Patents

Literature

178 results about "Rolling disk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

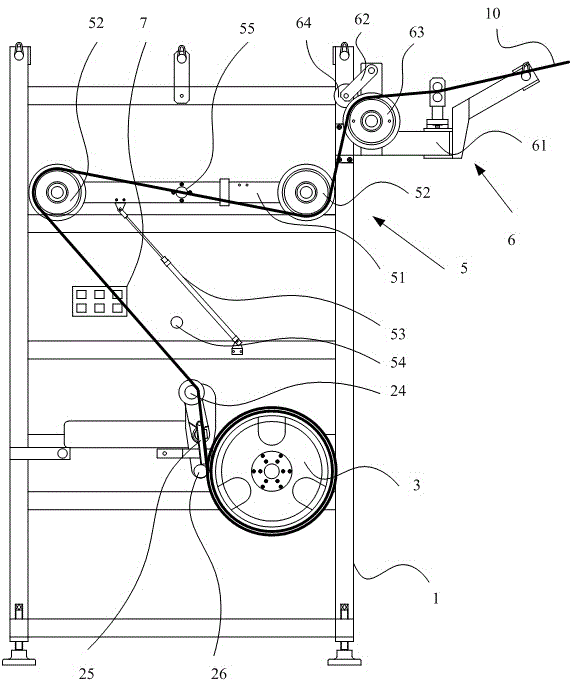

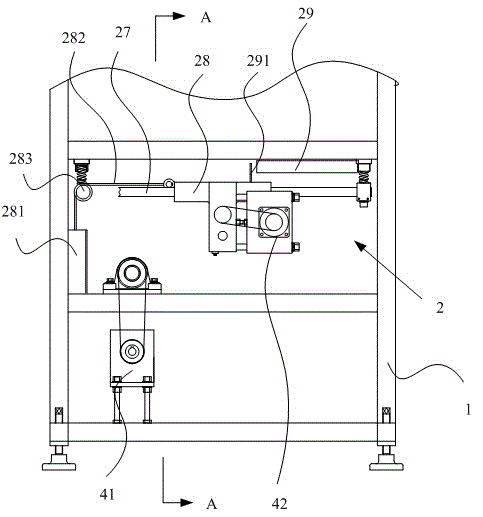

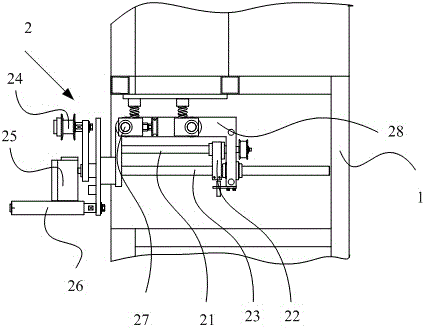

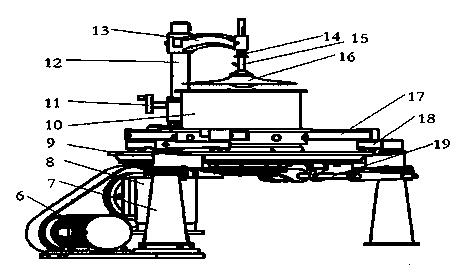

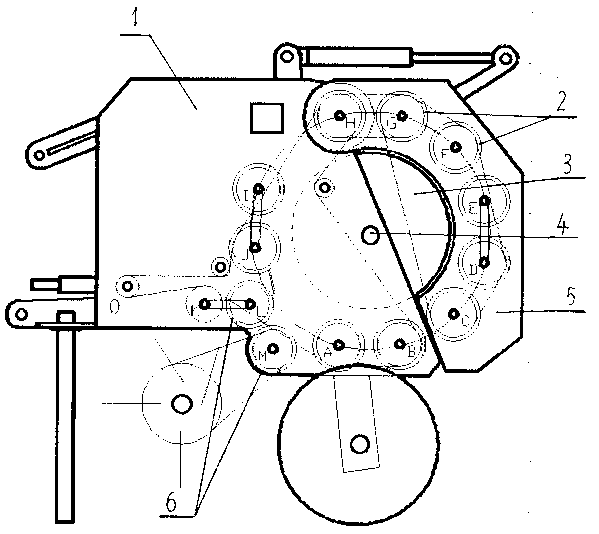

Rolling machine for packing belt

The invention provides a rolling machine for a packing belt. The rolling machine comprises a bracket, a servo winding displacement mechanism, a rolling disk, a motor and a servo motor, wherein the rolling disk is rotatably connected to the bracket, and the motor is in transmission connection with the rolling disk. The rolling machine also comprises a tension control mechanism arranged above the rolling disk, wherein the tension control mechanism comprises a swinging arm, a tensioning wheel and a first cylinder, the tensioning wheel and the first cylinder are arranged on two end parts of the swinging arm, the swinging arm is hinged on the bracket, one end of the first cylinder is connected to one end part of the swinging arm, the other end of the first cylinder is connected to the bracket, the servo winding displacement mechanism comprises a ball screw, a ball nut, a connecting rod and a guide wheel, the ball screw is rotatably connected to the bracket, the ball nut is threaded to the ball screw, the servo motor and the ball screw are in transmission connection with the connecting rod and are fixed on the ball nut, one end of the connecting rod penetrates through the first location hole arranged in the bracket and is connected with the guide wheel, and the guide wheel is arranged on one side of the rolling disk. According to the invention, the reliability of the rolling machine for the packing belt is improved.

Owner:QINGDAO XINDACHENG PLASTIC MACHINERY

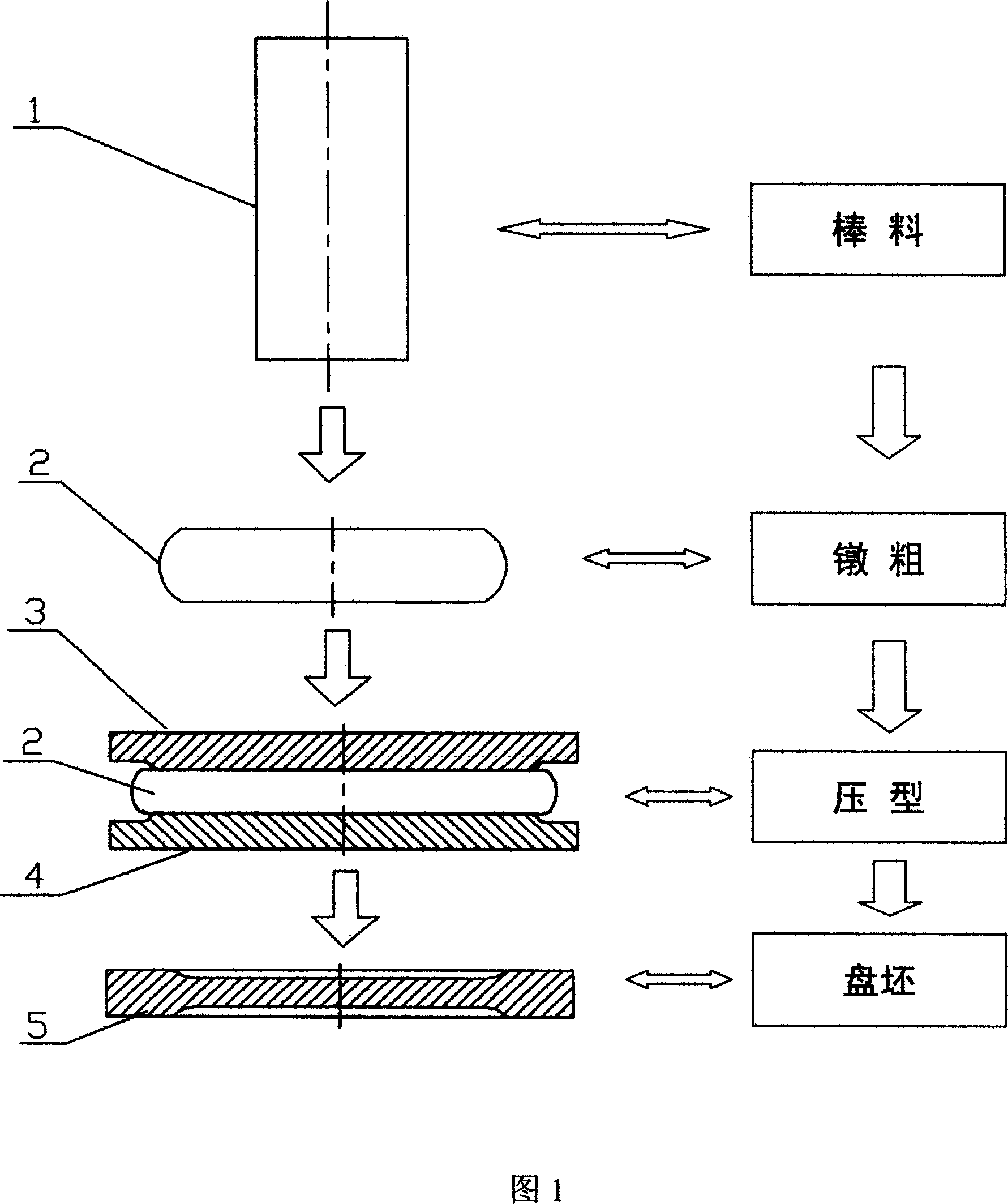

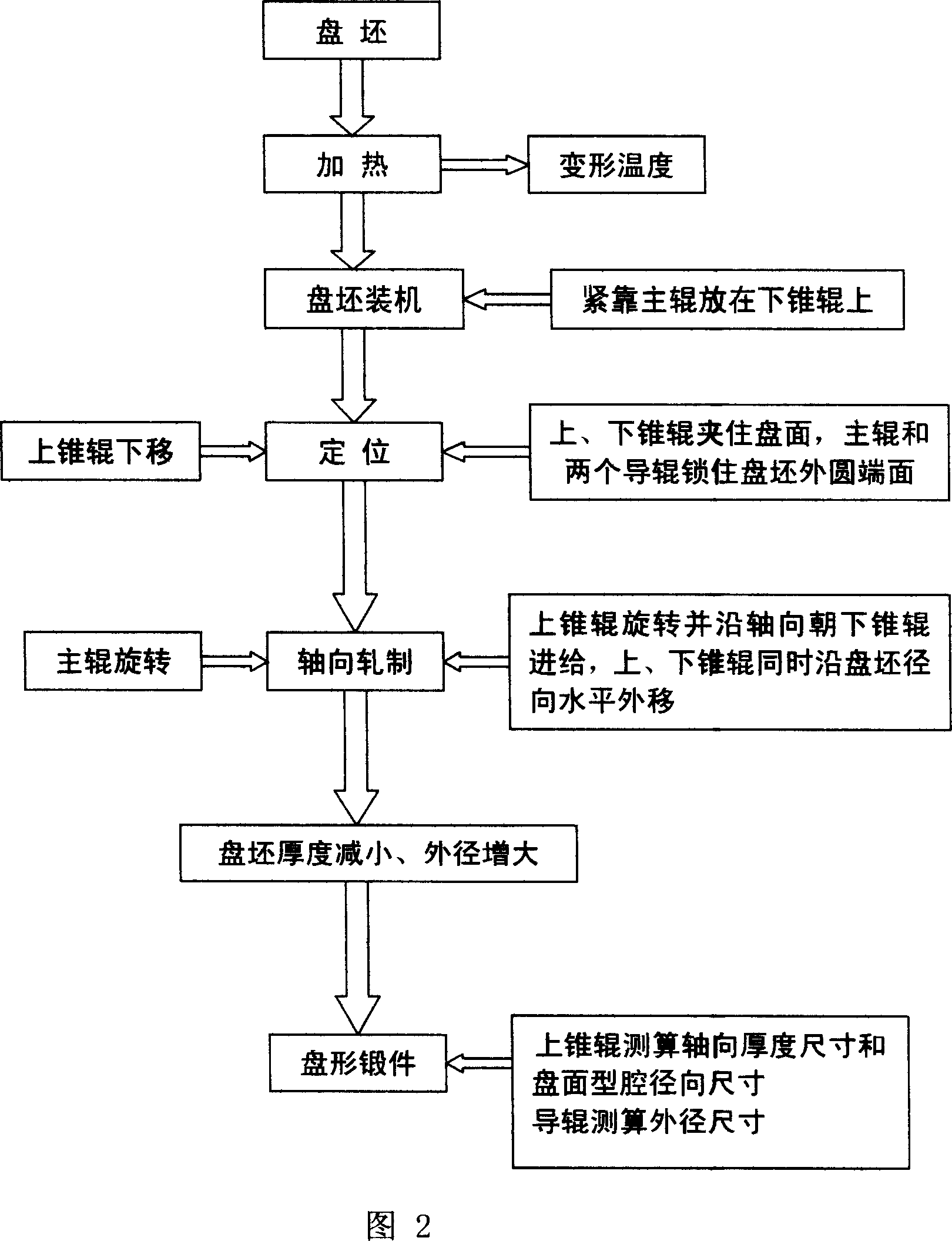

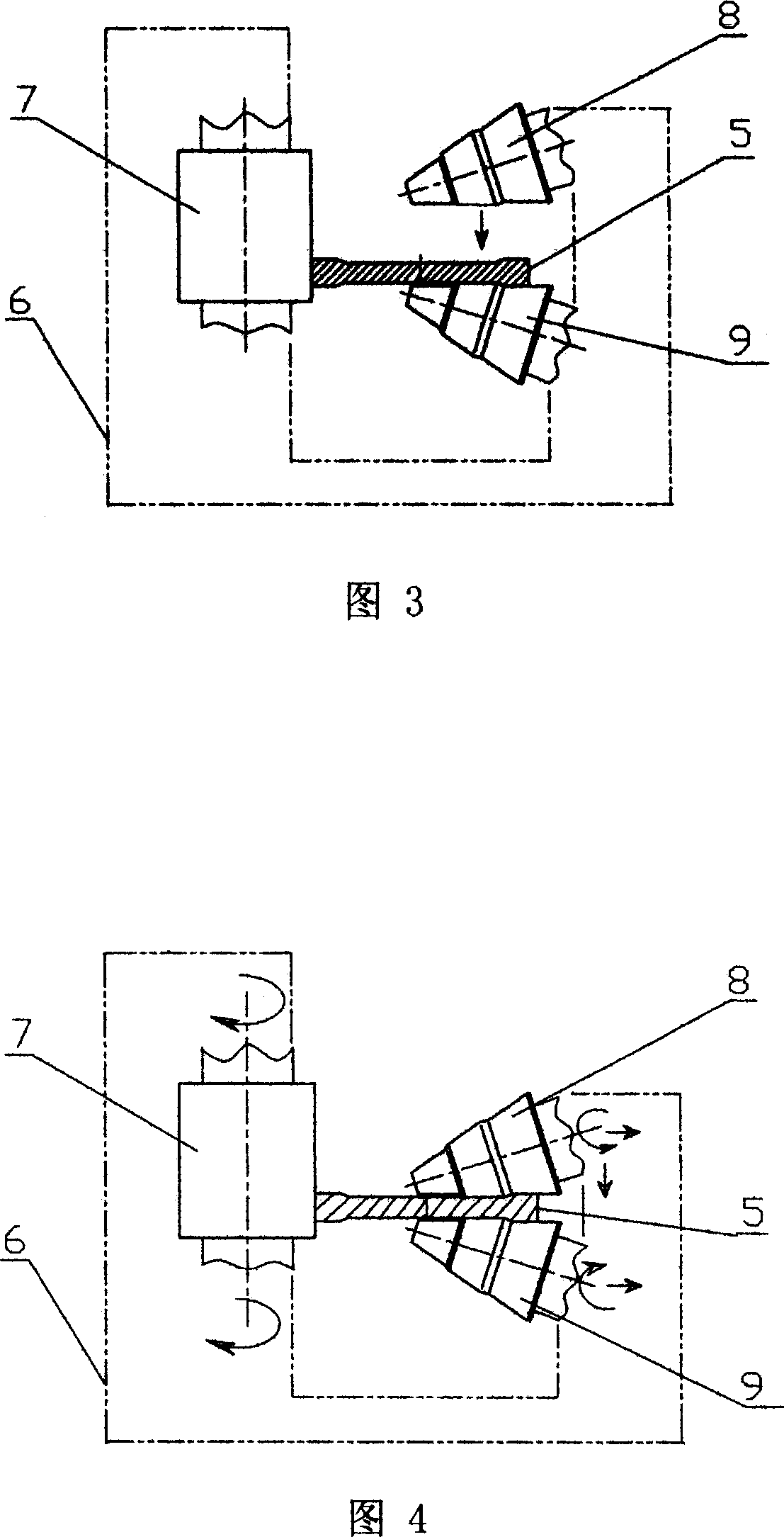

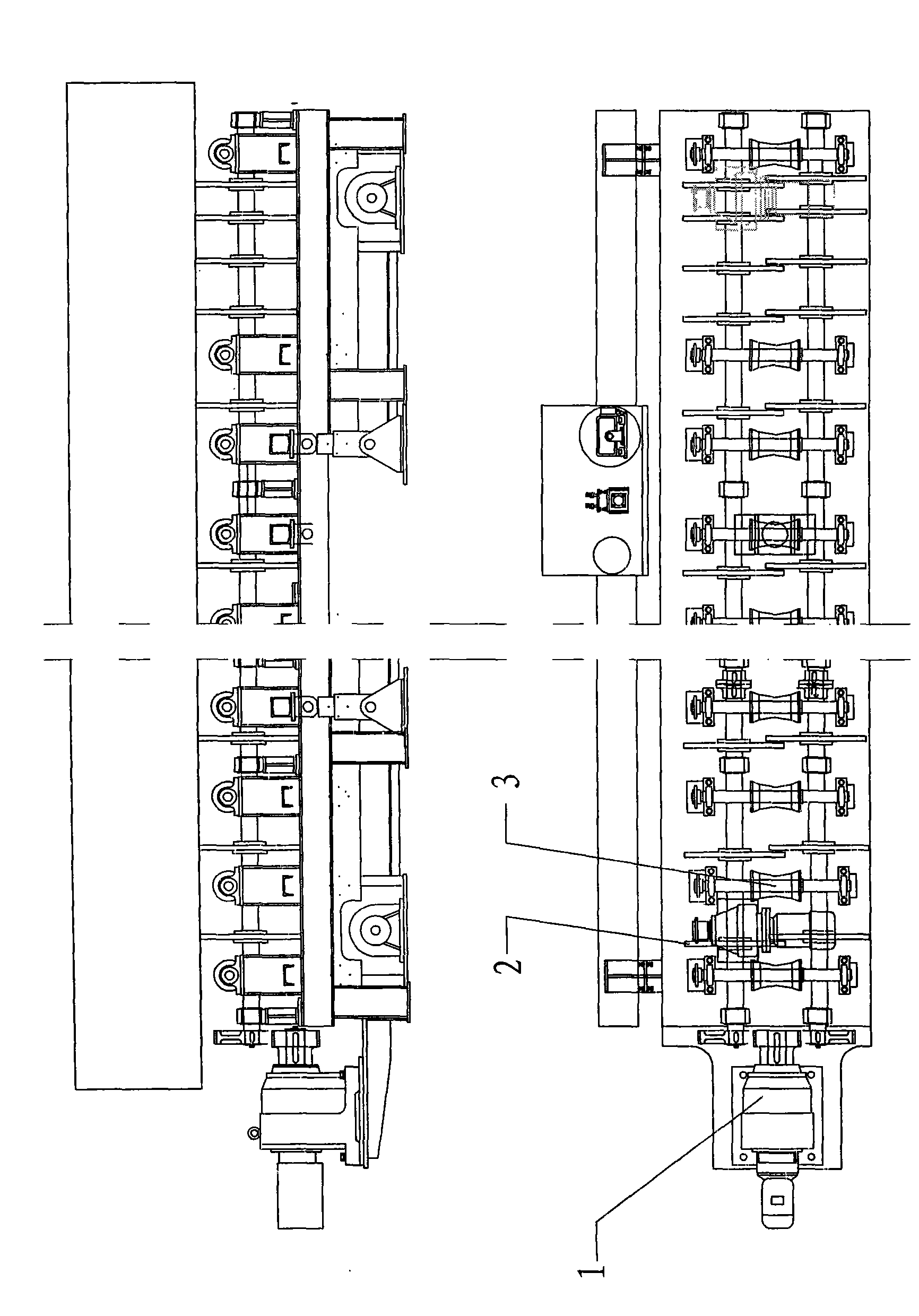

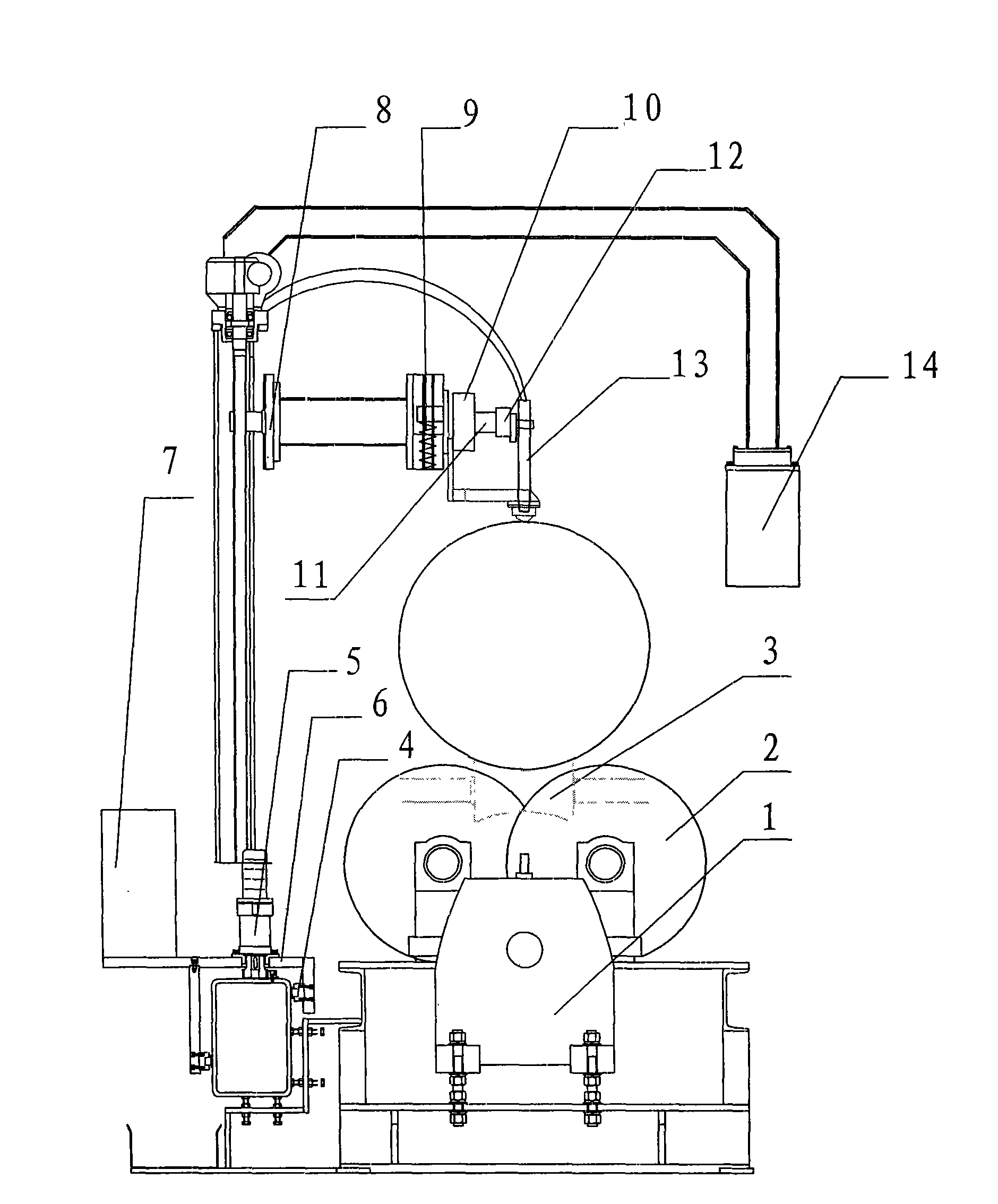

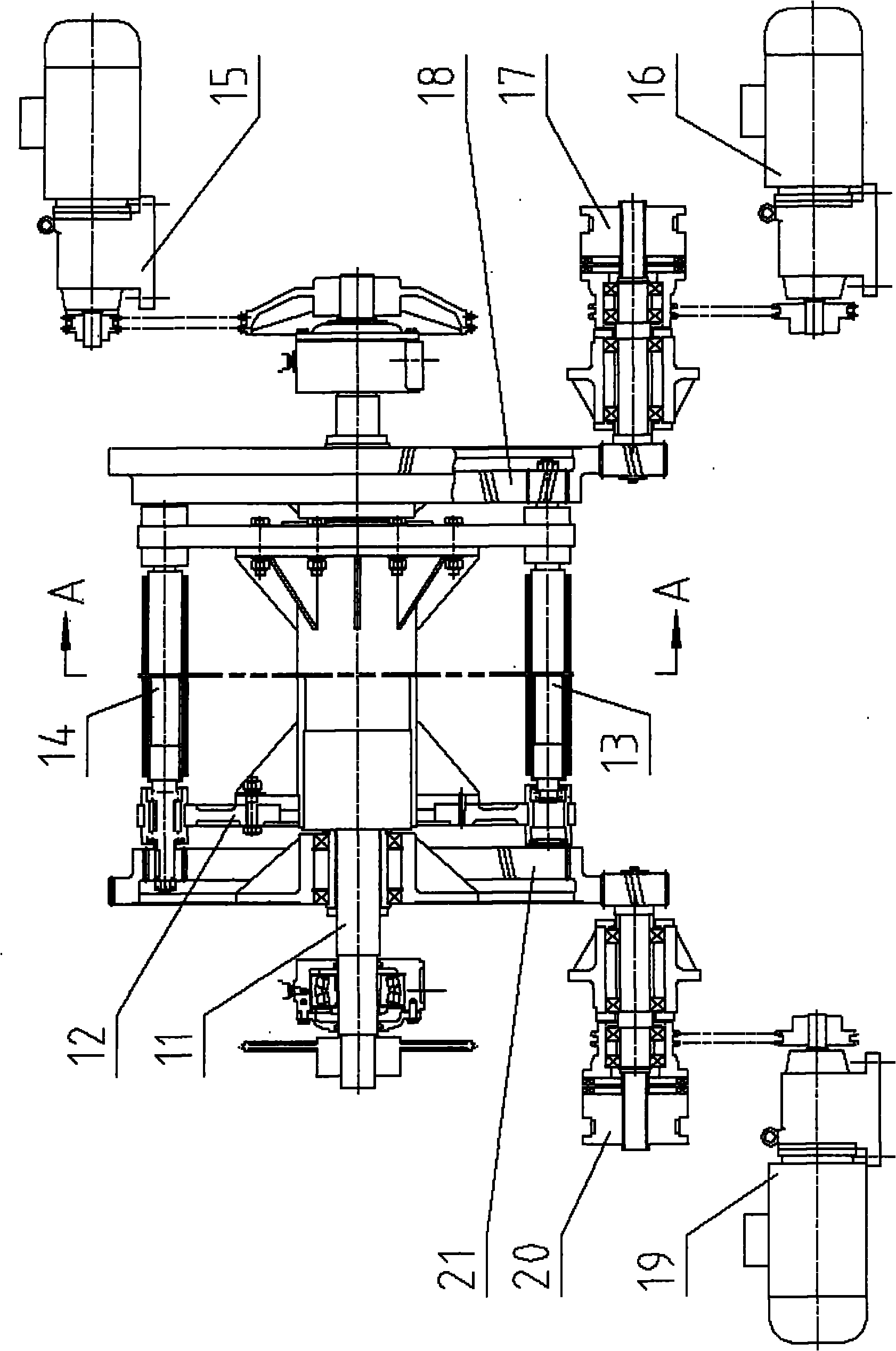

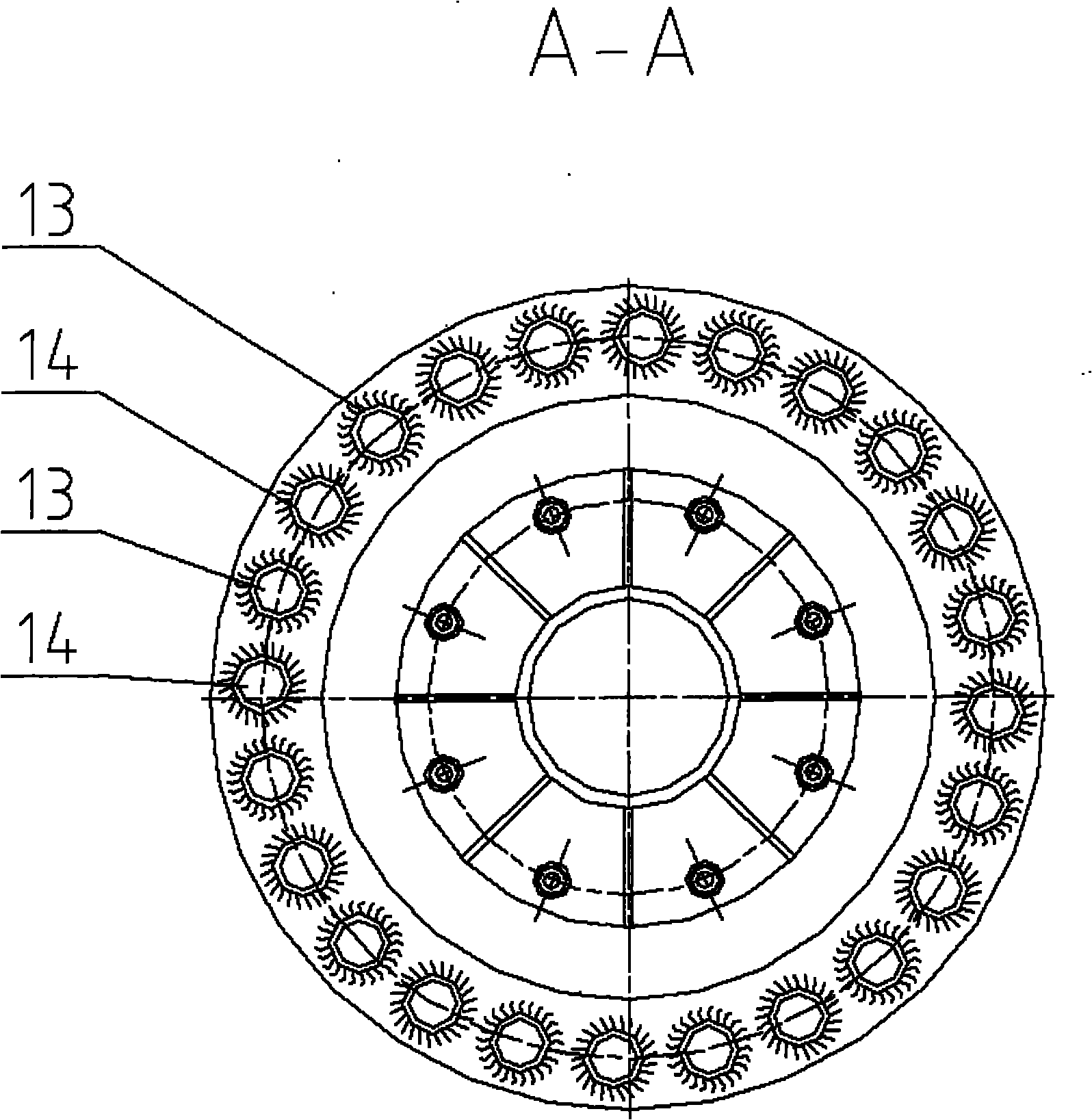

Rolling formation method for large and medium size solid plate-shape forge piece

ActiveCN1978125AAchieving continuous local plastic deformationAccording to the law of least resistanceRoll force/gap control deviceMeasuring devicesRolling diskRoll forming

The present invention relates to a roll-forming method of large-medium-size solid disk-shaped forge piece. Said rolling process includes the following steps: deforming metal rod material, heating, upsetting (pressure machine), cake blank, press moulding (pressure machine), solid disk blank, heating, loading and positioning (rolling machine), axial rolling (rolling machine), measuring and calculating size and obtaining solid disk-shaped forge piece. Its axial rolling force is 2X100000 kg-5X100000 kg, and its widening speed is 5 mm / s-15 mm / s. the rolled disk-shaped forge piece size is as follows; outer diameter is 800 mm-3000 mm and its axial thickness is 30 mm-250 mm.

