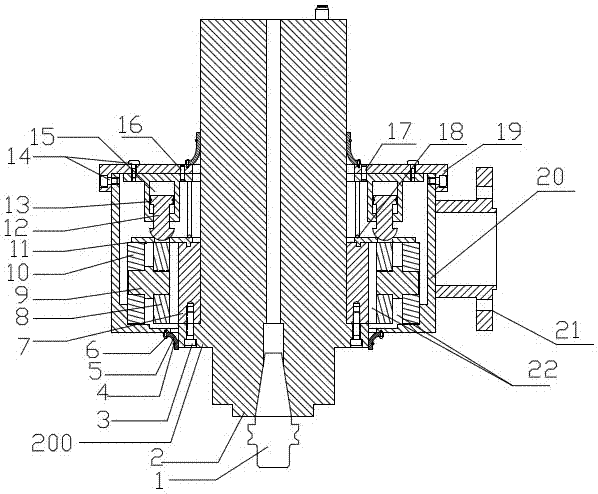

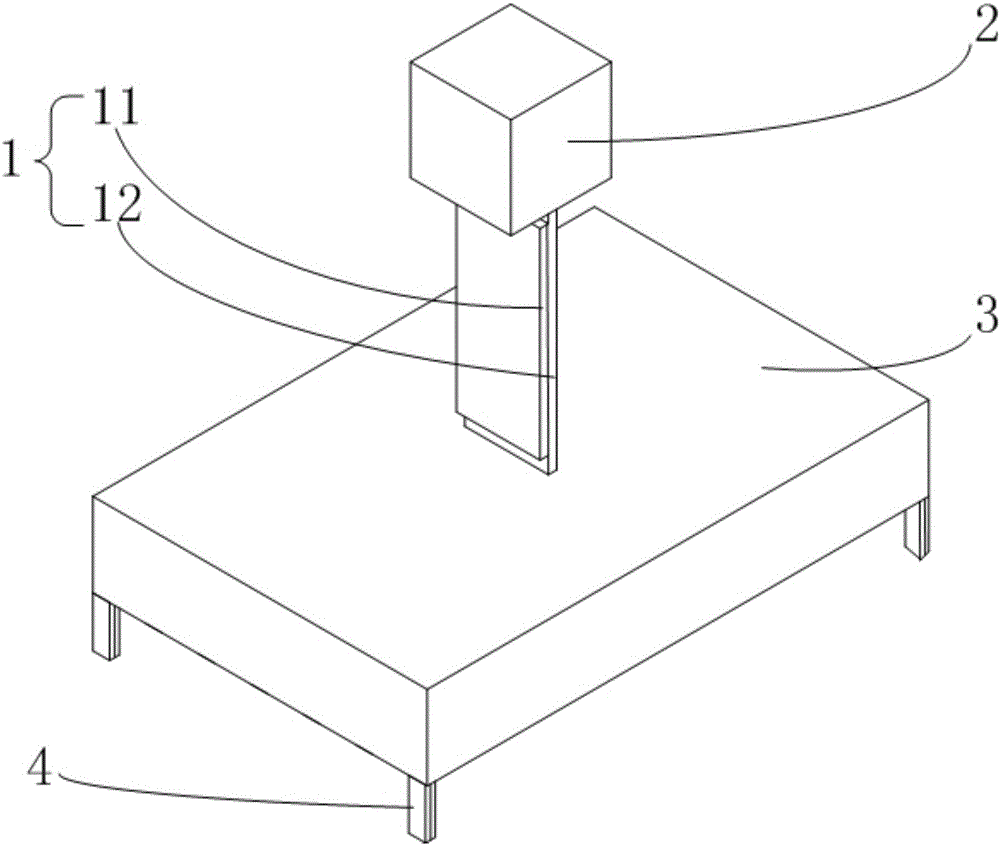

Self-adaptive grinding tool for vertical crankshaft

ActiveCN110524336AGuaranteed coaxialityPrevent rigid contactGrinding carriagesRevolution surface grinding machinesSelf adaptiveEngineering

The invention discloses a self-adaptive grinding tool for a vertical crankshaft and relates to the technical field of engine part grinding tools. The grinding tool comprises a positioning device for vertically clamping the crankshaft and a grinding device located on one side of the positioning device and used for self-adapting to the outline of the crankshaft. The crankshaft grinding tool solves the problems that in order to ensure the fastening of a crankshaft, the stress influence on the crankshaft is ignored in the grinding tool in the prior art; in order to achieve the purpose that when the crankshaft face is ground, the same grinding amount of the crankshaft face cannot be guaranteed; when parts with different widths of the crankshaft are ground, the displacement amount needs to be frequently adjusted; and due to limitation of a grinding wheel, the side wall of the crankshaft can be ground in an auxiliary mode manually with the help of an auxiliary tool.

