Tea leaf rolling machine

A kneading machine and tea technology, which is applied in the field of tea kneading processing equipment, can solve the problems of slow lifting speed of the pressure plate, long time spent, high broken tea rate, etc., and achieve the effects of improving production efficiency, improving tea quality, and increasing lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

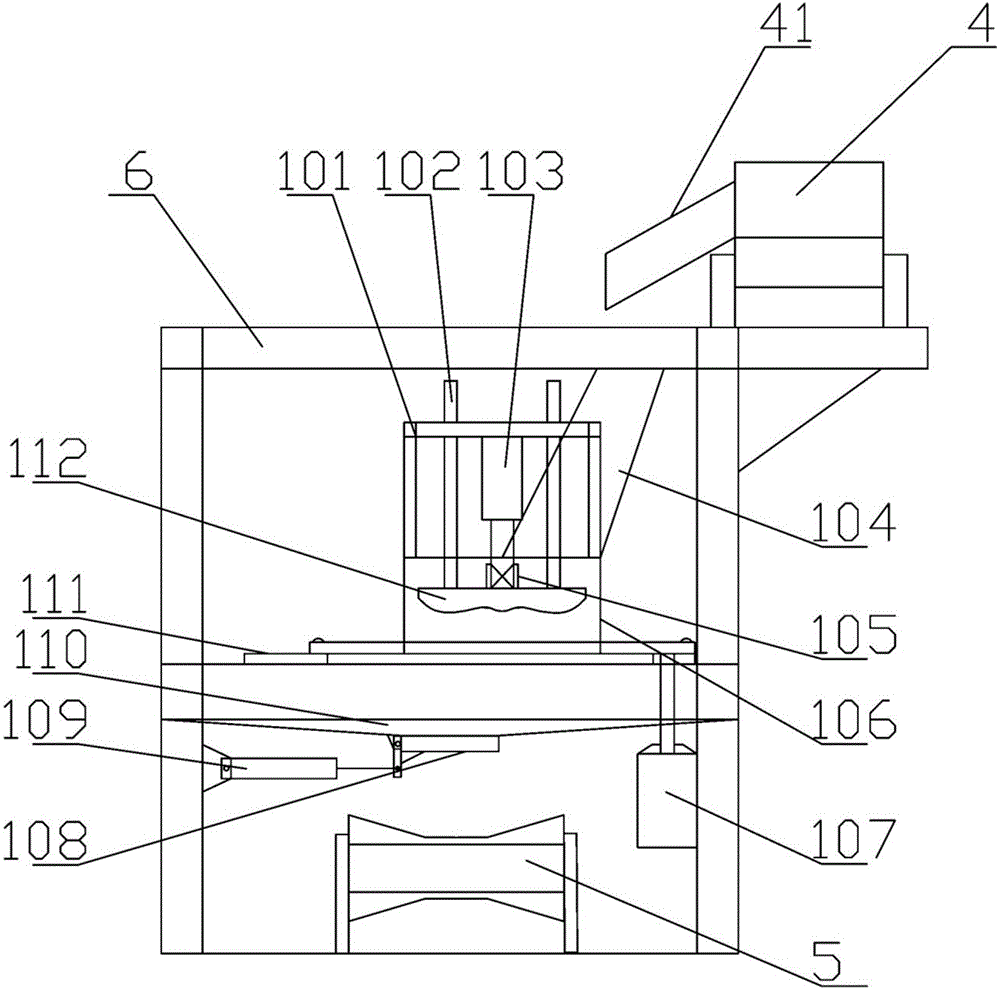

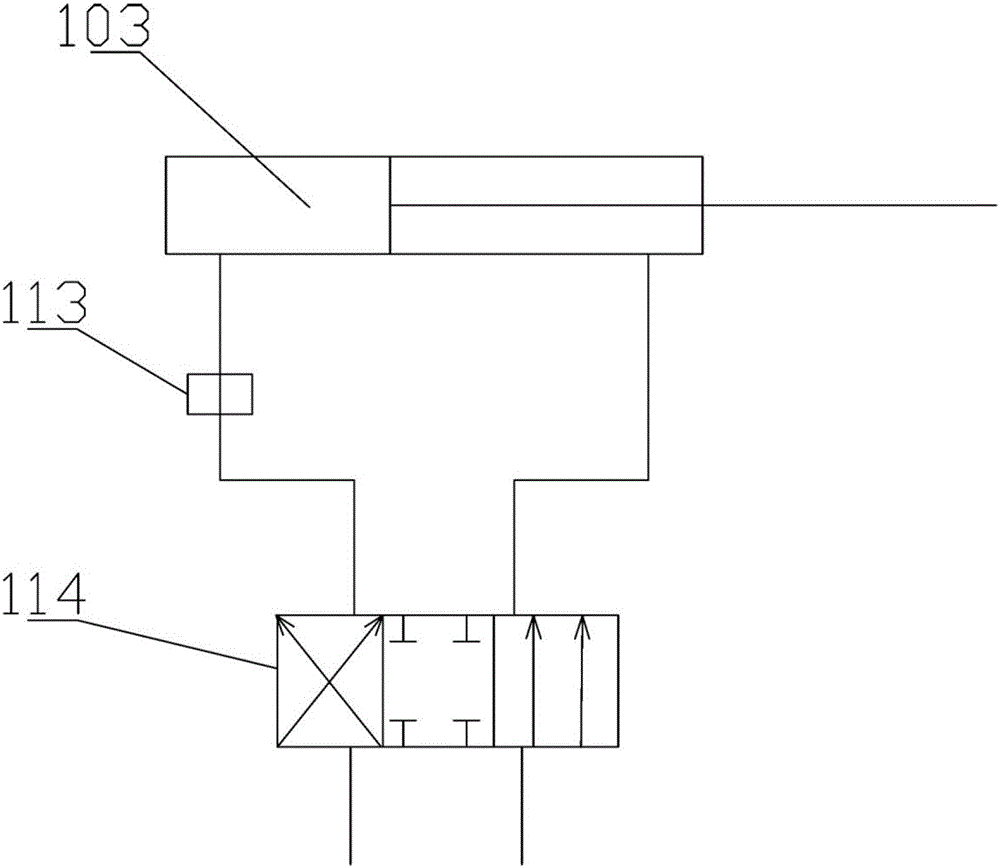

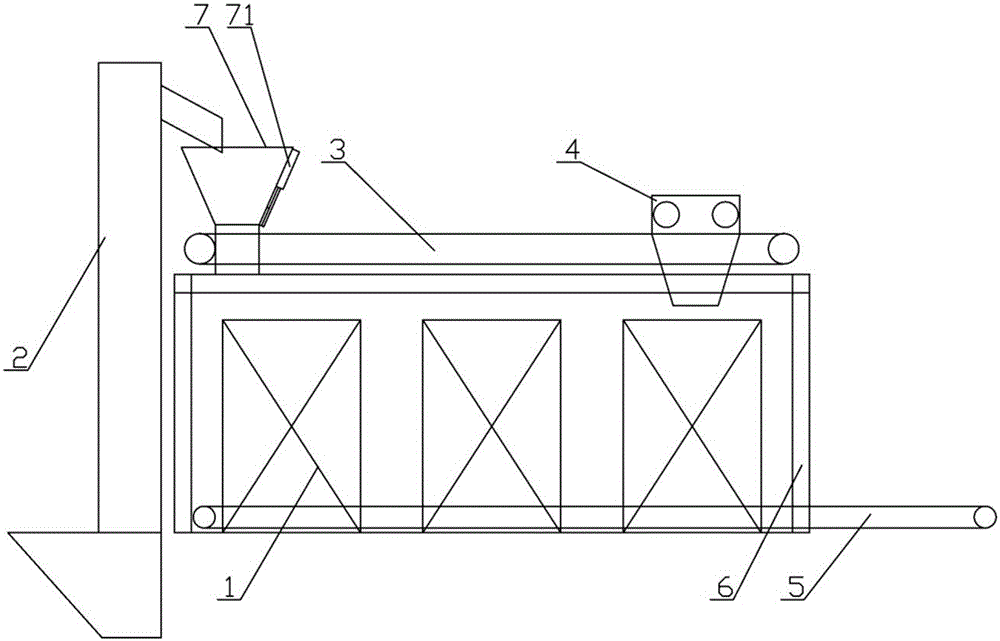

[0017] Such as figure 1 , 2 Among them, a tea kneading machine, the kneading disc 110 is fixedly installed, the kneading disc 110 is connected with the kneading cylinder 106 through a plurality of crank mechanisms 111, the crank mechanism 111 is also connected with the driving device for driving its rotation, and the kneading cylinder 106 is provided with a door Frame 101, door frame 101 is provided with lift cylinder 103, and the end of lift cylinder 103 is connected with pressure plate 112. This structure facilitates the automatic adjustment of the pressure of the pressure plate 112. Specifically, a pressure control valve 113 is provided in the air supply line of the lifting cylinder 103, and the pressure control valve 113 is connected to the control device. In this example, the pressure control valve 113 is set. In the air supply line of the lifting cylinder 103 rodless cavity. The pressure of the pressure control valve 113 is automatically controlled by the control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com