Owner:GUIZHOU ANDA AVIATION FORGING

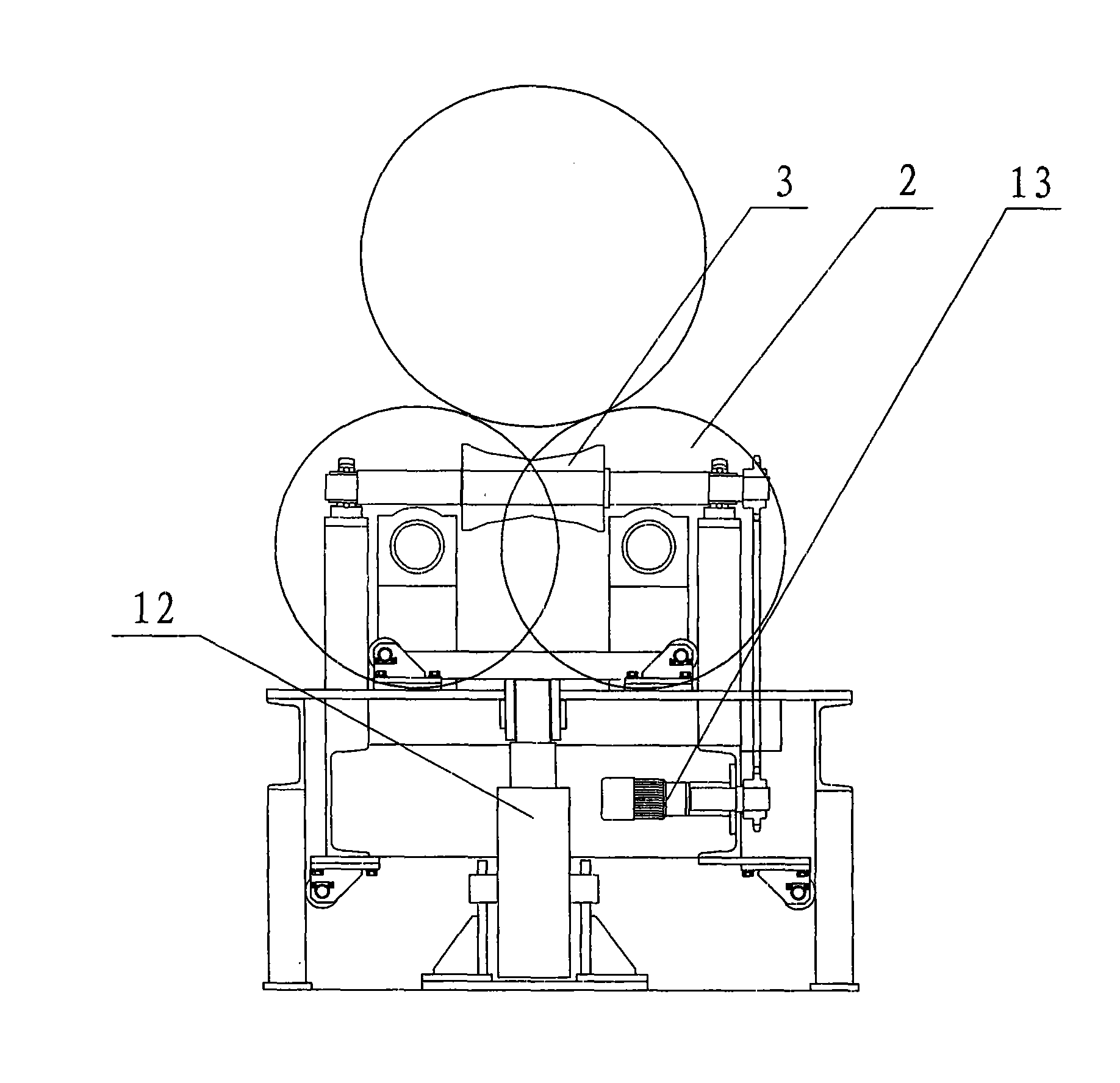

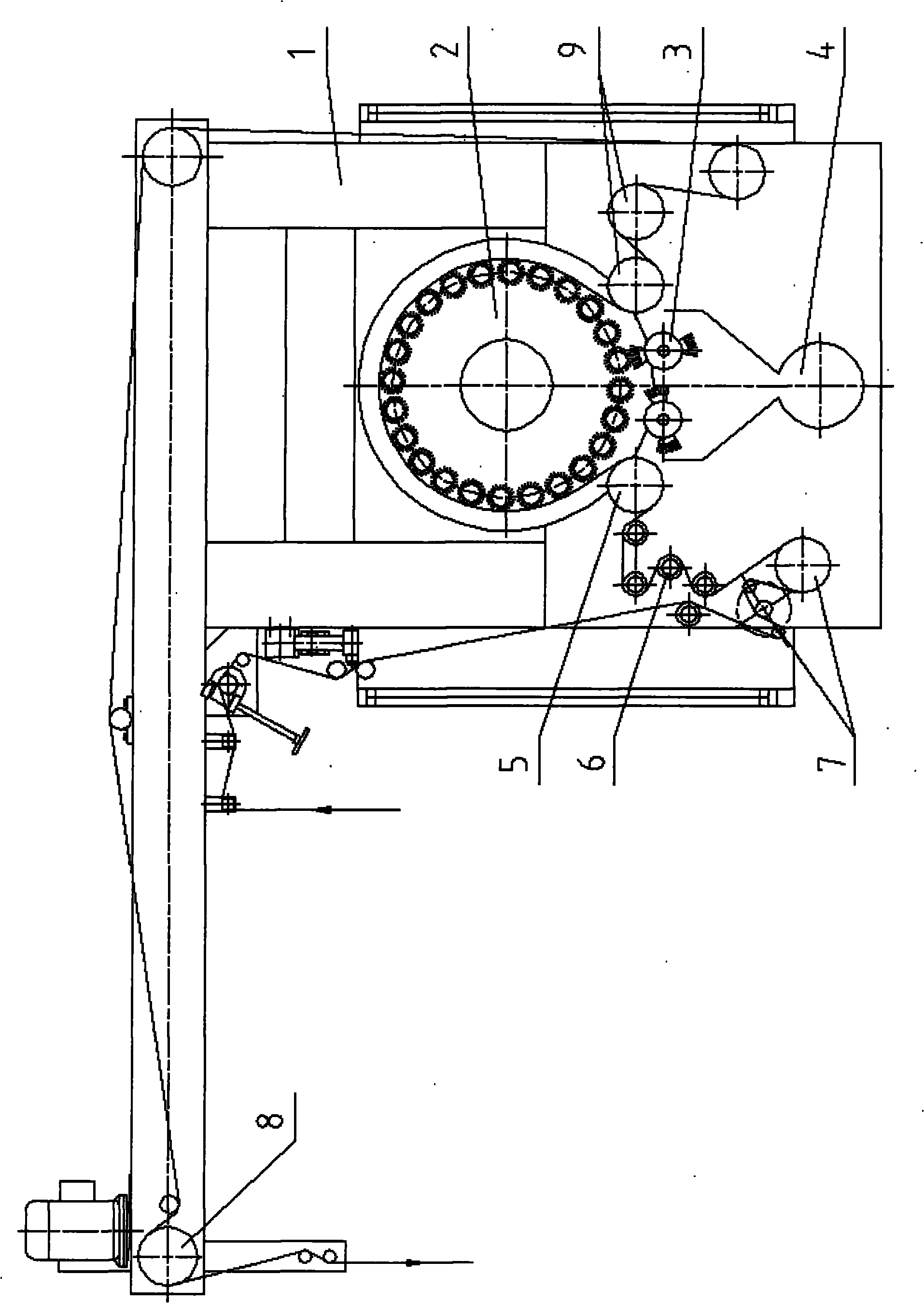

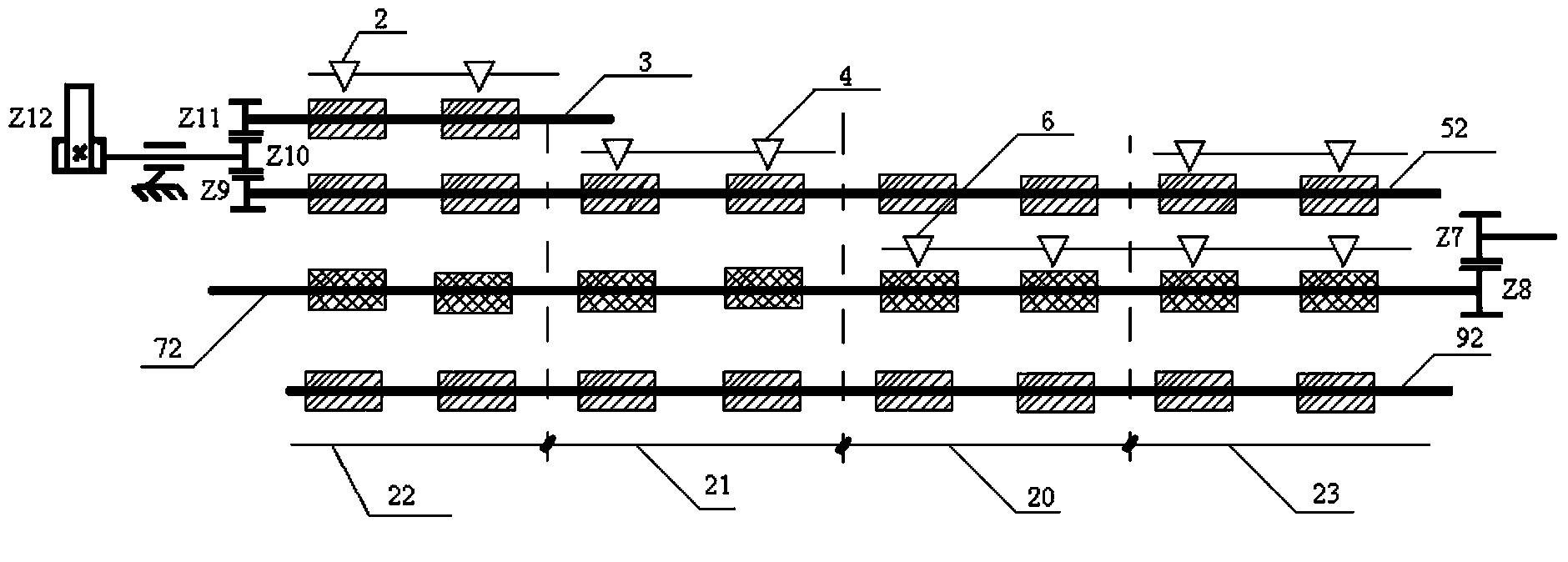

Rolling disc type two-axis numerical control pipeline cutting machine

InactiveCN101653872ARealize flow operationImprove cutting efficiencyWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlRolling disk

The invention discloses a rolling disc type two-axis numerical control pipeline cutting machine which is characterized by comprising a numerical control controller, a plasma power supply, a pair of rolling discs and a revolving device thereof, a lifting conveying roller way arranged on the machine station working face, a liner guide rail arranged at the horizontal lateral of the machine station working face, a trolley, an axial shifter and a cutting unit with adjustable height, wherein the pair of rolling discs and the revolving device thereof are arranged at the same horizontal height on themachine station working face; the trolley and the axial shifter are slidingly connected with the liner guide rail, the cutting unit is arranged in an integration way with the trolley and is arrangedabove the rolling discs, and the sliding direction of the trolley is parallel to the axial direction of the rolling discs. The rolling disc type two axis numerical control pipeline cutting machine isapplied to carry out cutting operation on a process pipeline, the rolling discs are driven by a numerical control driver to drive the pipeline to revolve and the trolley to axially move, thereby realizing two-axis program motion, finishing continuous cutting work and intersecting line cutting work of a pipe fitting, and having higher cutting efficiency and cutting accuracy. In addition, combined with a logistics conveying roller way, the invention can realize batch streamline cutting processing of the pipe fitting.

Owner:NANJING AUTO ELECTRIC

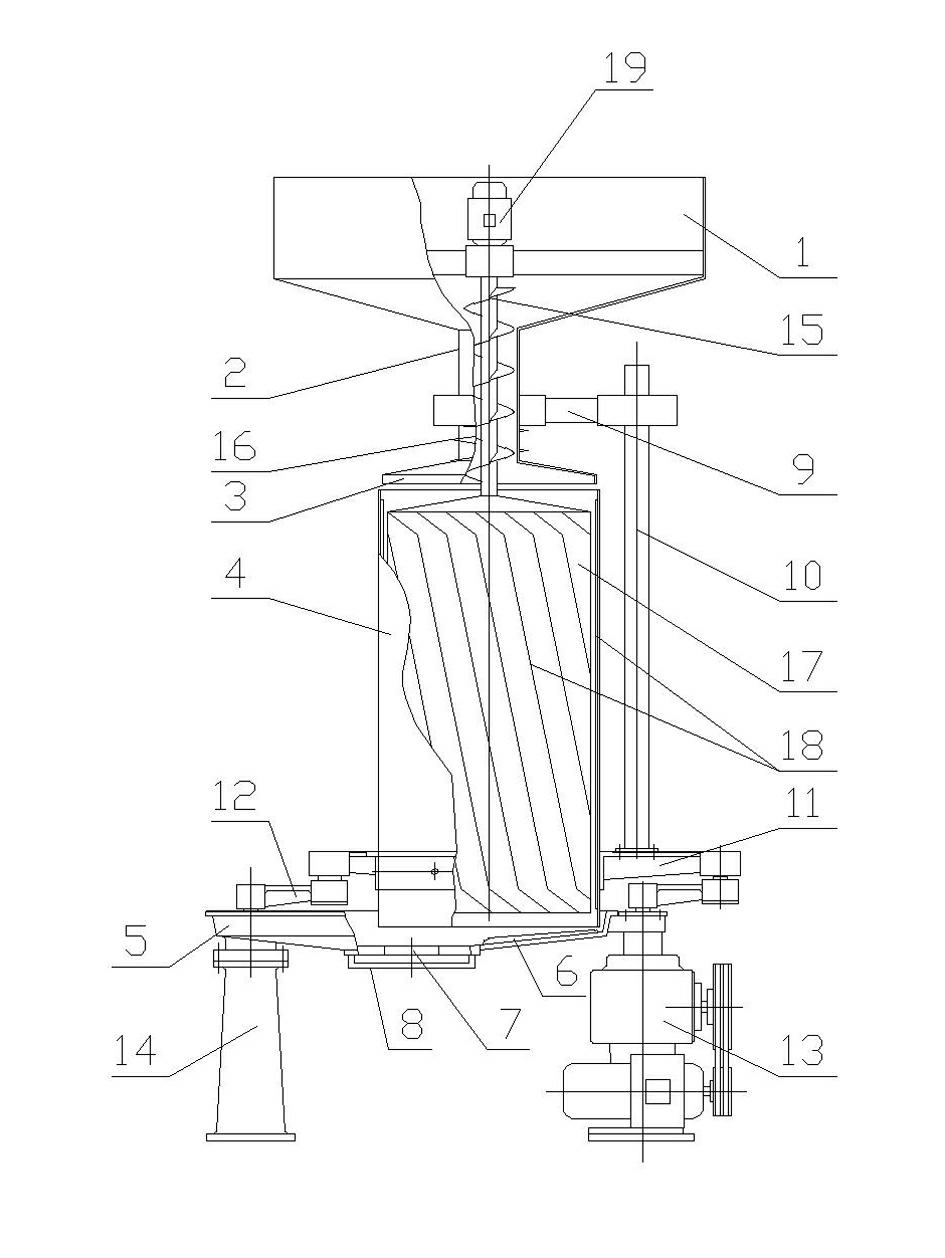

Tea leaf rolling device capable of realizing continuous feeding and discharging

ActiveCN102578311AImprove qualityUniform kneading qualityPre-extraction tea treatmentRolling diskEngineering

The invention relates to a tea leaf rolling device capable of realizing continuous feeding and discharging, which comprises a rack, a power transmission mechanism and a rolling disc. A tea outlet is arranged at the bottom of the rolling disc. A feed hopper is arranged above a rolling barrel. The feed inlet of the feed hopper is connected with a central feed pipe. A gland is arranged between the central feed pipe and the rolling barrel. A rotating shaft with an auger blade is arranged in the center of the feed hopper and the central feed pipe. A rotating roller which is provided with a closed upper end and a closed lower end and is coaxial with the rolling barrel is arranged at the lower end of the rotating shaft. Inclined rolling ribs are respectively distributed on the inner wall of the rolling barrel and the outer wall of the rotating roller. The inner wall of the rolling barrel and the outer wall of the rotating roller form a long and narrow primary rolling area. Under the drive of the auger blade of the rotating shaft, a feeding device can realize continuous tea leaf feeding, tea leaves are continuously and primarily rolled in the long and narrow rolling area, then the tea leaves are re-rolled, the machine is not required to be shut down during processing and continuous rolling is realized; and the rolling pressure and the rolling time are comparatively consistent, the tea leaf rolling quality is even, the rolling speed is fast and the promotion of tea leaf quality is facilitated.

Owner:ZHEJIANG ZHUFENG MACHINERY

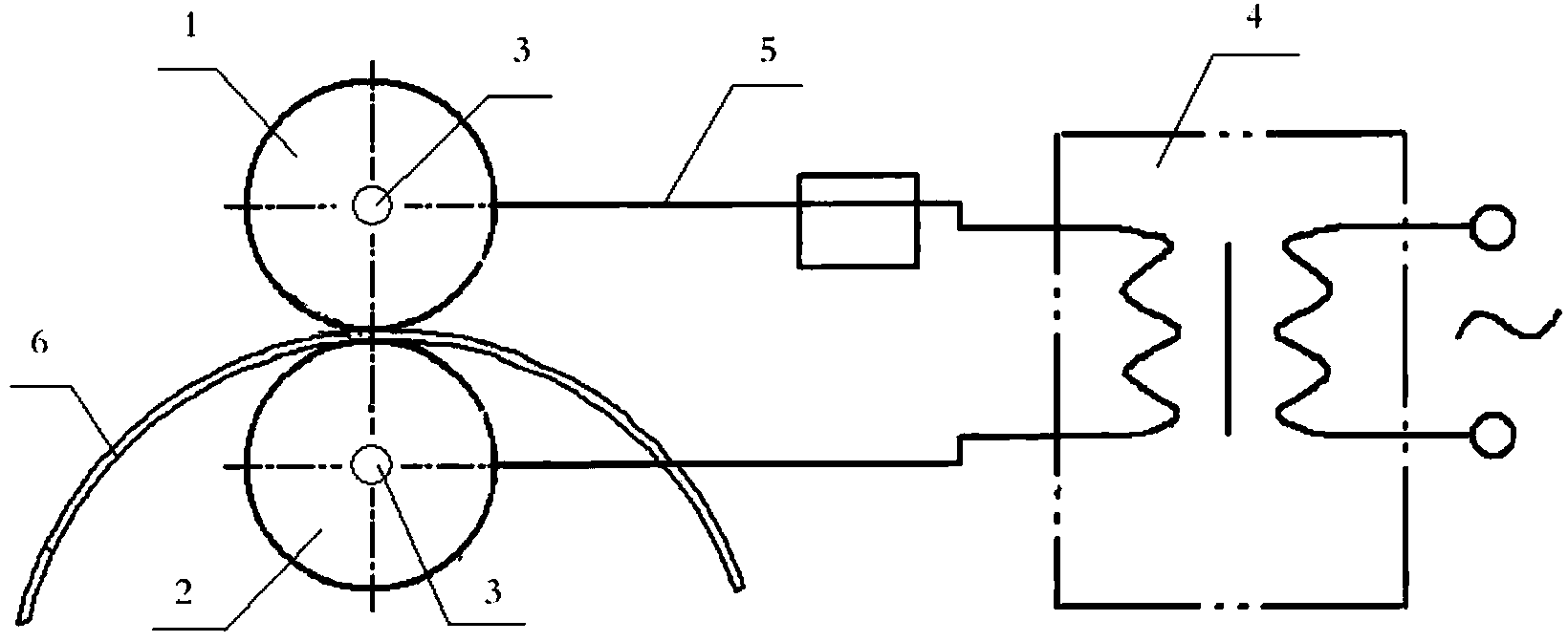

Deformation correcting method of circumferential weld of thin-wall titanium alloy welding casing

The invention relates to a deformation correcting method of the circumferential weld of a thin-wall titanium alloy welding casing. According to the technical scheme, the method is implemented through a hot rolling correcting device which is composed of an upper rolling disc, a lower rolling disc, pressurizing mechanisms, a power supply and a circuit; the method comprises the following steps of pressurization, electric heating and rolling. The deformation correcting method of the circumferential weld of the thin-wall titanium alloy welding casing can effectively reduce the material strength of deformed portions, improve material plasticity and accordingly correct the deformed portions and meanwhile avoid correcting cracks, and can meet the quality requirements of repairing and remedying failure parts of the thin-wall titanium alloy welding casing of an aero-engine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

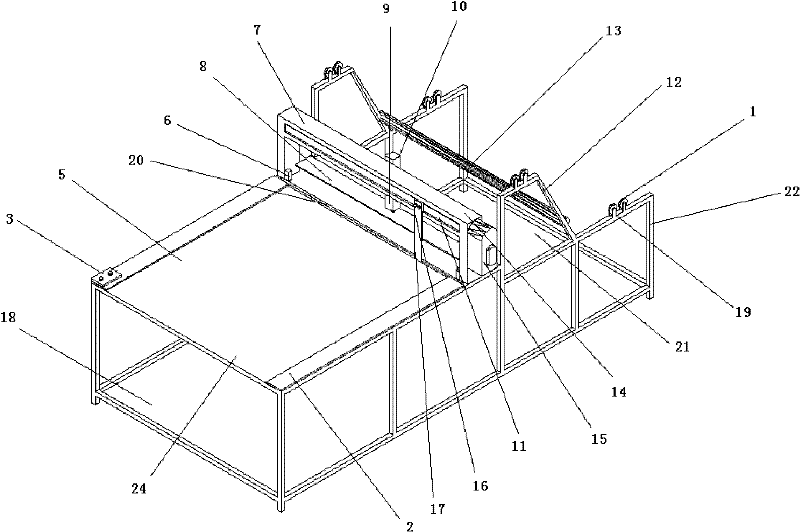

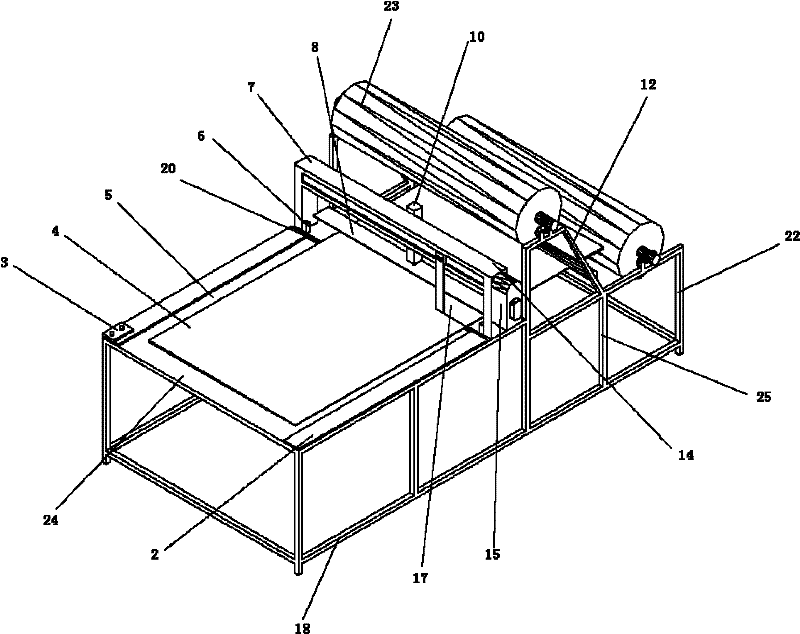

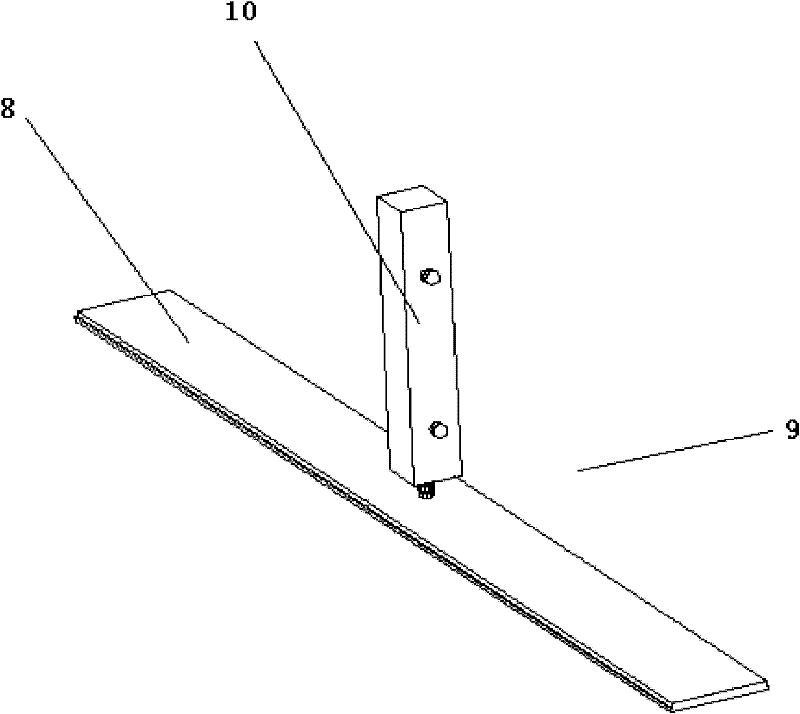

Semi-automatic clipping device for solar energy packaging material

ActiveCN102248547AReduce configurationReduce labor costsMetal working apparatusPolyesterRolling disk

The invention relates to a semi-automatic clipping device for a solar energy packaging material. The device comprises a base frame, wherein a platform part is formed on the upper end face of the base frame; a cutting mechanism for cutting the solar energy packaging material is arranged on the platform part; and a lifting support mechanism for placing the packaging material is arranged on the baseframe corresponding to one side of the cutting mechanism. In the device, the cutting mechanism is arranged on the platform part corresponding to the lateral upper side of a cutting slot, the lifting support mechanism is arranged on the platform part corresponding to one side of the cutting mechanism, and a material rolling disc can be supported by the lifting support mechanism; during operation, tedlar polyester tedlar (TPT) / ethylene vinyl acetate (EVA) materials are pressed by a pressing mechanism and then are cut by the cutting mechanism according to a specified length; the whole operation process can be finished by one person, so that labor cost is reduced due to low personnel configuration, and unnecessary waste is reduced and clipping efficiency and yield are improved due to a small number of clipping errors; and the device has a simple structure and a wide application range, is convenient to use and operate and is safe and reliable.