Owner:潍坊雷腾动力机械有限公司

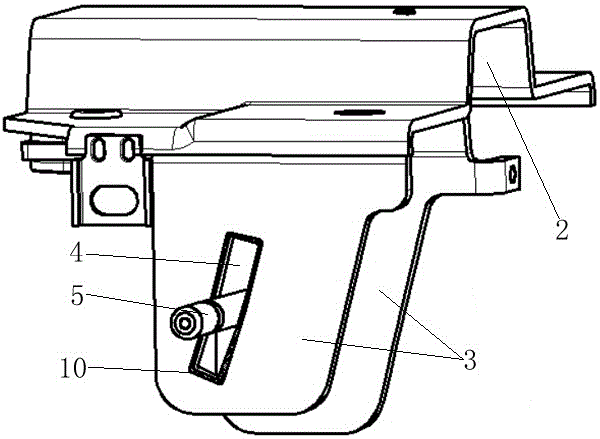

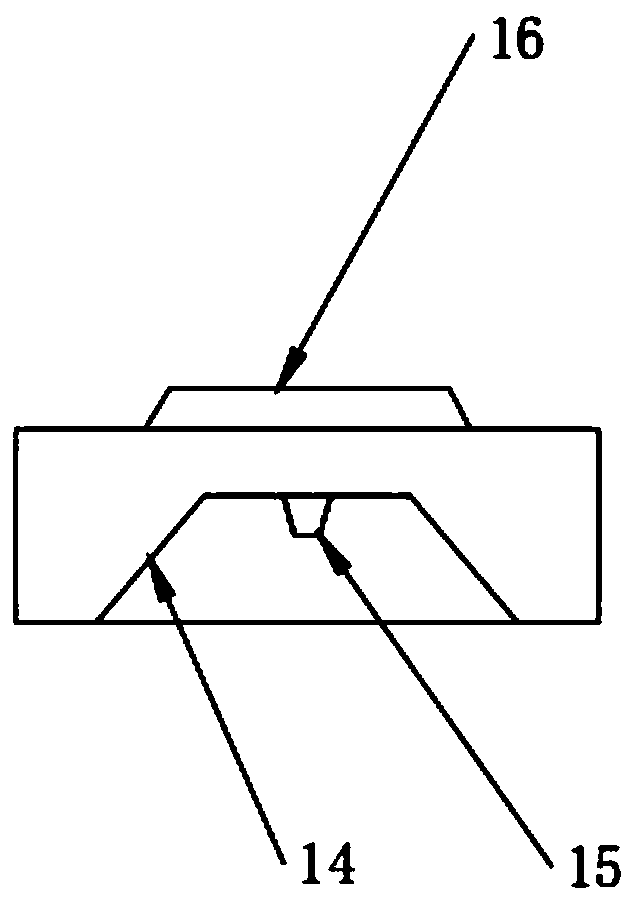

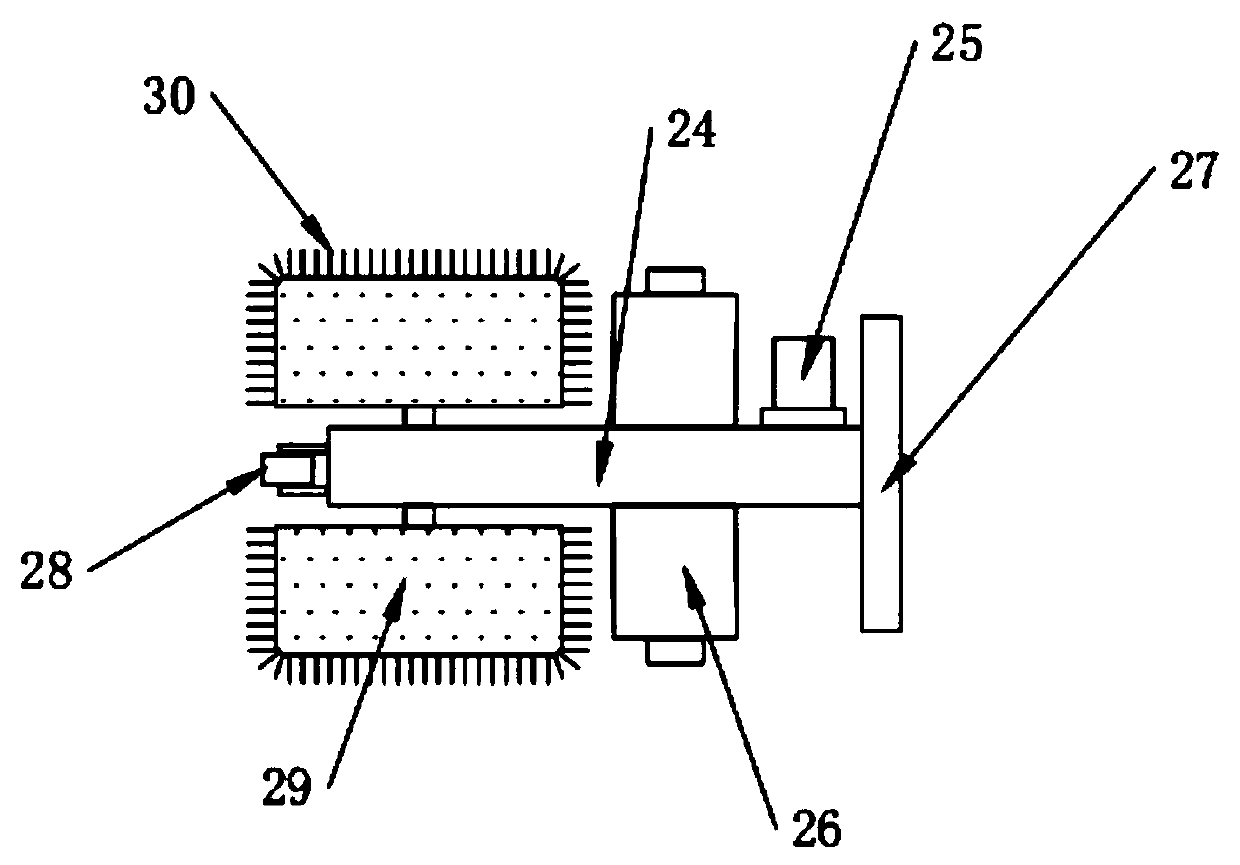

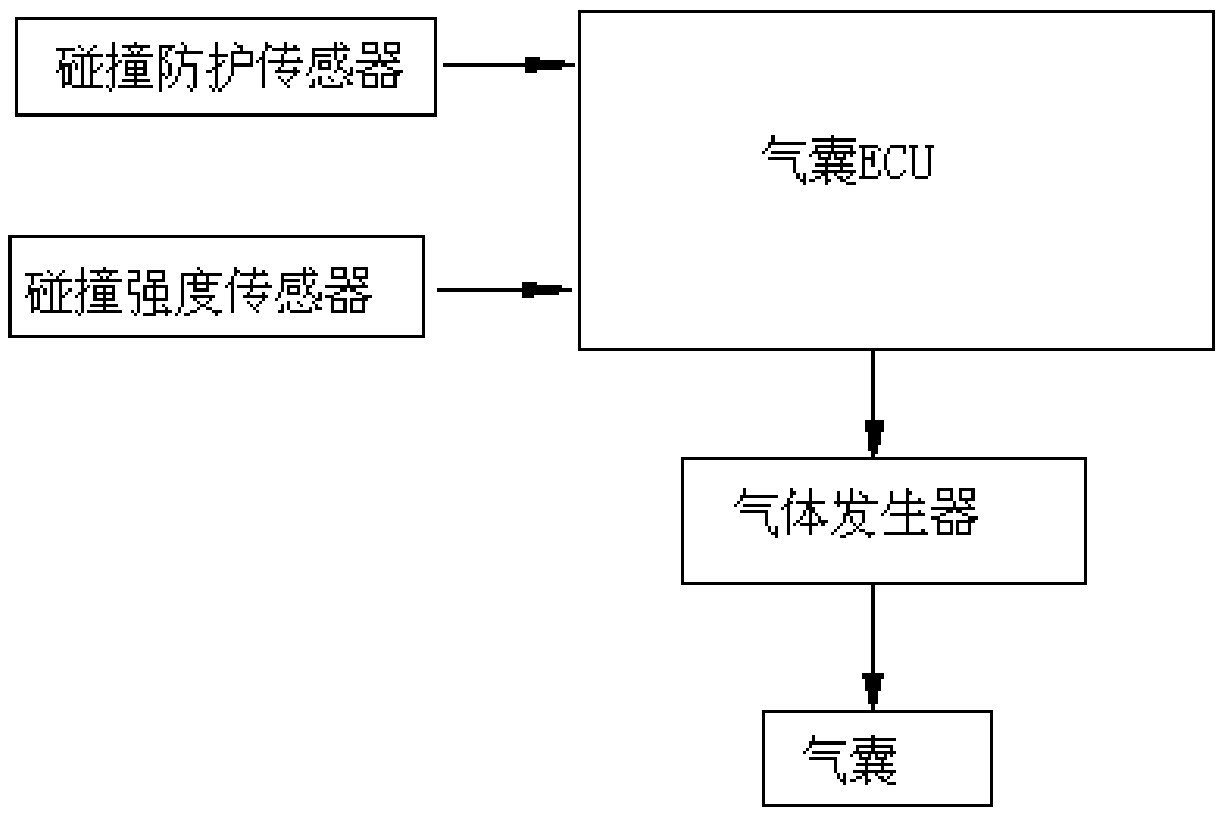

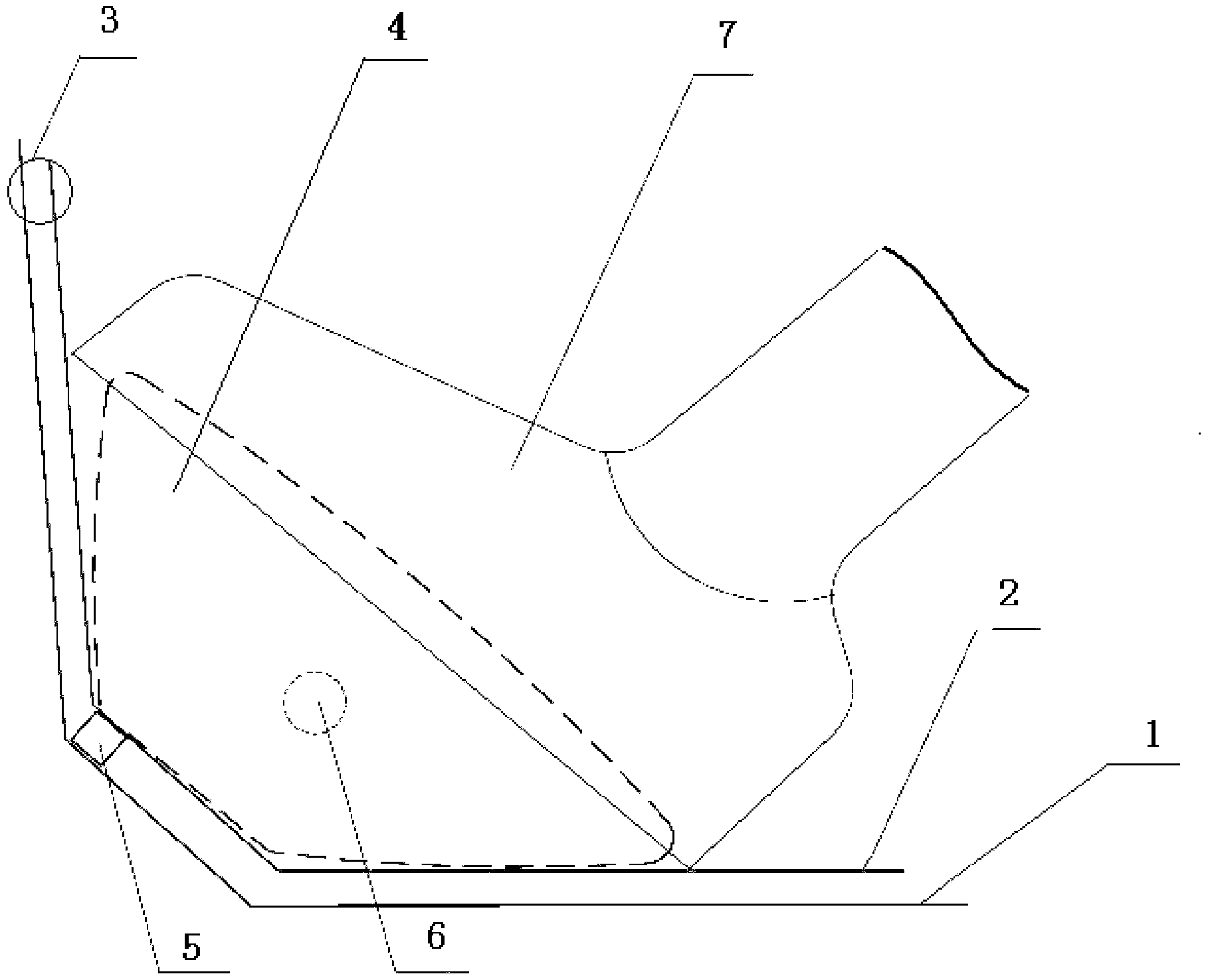

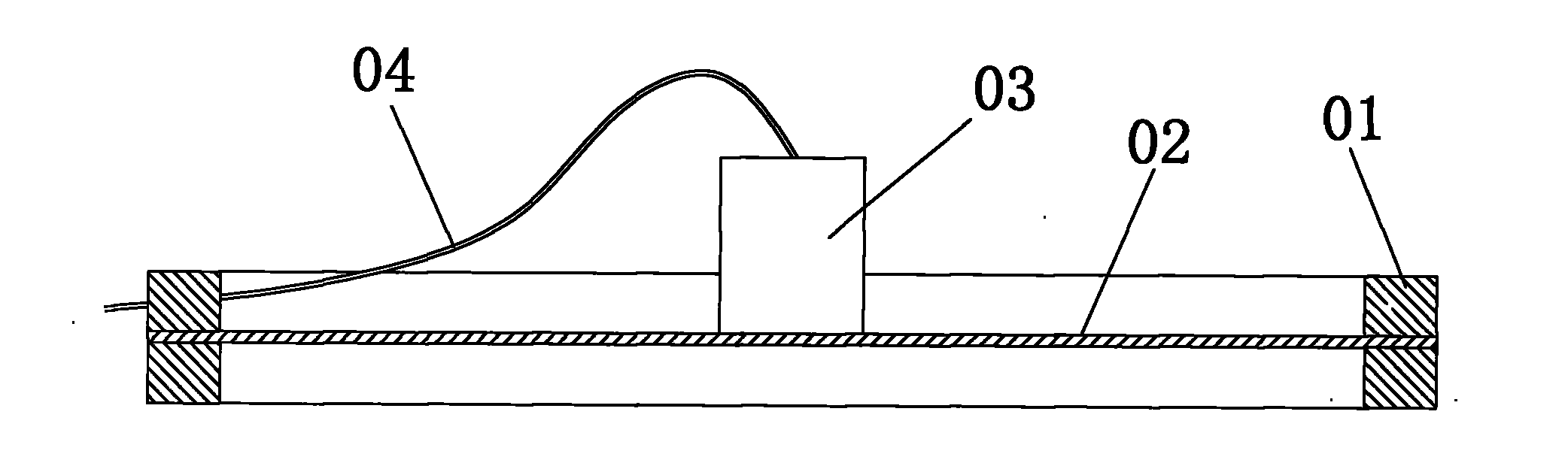

Air sac device for protecting feet of car passenger

ActiveCN103057506AAvoid damageAvoid rigid contactPedestrian/occupant safety arrangementEngineeringGas generator

The invention discloses an air sac device for protecting feet of a car passenger. The air sac device comprises an air sac, a sensor, an air generator and an air sac ECU (electronic control unit), wherein the air sac is arranged on a car floor of a transition area between a car front wall plate and the floor and at the position of feet of the car passenger. During collision of cars, the air sac ECU can control the air generator to inflate the air sac according to car state information detected by the sensor, so that the air sac can be inflated to protect the feet of the passenger.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

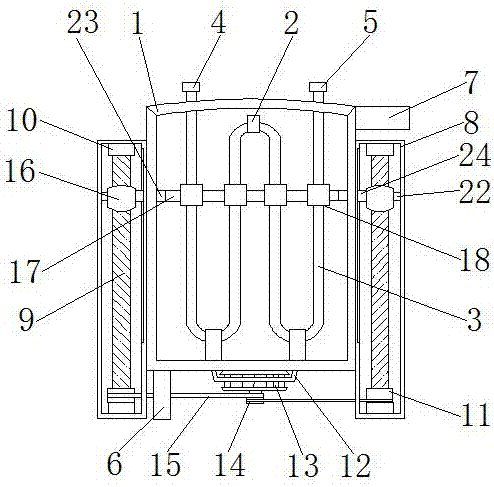

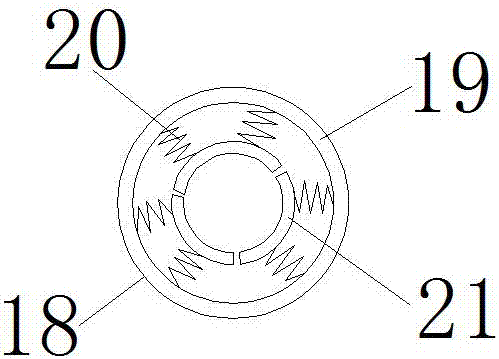

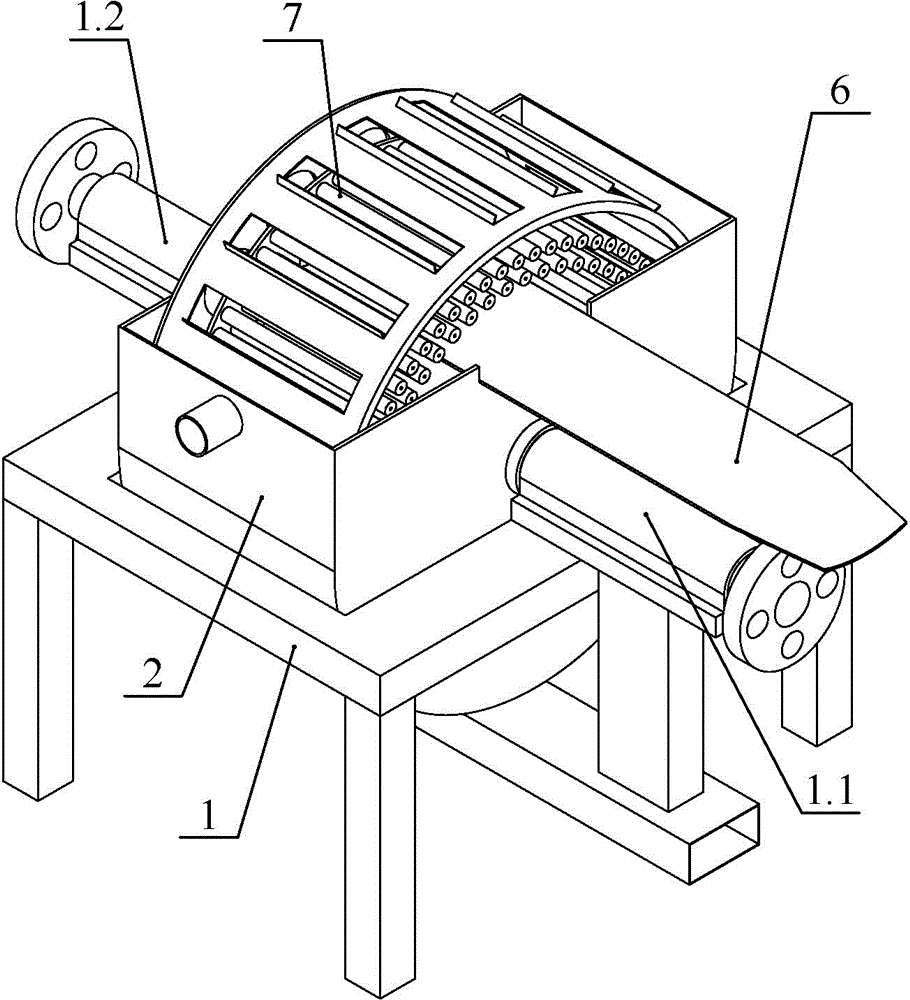

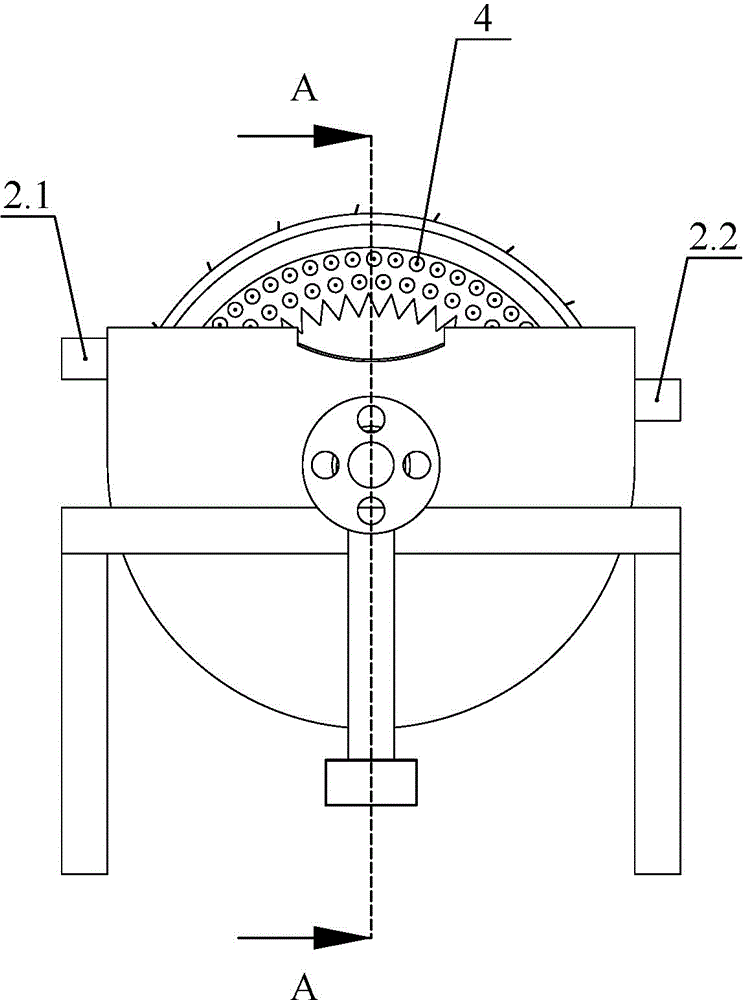

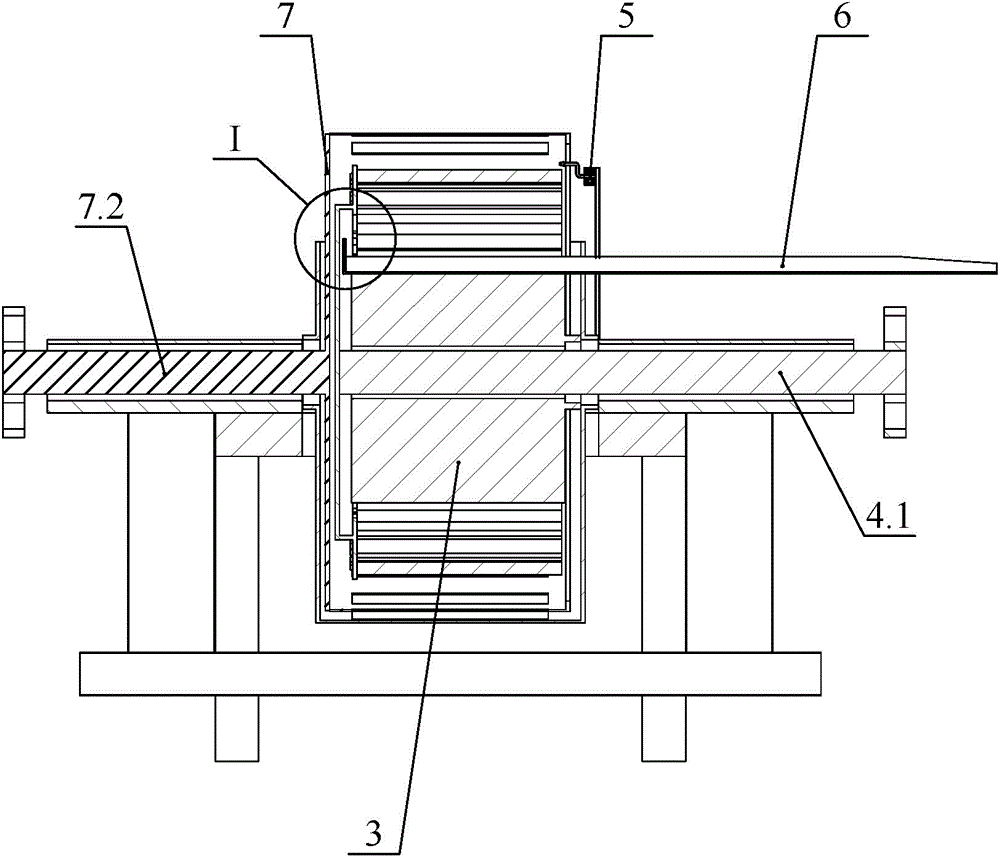

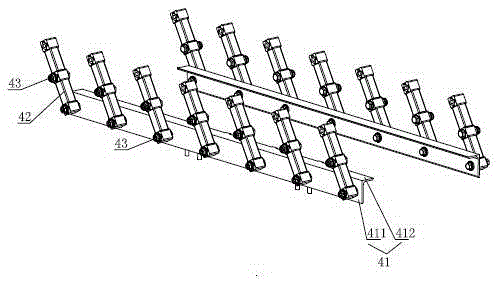

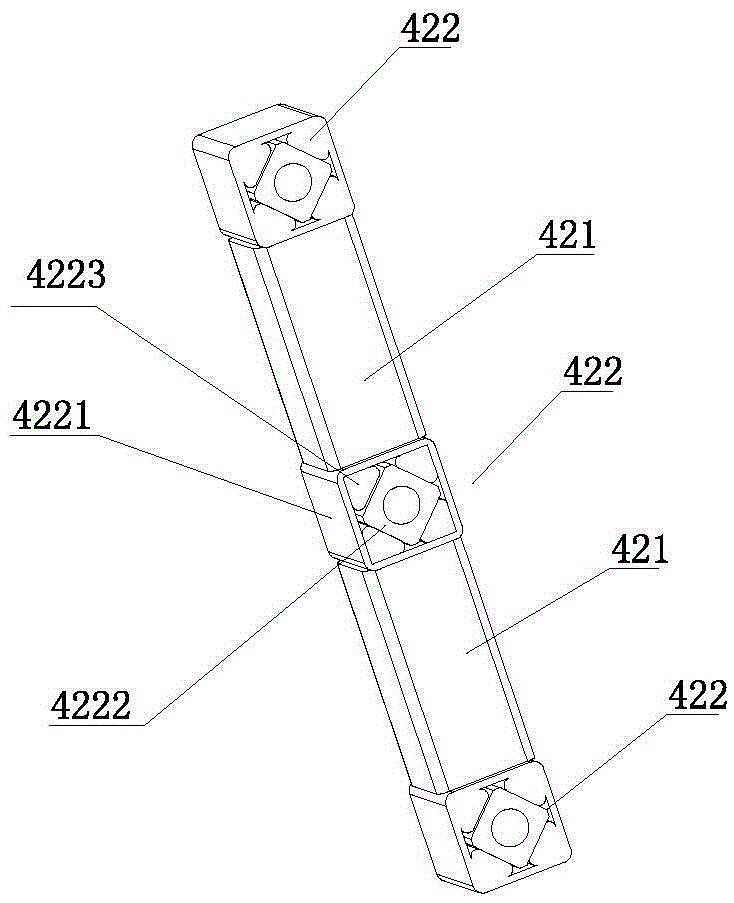

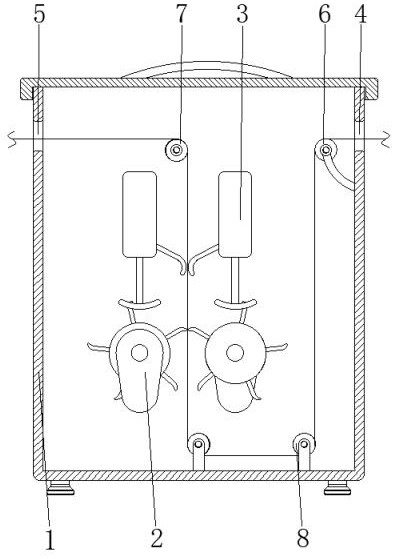

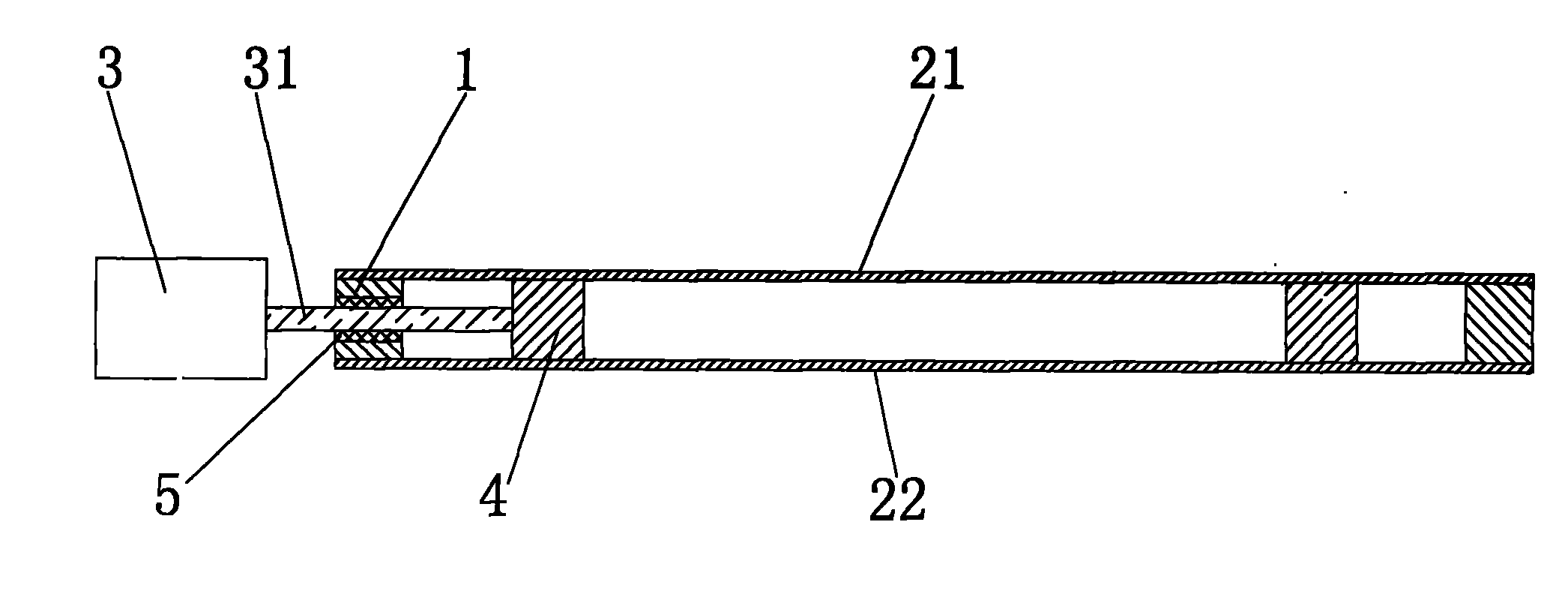