Owner:江苏润达光伏无锡有限公司

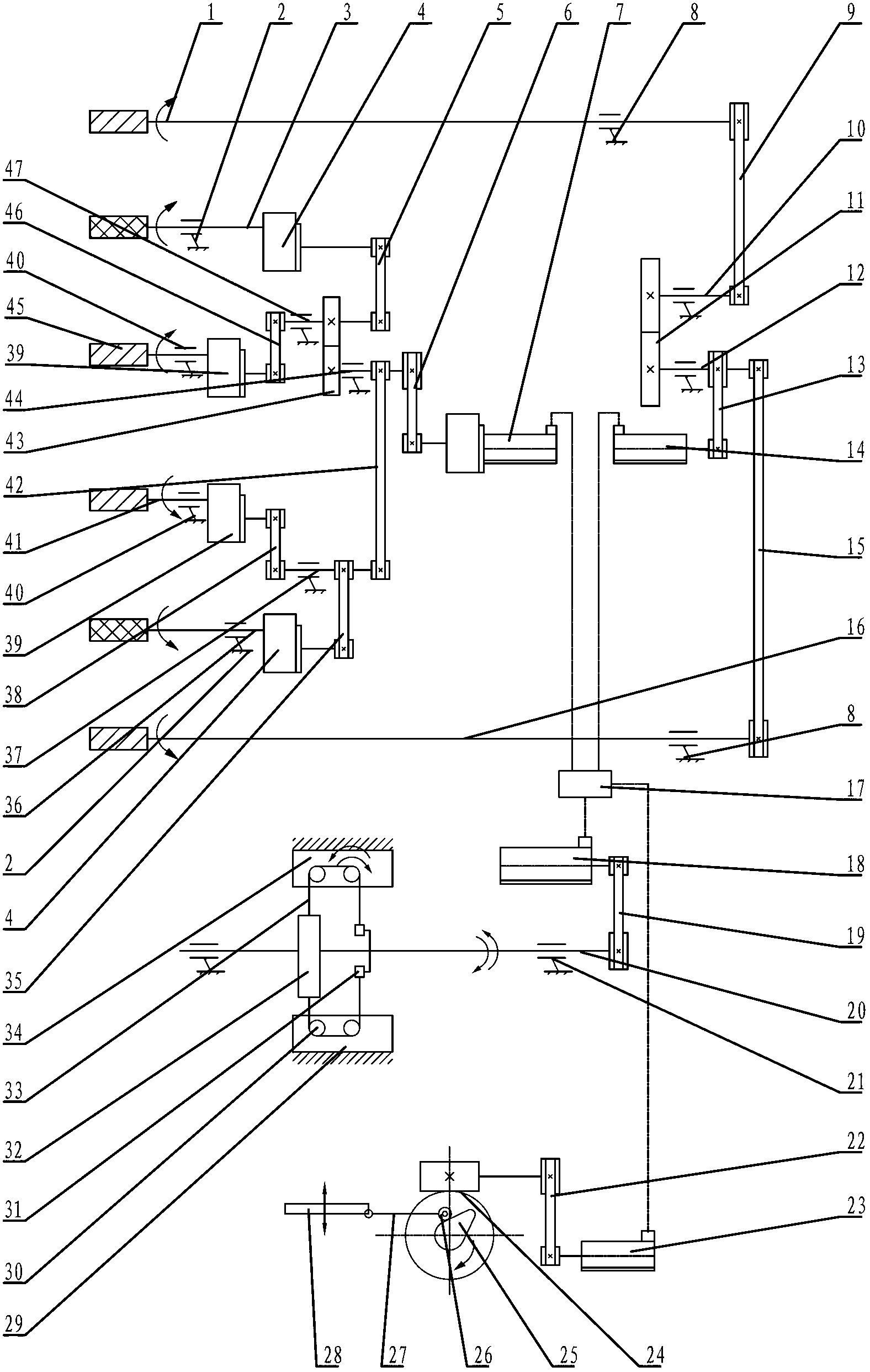

Driving device for wool spinning machine

ActiveCN102704059AReduce labor intensityReasonable structureContinuous wound-up machinesGear driveGear wheel

The invention relates to a driving device for a wool spinning machine. After a front roller motor decelerates, one path of front roller motor subjected to deceleration is connected with a front-right roller through the driving of a first belt; the other path of front roller motor subjected to deceleration is connected with a front-left roller through driving of a first intermediate gear pair and a second belt; after a rear-middle roller motor decelerates, one path of rear-middle roller motor subjected to deceleration is connected with an intermediate roller gearbox through driving of a third belt and a fourth belt; the other path of rear-middle roller motor subjected to deceleration is connected with the intermediate roller gearbox through driving of a second intermediate gear pair and a fifth belt; left and right intermediate rollers are connected with the intermediate roller gearbox; the third belt drives to be connected with a rear roller gearbox through the driving of a sixth belt; the second intermediate gear pair is connected with a rear roller gearbox through driving of a seventh belt; left and right rear rollers are connected with the rear roller gearbox; after a main motor decelerates, the main motor subjected to deceleration is connected with a spindle through a spindle belt via a main shaft and a rolling disk; and a lifting motor subjected to deceleration is connected with a ring rail through a worm gear and worm transmission pair, a stroke cam, a cam roller and a swing rod. The driving device disclosed by the invention has the advantages of simple structure, reduced amount of driving mechanisms and reduction of production cost.

Owner:常州市同和纺织机械制造有限公司

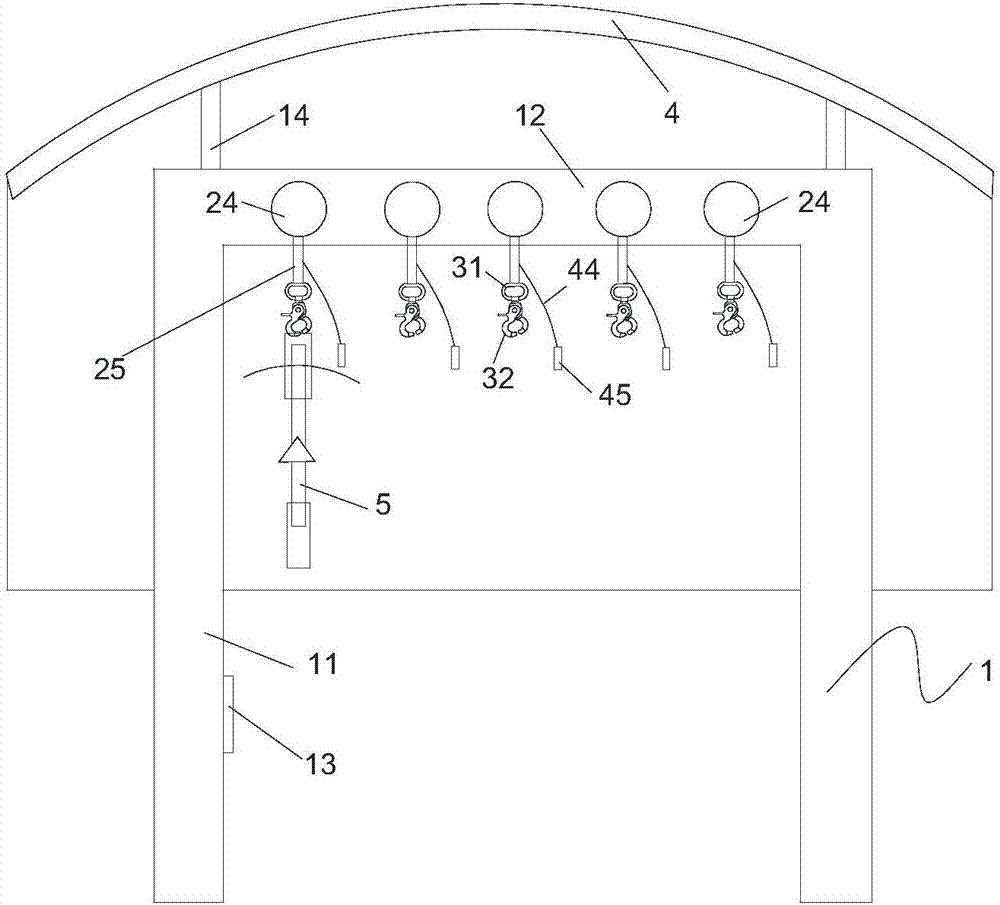

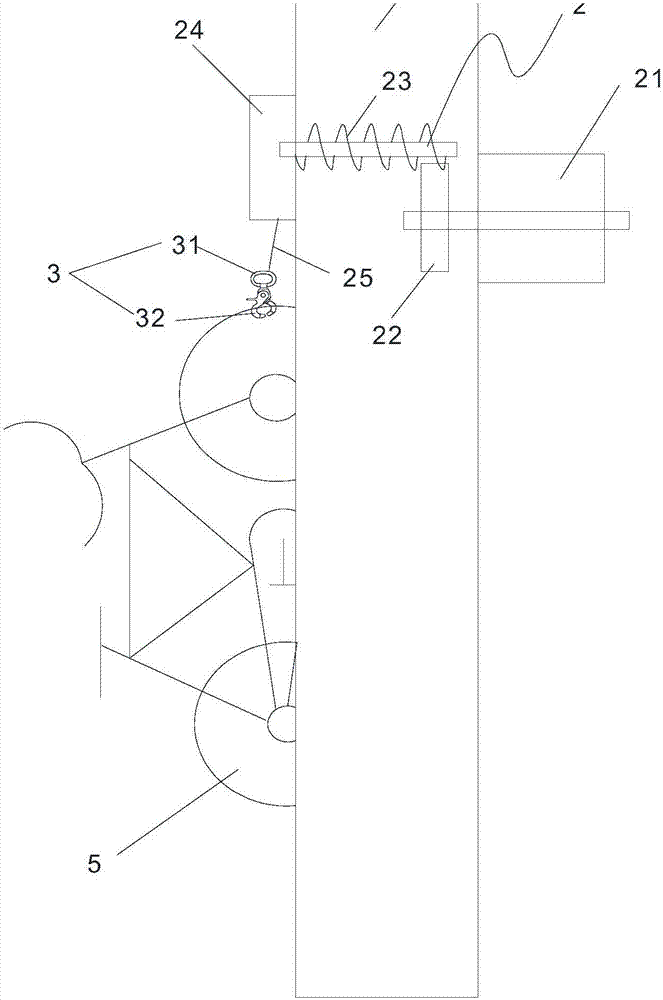

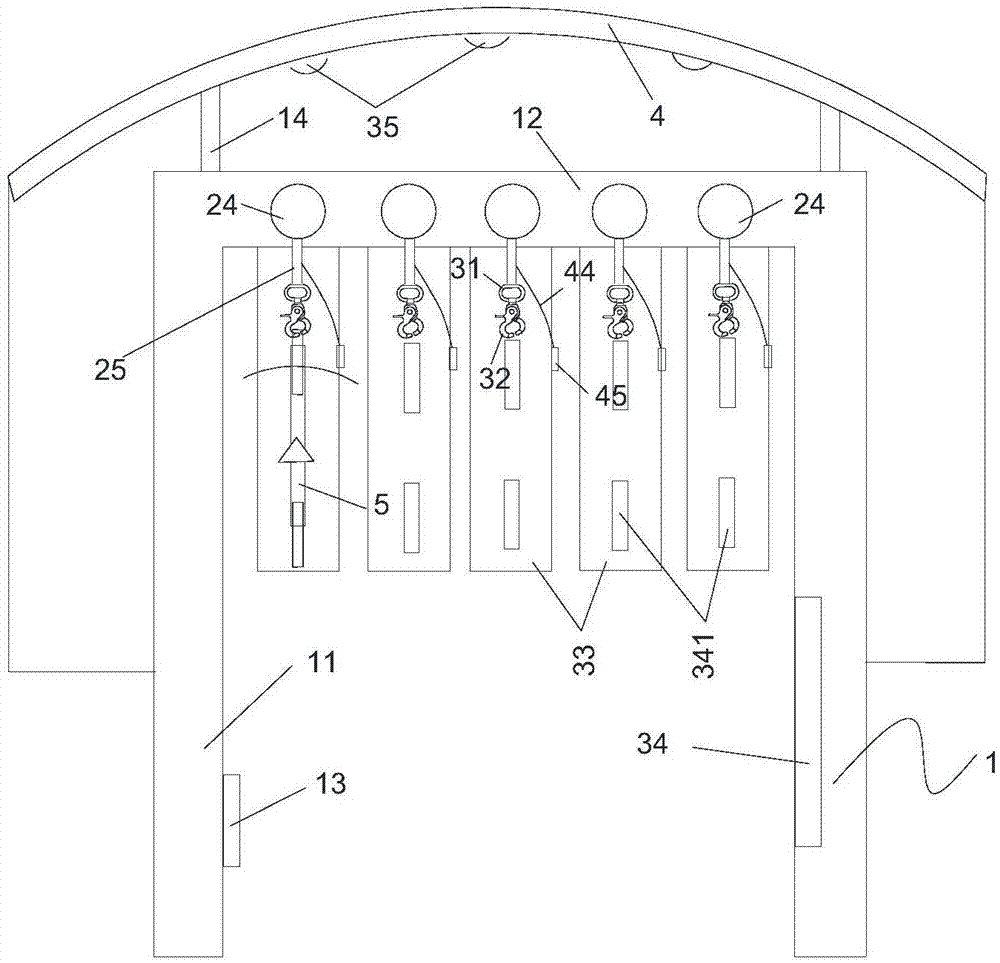

Multifunctional intellectualized shared bicycle deposit kiosk

InactiveCN107060404ASolve the problem of parking without taking up sidewalksEasy to storeRoof covering using slabs/sheetsRoof covering using tiles/slatesRolling diskComputer module

The invention relates to a multifunctional intellectualized shared bicycle deposit kiosk. The multifunctional intellectualized shared bicycle deposit kiosk comprises doorframe type supports arranged on the two sides of a sidewalk in a cross mode. A plurality of worm wheel and worm mechanisms are arranged on cross frames at the tops of the doorframe type supports, each worm wheel and worm mechanism comprises a motor, a turbine and a worm, the motors are arranged on the outer sides of the cross frames, and the turbines and the worms are arranged in cavities of the inner portions of the cross frames; motor shafts of the motors are connected with the turbines, and winding rolling disks are arranged on the end portions of the worms; the winding rolling disks are located on the outer sides of the cross frames, wire cables are wound on the winding rolling disks, and an assembly used for fixing shared bicycles is fixed to the tail portion of each wire cable; and supporting rods are vertically arranged on the peripheries of the cross frames of the doorframe type supports upwards, a mask body is erected on each supporting rod, and the peripheries of the tail portions of the mask bodies overshadow the tail portions of the shared bicycles after being deposited. According to the multifunctional intellectualized shared bicycle deposit kiosk, bicycles can be deposited well, and positioning modules or other parts of the bicycles can be charged.

Owner:张泽坤

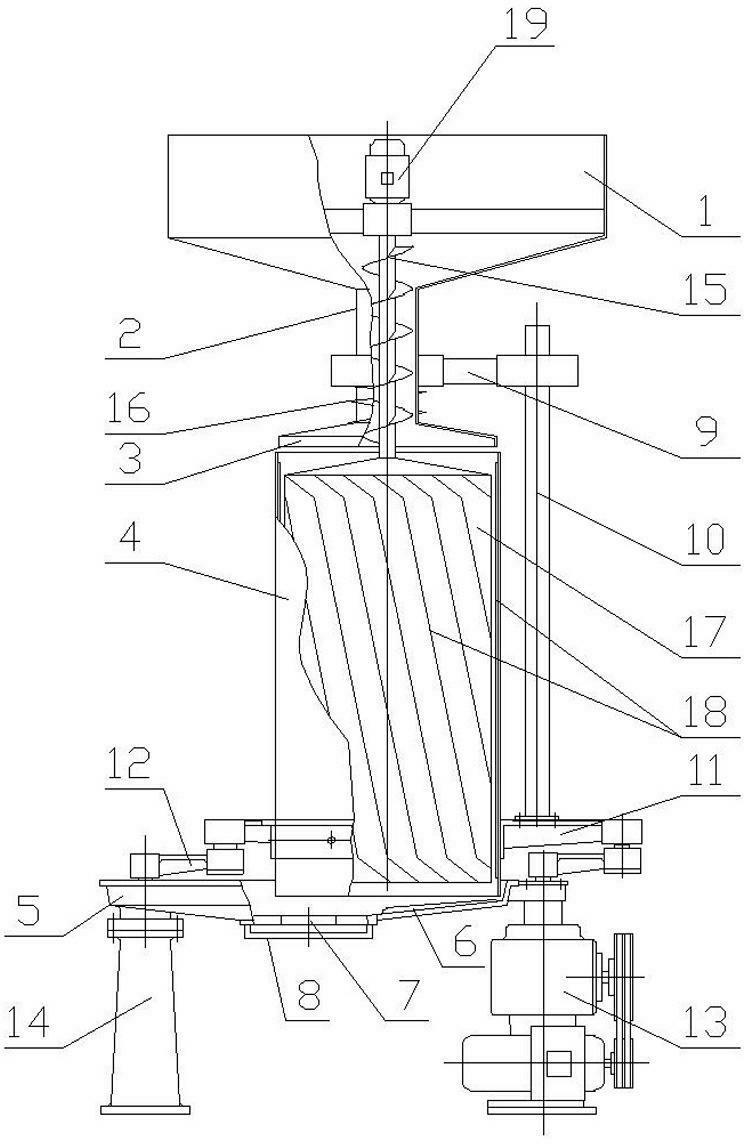

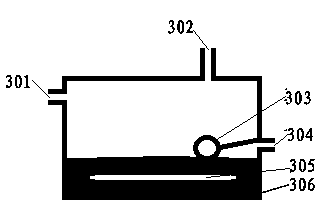

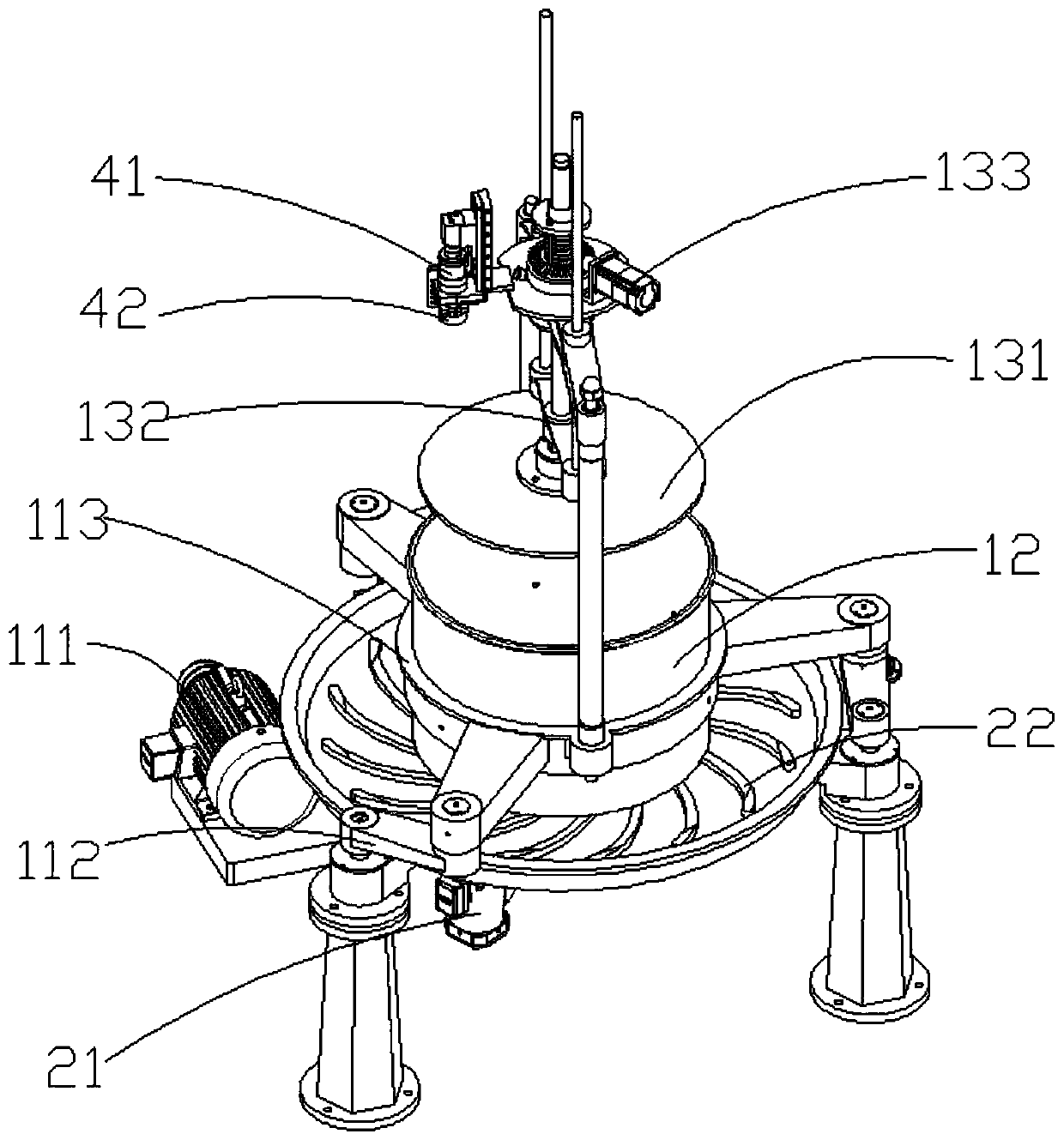

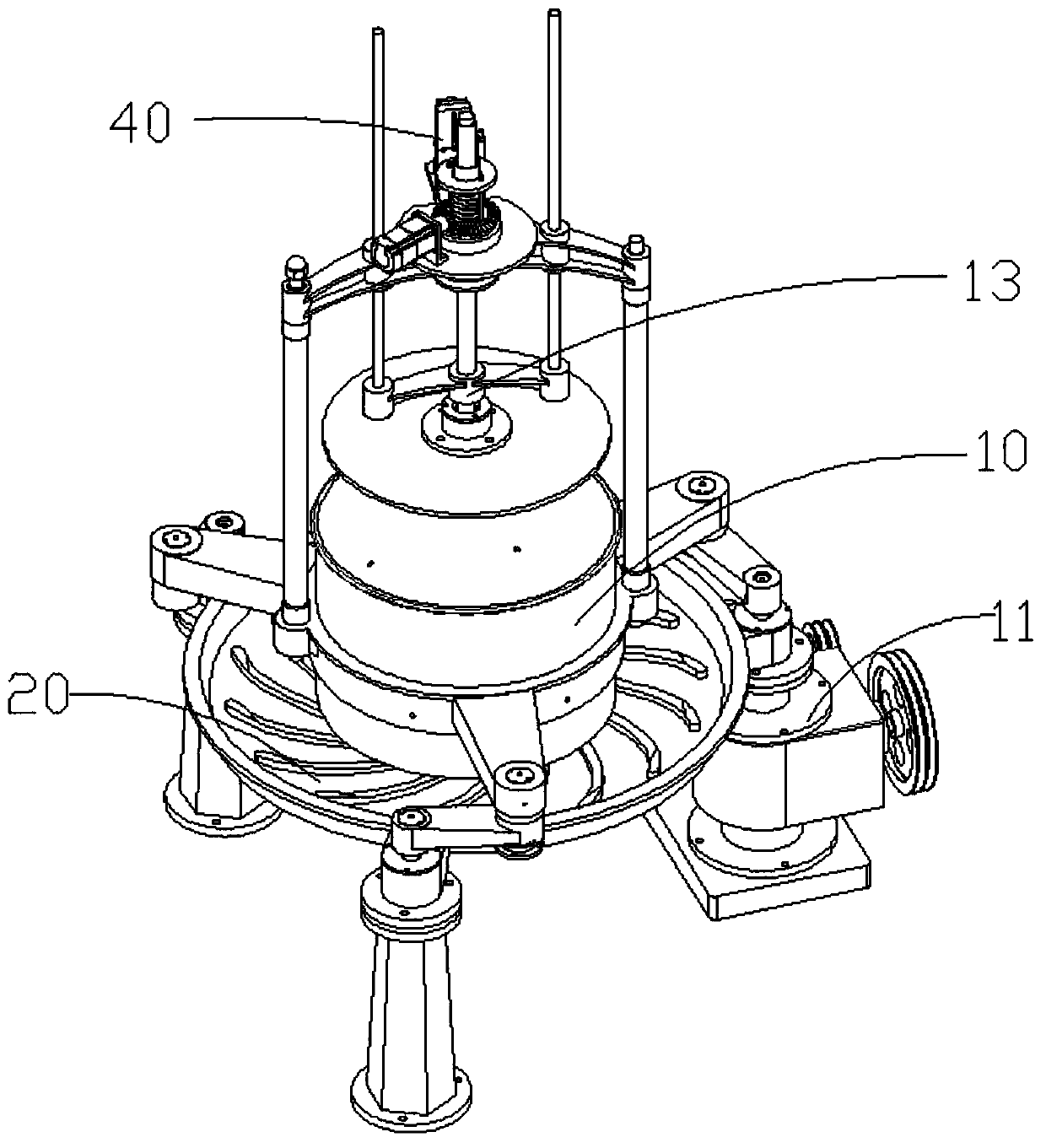

Congou black tea rolling and fermentation integrated machine and method for producing congou black tea

ActiveCN104186720ASimple structureImprove qualityPre-extraction tea treatmentTemperature controlRolling disk

The invention relates to a congou black tea rolling and fermentation integrated machine and a method for producing congou black tea and belongs to the technical field of tea leaf processing. The rolling and fermentation machine comprises a main machine, wherein the main machine comprises a rolling disk, a rolling barrel which is arranged on the rolling disk in a matching manner, and a rolling cover which is arranged on the rolling barrel in the matching manner, an oxygen making machine, an ultrasonic atomizing machine and a constant-temperature air heater are arranged on the main machine, an air inlet mechanism is arranged above the rolling cover, an air outlet mechanism is arranged in the middle of the bottom of the rolling cover, and the oxygen making machine, the ultrasonic atomizing machine, the constant-temperature air heater and the air inlet mechanism are connected through ventilation hoses. By combining the oxygen making machine, the ultrasonic atomizing machine, the constant-temperature air heater and the main machine of the rolling machine, the rolling machine has not only the functions of an ordinary rolling machine, but also the functions of automatic temperature control, moisture control and oxygen addition, so that tea leaves in the rolling machine can be rolled and the efficient fermentation of the tea leaves can be performed under oxygen-rich, high-moisture and constant-temperature conditions. By utilizing the rolling machine to ferment the congou black tea, the quality of the congou black tea is improved.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