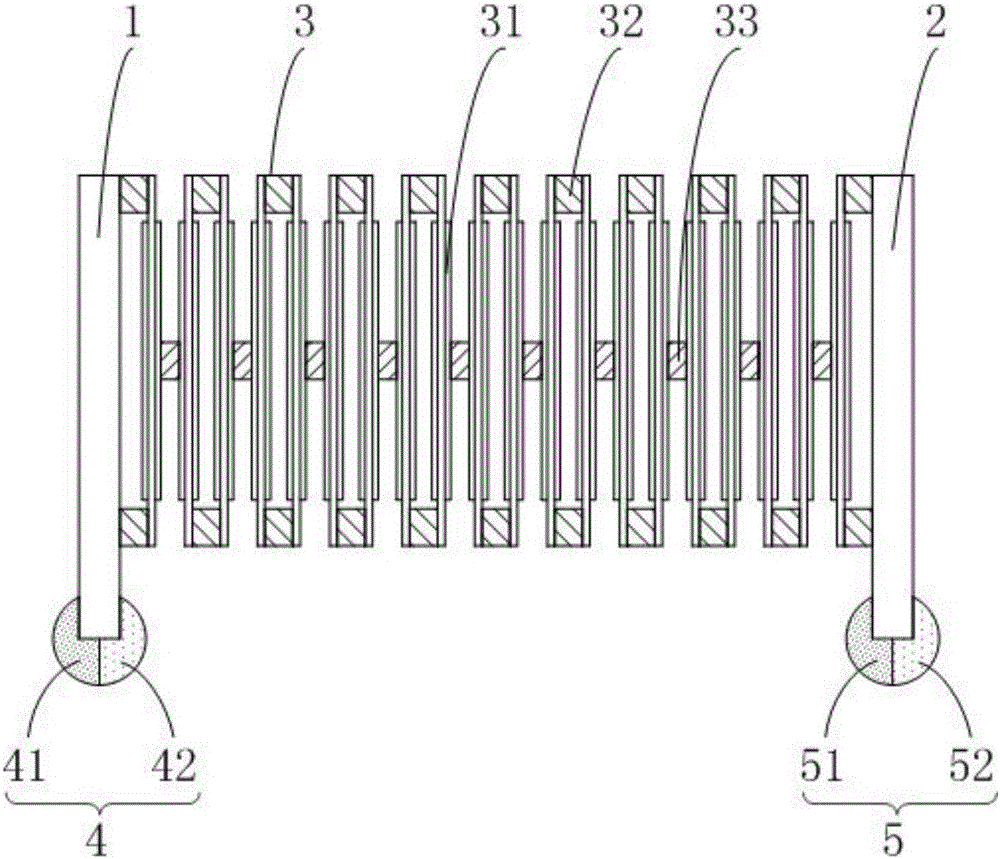

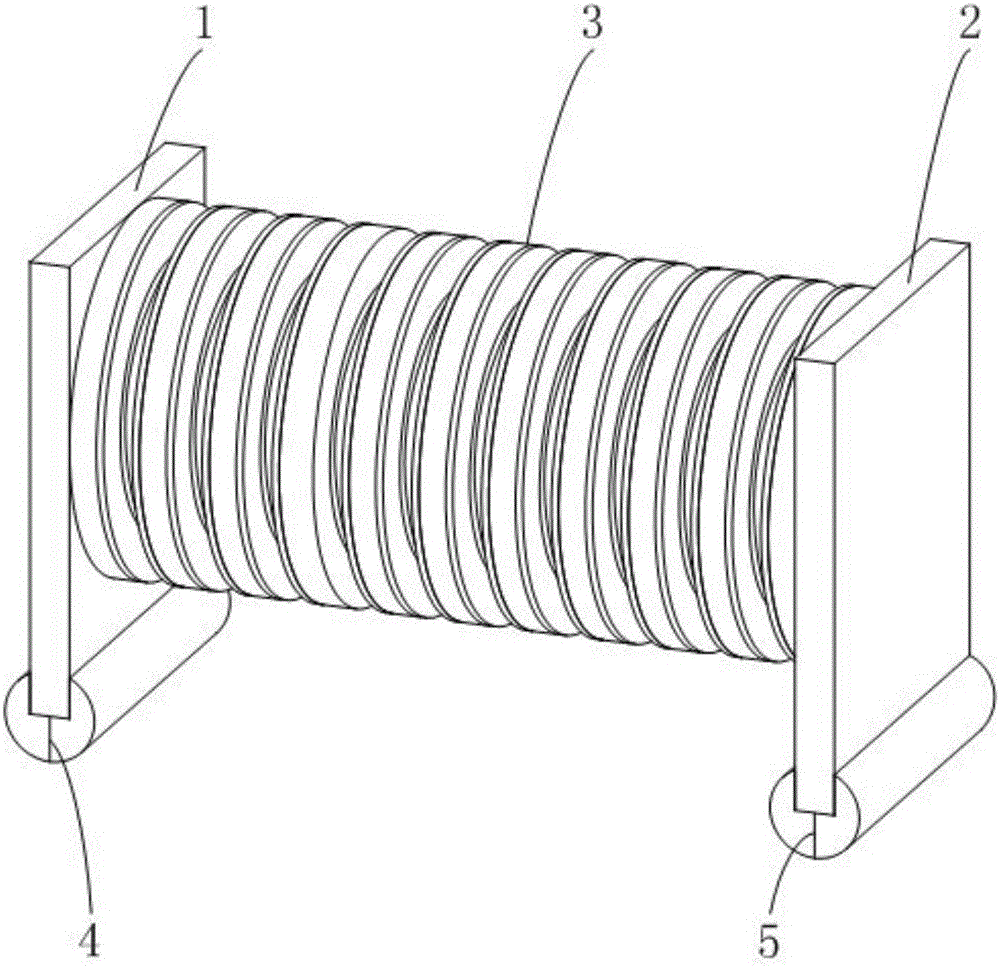

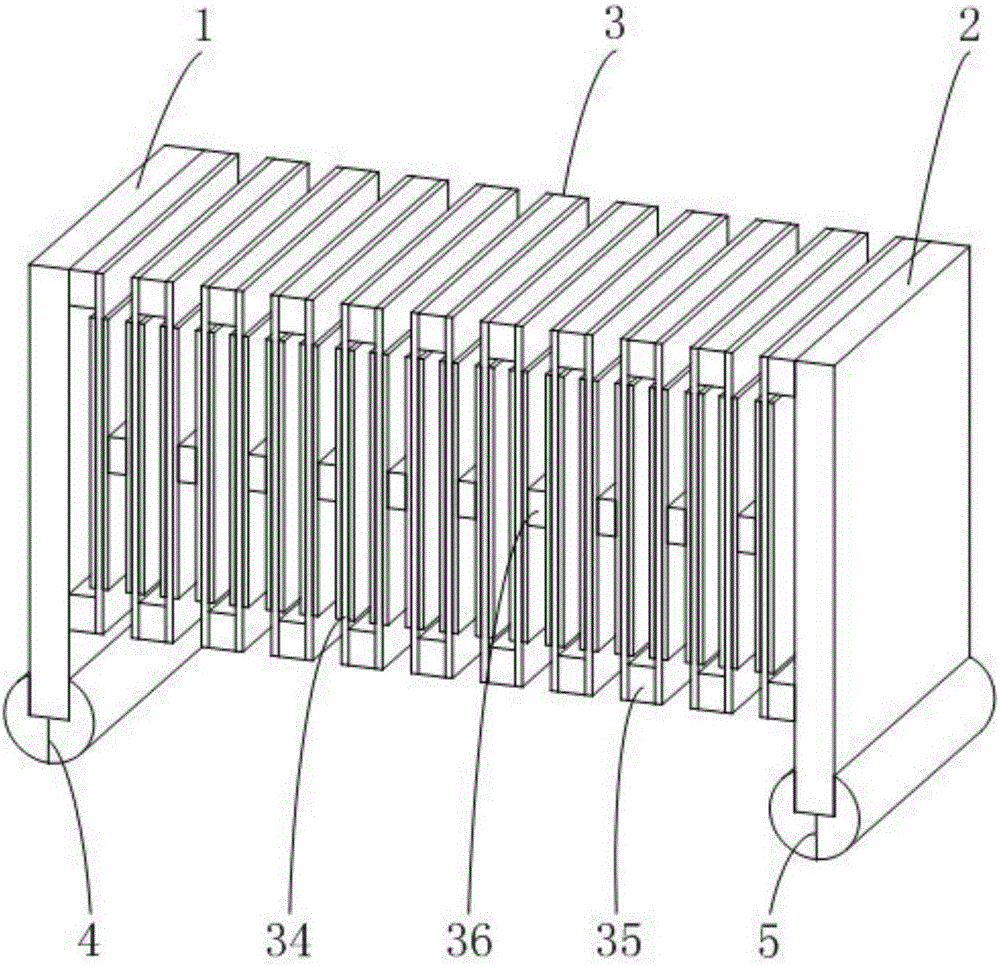

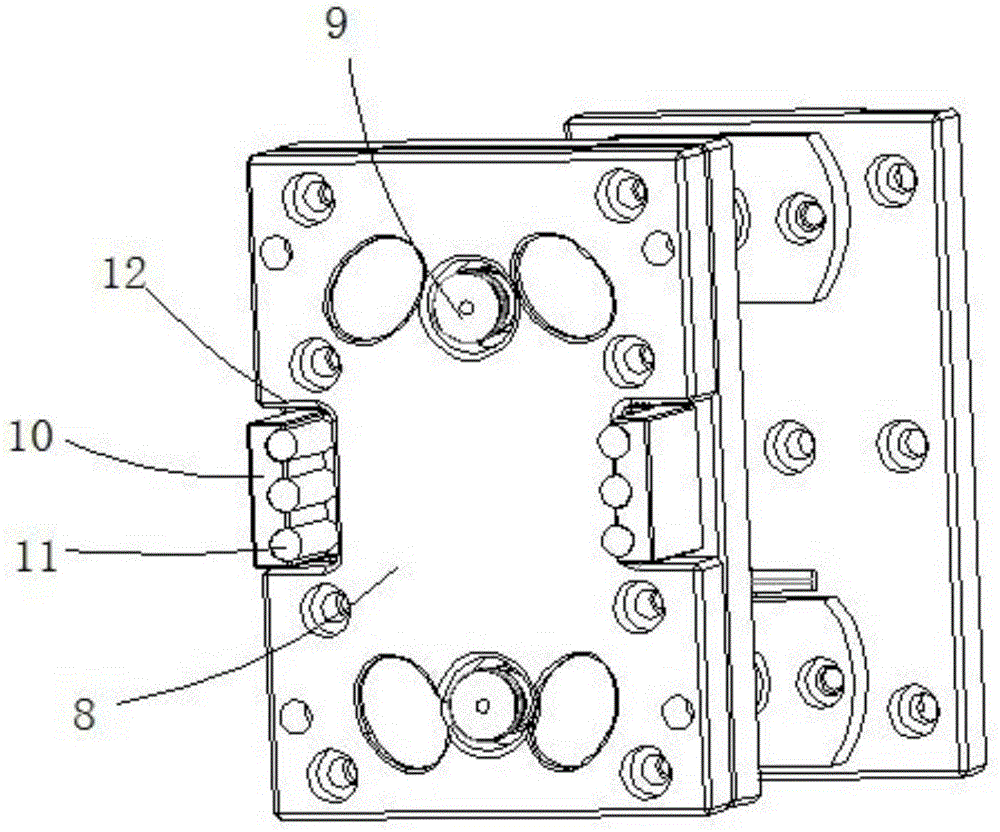

Method and device for deironing continuously in slurry in bi-twisting mode

InactiveCN103977888AGood iron absorption effectImprove slurry qualityMagnetic separationScrapEngineering

The invention discloses a method and device for deironing continuously in slurry in a bi-twisting mode, and belongs to the field of magnetically separating solids in slurry. Magnetic bars in magnetic bar groups are placed in a slurry barrel for adsorbing scrap iron in slurry, and then the scrap iron adsorbed on the magnetic bars is removed. The method and device for deironing continuously in slurry in a bi-twisting mode are characterized in that the magnetic bars in the magnetic bar groups are arranged horizontally; one part of the magnetic bars in the magnetic bar groups are positioned in the slurry, and the other part of the magnetic bars are all exposed out of the liquid level of the slurry; the magnetic bar groups rotate, so that the scrap iron adsorbed on the part of magnetic bars exposed out of the liquid level of the slurry is removed. The method and device for deironing continuously in slurry in a bi-twisting mode, which are provided by the invention, have the beneficial effects that the skillful design of a sandwiched wall cavity enables the slurry in the cavity to be in contact with the magnetic parts maximally, and the magnetic force is applied to the slurry uniformly, and a preferable deironing effect is obtained; the magnetic parts rotate continuously so that deironing is carried out uninterruptedly, and the deironing efficiency is improved greatly; the stability is extremely high, and the maintenance cost is extremely low.

Owner:钟娟英

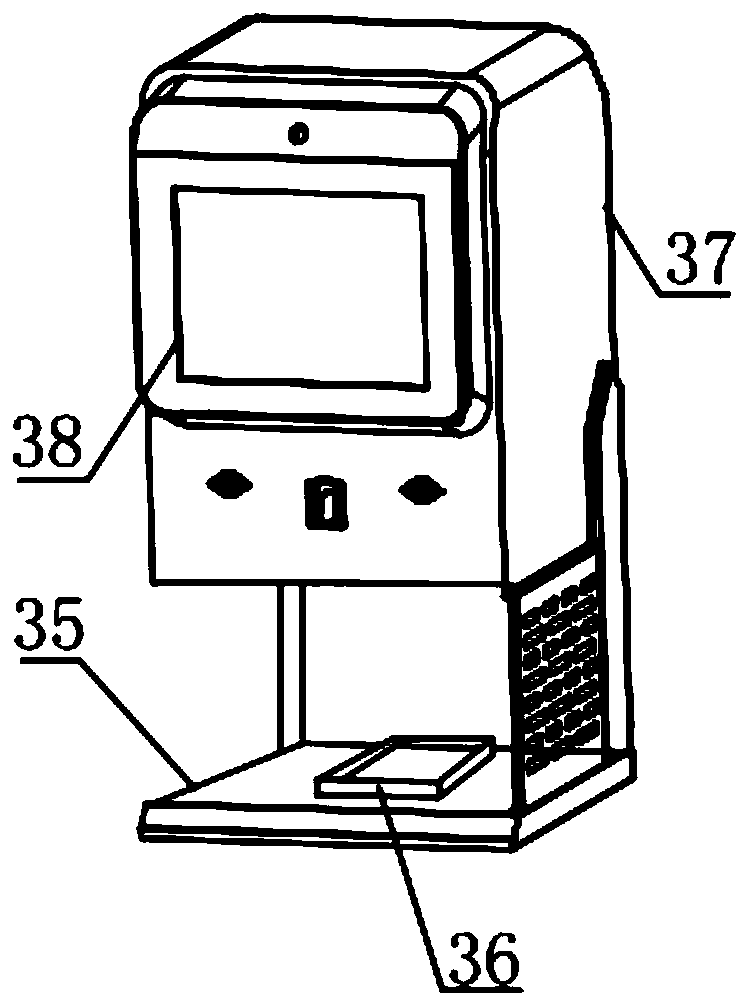

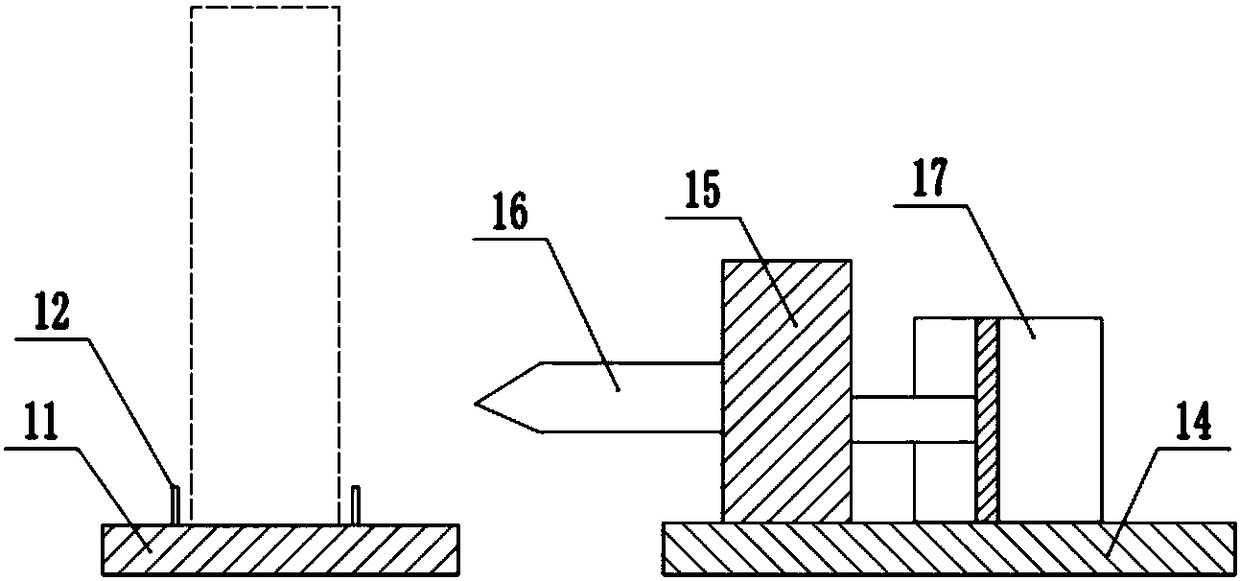

Full-automatic intelligent invoice seal machine

PendingCN110303782AFull Clarity GuaranteedAutomatically realize automatic oil supplyStampingMechanical pressure/force controlMechanical engineering

The invention relates to the technical field of invoice seal machines, in particular to a full-automatic intelligent invoice seal machine which comprises a working table, a displayer, a clamping component, a seal control mechanism, a first detecting element and a controller, wherein the working table is used for carrying a to-be-sealed invoice; the displayer is used for setting and selecting working procedure; the clamping component is used for clamping a seal; the seal control mechanism is used for driving the seal to move downward to finish sealing and to move upwards after sealing so as toreset the seal; the first detecting element is used for detecting the to-be-sealed invoice information; after detecting the invoice information, the first detecting element sends a signal to the controller; and the controller receives the signal of the detecting element and sends the signal to the seal control mechanism to finish sealing operation. The full-automatic intelligent invoice seal machine can automatically identify whether the invoice belongs to the allowable sealing range and automatically seal the invoice allowing to be sealed to greatly lower the manual labor intensity, effectively ensures the completeness and definition of each sealing, automatically supplies ink to a seal, and effectively improves the sealing efficiency and sealing quality.

Owner:青岛方天科技股份有限公司

Prepressing method for hanging basket jack

ActiveCN104746438AGuarantee welding qualityWelding quality matchesBridge erection/assemblyPile capJackscrew

The invention discloses a prepressing method for a hanging basket jack. To make the stress state of the pressure test loading process coincide with that of the practical construction work, the jack is adopted for conducting loading and prepressing to a hanging basket at the midspan of a beam bottom plate of a section 1#, namely a reaction frame is arranged on the end face of a web of a section 0#, by utilizing the opposite acting force of the reaction frame, the opposite acting force is transformed to the bottom plate of the hanging basket through the jack, a sleeper distributive girder or a square timber distributive girder and a wooden plate cushion for exerting the required prepressing load, the concrete load level of the heaviest section is simulated for conducting loading, the technical effects are achieved, namely the prepressing method for the hanging basket jack is convenient and timesaving, the consumption of material resources is little, it can be guaranteed that a pile cap foundation pit is backfilled timely, the construction of a block support foundation 0# is guaranteed, the bottom plate of the hanging basket is stressed more uniformly, the prepressing load of the hanging basket is closer to the practical construction conditions, the processing of the reaction frame and embedded components is simpler, and the operation is easier.

Owner:SINOHYDRO BUREAU 5

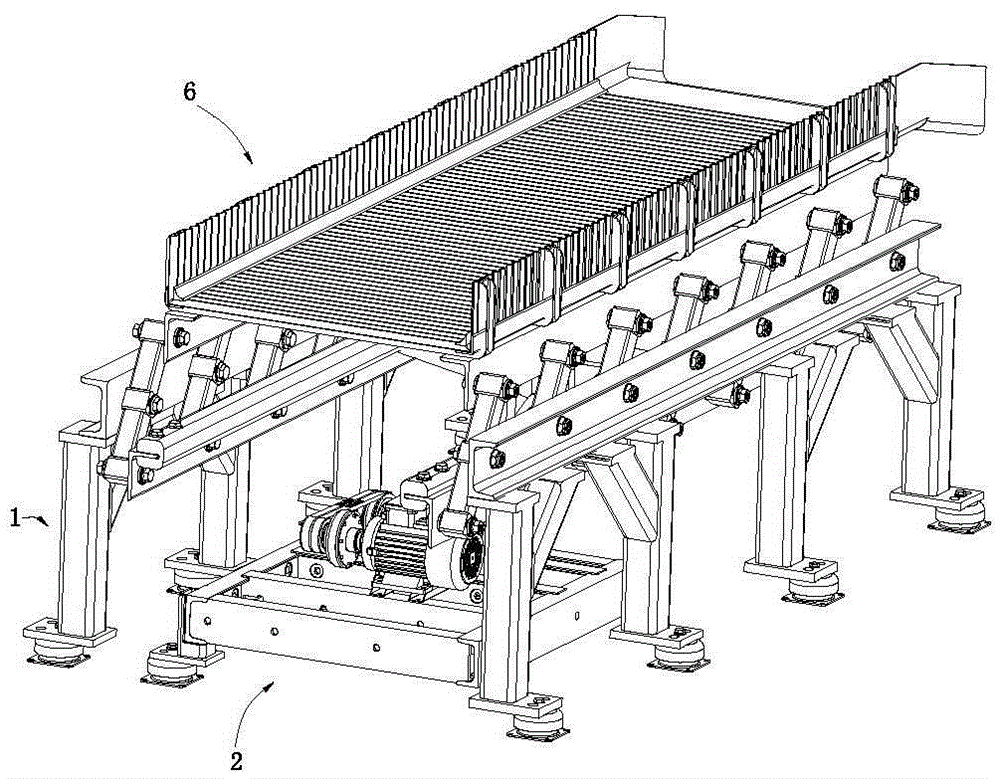

Vibration conveyor for automatic production

The invention discloses a vibration conveyor for automatic production. The vibration conveyor comprises a rack, a base, a driving system, a swinging device, a conveying supporting frame and a conveying device, wherein the base is arranged on the rack; the driving system is mounted on the base; the swinging device is hinged to the rack and driven by the driving system to swing; the conveying supporting frame is hinged to the swinging device, and the conveying device is arranged on the conveying supporting frame. According to the vibration conveyor adopting the aforementioned structure, the shock absorbing performance can be improved, and the supporting stability can be improved; the swinging device can swing uniformly, so that the swinging device can be protected, and as a result, the conveying device can be limited to deform.