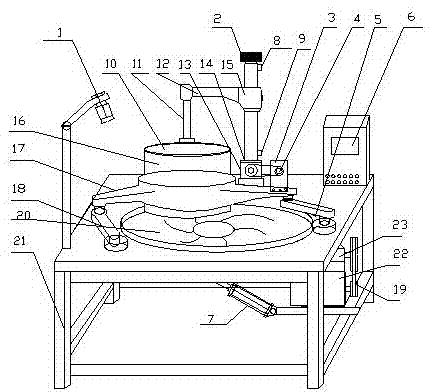

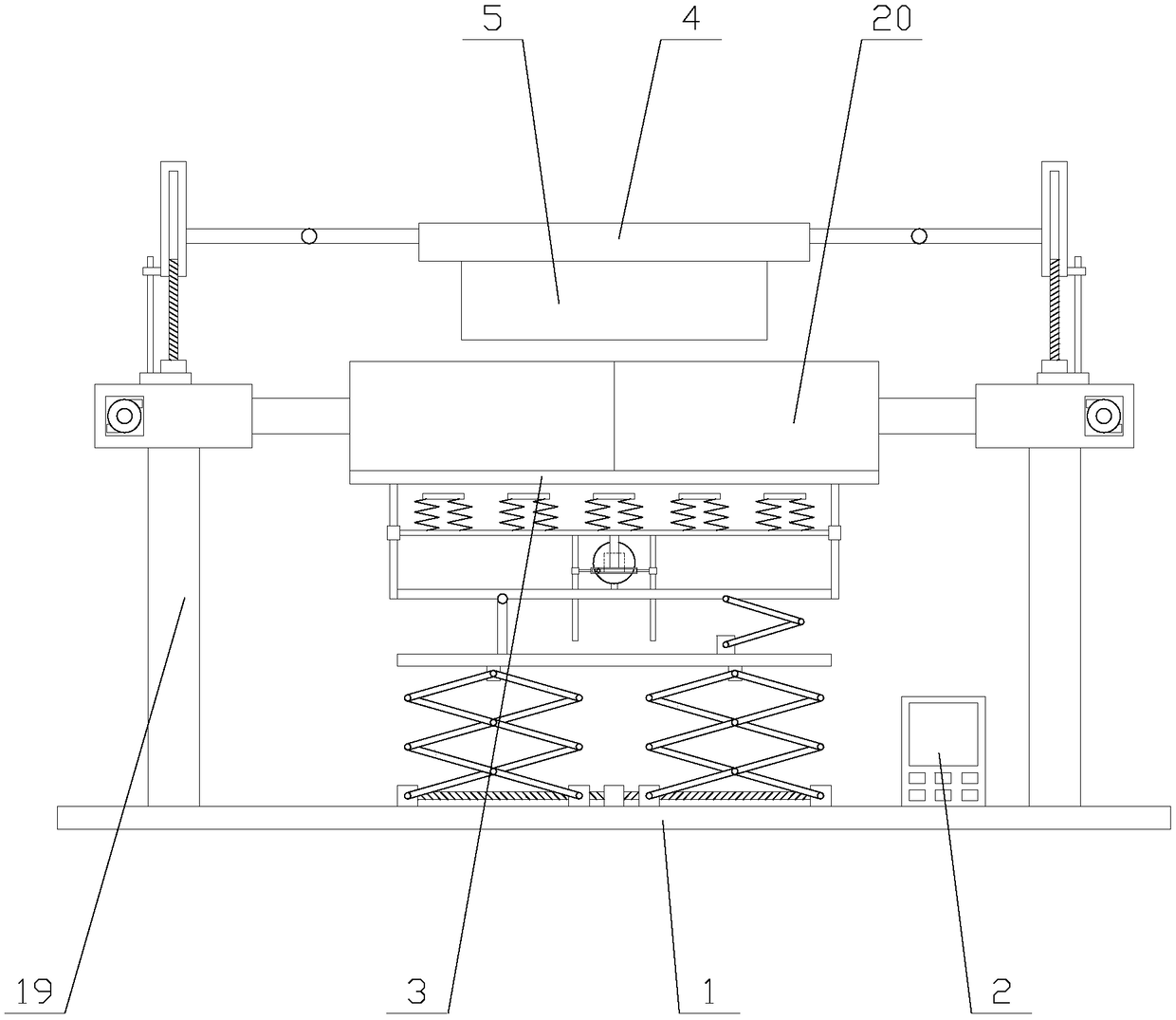

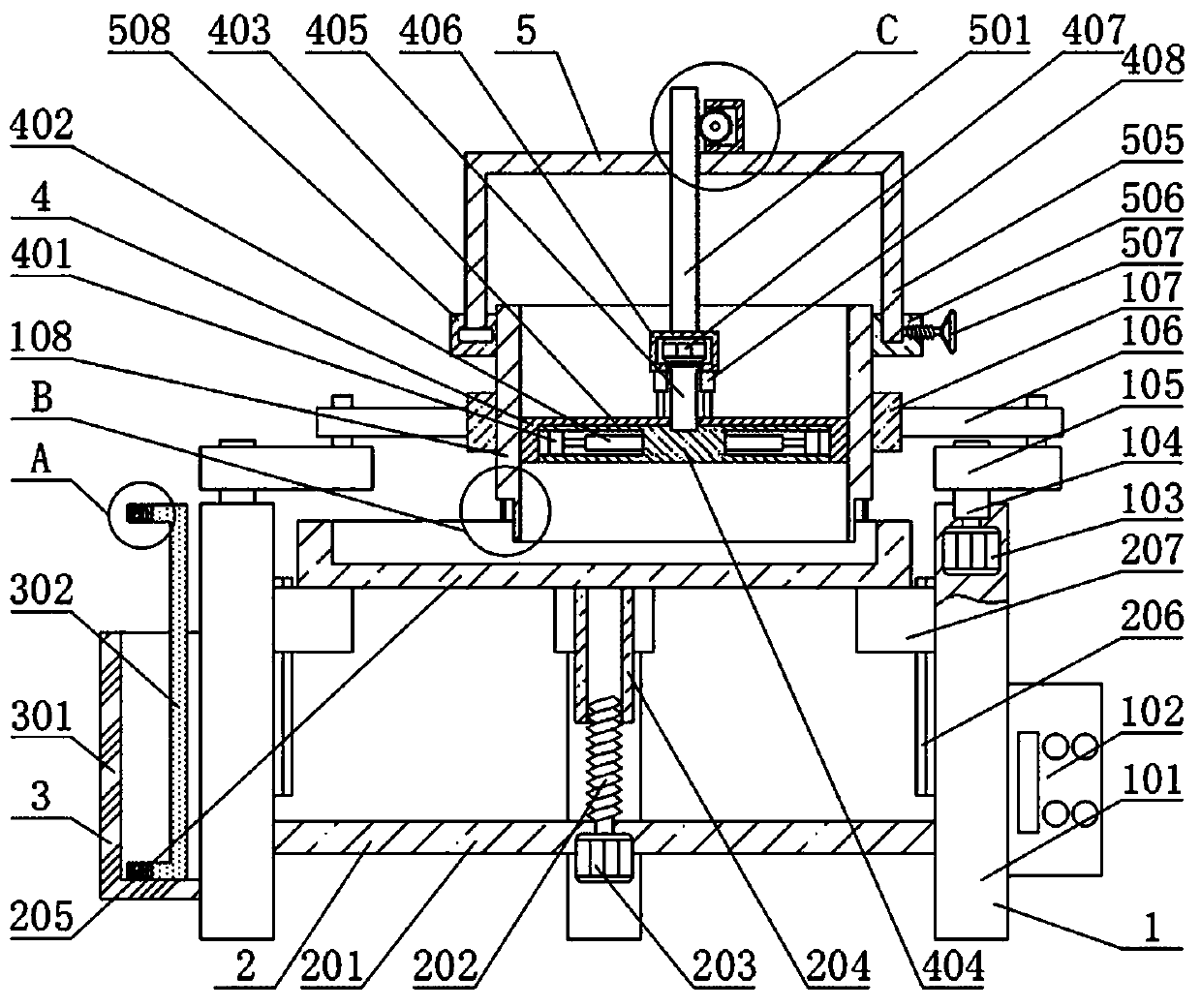

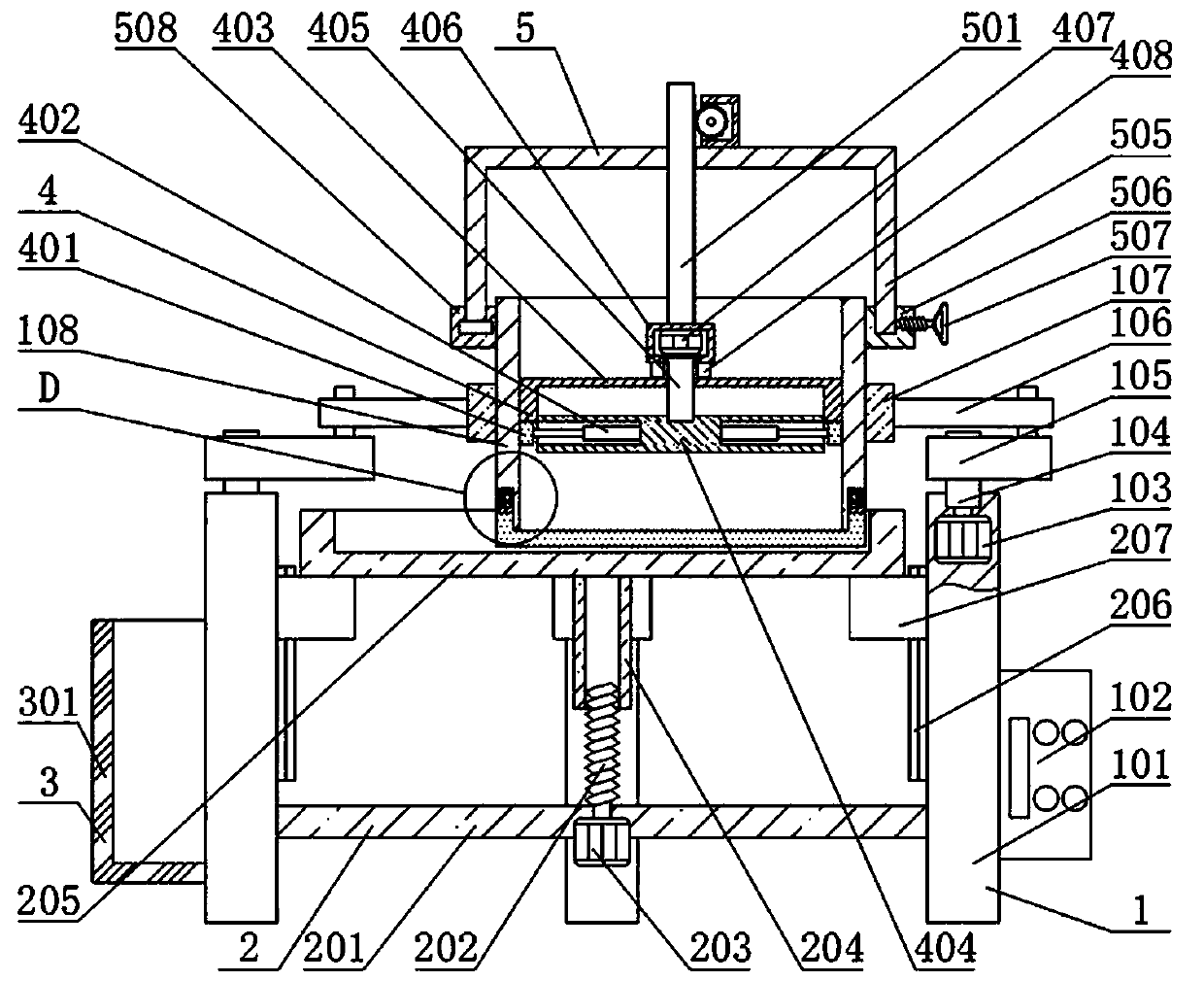

Intelligent pressure-regulating tea-leaf rolling machine

InactiveCN104757146AReduce labor intensityRealize intelligent controlPre-extraction tea treatmentMachine visionRolling disk

The invention relates to an intelligent pressure-regulating tea-leaf rolling machine. The machine is characterized by comprising a base, a rolling barrel, a rolling disk, a high-definition camera, an intelligent pressurizing mechanism, a rolling mechanism, an automatic discharging unit and a control box, wherein power is transmitted to a connecting rod which is connected with a rolling disk rack, the rolling barrel is fixedly connected with the rolling disk rack, and the rolling disk is installed above the base; the high-definition camera is connected with a frame via the connecting rod and is placed above the rolling disk; the intelligent pressurizing mechanism is composed of a stepping motor, a server, a synchronous belt pulley, a photoelectric encoder and a photoelectric switch; the rolling mechanism is composed of an electromotor, a reduction gearbox and a belt pulley; the automatic discharging device is composed of a proximity switch, an air cylinder and a solenoid valve; and the control box is composed of an intelligent tea-leaf rolling control system, a touch display screen and a button switch. The intelligent pressure-regulating tea-leaf rolling machine provided by the invention is based on machine vision technology and can automatically roll tea leaves which are of different varieties and produced in different periods to obtain high-quality tea leaves.

Owner:NANNING CHUANGYU TEA MACHINERY +1

Tea water-removal rolling device

InactiveCN108450583AExtended stayFully contactedPre-extraction tea treatmentRolling diskAmmonium chloride mixture

The invention belongs to the field of tea processing, and particularly discloses a tea water-removal rolling device. A water removal unit and a rolling unit are arranged on a rack. The water-removal unit consists of a roller rotatably connected to the rack and a hot-air fan fixedly arranged on the rack for driving the roller. One end of the roller, close to the rolling unit, is sleeved with a convex disk. The inner wall of the roller is fixedly connected with spiral conveying blades. One end of the roller, close to the rolling unit is provided with a discharge hole. An inclined feeding table is arranged at the discharge hole; the rolling unit comprises a rolling disc and a rolling roller arranged above the rolling disc. Projections are arranged on the rolling roller in the circumferentialdirection; the upper end of the rolling disk is fixedly connected with the lower end of the feeding table. An air bag layer is arranged at the upper end of the rolling disc. A second Y-shaped tube isarranged on the rack. The three terminals of the second Y-shaped tube are respectively communicated with an air outlet, the rolling roller and the air bag layer. Ammonium chloride crystal is placed atone end of the second Y-shaped tube, close to the roller. According to the invention, the device meets the requirements of mechanized conveying of tea in the process of water-removal and rolling.

Owner:贵州省凤冈县浪竹有机茶业有限公司

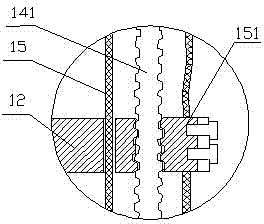

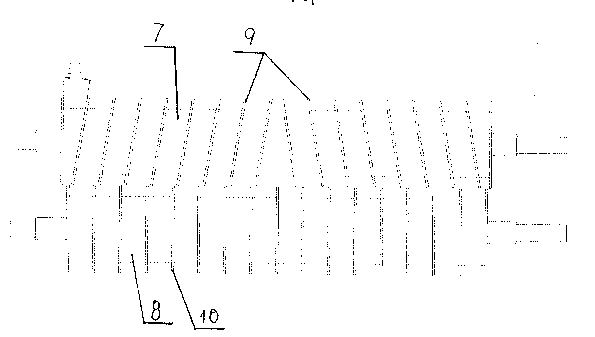

Novel computer-controlled bevel wheel roller raising machine

The invention discloses a novel computer-controlled bevel wheel roller raising machine, which comprises a frame, a cylinder, needle roller cleaning devices, a dust suction device, a tension device, a plurality of cloth feeding and expanding machines, a cloth feed traction device, a cloth discharge traction device and a cloth discharge plaiting device, wherein the needle roller cleaning devices and the dust suction device are arranged below the cylinder; the tension device, the cloth feeding and expanding machines, the cloth feed traction device and the cloth discharge traction device are arranged in front of the cylinder respectively; the cloth discharge plaiting device is arranged on the upper part of the frame; the cylinder consists of a spindle, a rolling disk fixed on the spindle and a needle roller arranged on the rolling disk; a transmission gear of the needle roller performs bevel wheel internal meshing transmission; a transmission chain of the needle roller is provided with a clutch device; and the whole machine is controlled by a PLC. The novel bevel wheel roller raising machine controlled by the computer has the advantages of larger transmission force, low noise, PLC automatic control and high production efficiency.

Owner:HAINING TEXTILE MACHINERY FACTORY

Automatic stretch film winding device

ActiveCN107010252AEasy to operateReduce intensityWrapping material feeding apparatusConveyor wrappingRolling diskEngineering

The invention discloses an automatic stretch film winding device. The automatic stretch film winding device comprises a film feeding mechanism, a power mechanism, a rolling disk, a film clamping and sending mechanism and a film cutting mechanism. A stretch film is clamped by a film clamping claw and pulled by a stretch film winding rod to be wound around a rolling object. The stretch film winding rod is fastened on the end face of a rotating disk, a pushing air cylinder is fixed to the stretch film winding rod, a MINI air cylinder base is tightly connected with a piston rod of the pushing air cylinder, and a MINI air cylinder is fixed to the MINI air cylinder base. A mechanical clamp air cylinder and a film cutting air cylinder are fixed to a film clamping and cutting air cylinder base, a film cutting blade is arranged in a film cutting blade base, and the film cutting blade base is fixed to a piston rod of the film cutting air cylinder. By means of the automatic stretch film winding device, the manual operation intensity is remarkably lowered, the labor cost is obviously reduced, and a unit technical module can be established for the design of a standard unattended operation automatic reel machine.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