Owner:黄丽

Clamping device for camshaft machining

ActiveCN106965011AAchieve lockingAchieve rotationPositioning apparatusMetal-working holdersCommunicating vesselsEngineering

The invention belongs to the technical field of machining and discloses a clamping device for camshaft machining. The clamping device comprises a base. The base is provided with a first supporting column, a U-shaped communicating vessel and a second supporting column. The U-shaped comprises a first transverse pipe, a second transverse pipe and a vertical pipe. The clamping device further comprises an L-shaped positioning column and a locking column. The lower end of a long pole of the positioning column is connected with a first transverse push rod. The lower end of the long pole of the locking column is connected with a second transverse push rod. The right end of the first transverse push rod is connected with a first piston. The right end of the second transverse push rod is connected with a second piston. A gear is arranged between the first transverse push rod and the second transverse push rod. The first transverse push rod and the second transverse push rod are both provided with racks. Air holes are formed in the first transverse push rod. Through holes are formed in the long pole of the positioning column. A mounting groove is formed in the top end of the long pole of the positioning column. A transverse protrusion block and a vertical positioning block are arranged in the mounting groove. A rotary shaft is arranged on the left side of the positioning block. A cam and a torsional spring are connected to the rotary shaft. The problem that the clamping efficiency in the prior art is low is solved.

Owner:南通利联机床制造有限公司

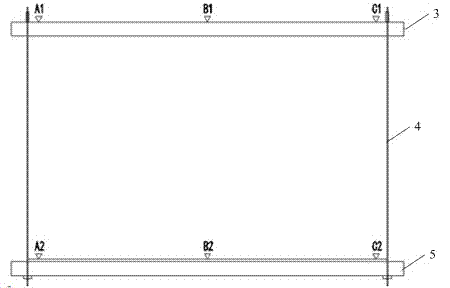

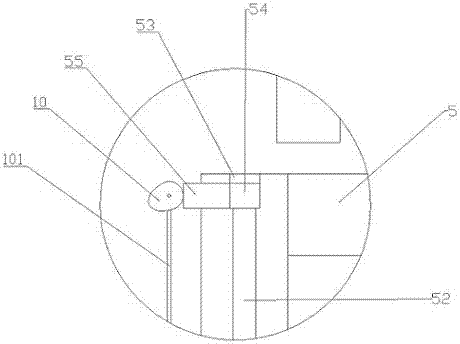

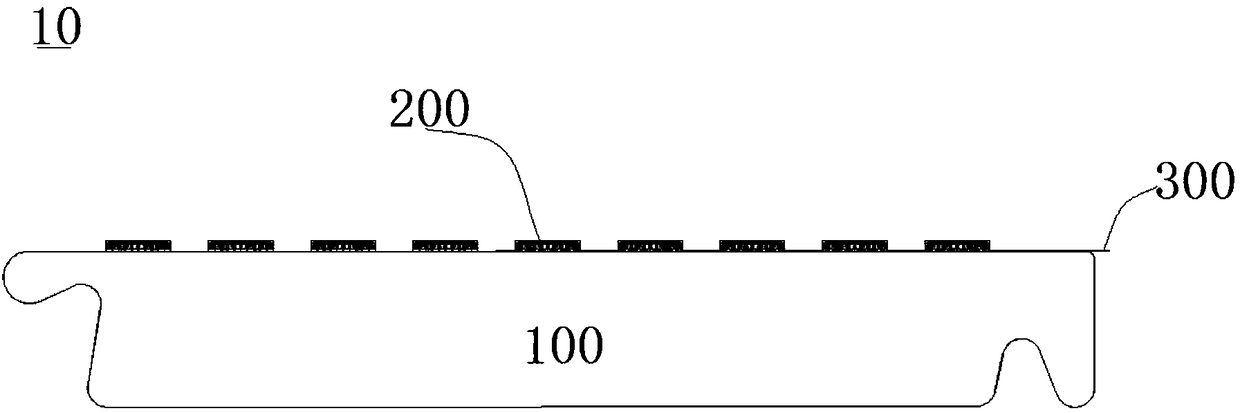

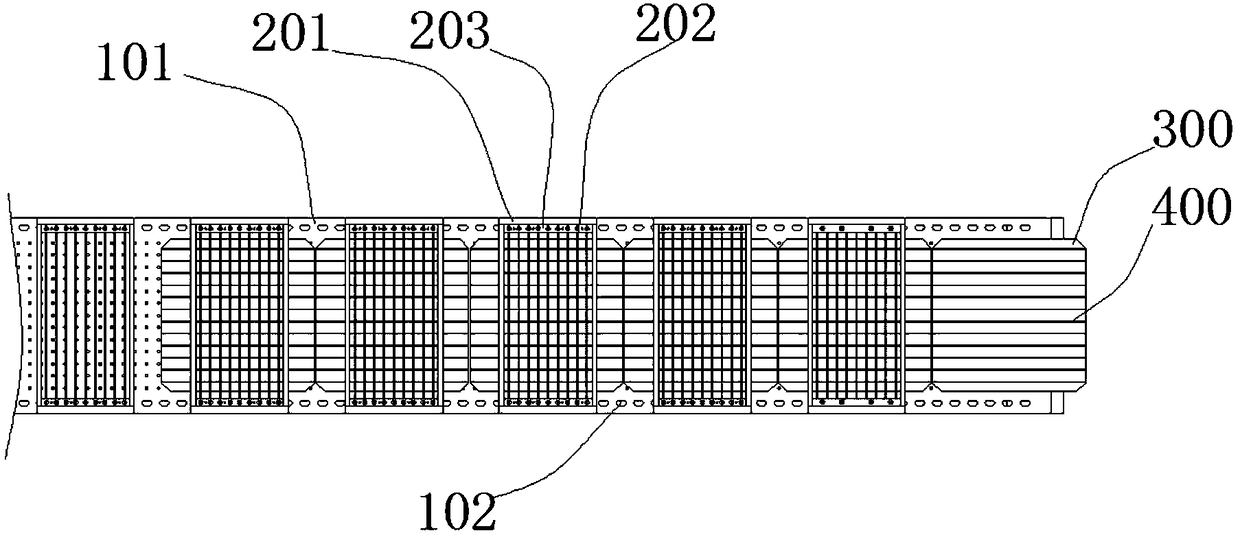

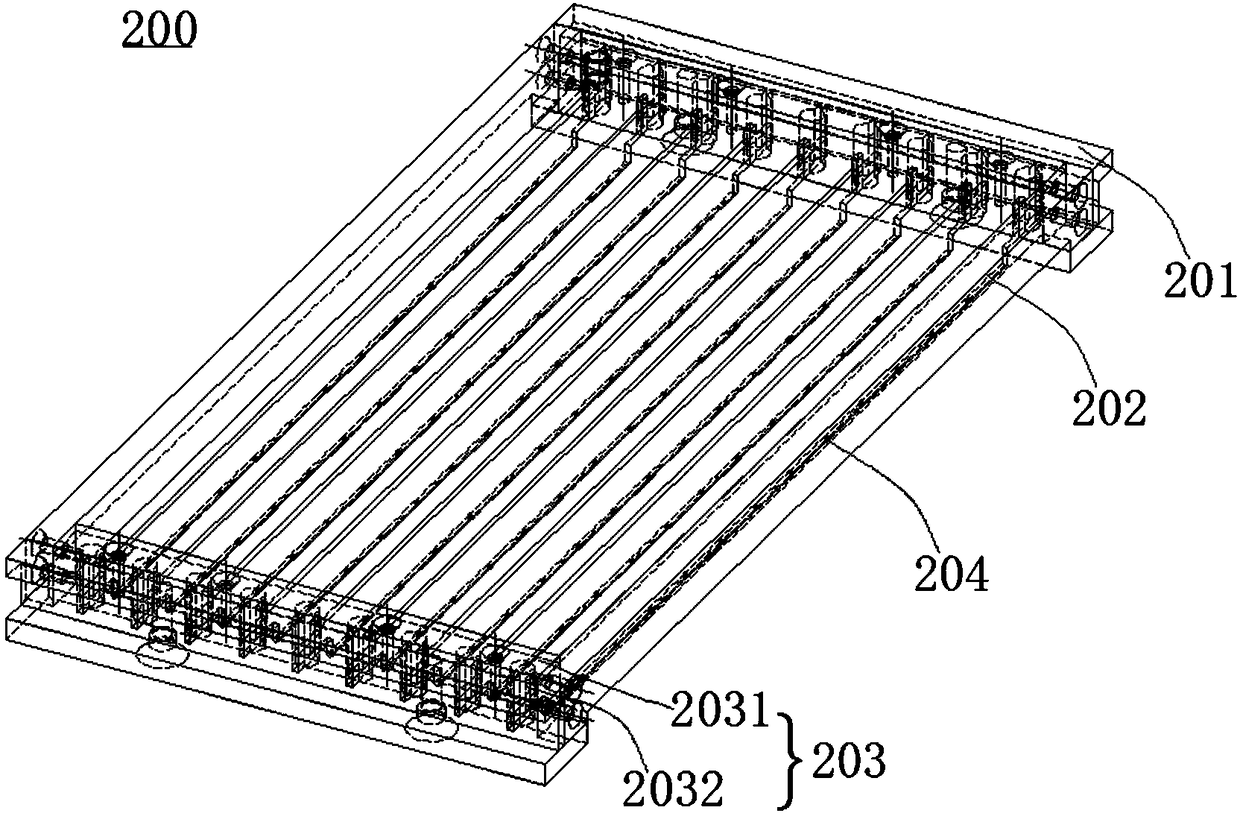

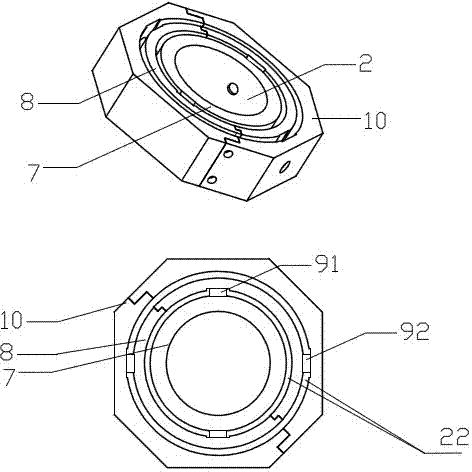

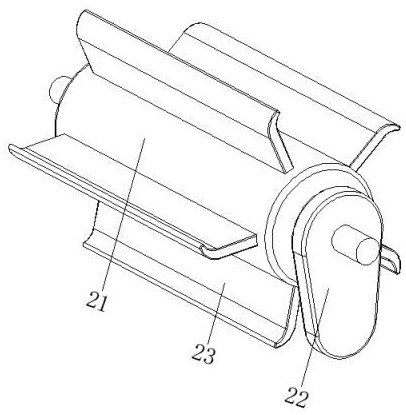

Dense grid solder strip pressing device, dense grid battery string welder and string welding method thereof

InactiveCN108555497AAvoid damageReduce breakage rateFinal product manufactureWelding/cutting auxillary devicesEngineeringSoldering

The invention discloses a dense grid solder strip pressing device. The dense grid solder strip pressing device comprises a frame, a pressing strip, spring pressing mechanisms and a solder strip clamping groove; the frame is internally provided with the pressing strip, and the spring pressing mechanisms are arranged at both ends of the frame; and the solder strip clamping groove is formed in the pressing strip. The invention further provides a dense grid battery string welder including the dense grid solder strip pressing device and a string welding method thereof. The dense grid solder strip pressing device is provided with the solder strip clamping groove which is used for clamping a solder strip so as to press the solder strip to a welding spot of a battery piece, the coincide of the solder strip and the welding spot of the battery piece is effectively kept, so that the solder strip is prevented from moving misalignedly, and the phenomenon of poor soldering is avoided.