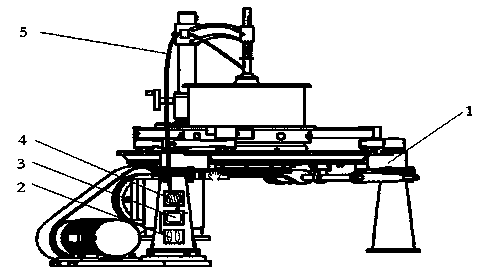

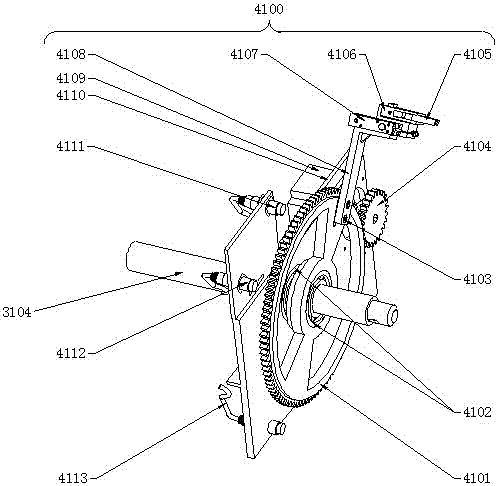

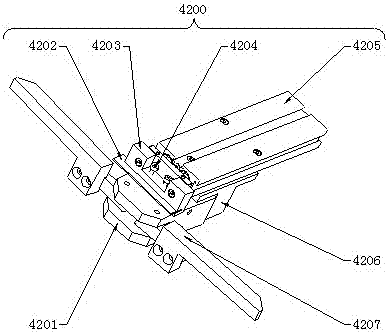

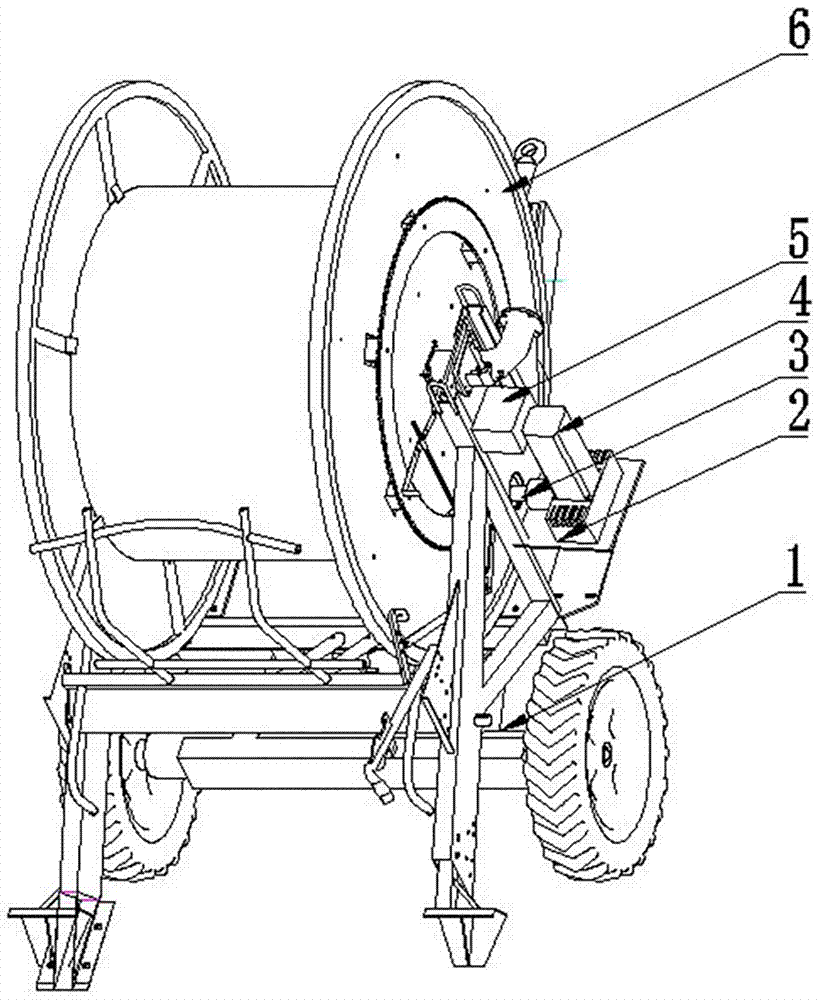

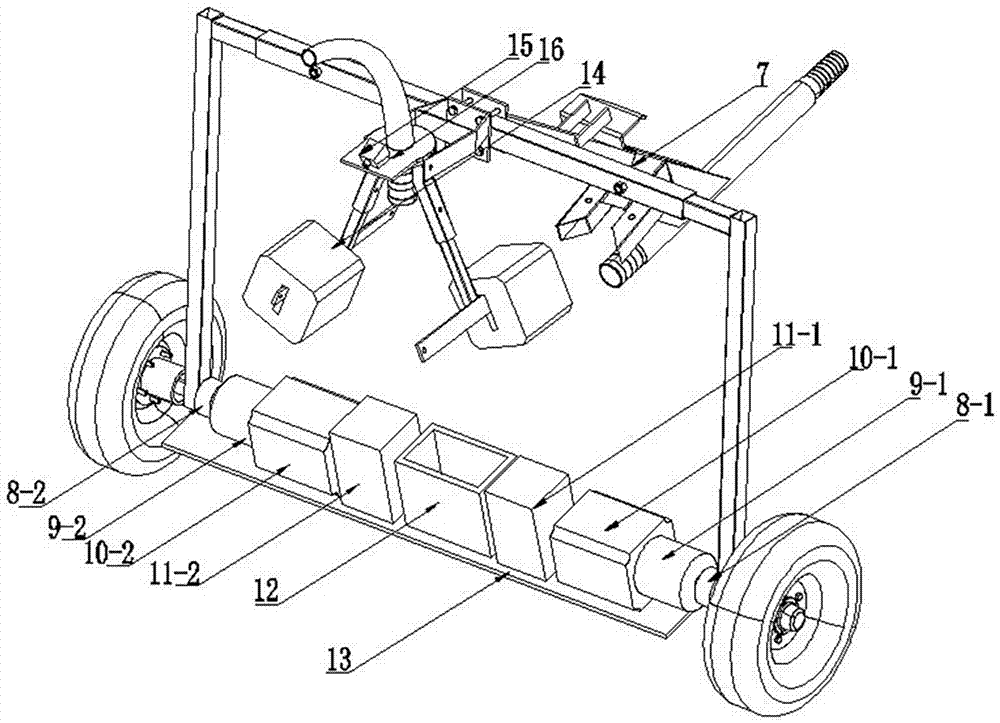

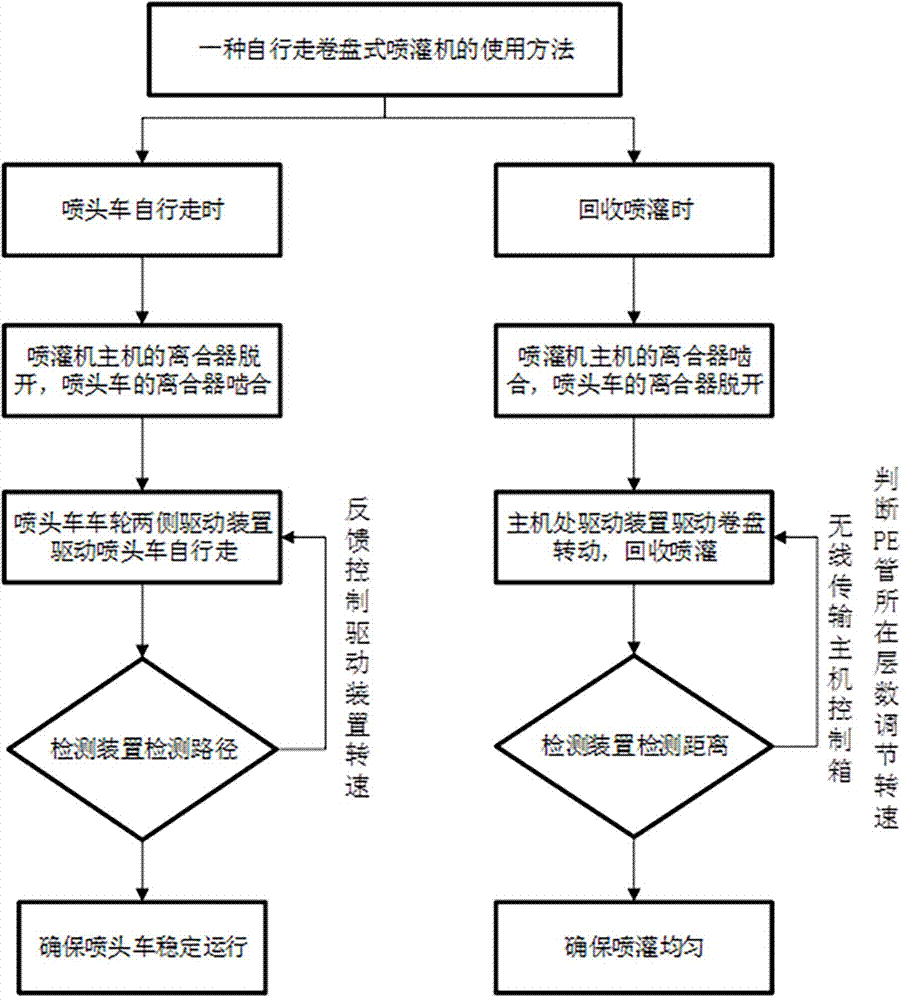

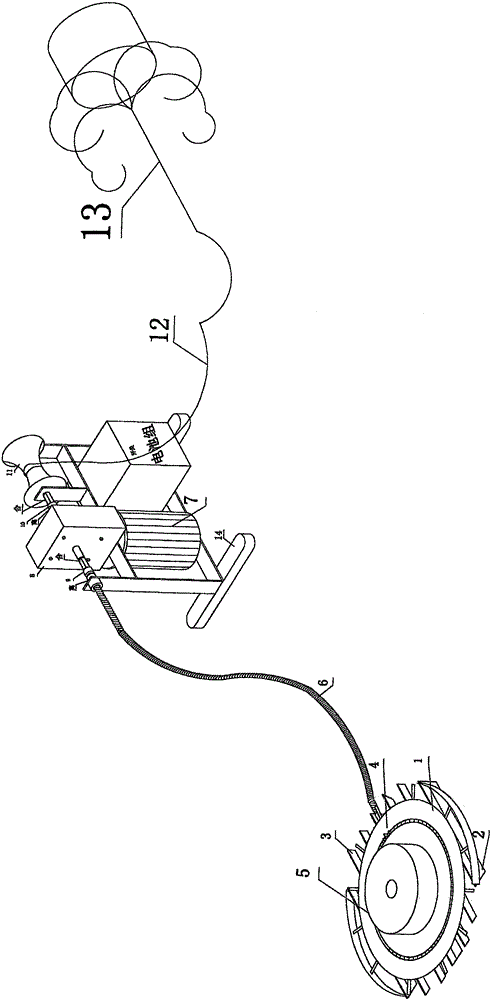

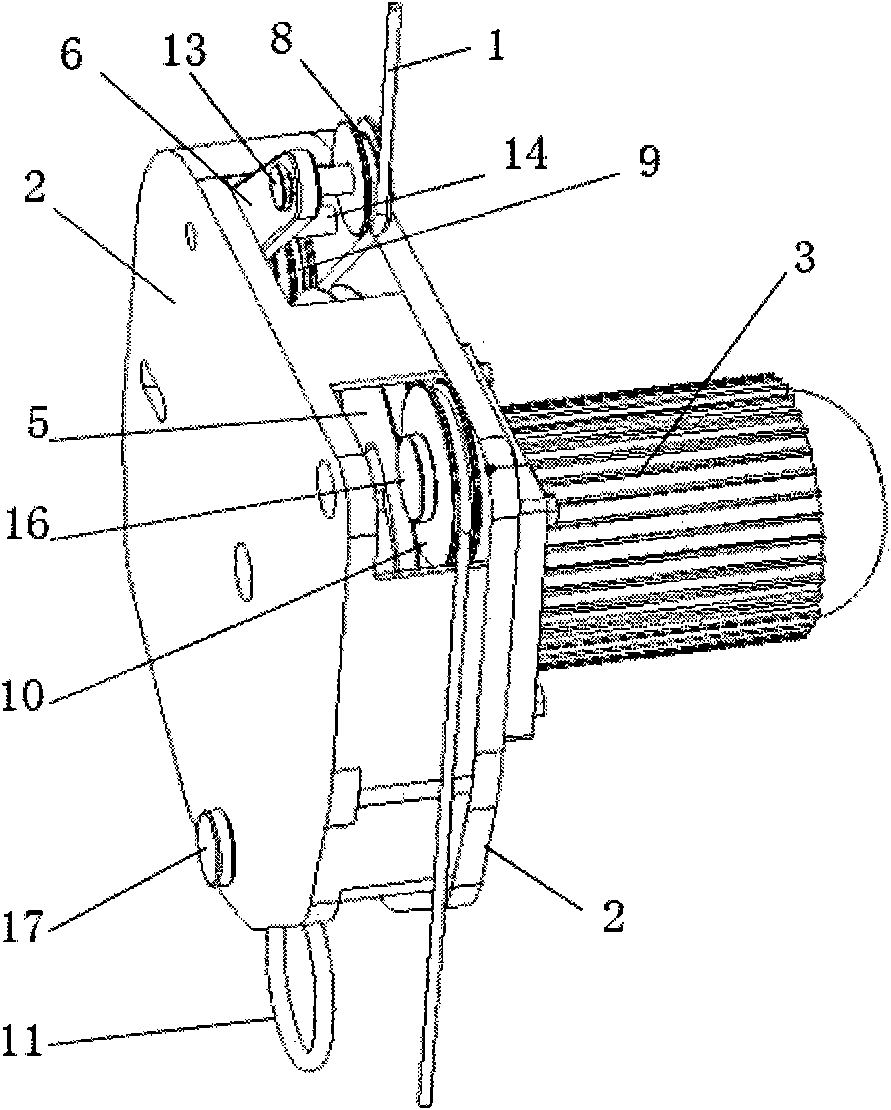

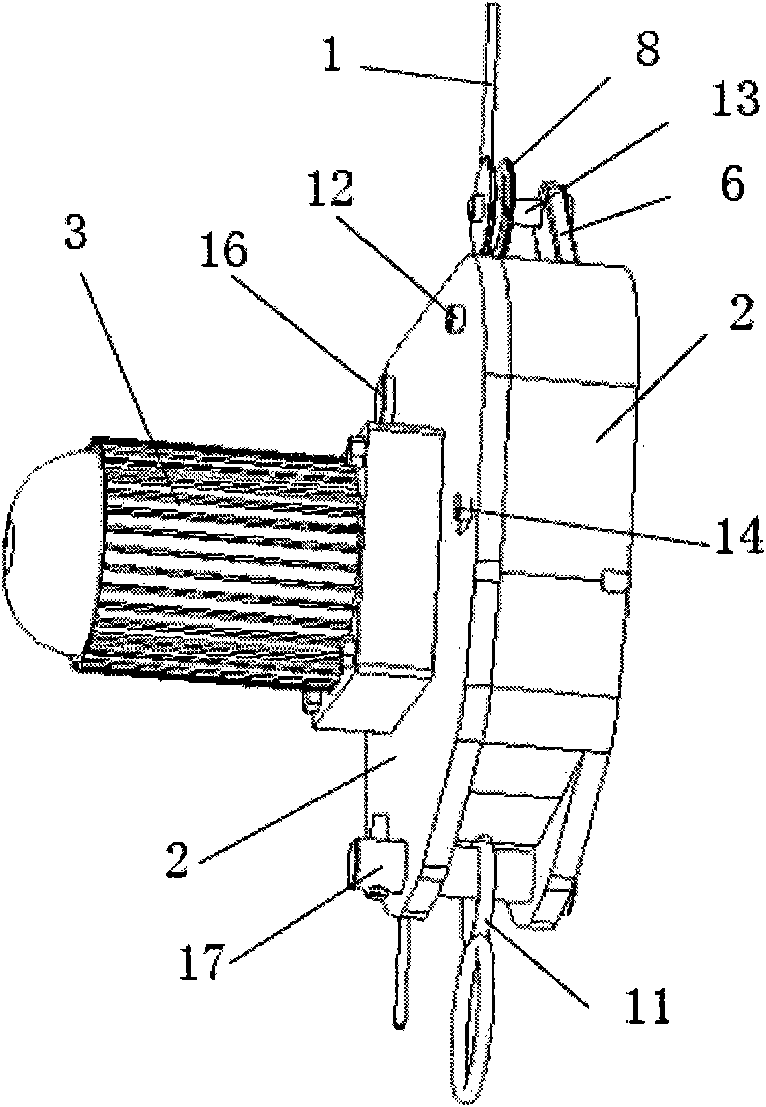

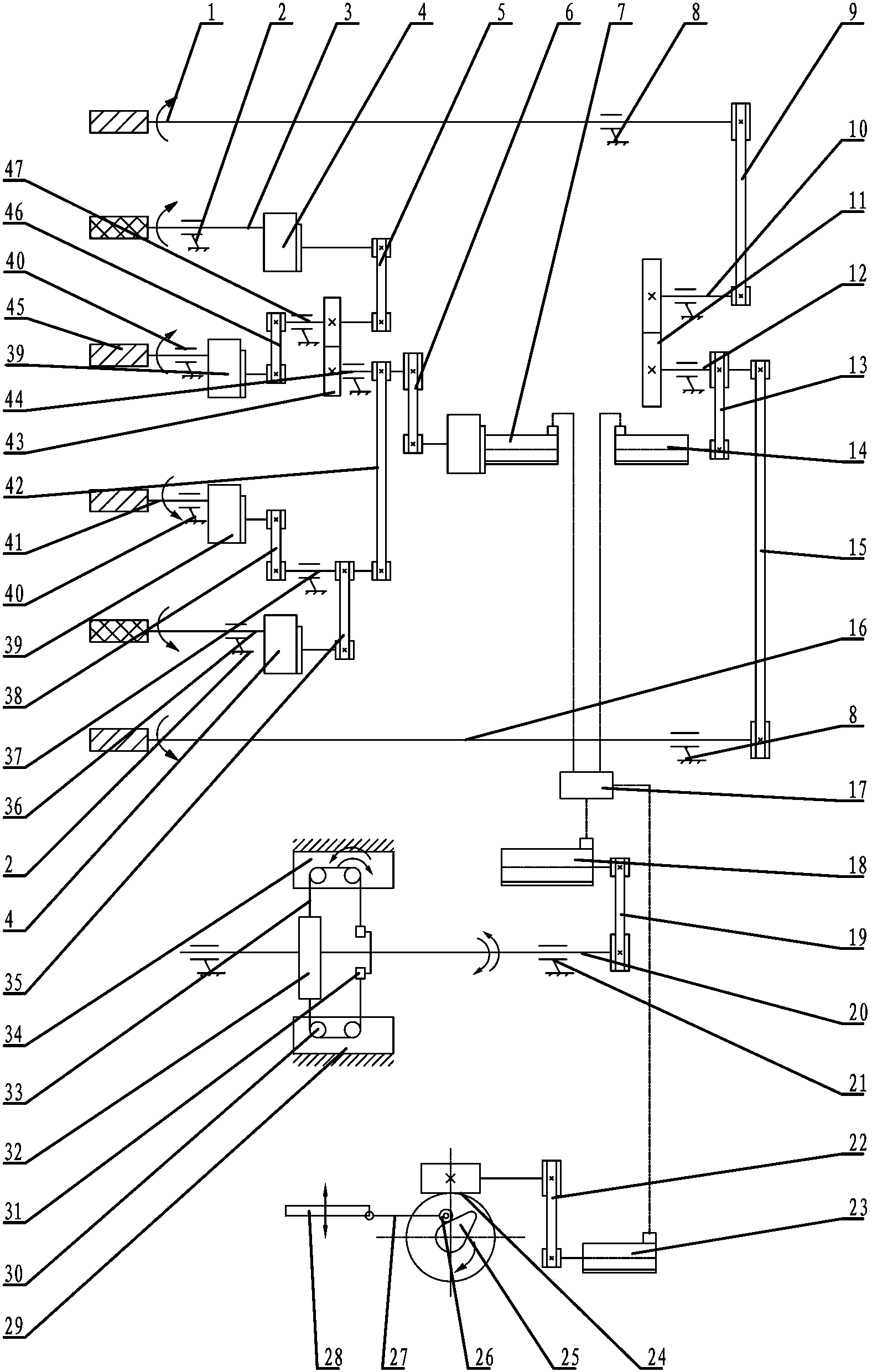

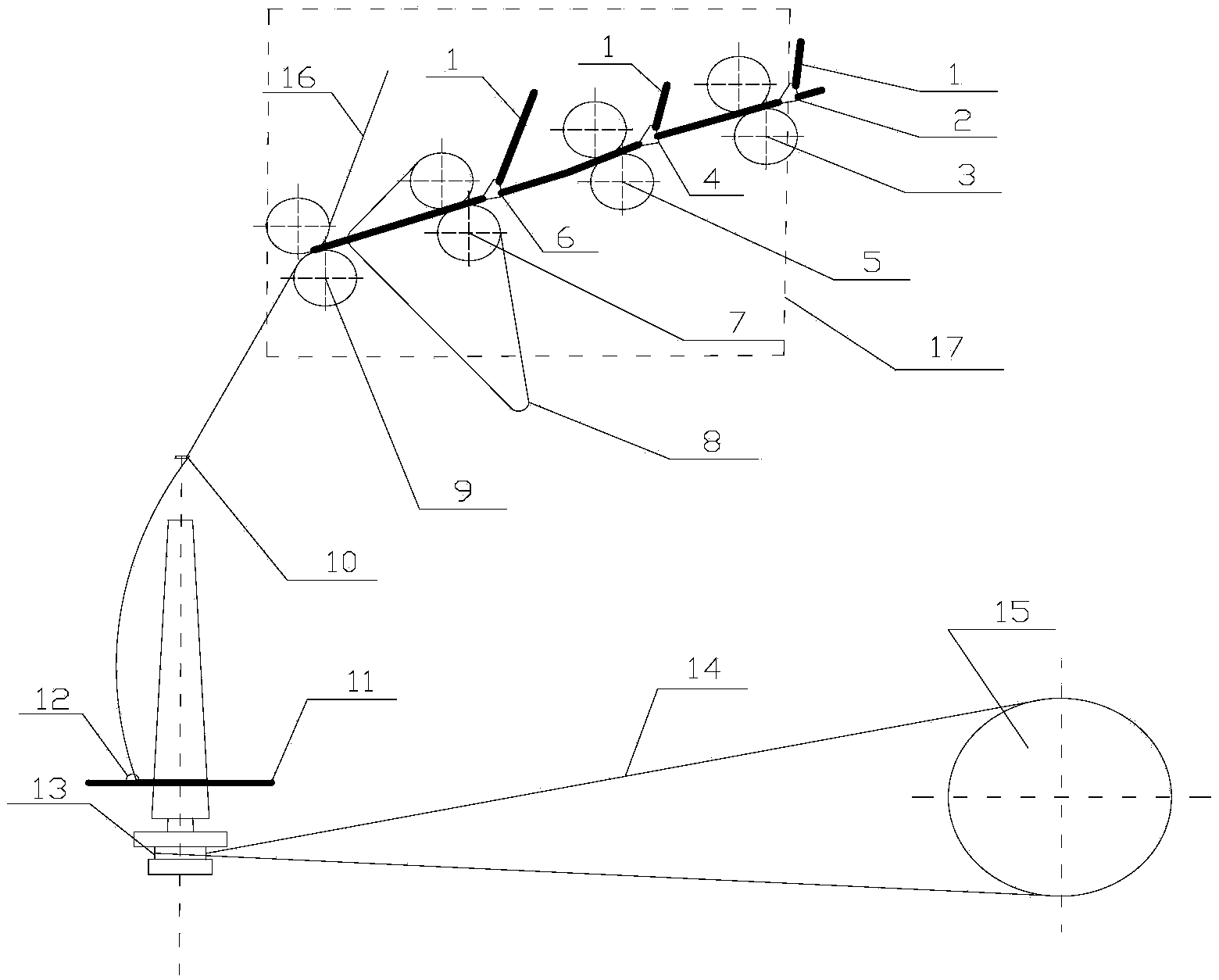

Automatic walking rolling disk type sprinkler and use method thereof

InactiveCN106857191AGuaranteed uniformitySolve the problem of interlayer differenceWatering devicesCultivating equipmentsInter layerRolling disk

The invention discloses an automatic walking rolling disk type sprinkler and use method thereof. The sprinkler comprises a sprinkler main machine and a nozzle car. The nozzle car is connected with the sprinkler main machine through a PE PIPE. The nozzle car comprises a sprinkler car frame, a storage battery, a drive motor, a clutch, a reducer gear box, a control box, a head camera and a detection device. The sprinkler main machine comprises a drive device, a transmission device, a clutch, a control box, a rolling disk and a chassis. When the sprinkler walks automatically, the clutch of the nozzle car is in a detached state, the clutch of the main machine is meshed together. The nozzle car walks automatically. When the sprinkler is recovered, the clutch of the main machine is meshed together, the clutch of the nozzle car is in the detached mode, the drive device drives the rolling disk to recover the sprinkler through the transmission device. The automatic walking rolling disk type sprinkler can automatically walk in designated places for sprinkling irrigation, the structure is simple and reliable, the use is convenient. The distance between the nozzle car and the sprinkler main machine can be detected through the detection device to judge the layer number of PE pipes, therefore the real-time regulation of rotating speed is achieved. The sprinkler solves the problem of inter-layer differences well, and has a broad practicality.

Owner:CHINA UNIV OF MINING & TECH

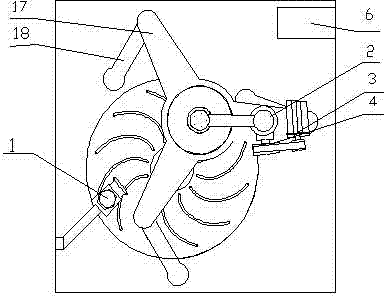

Pond water plant cutting machine

InactiveCN105230235AManual labor is easyHappy manual laborHarvestersEnvironmental resistanceRolling disk

The invention belongs to the field of aquacultural machines. The operating process comprises: putting a pond water plant cutting machine on a boat, using a reduction gearbox 8 and a DC motor 7 of the machine to drive a flexible shaft 6 and a gear 4, and a cutting disk 1 which is sunk underwater rotating, and under the driving of the small boat, the cutting disk 1 cutting water plants in the range of the cutting disk 1 from roots, after the water plants float and gather in a certain corner along a wind direction, using another function of the machine, that is, a winch including a rolling disk 11, a steel rope 12, and an iron floating anchor 13, throwing the iron floating anchor 13 on the water plants, since the iron floating anchor 13 is provided with a buoy, the iron floating anchor 13 cannot sink, and the iron floating anchor 13 floating on water surface to hook the water plants, a part of the water plants being pulled on cart carrying the water plants, for environmental treatment, so as to improve production efficacy.

Owner:沈前保

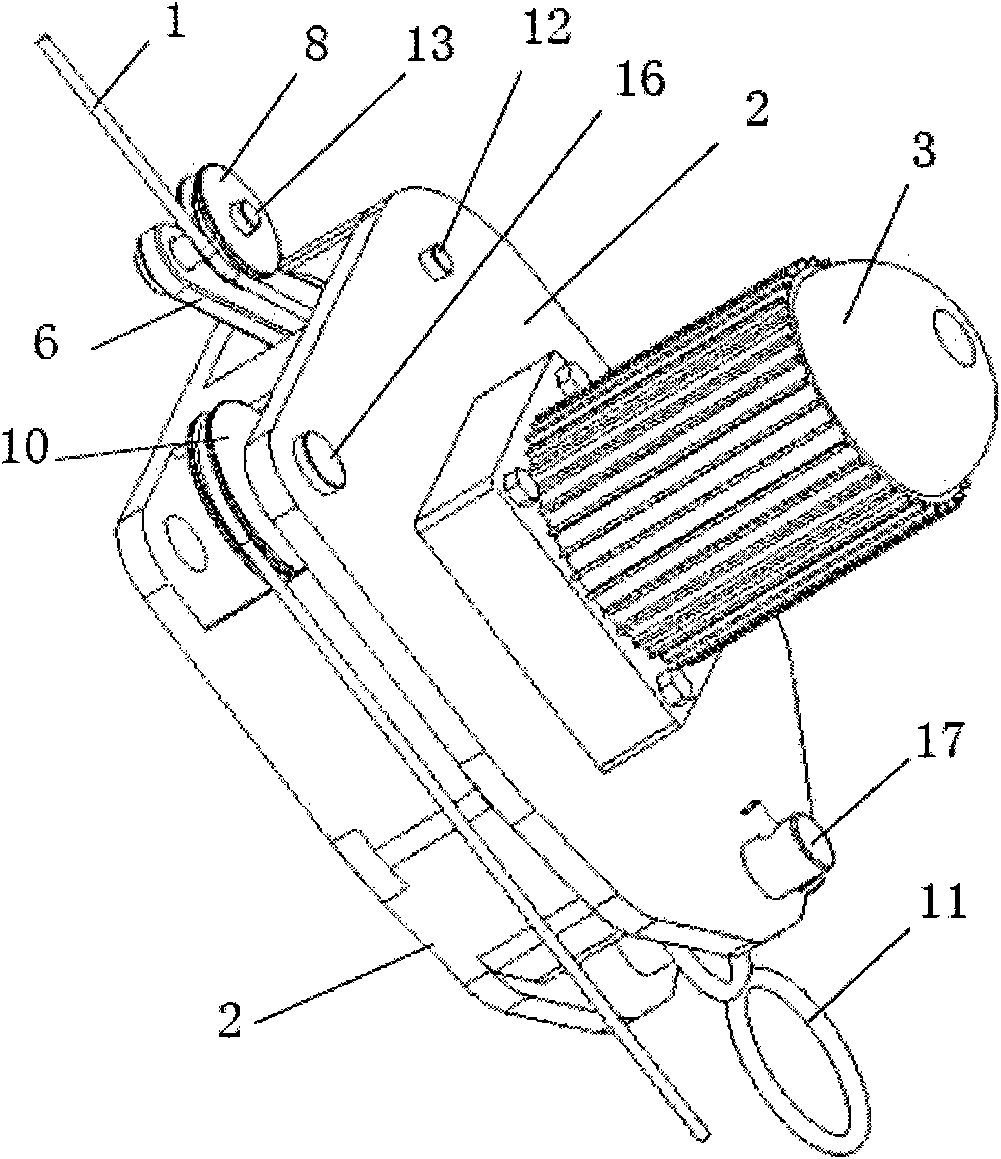

Electric climbing device and application device thereof

The invention discloses an electric climbing device which comprises a casing, a work rope, a rope pressing mechanism, a hanging ring, a motor and an electric motor manipulator, wherein a rope-rolling disk is fixedly arranged in the casing; the casing body is provided with a rope inlet and a rope outlet; the work rope enters the inner part of the casing from the rope inlet, and rounds the rope-rolling disk to pass through the casing from the rope outlet; the rope pressing mechanism is pressed by the work rope at the rope inlet and simultaneously exerts pressing force on the work rope on the rope-rolling disk; the hanging ring is fixedly arranged on the casing; an output shaft of the motor is connected with the rope-rolling disk in a coupling mode; and the electric manipulator controls positive rotation, reverse rotation and stoppage of the electric motor. The invention has the advantages that firstly, the stroke is not limited, secondly, a load pressing rope is absolutely reliable, thirdly, the load pressing rope and run are automatically converted by run commands of the electric motor, fourthly, the work rope executes dual functions of brake of a safety pressing rope at any time, fifthly, the load pressing rope belongs to soft brake without impact, is absolutely reliable, and can brake load for a long time, and sixthly, the work rope has very little abrasion and long service life.

Owner:CCCC FOURTH HARBOR GEOTECHN ENG +2

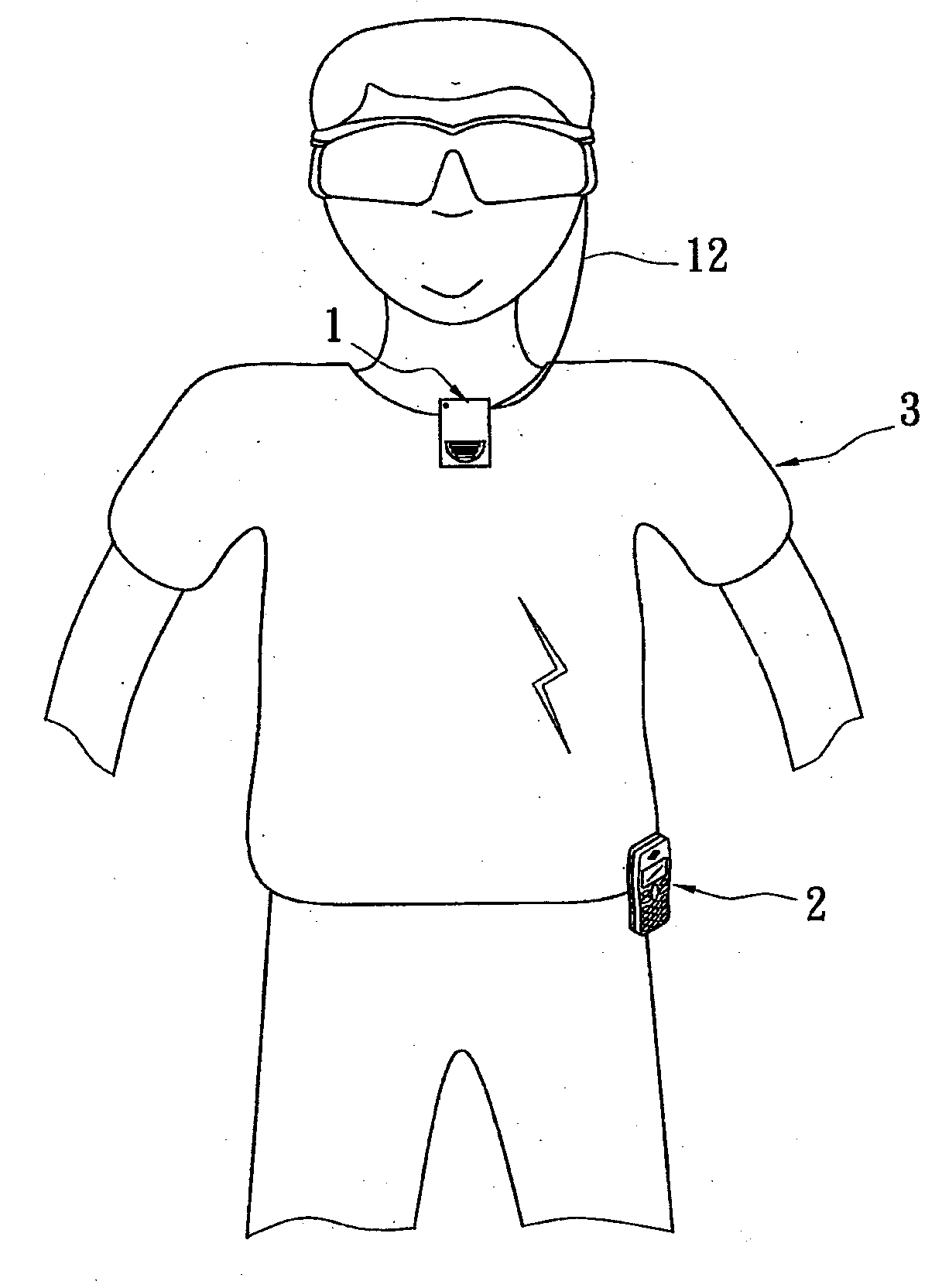

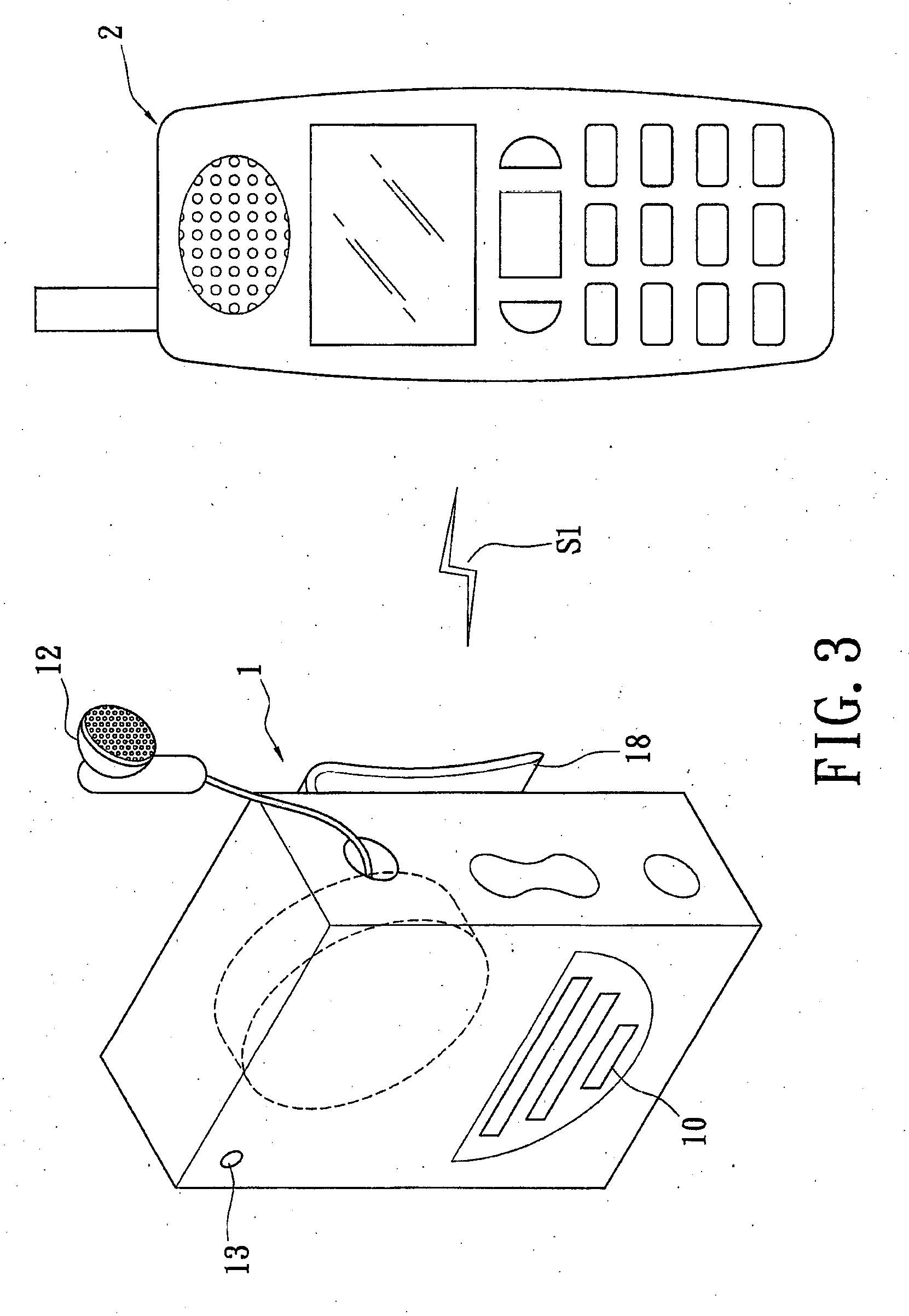

Portable bluetooth speaker

InactiveUS20080287166A1Improve communication qualityDevices with bluetooth interfacesTelephone set constructionsRolling diskHeadphones

A portable Bluetooth speaker includes a Bluetooth module for communicating wirelessly with a Bluetooth communication device and outputting a voice signal, a voice switching module connected with the Bluetooth module for receiving the voice signal, a speaker connected with the Bluetooth module, a wire-receiving unit having a wire slot, a wire-rolling disk, a communication wire, a volute spring, and a judging unit connected with the voice switching module and the wire-receiving unit. Due to the volute spring, the communication wire can be extended or received. One end of the communication wire is connected with the voice switching module. The second end of the communication wire is connected with the earphone. The judging unit outputs a judging signal to the voice switching module for switching the voice signal according to the communication wire being extended or received.

Owner:LIN PI FEN

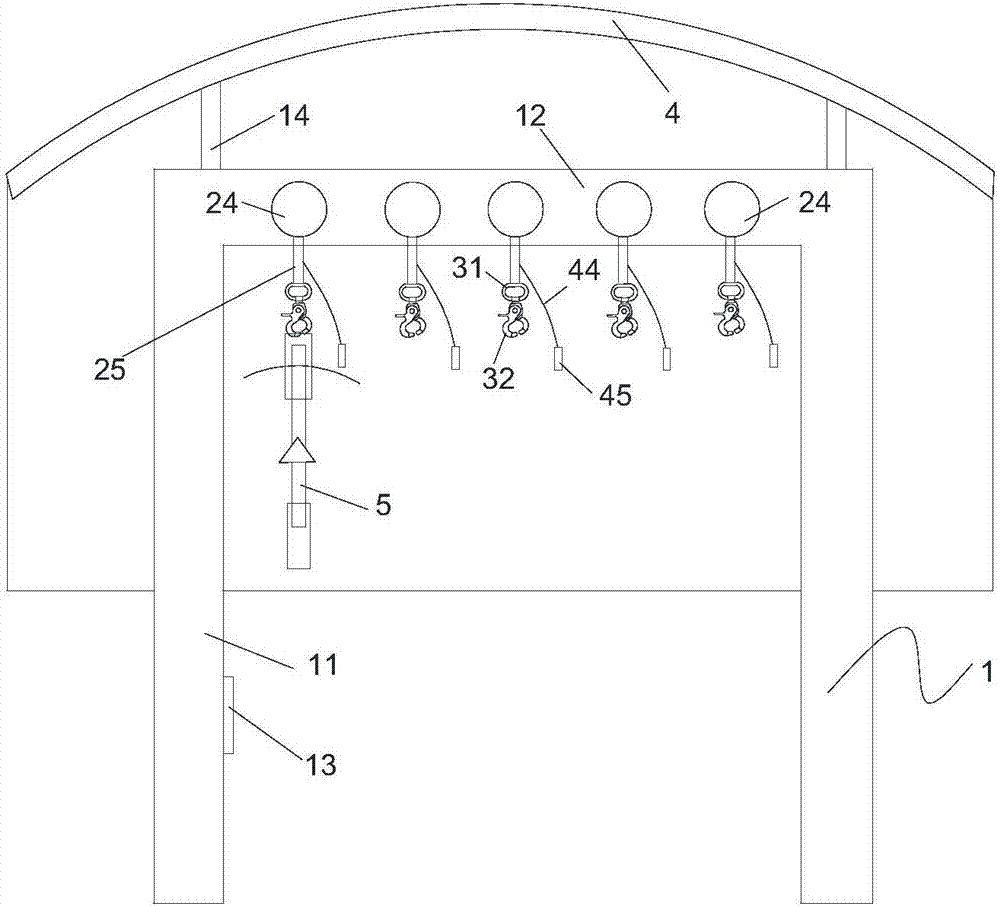

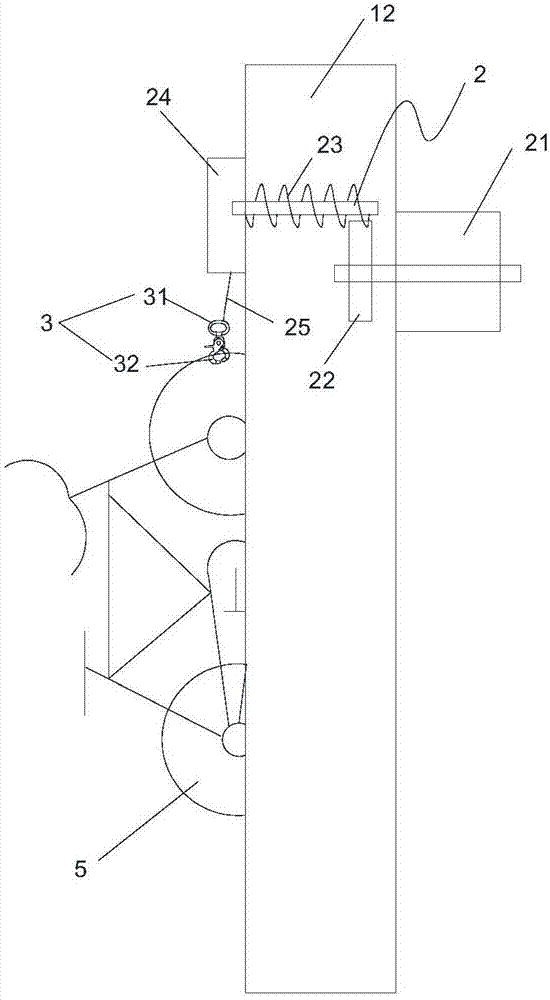

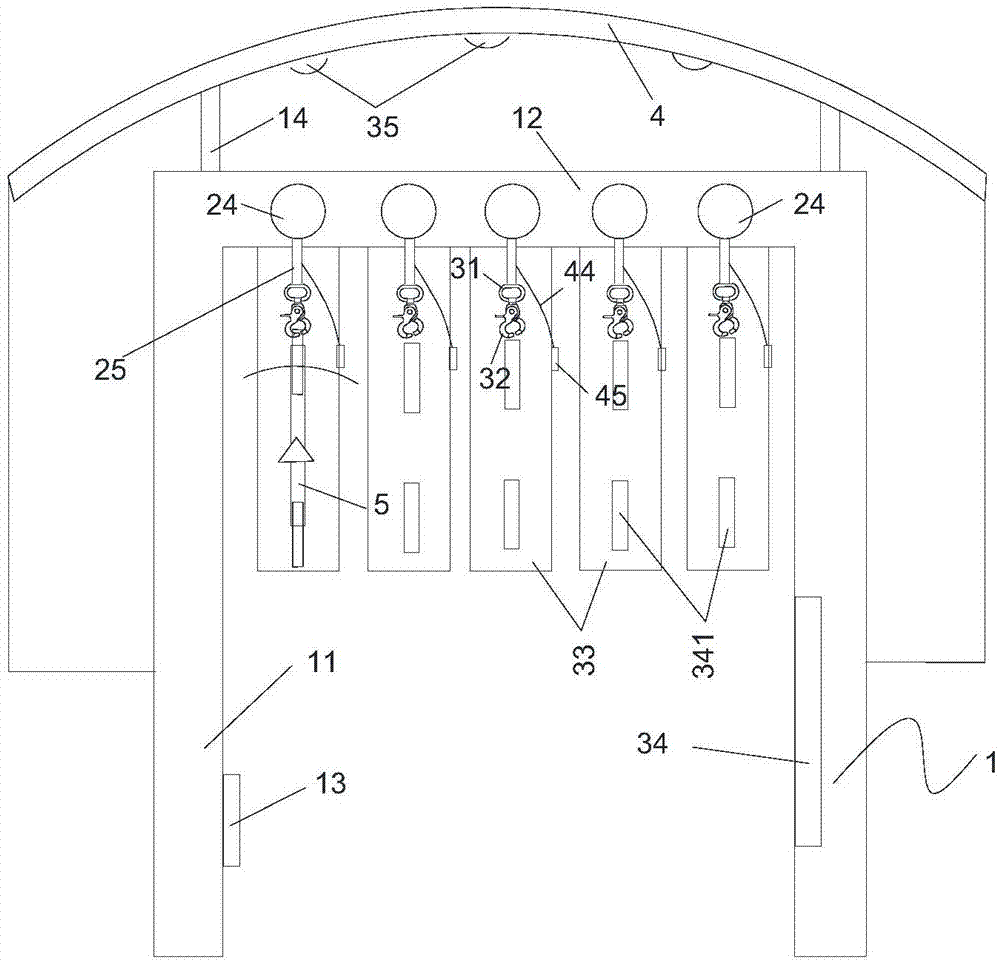

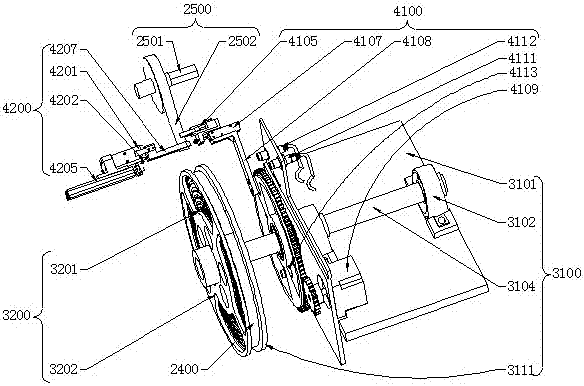

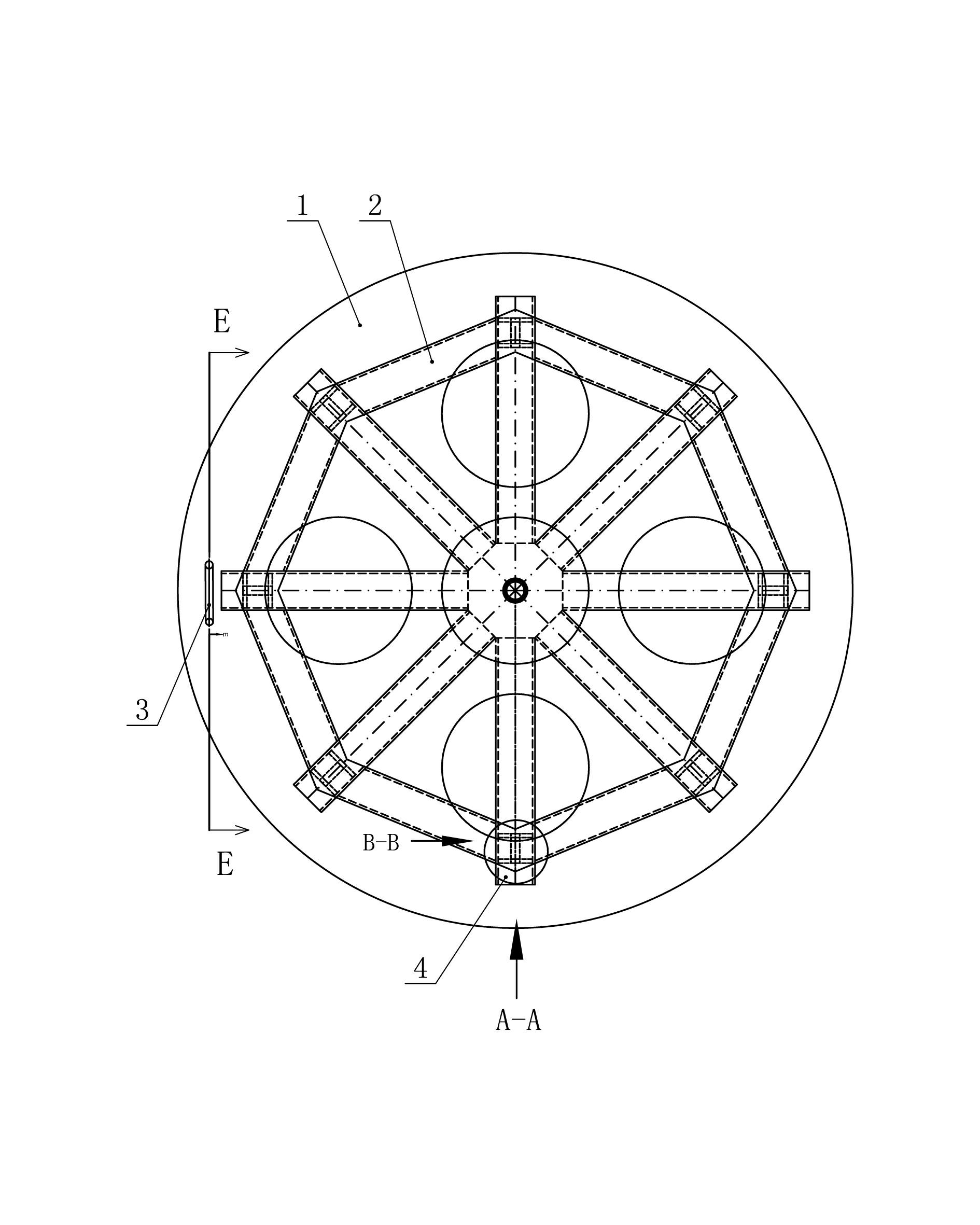

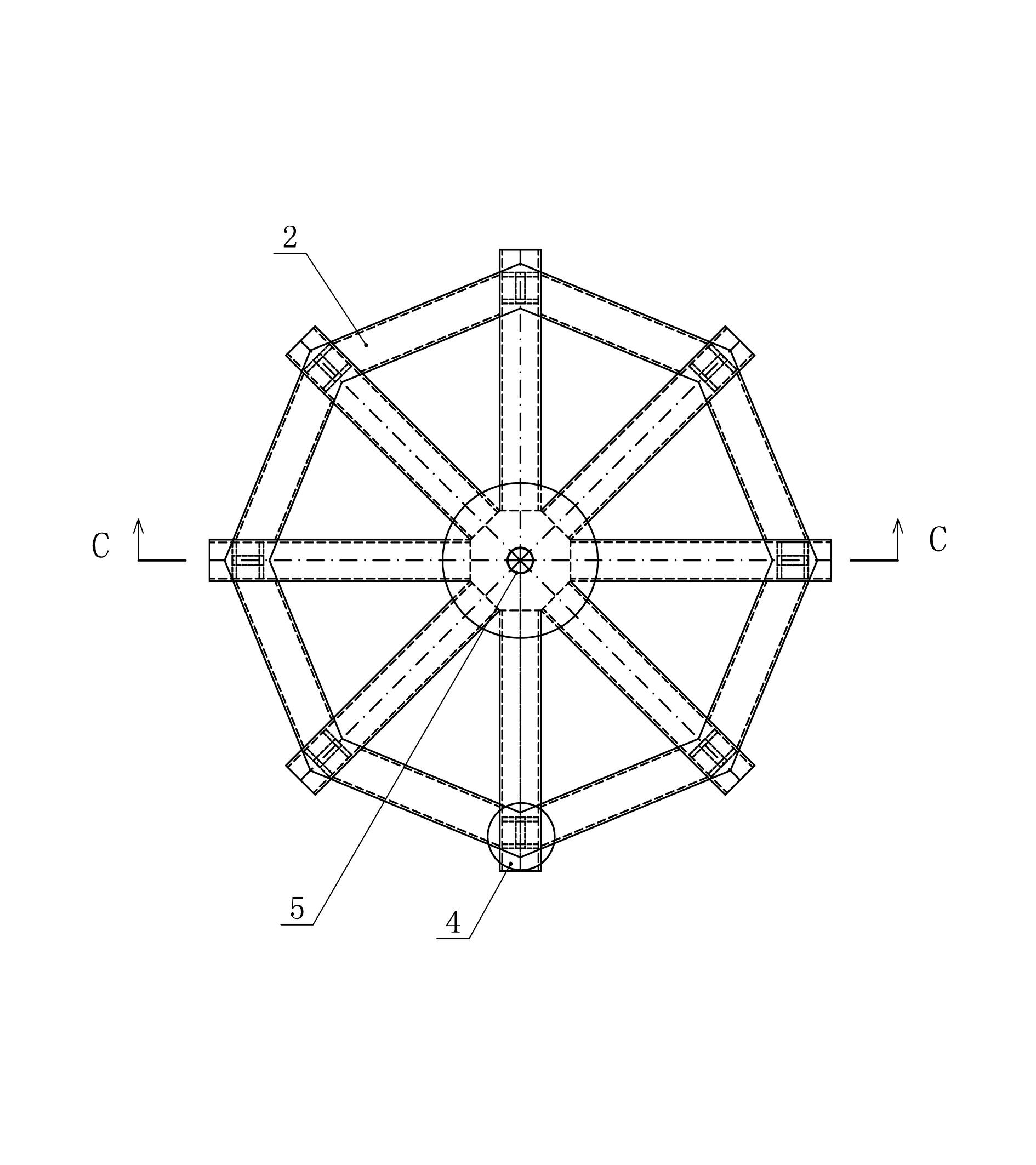

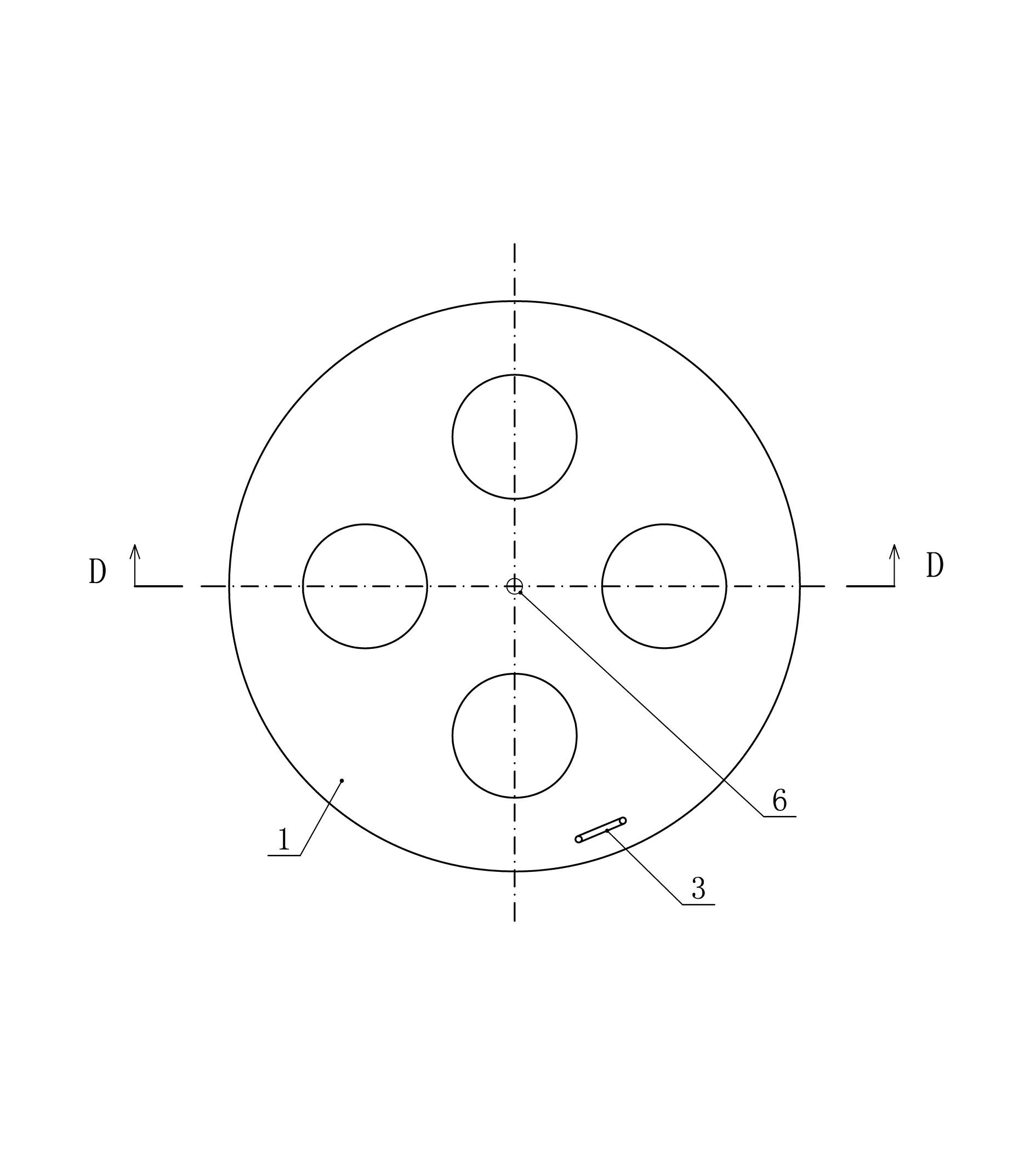

Bundling mechanism of roll disk type round bundle pick-up bundling machine

The invention relates to a bundling mechanism of a roll disk type round bundle pick-up bundling machine and belongs to agricultural machinery. Driving shafts are respectively assembled in a rotatable mode symmetrically and coaxially on a left side wall and a right side wall of a front bundling chamber, two grass rolling side disks are respectively fixedly arranged on the driving shafts on the left side wall and the right side wall of the front bundling chamber, and front side parts and rear side parts of the two grass rolling side disks are respectively arranged in the front bundling chamber and a rear bundling chamber and are positioned at the inner side of a grass rolling steel roll system. The mechanism has a simple structure, large working feed quantity, high working efficiency, good working quality and fewer use faults, and the power consumption is reduced.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

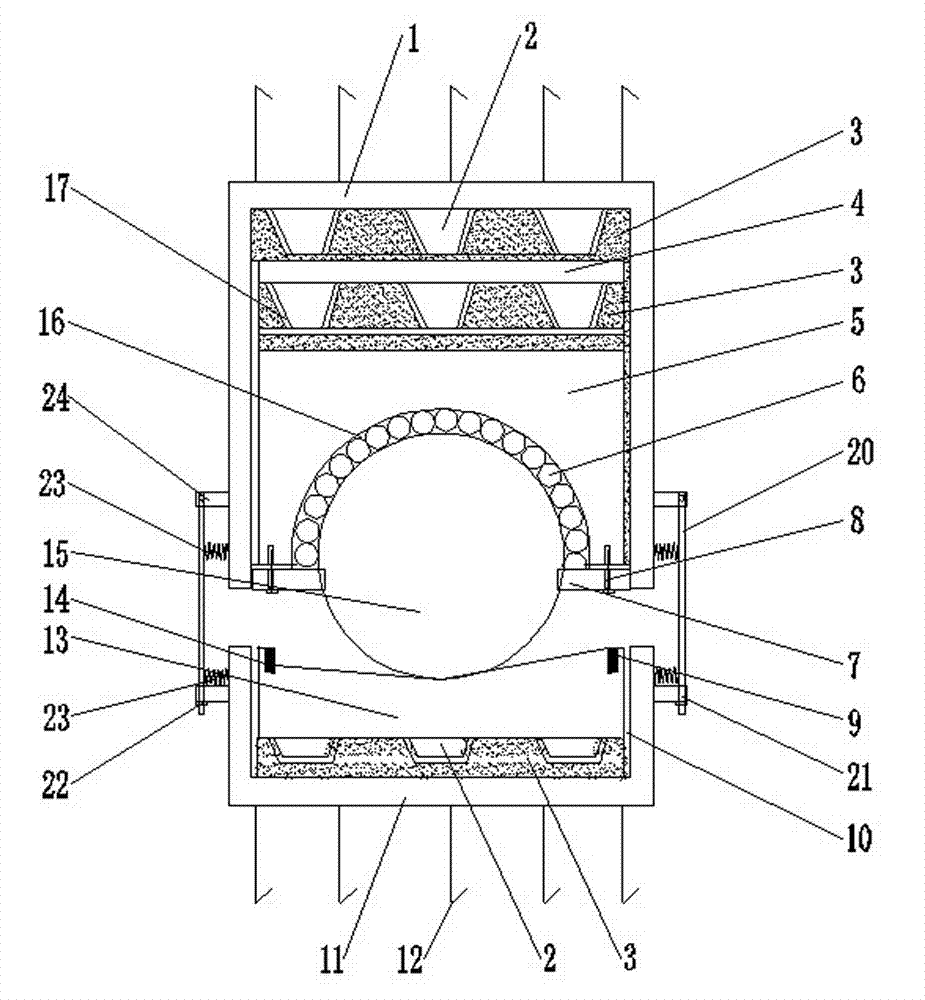

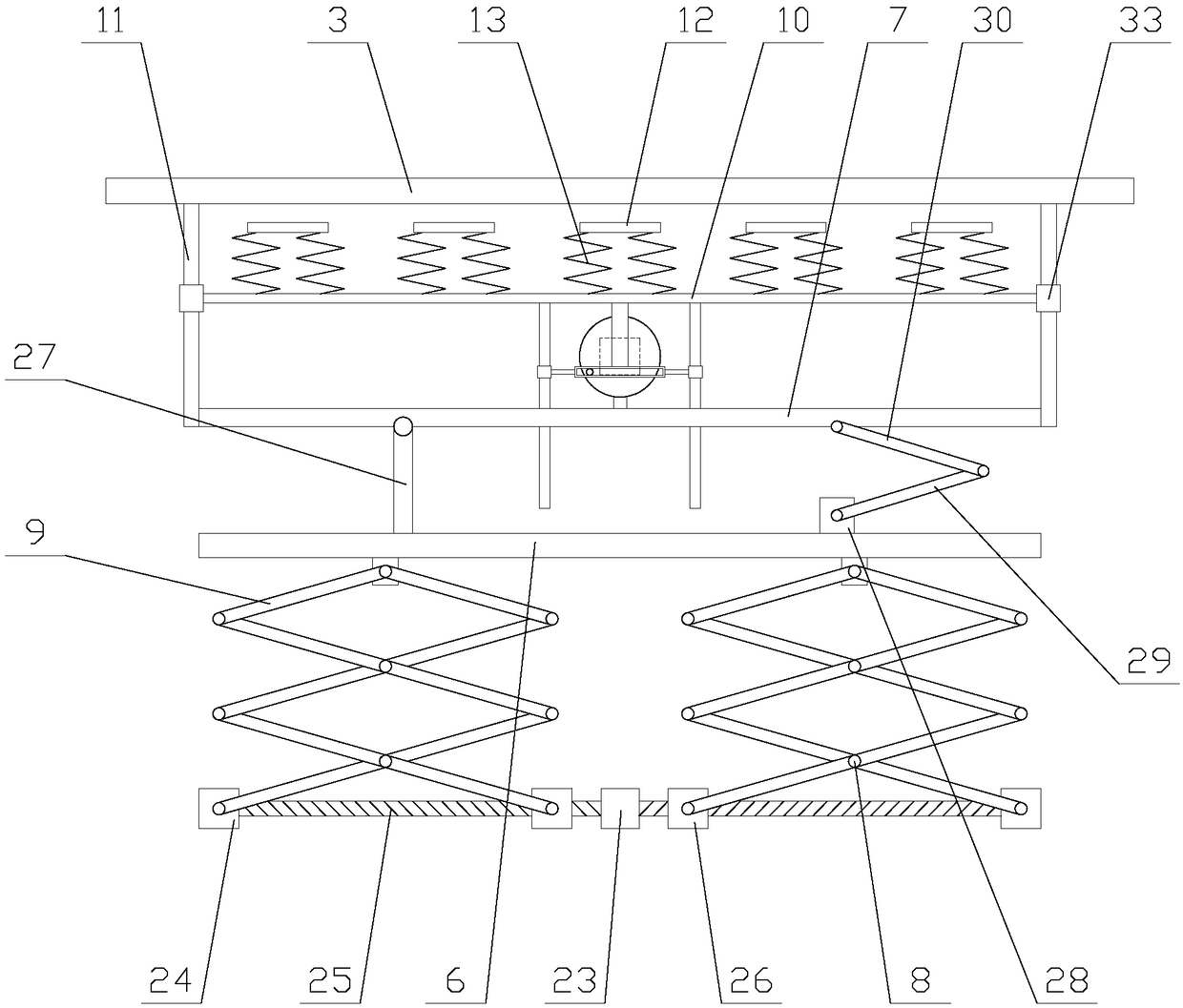

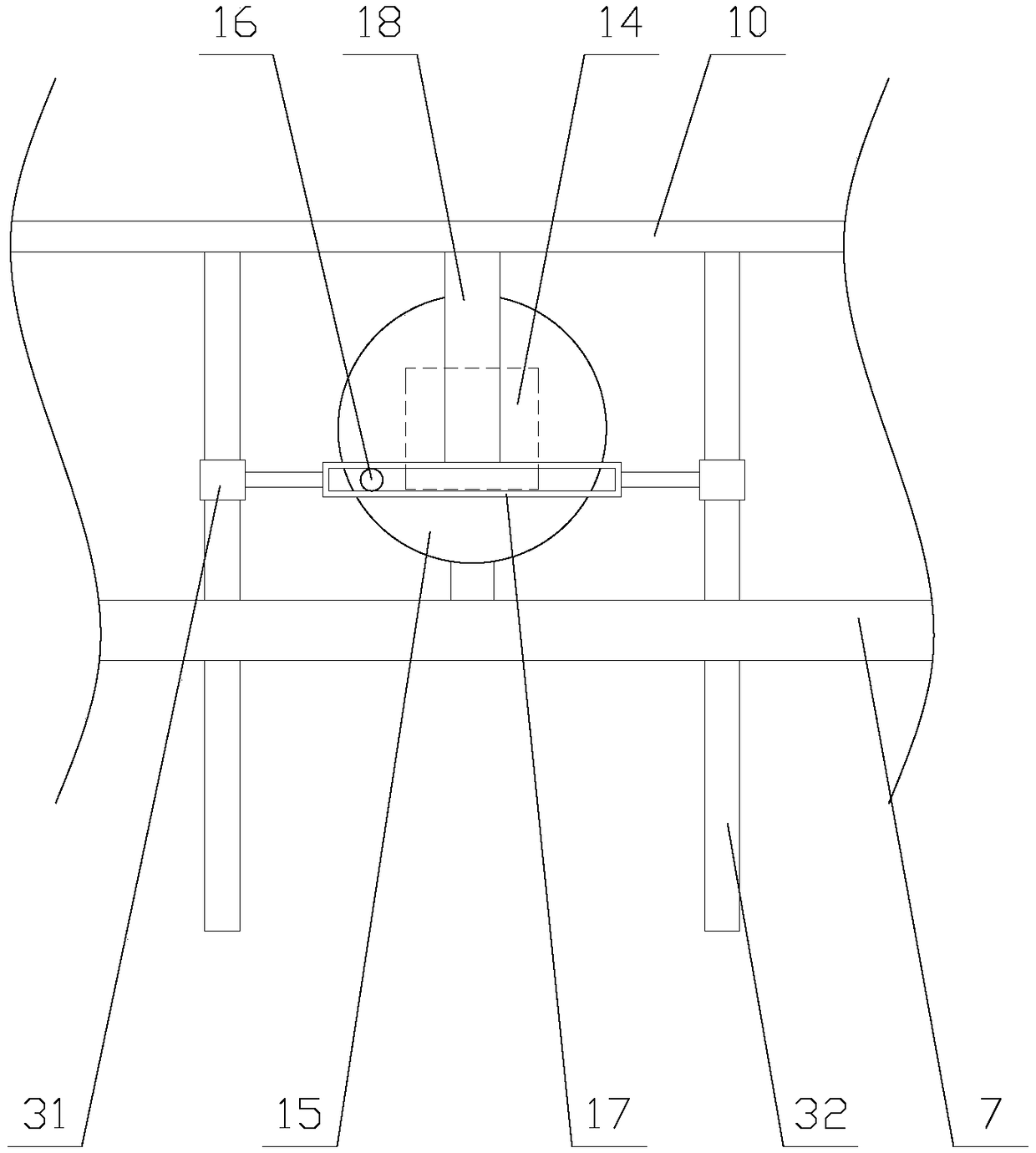

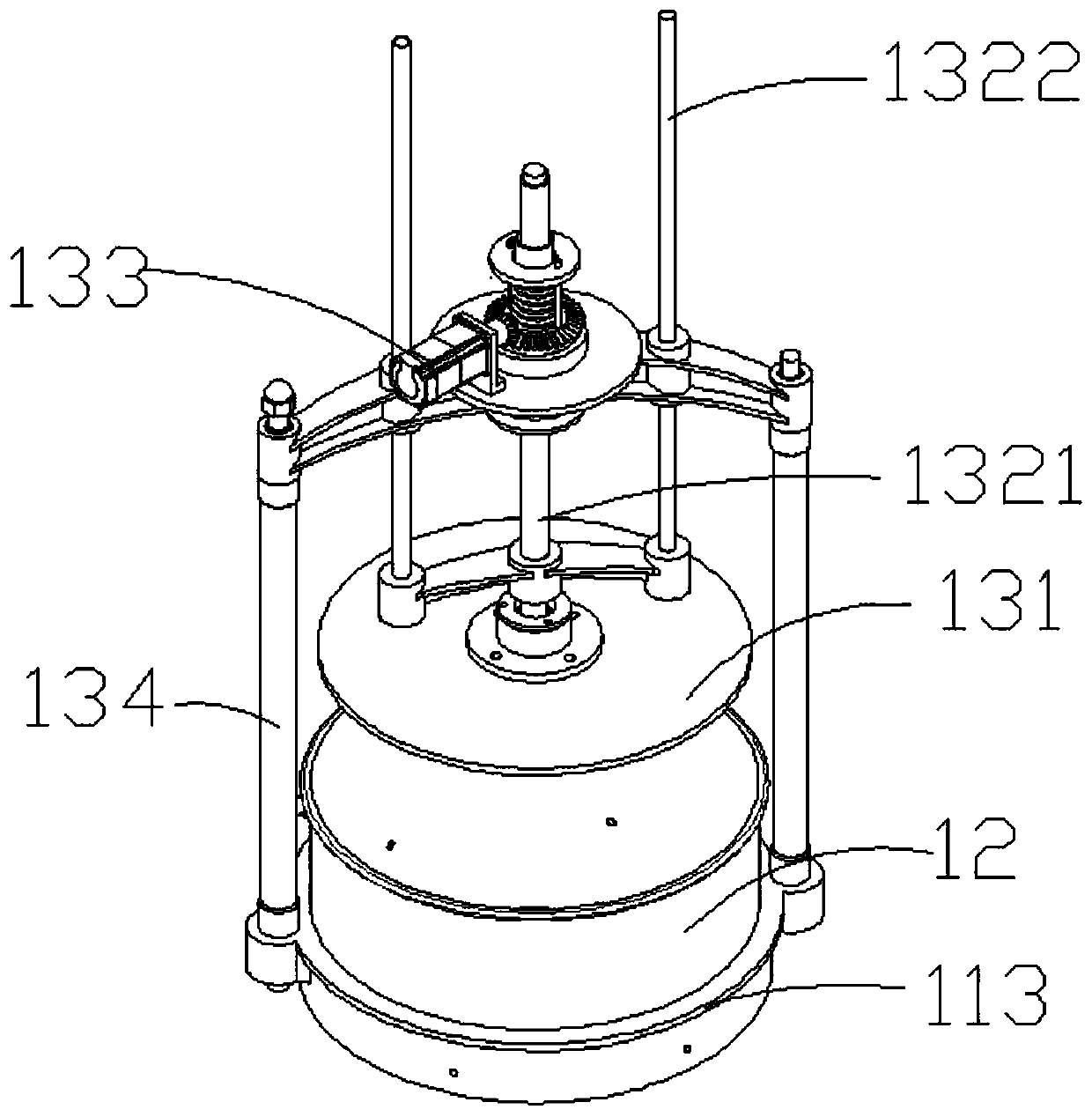

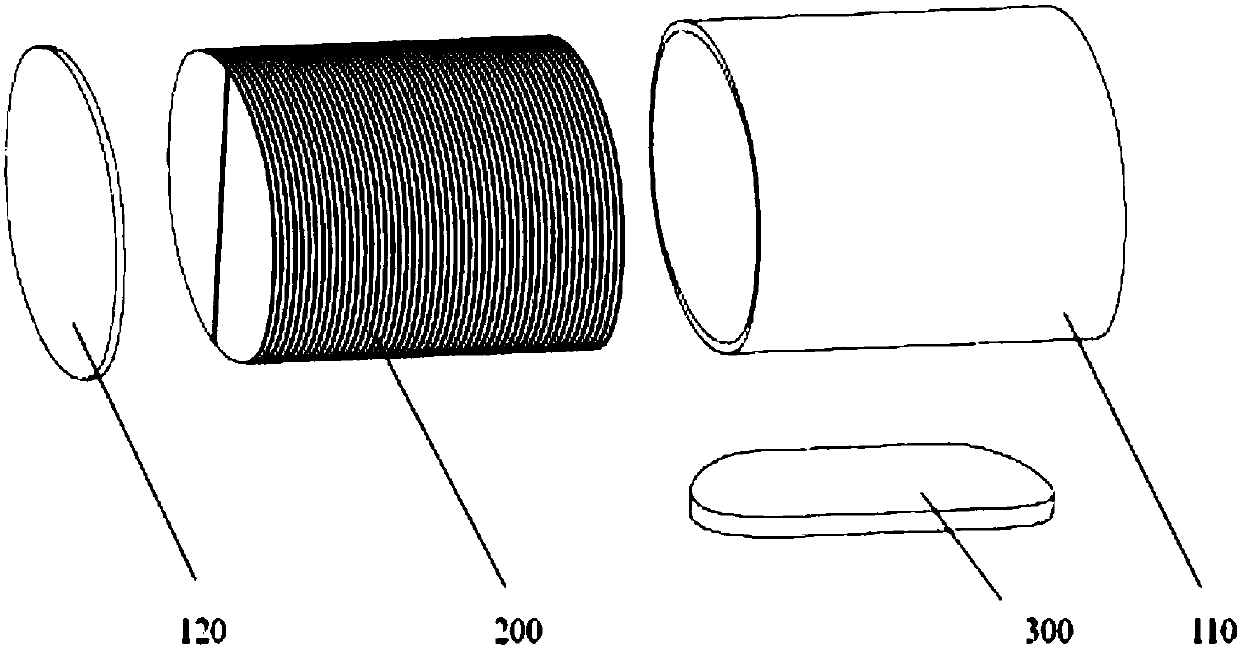

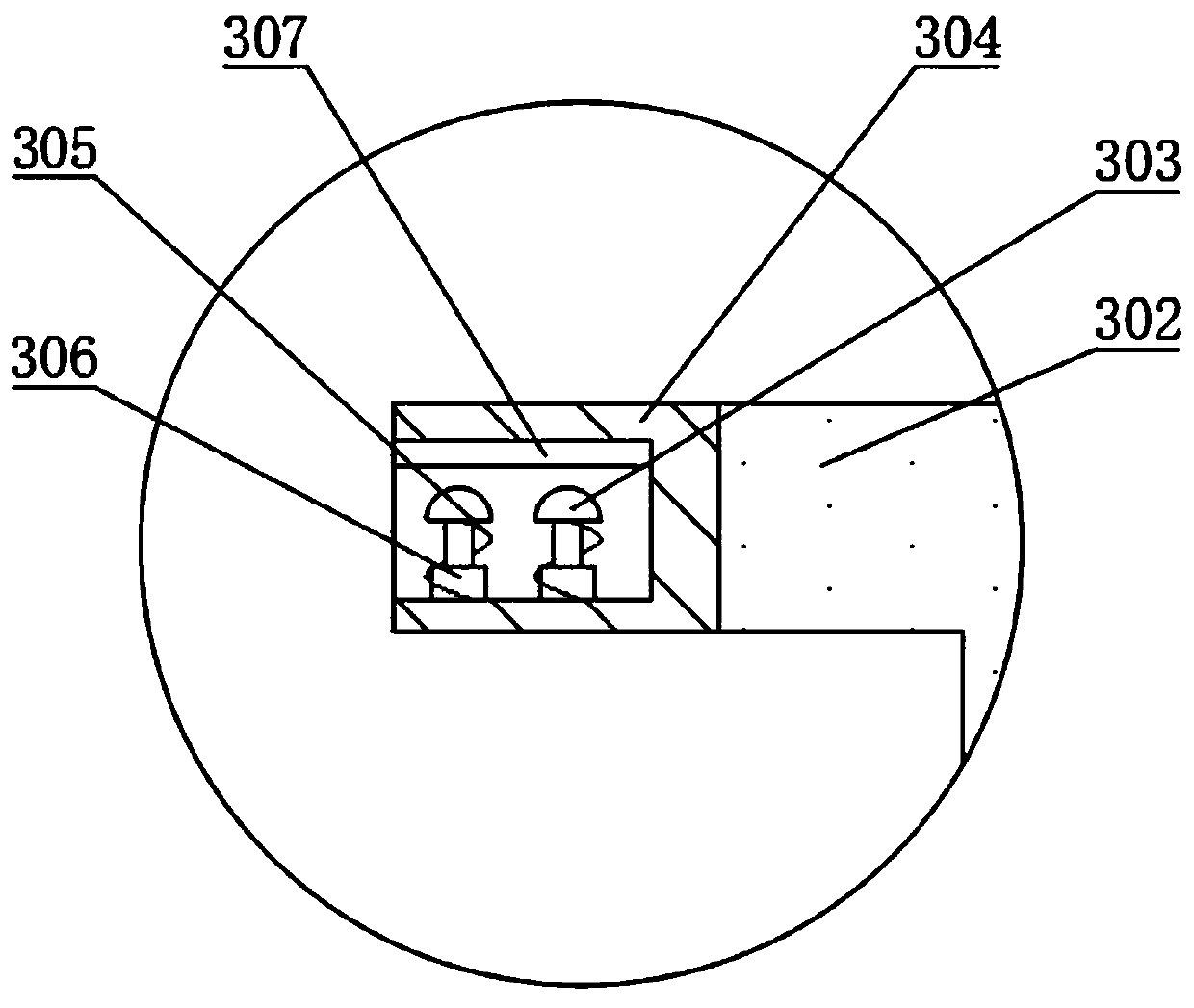

Isolated rolling type vibration damping device

InactiveCN102787679AWeaken Shockwave EnergyBlock and convert shock wave energyShock proofingBreaking strengthBall bearing