Owner:深圳光远智能装备股份有限公司

Clamping device for groove shaped like Chinese character 'wang'

InactiveCN108581558AAvoid replacementLow costPositioning apparatusMetal-working holdersChinese charactersGear wheel

The invention relates to the technical field of machining of grooves shaped like a Chinese character 'wang' and discloses a clamping device for a groove shaped like a Chinese character 'wang'. The clamping device comprises a fixing frame and a motor; a first clamping block and a second clamping block are arranged on the top of a rack; a supporting board is arranged between the first clamping blockand the second clamping block; an air flue is arranged inside the first clamping block and provided with an annular cavity; an oblique opening is formed in the annular cavity; a wind flue is arrangedinside the second clamping block; a guide rod is fixed to the second clamping block; a chute and a sliding shaft are arranged on the lower portion of the supporting board; a convex block is fixed tothe bottom of the sliding shaft; an auxiliary bevel gear and a rotary shaft are arranged on one side of the sliding shaft; a spiral slide is arranged on the rotary shaft; a screw rod is fixed to therotary shaft; the auxiliary bevel gear is engaged with a main bevel gear; the main bevel gear and the motor are fixedly connected; a spiral track is arranged on a rotary rod; an air tank is arranged below the sliding shaft and internally provided with a piston board; one side of the air tank communicates with the annular cavity through an electromagnetic valve; and the other side of the air tank communicates with the wind flue through a one-way valve. The clamping device is simple in structure, a machining board for machining the groove shaped like the Chinese character 'wang' is convenient totake out, and waste scraps are convenient to collect.

Owner:重庆市乐珐机电有限责任公司

Flexible grinding mechanism

InactiveCN103934750AExtended service lifeAvoid rigid contactEdge grinding machinesGrinding machine componentsEngineeringMechanical engineering

The invention discloses a flexible grinding mechanism. The flexible grinding mechanism comprises an electric spindle, a cutter handle, an inner cylinder sleeve, an outer cylinder sleeve, an anti-rotating barrel and hinge pins, wherein the cutter handle is arranged at the lower end of the electric spindle. The hinge pins comprise the first hinge pins and the second hinge pins. The electric spindle is sleeved with the inner cylinder sleeve, the inner cylinder sleeve is sleeved with the outer cylinder sleeve, and the inner cylinder sleeve and the outer cylinder sleeve are connected through the two hinge pins. The outer cylinder sleeve is sleeved with the anti-rotating barrel, and the outer cylinder sleeve and the anti-rotating barrel are connected through the two second hinge pins. The first hinge pins and the second hinge pins are symmetric about the electric spindle respectively, and the connecting line of the first hinge pins and the connecting line of the second hinge pins are perpendicular to each other. Floating gaps are formed between the inner cylinder sleeve and the outer cylinder sleeve and between the outer cylinder sleeve and the anti-rotating barrel. According to the flexible grinding mechanism, in the working process, rigid contact between a cutter and a workpiece is avoided, the cutter, the electric spindle and a robot are protected, and service life is prolonged.

Owner:JIANGSU BEIREN ROBOT SYST CO LTD

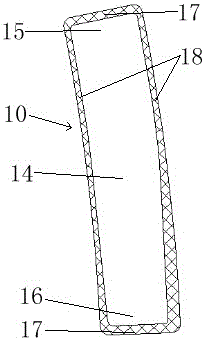

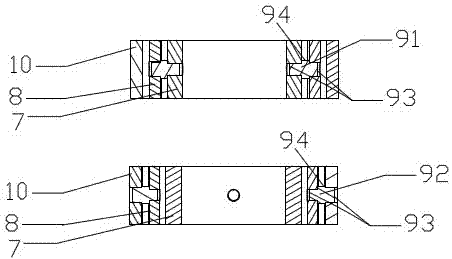

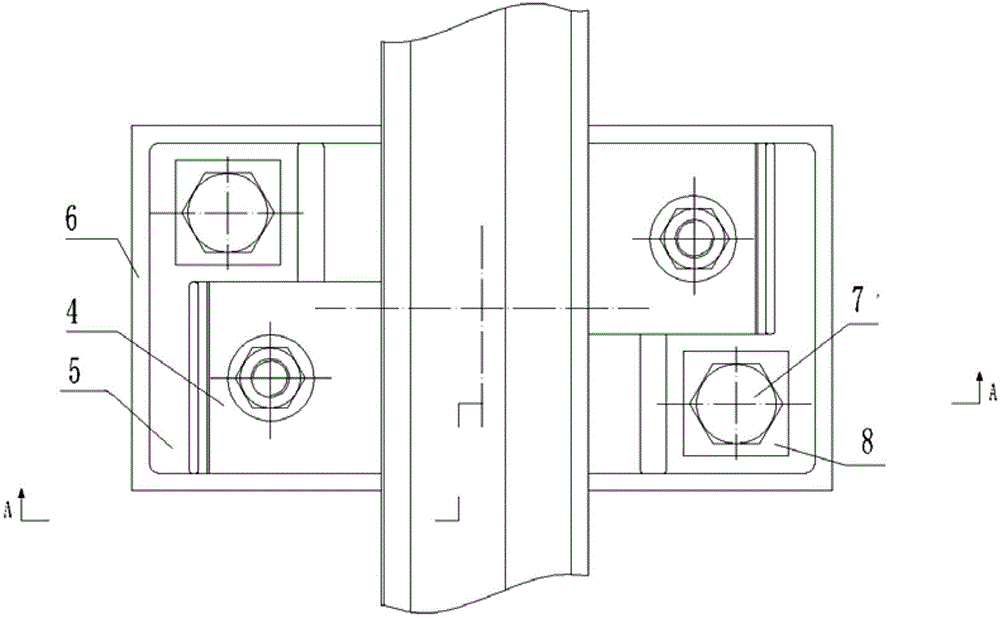

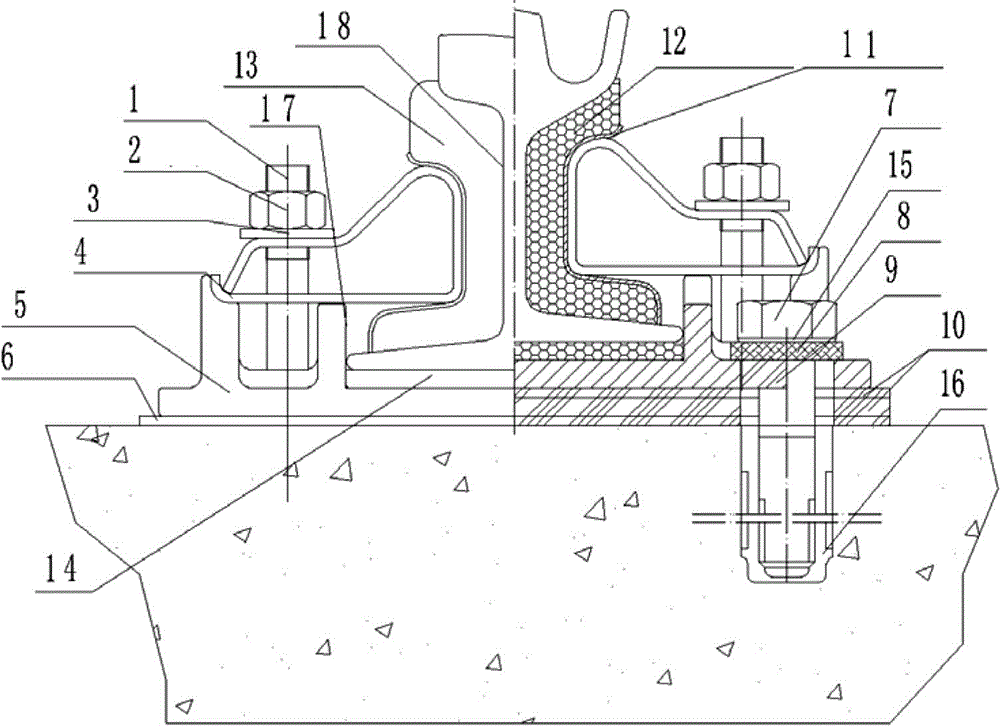

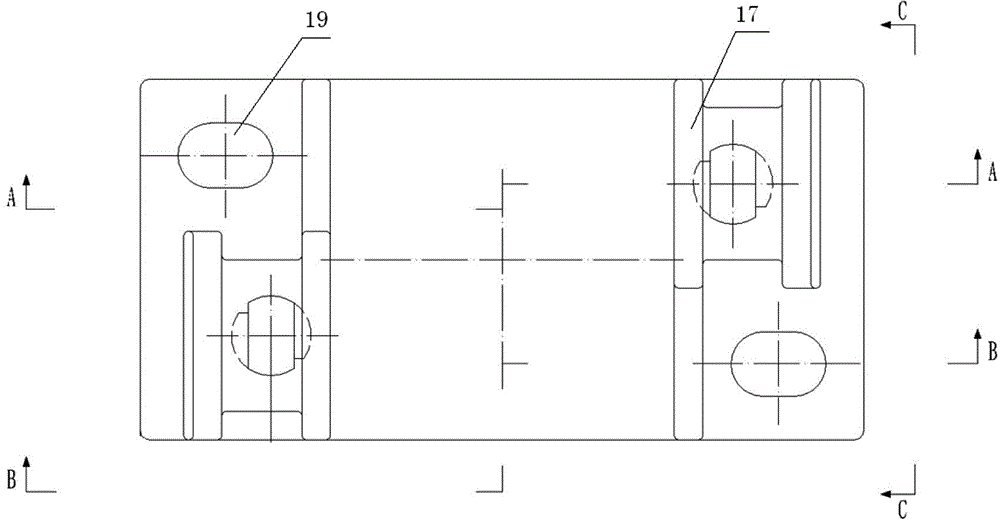

Vibration damping fastener for groove type rail of streetcar

InactiveCN104131497AReduce vibrationReduce lateral vibrationRail fastenersTrack superstructureEngineeringFastener

The invention provides a vibration damping fastener for a groove type rail of a streetcar. The vibration damping fastener comprises a vibration damping strip which is arranged at the waist part of the groove type rail, a positioning iron plate and a positioning spring piece which are used for extruding and fixing the vibration damping strip, wherein the positioning spring piece enables the vibration damping strip to be tightly bonded to the waist part of the groove type rail through the positioning iron plate. For the vibration damping fastener for the groove type rail, by adoption of the ingenious design of the shape and the structure of each part and the connection, the multi-stage vibration damping is realized, the rigid connection is reduced, and thereby, and the purposes of reducing the vibration of the rail and reducing the noise pollution are achieved.

Owner:BEIJING JIUZHOUYIGUI SHOCK & VIBRATION ISOLATION

Cloth cleaning device for textile processing

ActiveCN113584769AAvoid deformationAvoid breakingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsMechanical engineeringIndustrial engineering

The invention discloses a cloth cleaning device for textile processing. The device comprises a box body, a flexible cleaning device and a water removal device; the flexible cleaning device is arranged in the center of the interior of the box body and close to the bottom; the water removal device is arranged in the box body and located above the flexible cleaning device; a driving roller is rotationally connected between the two corresponding sides of the inner wall of the box body; a cam is arranged at one end of the driving roller; a brush cleaning device is arranged in the driving roller and located at the surface position; and the brush cleaning device is connected with the driving roller in a matched mode. The invention relates to the technical field of textile processing equipment. According to the cloth cleaning device for textile processing, the effects of flexible cleaning and moisture removal are achieved; the cloth can be flexibly cleaned, so that rigid contact is avoided, the cloth is not prone to deformation or damage, and the cleaning efficiency is high; moisture attached to the cloth is removed in time, so that subsequent rapid drying is facilitated; and the safety and reliability are achieved, and the use performance is improved.