The invention discloses an isolated rolling type vibration damping device comprising a rolling part and a rolling disk part. According to the rolling part, a round table post 2, a rubber cushion 3, a pressure plate 4, a ball bearing seat 5, a steel ball 6 and a rolling ball 15 are sequentially installed in a control box 1 at the top from top to bottom and are also provided with clearances with the inner side of the control box 1 at the top. According to the rolling disk part, the rubber cushion 3, the round table post 2, a rolling disk seat 10 and a rolling disk 13 are installed in a control box 11 of a base from bottom to top and are also provided with clearances with the inner side of the control box 11 of the base. The inner shape of the upper part of the rolling disk 13 is a recessed body comprising a matching face contacting with the rolling ball 15 and an inclined straight face in smooth transition with the matching face, the periphery of the upper part of the recessed body is provided with a blocking edge 9, an annular rubber cushion 14 is installed at the inner side face of the blocking edge 9, and the middle point of the vertical lower part of the rolling ball 15 and the middle point of the inner shape of the upper part of the rolling disk 13 are installed in a butt-joint way when the isolated rolling type vibration damping device is used. According to the isolated rolling type vibration damping device, the problems that a foundation of a building and a main body structure are integrally connected, the breaking strength and the energy of seismic waves, which are transmitted to the main body structure, can not be isolated and converted and the building is easily destroyed by vibration waves can be effectively solved. The shock resistance of the building is enhanced, and the economic loss is reduced.

Owner:李富奎

Tea leaf rolling machine convenient to clean

InactiveCN108835305AClean thoroughlyAchieve cleanupPre-extraction tea treatmentDrive wheelRolling disk

The invention relates to a tea leaf rolling machine convenient to clean. The tea leaf rolling machine comprises a base, a supporting device, a rolling disk, a driving block, a pressurizing block and aplurality of driving mechanisms, wherein the supporting device comprises a lifting mechanism, a lifting board, a veering mechanism, a veering board and a vibrating mechanism; the vibrating mechanismcomprises a reciprocating assembly, a reciprocating board, two vertical rods and a plurality of vibrating assemblies; the reciprocating assembly comprises a first motor, a driving wheel, a driving rod, a reciprocating frame and a connecting board; and each driving mechanism comprises bearing columns, a moving assembly, arc-shaped boards, elastic assemblies, a connecting rod, a rotating disk and ahorizontal rod. According to the tea leaf rolling machine convenient to clean, through the moving assemblies, after all the arc-shaped boards are mutually away from each other, the rolling disk is driven by the lifting mechanism to move upwards, and tea leaves on the inner sides of the arc-shaped boards are scraped away, so that cleaning of the arc-shaped boards is realized; and in addition, afterthe veering mechanism is used for driving the rolling disk to incline, the vibrating mechanism is used for beating the lower part of the rolling disk, so that the tea leaves on the rolling disk slipdownwards, cleaning of the rolling disk is realized, and the practicality of the equipment is improved.

Owner:南安市威速电子科技有限公司

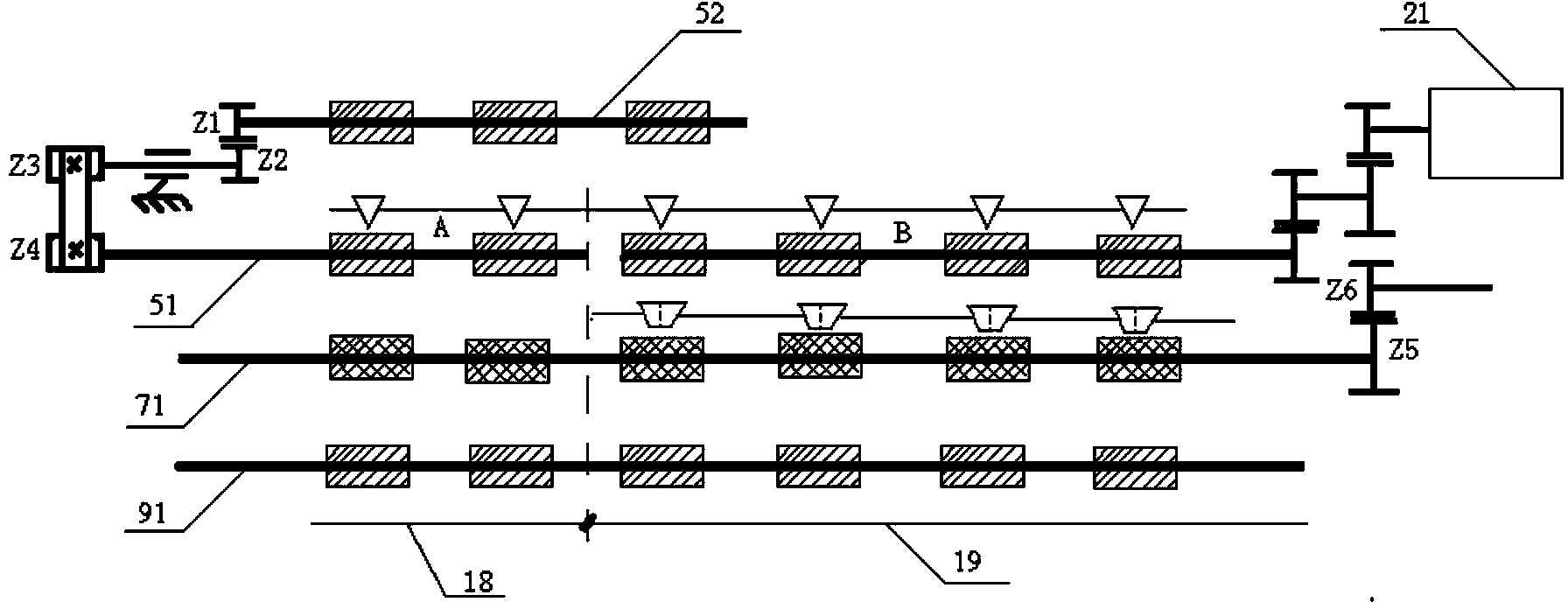

Driving device for wool spinning machine

ActiveCN102704059BReduce labor intensityReasonable structureContinuous wound-up machinesGear driveGear wheel

The invention relates to a driving device for a wool spinning machine. After a front roller motor decelerates, one path of front roller motor subjected to deceleration is connected with a front-right roller through the driving of a first belt; the other path of front roller motor subjected to deceleration is connected with a front-left roller through driving of a first intermediate gear pair and a second belt; after a rear-middle roller motor decelerates, one path of rear-middle roller motor subjected to deceleration is connected with an intermediate roller gearbox through driving of a third belt and a fourth belt; the other path of rear-middle roller motor subjected to deceleration is connected with the intermediate roller gearbox through driving of a second intermediate gear pair and a fifth belt; left and right intermediate rollers are connected with the intermediate roller gearbox; the third belt drives to be connected with a rear roller gearbox through the driving of a sixth belt; the second intermediate gear pair is connected with a rear roller gearbox through driving of a seventh belt; left and right rear rollers are connected with the rear roller gearbox; after a main motor decelerates, the main motor subjected to deceleration is connected with a spindle through a spindle belt via a main shaft and a rolling disk; and a lifting motor subjected to deceleration is connected with a ring rail through a worm gear and worm transmission pair, a stroke cam, a cam roller and a swing rod. The driving device disclosed by the invention has the advantages of simple structure, reduced amount of driving mechanisms and reduction of production cost.

Owner:常州市同和纺织机械制造有限公司

Multi-assortment spun yarn proofing machine

ActiveCN104313735AMeet the process requirementsEasy to spinDrafting machinesContinuous wound-up machinesRolling diskEngineering

The invention discloses a multi-assortment spun yarn proofing machine which comprises a three-roller ring spinning frame body. The three-roller ring spinning frame body is divided into a first side and a second side which are opposite, the first side comprises a first side draft zone and a first side twisting zone, the first side draft zone comprises a first-side front roller, a first side middle roller and a first side rear roller, and the first side twisting zone comprises a plurality of wharves and rolling plates; the second side comprises a second side draft zone and a second side twisting zone, the second side draft zone comprises a second side front roller, a second side middle roller, a second side rear roller and a fourth roller, and the second side twisting zone comprises a plurality of wharves and a plurality of rolling plates. Combinations which can be proofed simultaneously are 3-4 kinds of common yarn counts with different specifications or ones added with satin-colored yarns or bunchy yarns or added with twisted yarns with multiple twisting specifications. The multi-assortment spun yarn proofing machine is compact in structure and efficient and accurate in proofing, and requirements of the multi-assortment spun yarns being proofed simultaneously on the same spinning frame are met.

Owner:ZHEJIANG HUAFU COLOR TEXTILE +1

Tea leaf rolling device

ActiveCN110547344AImprove kneading effectGood kneading and tumbling effectPre-extraction tea treatmentSimultaneous control of multiple variablesRolling diskControl system

The invention discloses a tea leaf rolling device. The tea leaf rolling device comprises a rolling bucket, a rolling disk and a control system, wherein a first transmission mechanism drives the rolling bucket to be in revolution motion in the horizontal direction; the rolling bucket comprises a bucket body of which the two ends are opened and a pressure mechanism located above the bucket body; thebucket body is used for accommodating tea leaves; the pressure mechanism can extend from the upper part of the bucket body into the bucket body, and exert vertical downward pressure on the tea leaves; the rolling disk is located below the rolling bucket; an edge bone frame is arranged above the rolling disk; the edge bone frame is driven by a second transmission mechanism to be in circumferentialrotation in the horizontal direction; the bucket body, the pressure mechanism and the edge bone frame mutually cooperate to perform rolling work on the tea leaves; a tea outlet is formed in the middle part of the rolling disk; and the control system is connected with the first transmission mechanism, the pressure mechanism and the edge bone frame to control the first transmission mechanism, the pressure mechanism and the edge bone frame to perform rolling work on the tea leaves. According to the tea leaf rolling device disclosed by the invention, the rotatable edge bone frame is designed, sothat the control of the rolling speed is realized, and the tea leaf rolling effect is improved.

Owner:湖南三十九铺茶业有限公司

Multifunctional intelligent shared-bicycle storage kiosk

ActiveCN107269050ASolve the problem of parking without taking up sidewalksEasy to storeCharging stationsCycle standsRolling diskElectric machinery

Owner:张文

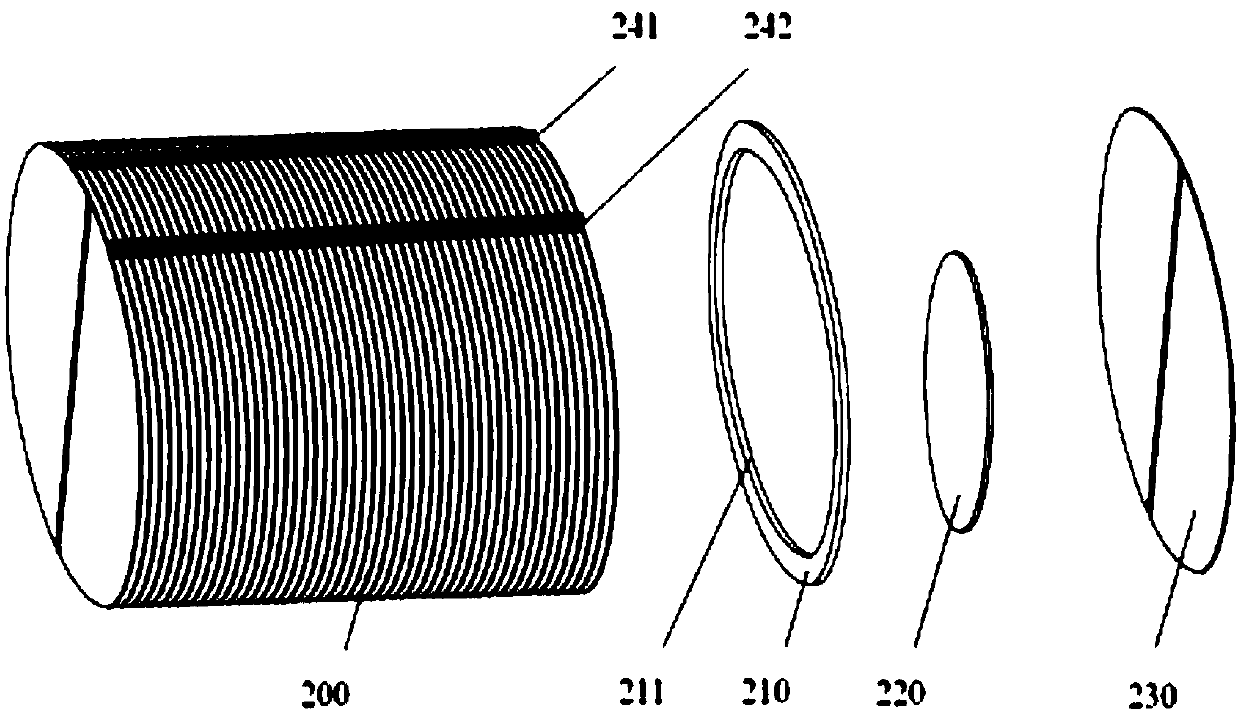

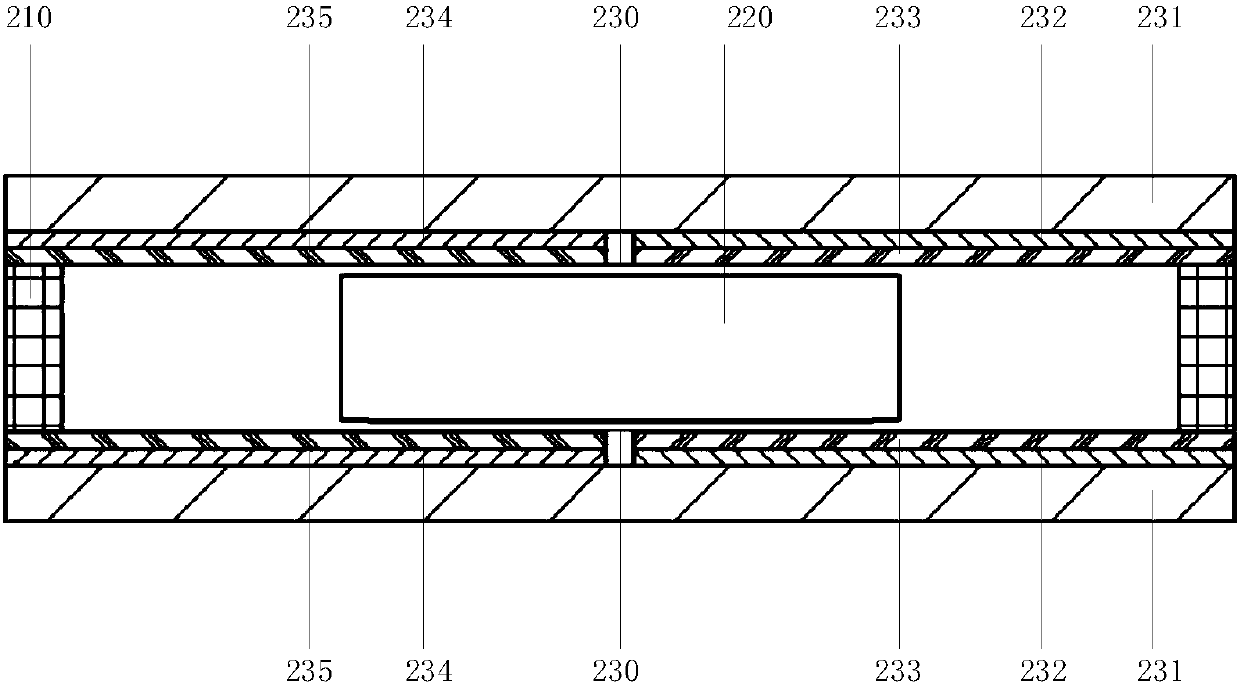

Friction nanogenerator

The invention relates to the field of nano new energy and wave energy collection, and discloses a friction nanogenerator. The friction nanogenerator comprises a shell body and a generator assembly, wherein the generator assembly is arranged inside the shell body; the generator assembly comprises a plurality of generator units; each generator unit comprises two oppositely arranged blocking pieces,a rolling disk positioned between the two blocking pieces, and a rollway arranged on the circumferential side of the rolling disk and matched with the two blocking pieces to form a rolling disk motioncavity; the rolling disk can be arranged in the rolling disk motion cavity in a rolling manner relative to the blocking pieces along the inner surface of the rollway; and at least one of the blockingpieces comprises a base plate, and a first friction electrode unit and a second friction electrode unit which are arranged on one side, facing the rolling disk, of the base plate and are mutually insulated. The friction nanogenerators is compact in structure, can generate an alternating current and loading the alternating current to a load by means of friction electrode layers under the action ofwave excitation based on motion of the rolling disk, realizes the absorption of the wave energy and converts the wave energy into electric energy.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Ground pay-off rack

The invention discloses a ground pay-off rack which comprises a fixed disk, a fixed disk pipe shaft arranged in the center of circle of the fixed disk, a roller disk nested in the fixed disk, and a roller disk pipe shaft arranged in the center of circle of the fixed disk, wherein the fixed disk is formed by welding the fixed disk pipe shaft and a round steel plate and the roller disk is formed by welding the roller disk pipe shaft with channel steel. The ground pay-off rack is used for paying off ground wires. During construction, a wire carrier is put on the ground pay-off rack and then paid off without a wire unlading vehicle. The ground pay-off rack is suitable for a narrow construction space where the vertical pay-off rack can not be laid.

Owner:枣庄矿业(集团)有限责任公司供电工程处

Rolling equipment for processing black tea and tea making method based on rolling equipment

PendingCN110663782AEasy to take outInstalled and disassembledPre-extraction tea treatmentHollow article cleaningRolling diskBlack teas

The invention relates to the technical field of tea production, and in particular to a rolling equipment for processing black tea and a tea making method based on the rolling equipment. The rolling equipment comprise a main body device, a lifting device, a first cleaning device, a second cleaning device and an adjusting device, wherein an inner side of a bottom end of the main body device is fixedly connected with the lifting device, a left end of the main body device is fixedly connected with the first cleaning device, and a top end of the main body device is fixedly connected with the adjusting device. According to the rolling equipment, a cleaning brush, a connecting shaft, a fixed shell and the like are provided, when tea stain on an inner wall of a placing bucket needs to be cleaned by the cleaning brush, a position of the cleaning brush can be adjusted, and then the inner wall of the placing bucket can be cleaned by rotating the cleaning brush; a gear, a fixed seat, a limit ring,a locked handwheel and the like are provided, when tea leaves are rolled by a rolling disk, the tea leaves in the placing bucket need to be pressed down through a pressing plate, and a position of the pressing plate can be adjusted by an action of a rack and the gear.

Owner:桐柏县鑫茗农业有限公司

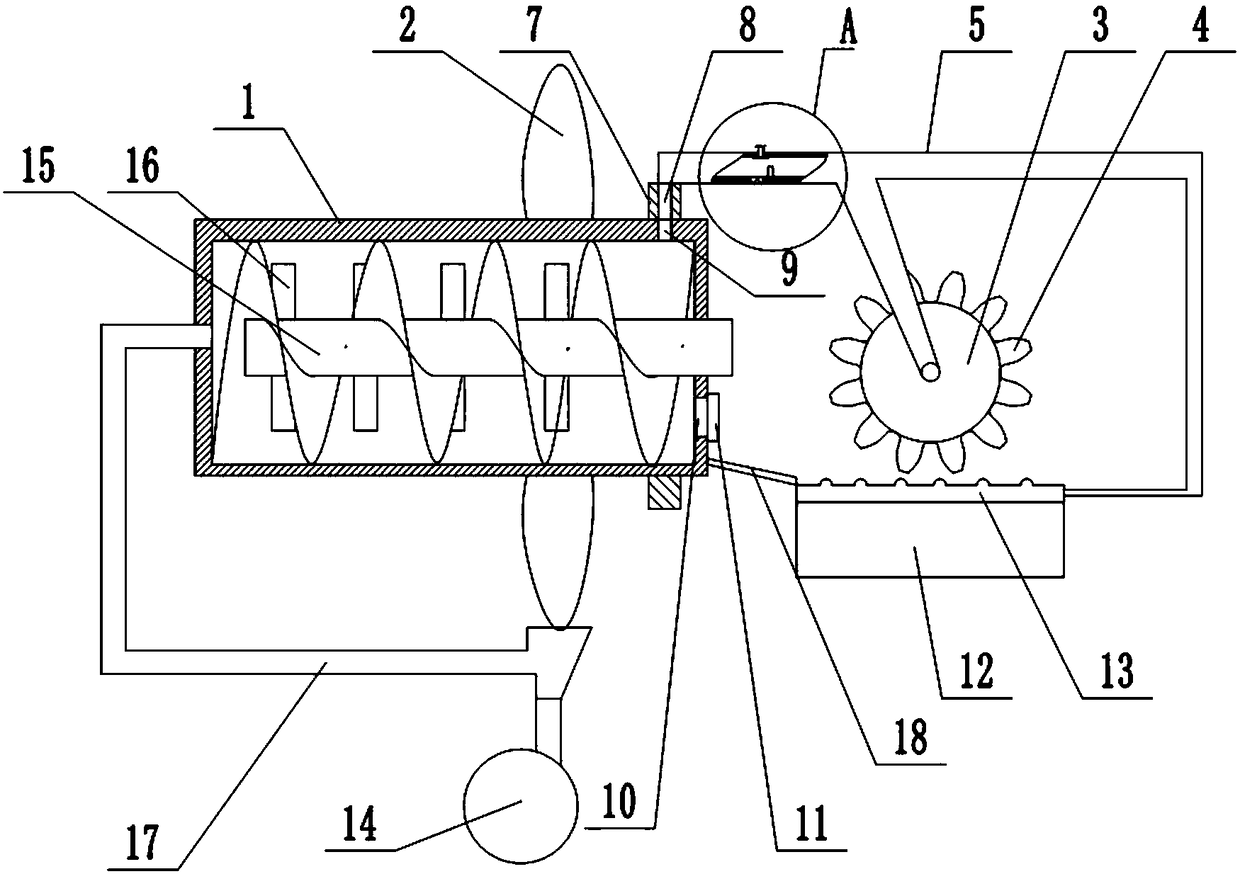

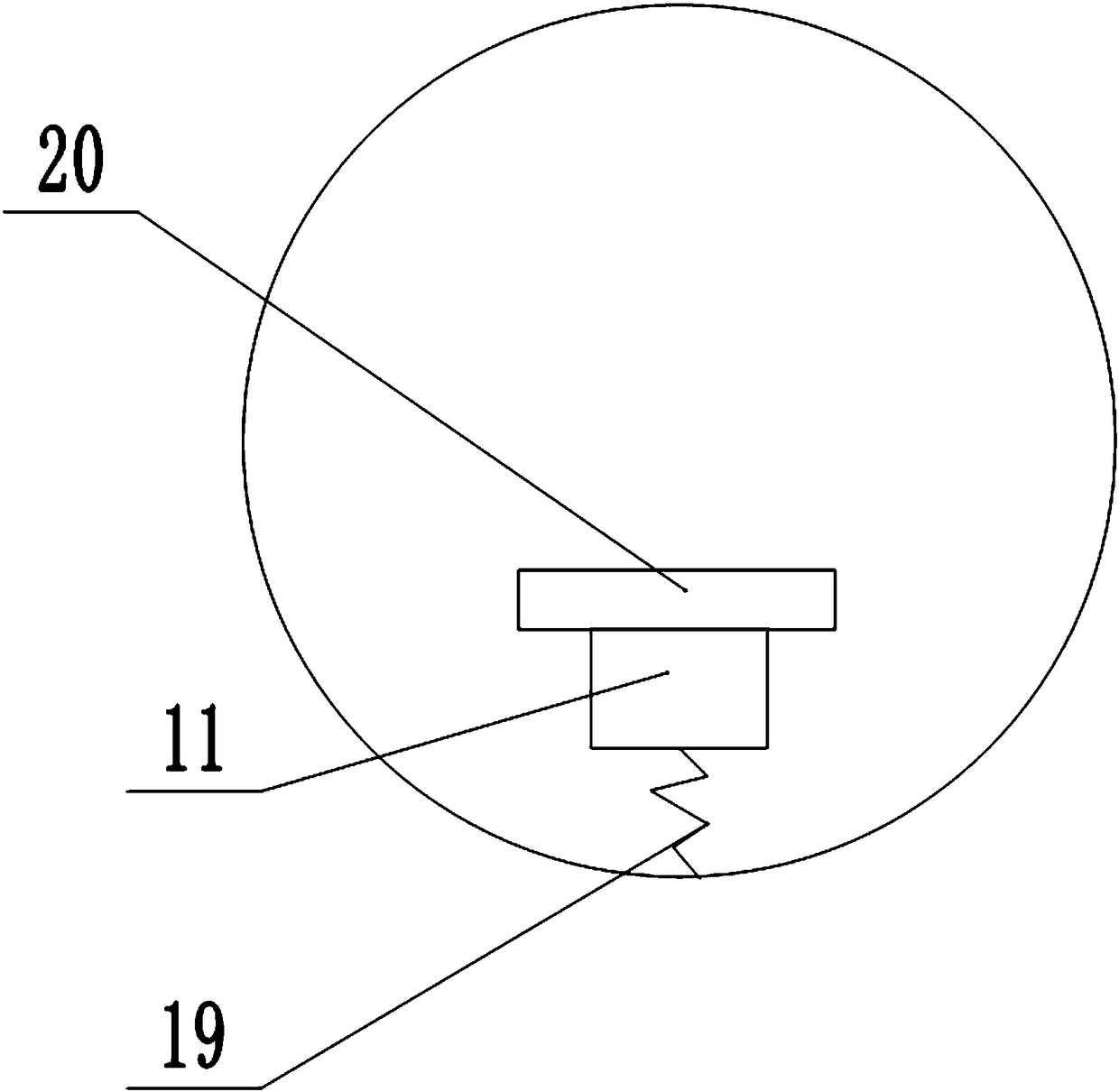

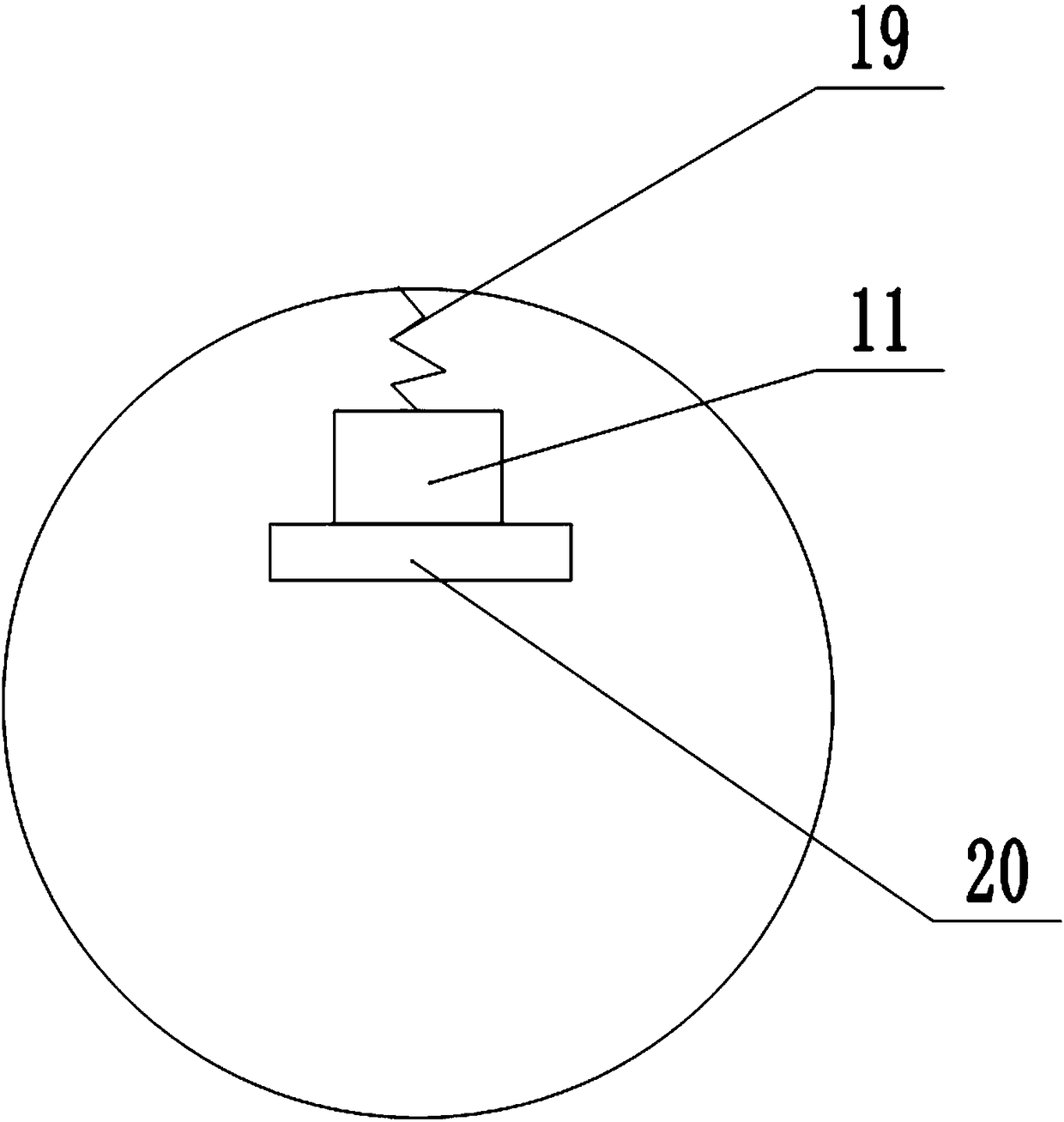

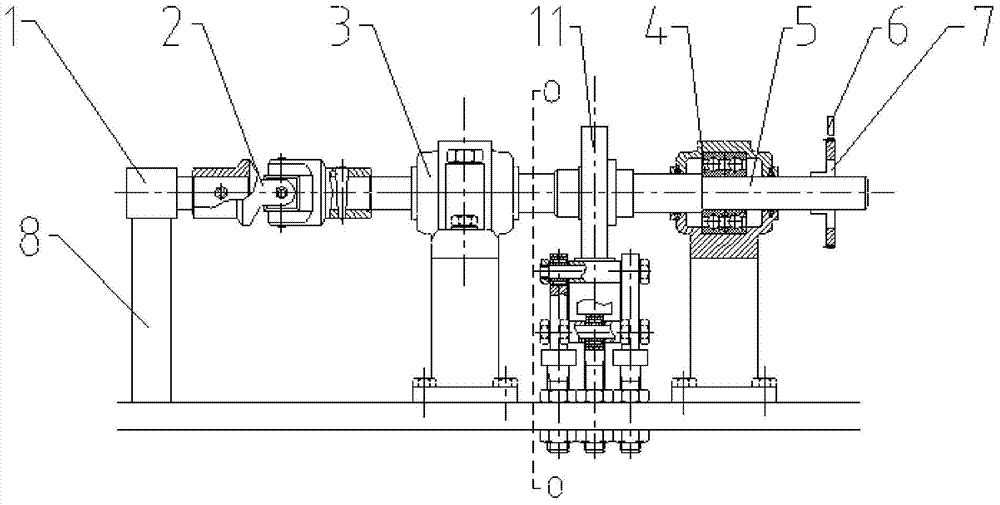

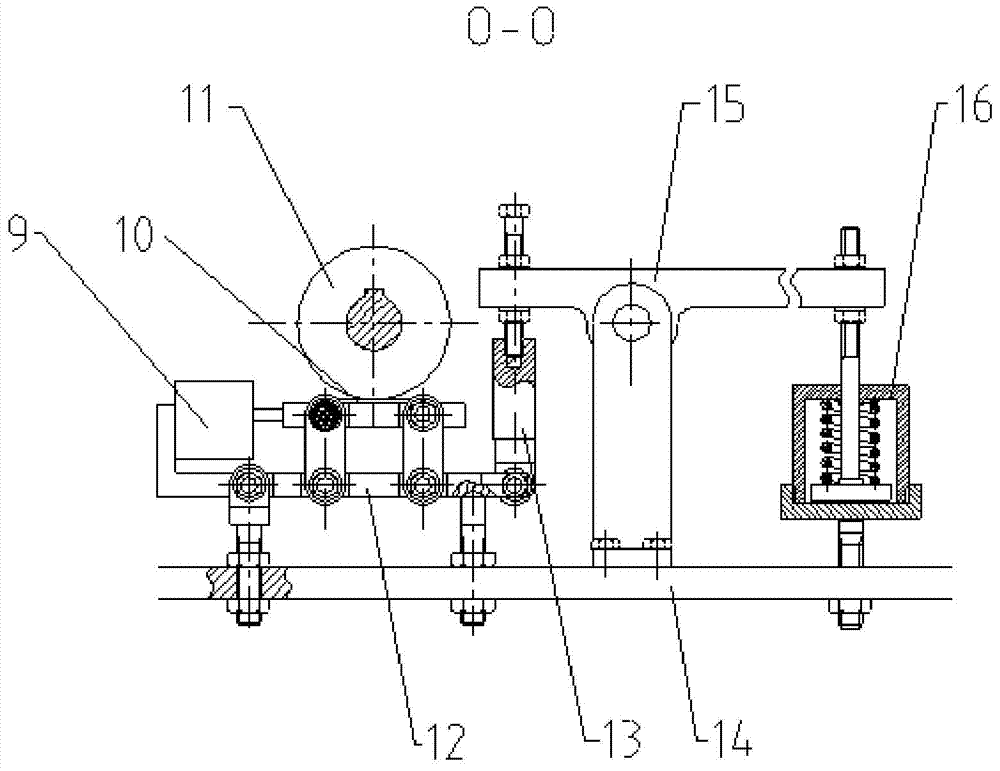

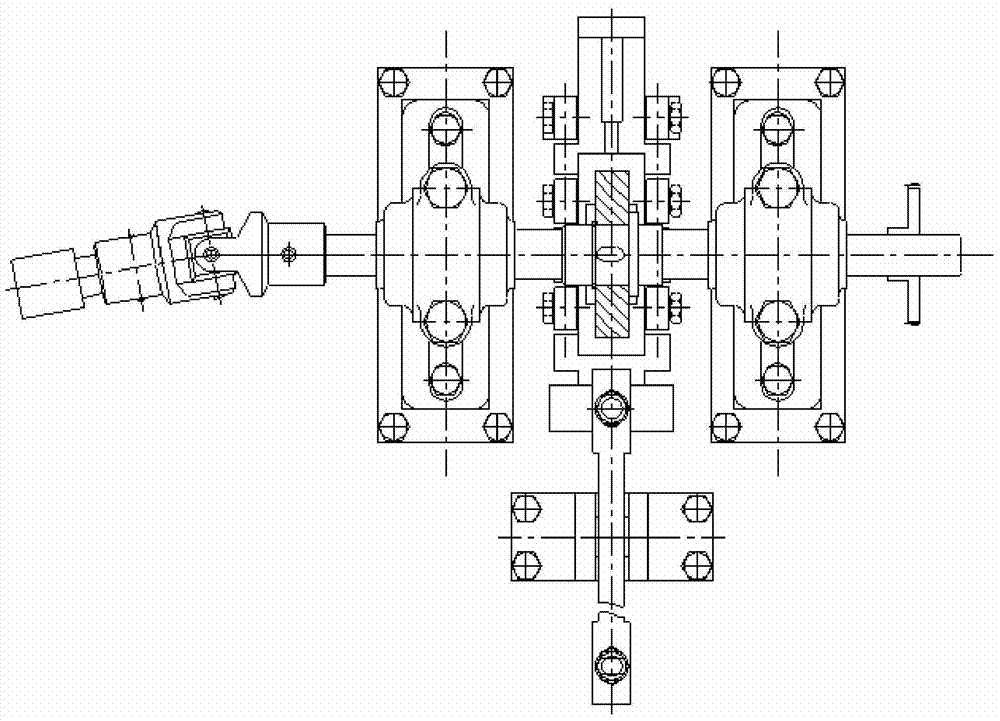

Quantitative analysis experiment device of influence rule on tooth surface friction force by torsional vibration of shaft system

The invention provides a quantitative analysis experiment device of an influence rule on tooth surface friction force by torsional vibration of a shaft system. A motor (1) is installed on a base (14), an output shaft of the motor (1) is connected with one end of a shaft (5) through a cardan joint assembly (2) and the shaft (5) is supported by a front bearing assembly and a rear bearing assembly. A rolling disc (11) is fixed on the shaft (5) and is in contact with a friction sheet (10). The friction sheet (10) is arranged on a friction sheet supporting assembly (12) which is connected with a lever assembly (15) through a vertical force sensor (13). The lever assembly (15) is connected with the base (14) through a loading assembly (16). A horizontal force sensor (9) is connected with the friction sheet supporting assembly (12) and a tooth disc (7) is arranged at the other end of the shaft (5). A magnetoelectricity sensor (6) is matched with the tooth disc (7). The quantitative analysis experiment device of the influence rule on the tooth surface friction force by torsional vibration of the shaft system is applied to study on the influence rule of torsional vibration of the shaft system on the tooth surface friction force.

Owner:HARBIN ENG UNIV

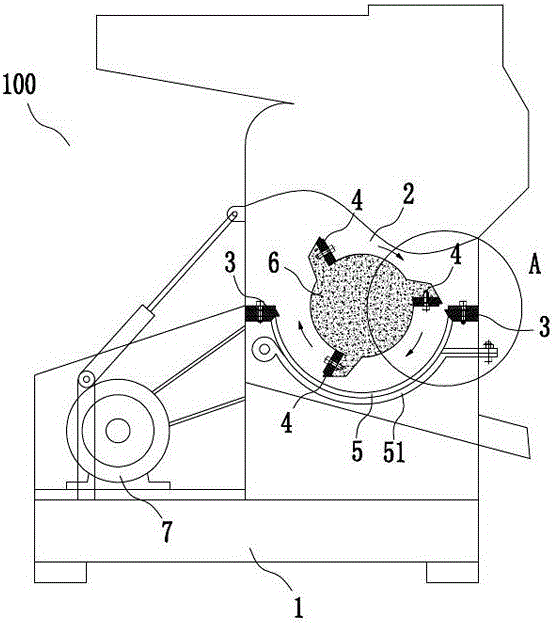

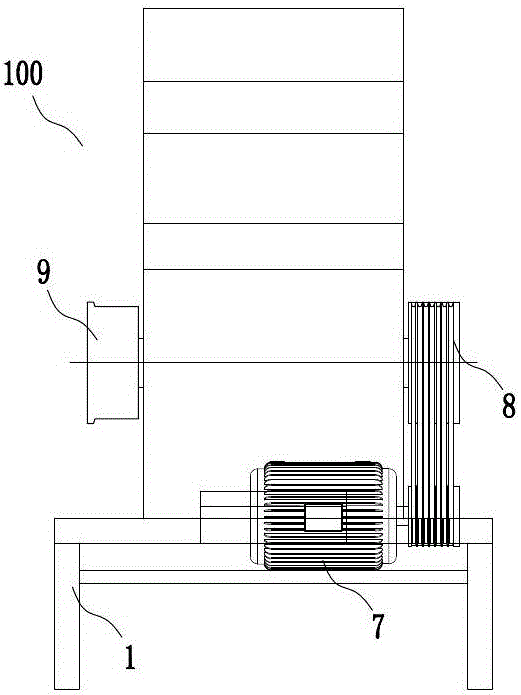

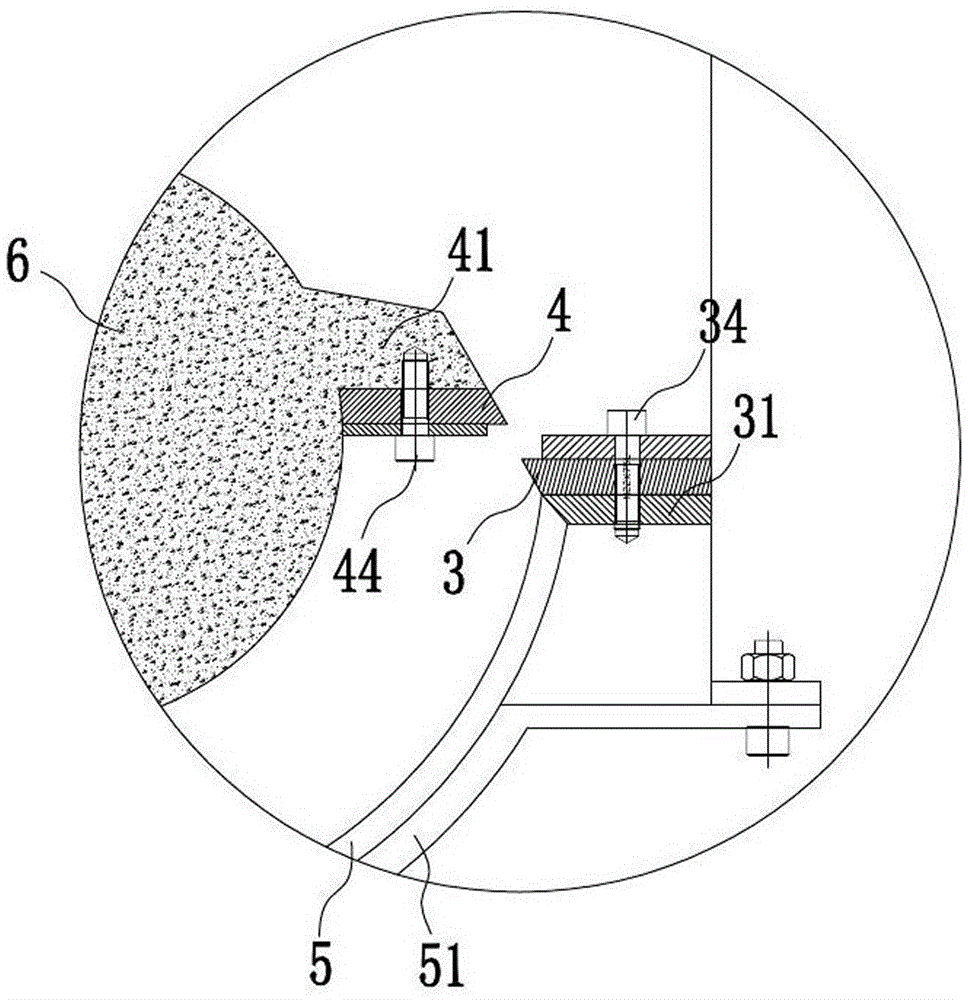

Plastic shoe tree crusher, shoe tree crushing production line and crushing method

ActiveCN105690601AIncrease crushing outputReduce laborPlastic recyclingGrain treatmentsProduction lineEngineering

The invention discloses a plastic shoe tree crusher, a shoe tree crushing production line and a crushing method. The plastic shoe tree crusher comprises a rack, a crushing cavity, fixed cutters, movable cutters, a discharging screen, a movable cutter rolling disc and a motor. The movable cutter rolling disc is arranged in the crushing cavity. A plurality of rows of movable cutter grooves are formed in the movable cutter rolling disc in the radial direction. Each row of movable cutter grooves are provided with a plurality of movable cutter bases distributed in a staggered manner. The movable cutters are fixedly arranged in the movable cutter bases, and the cutting edges of the movable cutters are higher than the outer surface of the movable cutter rolling disc. One fixed cutter base is arranged at the front end of the crushing cavity, one fixed cutter base is arranged at the rear end of the crushing cavity, the fixed cutters are fixedly arranged in the fixed cutter bases, and the cutting edges of the fixed cutters are higher than the inner surface of the crushing cavity. The motor is used for driving the movable cutter rolling disc to rotate, and the discharging screen is arranged at the lower end of the crushing cavity. In the movable cutter rolling disc rotating process, shoe tree crushing is caused due to gaps between the cutting edges of the movable cutters and the cutting edges of the fixed cutters, and crushed shoe tree materials pass through the discharging screen and then are output. According to the plastic shoe tree crusher, the shoe tree crushing production line and the crushing method, the crushing yield is high, the manual work is little, the crushing cost is low, and plastic shoe trees with metal can be directly crushed.

Owner:DONGGUAN JIANFA SHOE MATERIAL CO LTD

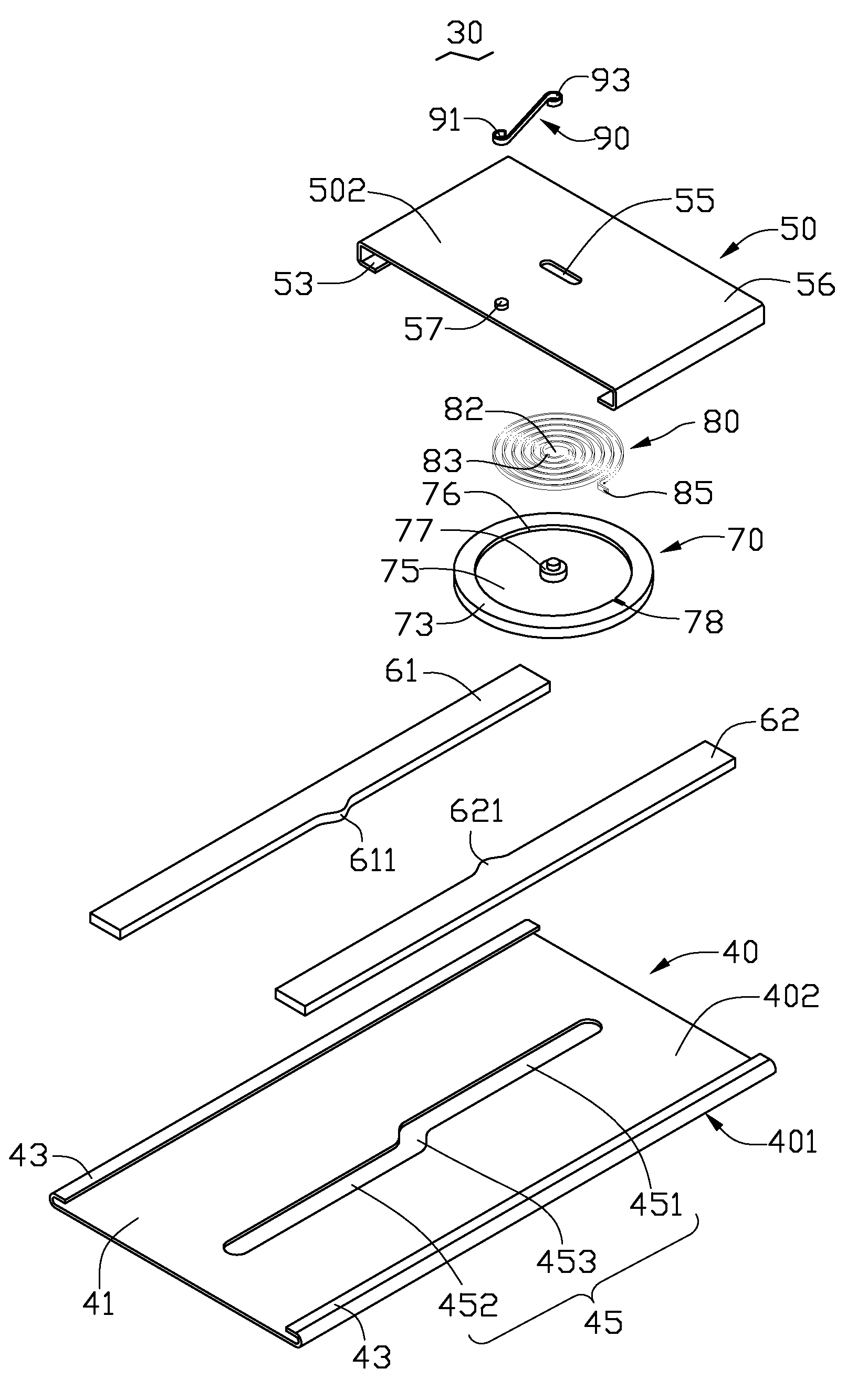

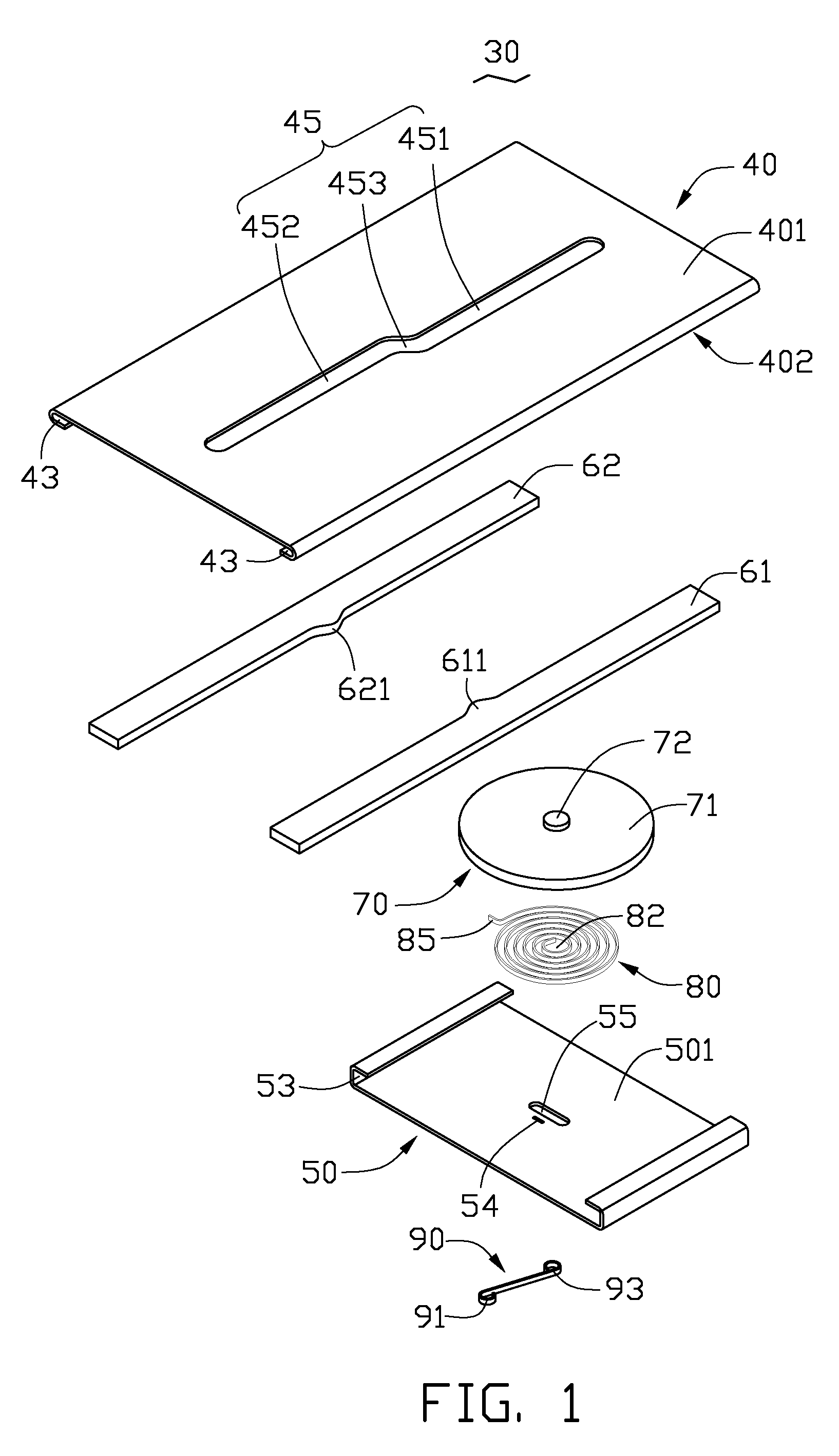

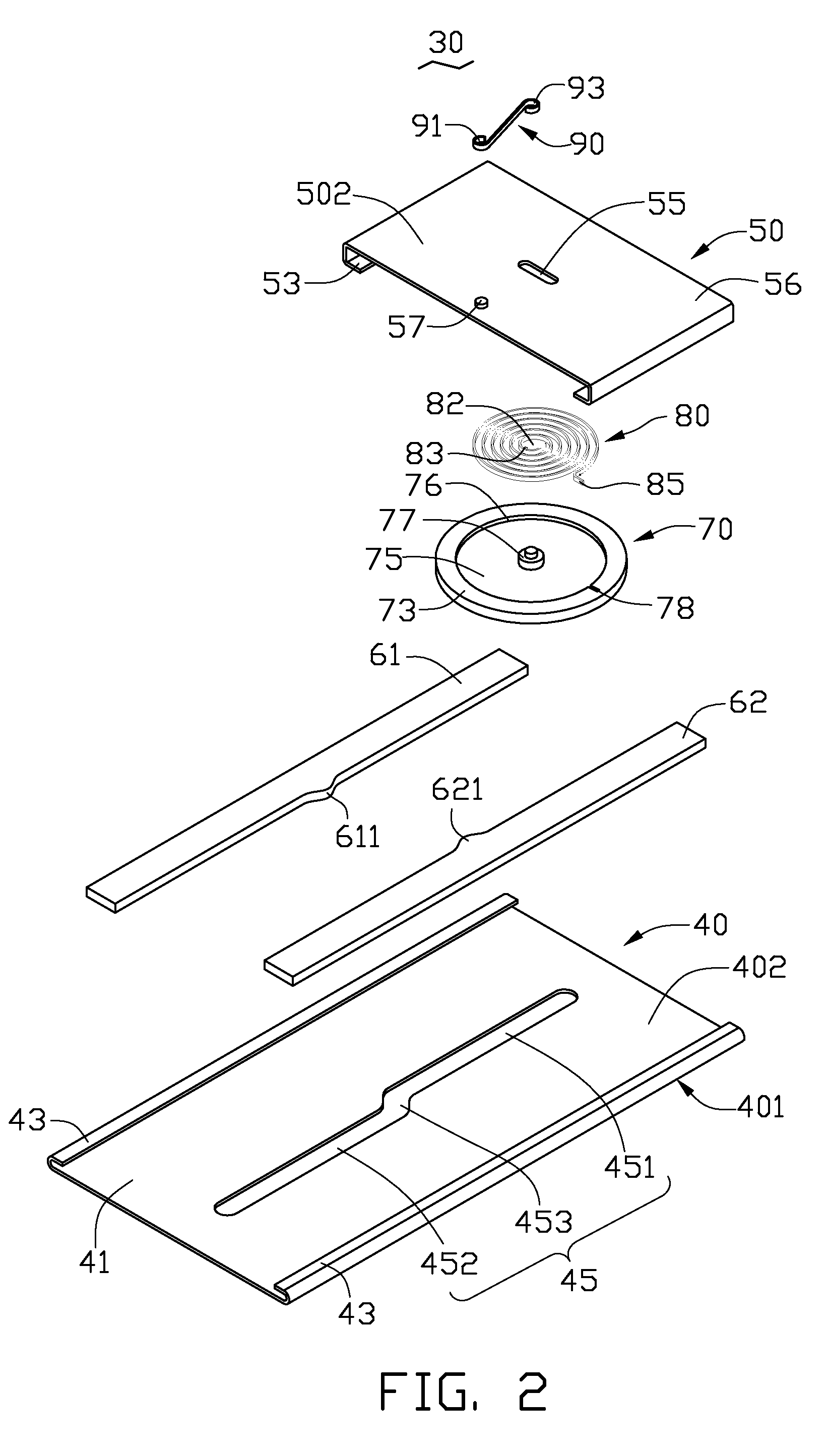

Sliding mechanism

A sliding mechanism used in a portable electronic device is described. The sliding mechanism includes a body section, a cover section, a rolling disk and a coil spring. The rolling disk is fixed to the cover section. A center of the coil spring is fixed to a center of the rolling disk. An end of the coil spring is fixed to a periphery of the rolling disk. When the rolling disk rotates relative to the body section, the coil spring generates a force towards or against the sliding direction of the cover section.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com