Owner:南通刚正纺织品有限公司

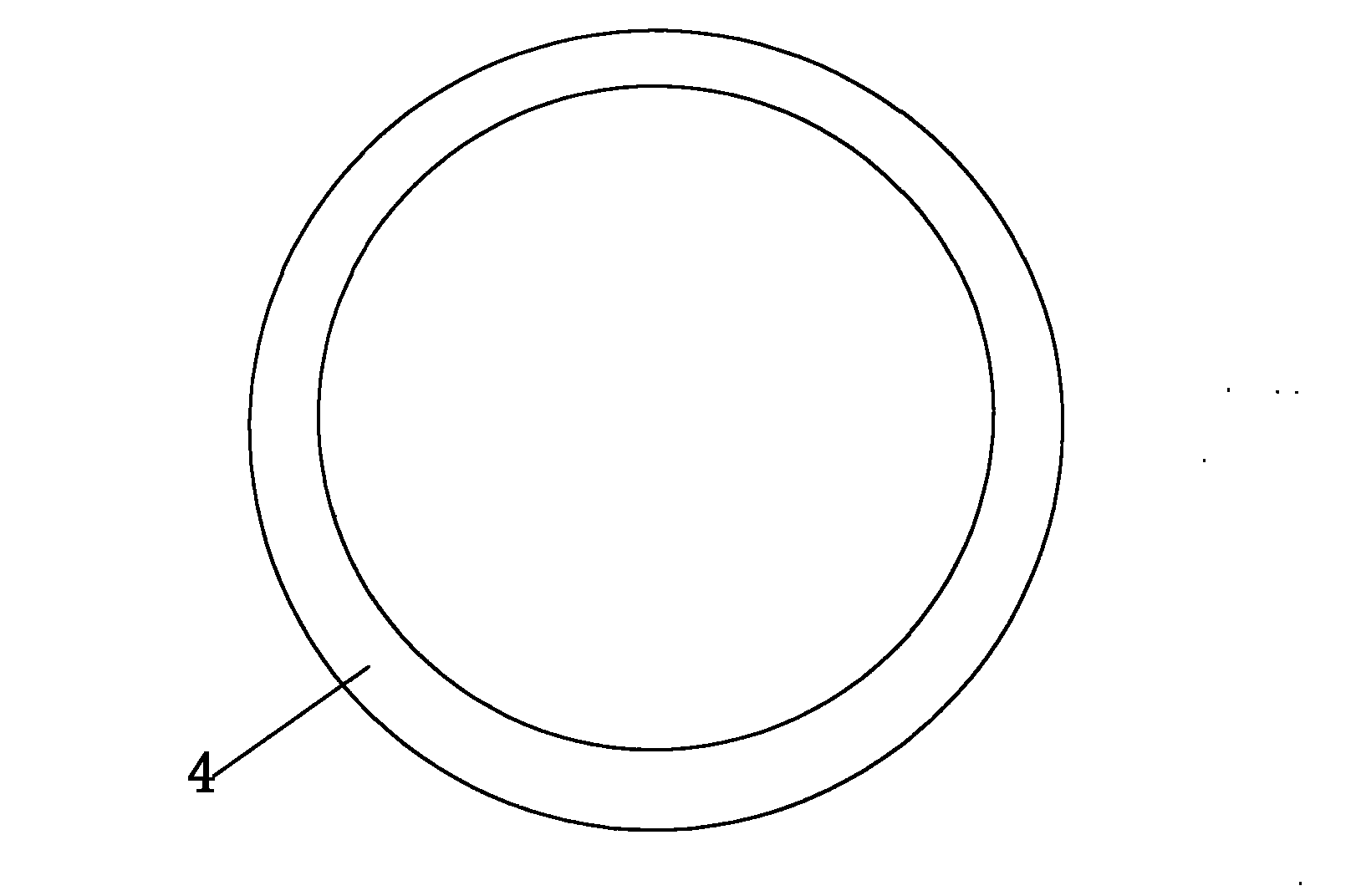

Ultrasonic vibration screen and method for filtering and screening powder by using same

The invention relates to an ultrasonic vibration screen. The ultrasonic vibration screen comprises a bracket, a screen and an ultrasonic vibration head, wherein the screen is arranged on the bracket; the ultrasonic vibration head is arranged on the outer side of the bracket; the ultrasonic vibration head is provided with a vibration-transmitting shaft; a shaft hole is formed on the bracket; the vibration-transmitting shaft is inserted into the shaft hole from the outer side of the bracket and the end part of the vibration-transmitting shaft passes through the shaft hole; the end part of the vibration-transmitting shaft is connected with a vibration ring; and the vibration ring is close to the surface of the screen. A method for filtering and screening powder by using the ultrasonic vibration screen is characterized in that: the ultrasonic vibration head separated from the screen transmits vibration generated by the ultrasonic vibration head to the vibration ring through the vibration-transmitting shaft; and the vibration ring acts on the screen, so that the screen is vibrated up and down, large-particle powder is isolated by the screen, small-particle powder penetrates the screen, and the powder can be filtered and screened. By the ultrasonic vibration screen and the method for filtering and screening the powder by using the same, working efficiency is high; the screen is easy to clean and is difficult to break through vibration; and service life is long.

Owner:YU TUNG ZHONGSHAN ENG

Test device and test method for bending, fracture and creep of layered rock cantilever

InactiveCN110186779AGain long-term flexural strengthReduce frictionMaterial strength using steady bending forcesPresent methodFracture mechanics

The invention discloses a test device and a test method for the bending, fracture and creep of a layered rock cantilever. The device comprises a fixed support base, a counterforce frame, a limiting plate, a roller device, a flexible cushion layer, a weight, a connector, a screw, a non-contact displacement meter, a horizontal guide rail and non-contact strain field test equipment. By using the device, the long-term bending, fracture and creep test research of the cantilever of the rock material can be achieved, so that the long-term bending strength, deformation fracture evolution law, fracturemechanical mechanism and the like of the rock and the layered rock are acquired, and a theoretical support is provided for the long-term stable assessment on the bending and damage of the engineeringrock cantilever. The device has the advantages of convenient test operation and high measurement accuracy, meanwhile, the device is simple and reasonable in structure, small in instrument loss, low in test cost, and capable of meeting the bending and creep test requirements of the layered rock. The method is simple, quick, and accuracy to measure.

Owner:HEBEI UNIV OF TECH

A textile washing device

InactiveCN105780347BOffset the impactAvoid Stretch DeformationTextile treatment machine arrangementsTextile treatment by spraying/projectingWater flowMechanical engineering

The invention relates to the textile field and particularly relates to a textile fabric flushing device. Through the textile fabric flushing device, the textile fabric can be thoroughly cleaned, and the fabric texture can be improved while tensile deformation of the fabric caused by water flow impact and consequent influence on the fiber structure of the fabric are prevented. The textile fabric flushing device comprises a box body, wherein the box body is of a cuboid hollow structure; a partition plate is arranged in the box body; the box body is divided into two spaces by the partition plate; the partition plate is placed obliquely; a drain pipe is arranged on the side wall of the box body and communicated with the inside of the box body and positioned above the partition plate; a feed port and a discharge port are formed in the two side walls of the box body respectively and communicated with the inside of the box body and are of a rectangular structure; and a liquid box is arranged on the lower surface inside the box body and is of a cuboid hollow structure. The textile fabric flushing device has the advantages of high efficiency and low cost and is suitable for cleaning textile fabric.

Owner:苏州新德龙纺织有限公司

Perforating device

ActiveCN108405901AEasy to adjustEasy to processMetal working apparatusBoring/drilling machinesGear wheelEngineering

The invention relates to a perforating device. The perforating device comprises a machine frame and a circular sliding way. A driving mechanism is arranged on one side of the machine frame, and a drilling mechanism is arranged on the other side of the machine frame. The driving mechanism comprises two supporting platforms which are arranged in an opposite mode. A threaded rod is rotatably connected between the two supporting platforms. The threaded rod meshes with two driving gears. The driving gears are rotatbly connected to the machine frame. Through holes are formed in the driving gears. Limiting blocks are arranged on the sides of the through holes. Moving rods are movably connected into the through holes. The other ends of the moving rods penetrate through the through holes and are slidably connected into the circular sliding way. Supporting plates are arranged above the driving gears. The moving rods are rotatably connected with supporting rods. The other ends of the supporting rods are fixedly connected to the bottom portions of the supporting plates. Operation plates are arranged above the supporting plates. First cylinders are arranged at two ends of the supporting plates.Piston rods of the first cylinders are fixedly connected to the bottom portions of the operation plates. According to the perforating device, a workpiece can be drilled with different hole diameters,and the application scope is wide.

Owner:CHONGQING YOUBO MACHINERY MFG

Tandem piezoelectric directional driver

ActiveCN105846713AExtended service lifeLow working surface requirementsPiezoelectric/electrostriction/magnetostriction machinesEngineeringRobot

The invention relates to a tandem piezoelectric directional driver, which comprises a first support leg, a second support leg, a tandem piezoelectric vibrator, a first foot bearing and a second foot bearing, wherein the tandem piezoelectric vibrator is in a cylinder structure which is formed by combining a plurality of round piezoelectric vibrators, a plurality of connection rings and a connecting pole; the first support leg and the second support leg are symmetrically pasted at two ends of the tandem piezoelectric vibrator; the first foot bearing and the second foot bearing are formed by compounding two materials with different friction coefficients and are arranged on the first support leg and the second support leg respectively; the tandem piezoelectric vibrator is electrified for telescopic deformation; and the materials with different friction coefficients on the two foot bearings are in contact with the working surface, so that the directional driving capability is generated; and the tandem piezoelectric directional driver is manly applied to the field of a bionic robot, detection and rescue and the like as a driver, and has the advantages of high driving capability, high environmental adaptability and the like.

Owner:谐振机电精密技术(苏州)有限公司

Curved surface grabbing mechanism

InactiveCN105619443AAvoid rigid contactProtection from being crushedGripping headsEngineeringCushion

Owner:BOZHON PRECISION IND TECH CO LTD

Inertia piezoelectric driver

ActiveCN105915105AImprove applicabilityImprove environmental applicabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsElastic substrate

The invention relates to an inertia piezoelectric driver. The inertia piezoelectric driver comprises a piezoelectric oscillator, a mass block, a base and composite cantilevers. Two ends of the piezoelectric oscillator are respectively and fixedly connected with the mass block and the base. The composite cantilevers are of a thin sheet structure and are respectively formed by lamination of a high friction elastic material and a low friction elastic material. The friction coefficient of the high friction elastic material is larger than that of the low friction elastic material. The four composite cantilevers are arranged on the lower surface of the base. The bonding surface between a piezoelectric ceramic and an elastic substrate is perpendicular to the upper surface of the base. The intersection line between the elastic substrate and the upper surface of the substrate is parallel to the lamination surface of the high friction elastic material and the low friction elastic material. The inertia force and two different friction coefficients of the composite cantilevers are utilized to enable the driver to move upwards. As a simple piezoelectric driving device, the inertia piezoelectric driver can be applied to the fields of software robots, detection and rescue, and biomedical treatment, and the inertia piezoelectric driver has the advantages that the structure is simple, the size is small and the applicability is high.

Owner:谐振机电精密技术(苏州)有限公司

Tea leaf rolling machine

InactiveCN106472729AImprove qualityAvoid rigid contactPre-extraction tea treatmentAutomatic controlRolling disk

The invention relates to a tea leaf rolling machine, wherein a rolling disc is fixedly arranged and is connected to a rolling cylinder through a plurality of crank mechanisms, the crank mechanisms are connected to a driving device for driving the crank mechanisms to rotate, the rolling cylinder is provided with a door frame, the door frame is provided with a lifting gas cylinder, the end head of the lifting gas cylinder is connected to a pressing disc, the gas supply pipeline of the lifting gas cylinder is provided with a pressure control valve, and the pressure control valve is connected to a control device. According to the present invention, by using the structure, the automatic control of the rolling pressure is conveniently achieved; with the arranged elastic connection member, the rigid contact between the pressing disc and the rolling disc can be avoided so as to reduce the tea leaf breaking rate and improve the quality of the tea leaf; and the lifting rate of the pressing disc can be improved, and the production efficiency can be improved.

Owner:HUBEI DENGCUN GREEN TEA GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com