Rolling disc type two-axis numerical control pipeline cutting machine

A pipe cutting machine, roller-type technology, applied in welding/cutting auxiliary equipment, tubular items, auxiliary devices, etc., can solve the problems of low cutting efficiency, high production cost, and inability to guarantee cutting accuracy, and achieve high cutting The effect of efficiency and cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

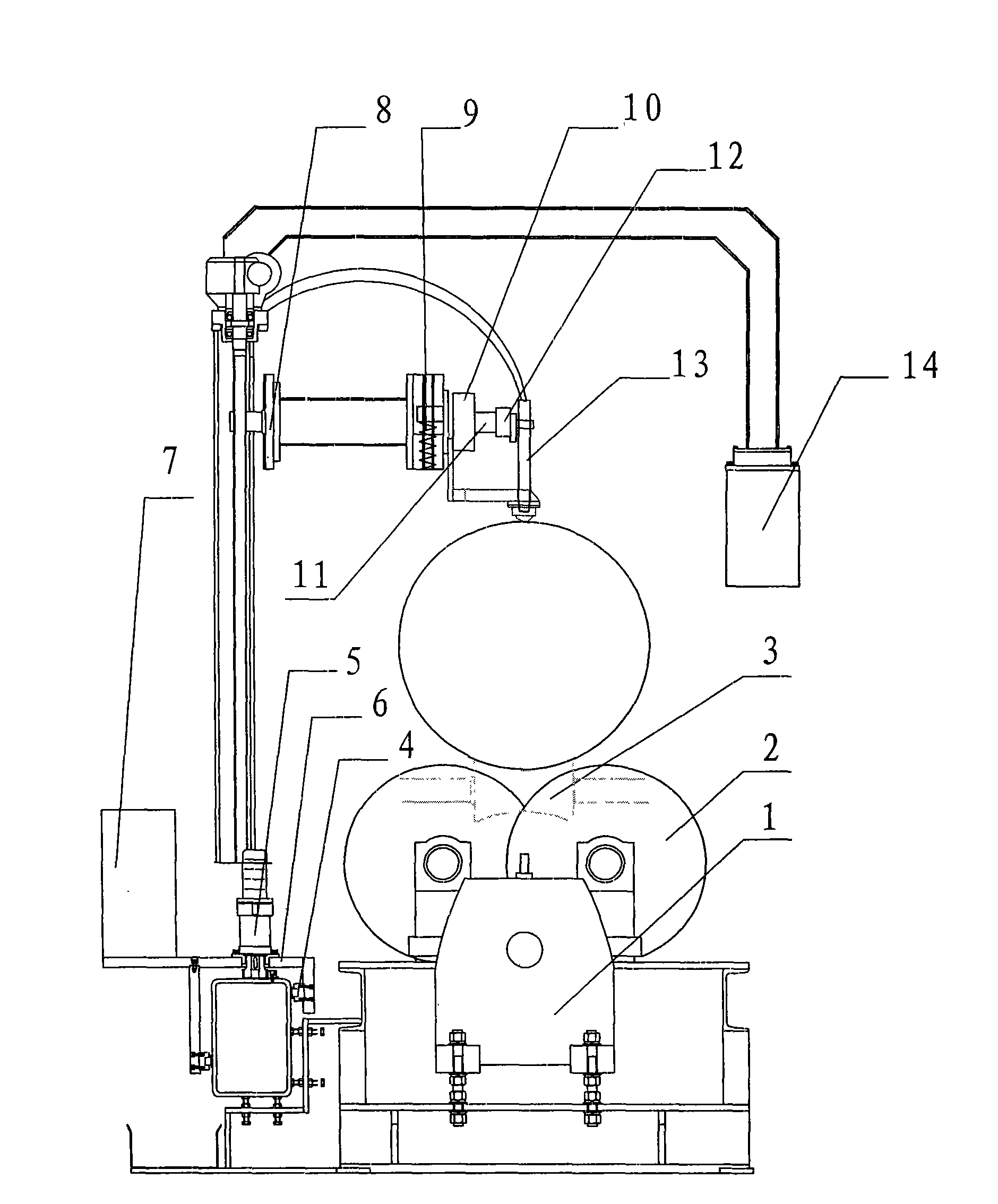

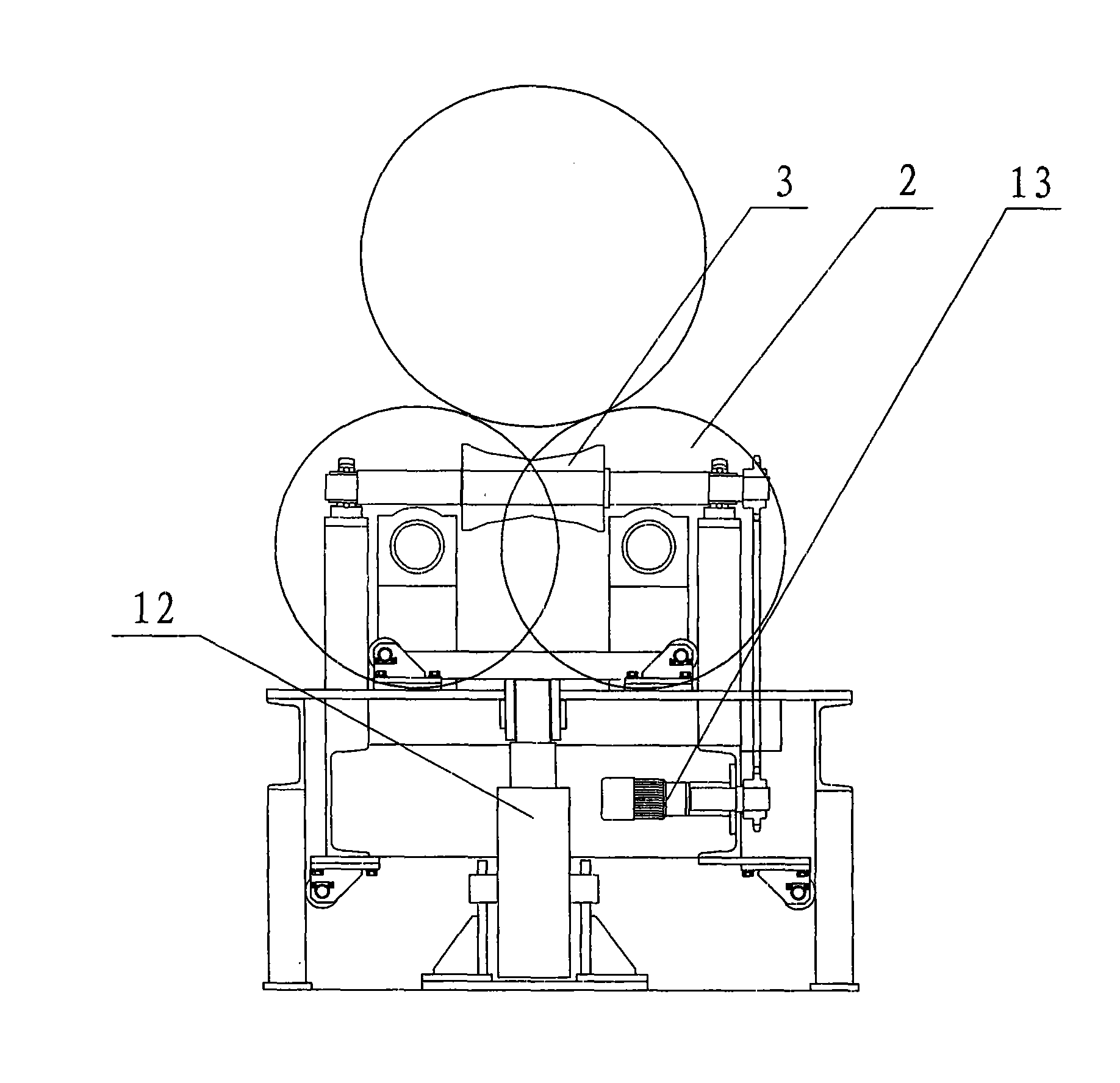

[0016] The present invention aims at realizing the technical requirements of flame and plasma cutting of pipe fixed-length cutting, pipe end bevel, intersecting contour line interface and opening cutting in one cutting, and uses two-axis numerical control technology, and uses two kinds of flame and plasma cutting The method uses the rolling plate to drive the pipe to rotate and the trolley to move axially to realize the two-axis program action and complete the continuous cutting and intersecting line cutting of the pipe fittings. The cutting efficiency is high, the cutting precision is high, easy to operate, and it is compatible with logistics transportation. The roller table combination can complete the conveying, cutting and prefabrication production.

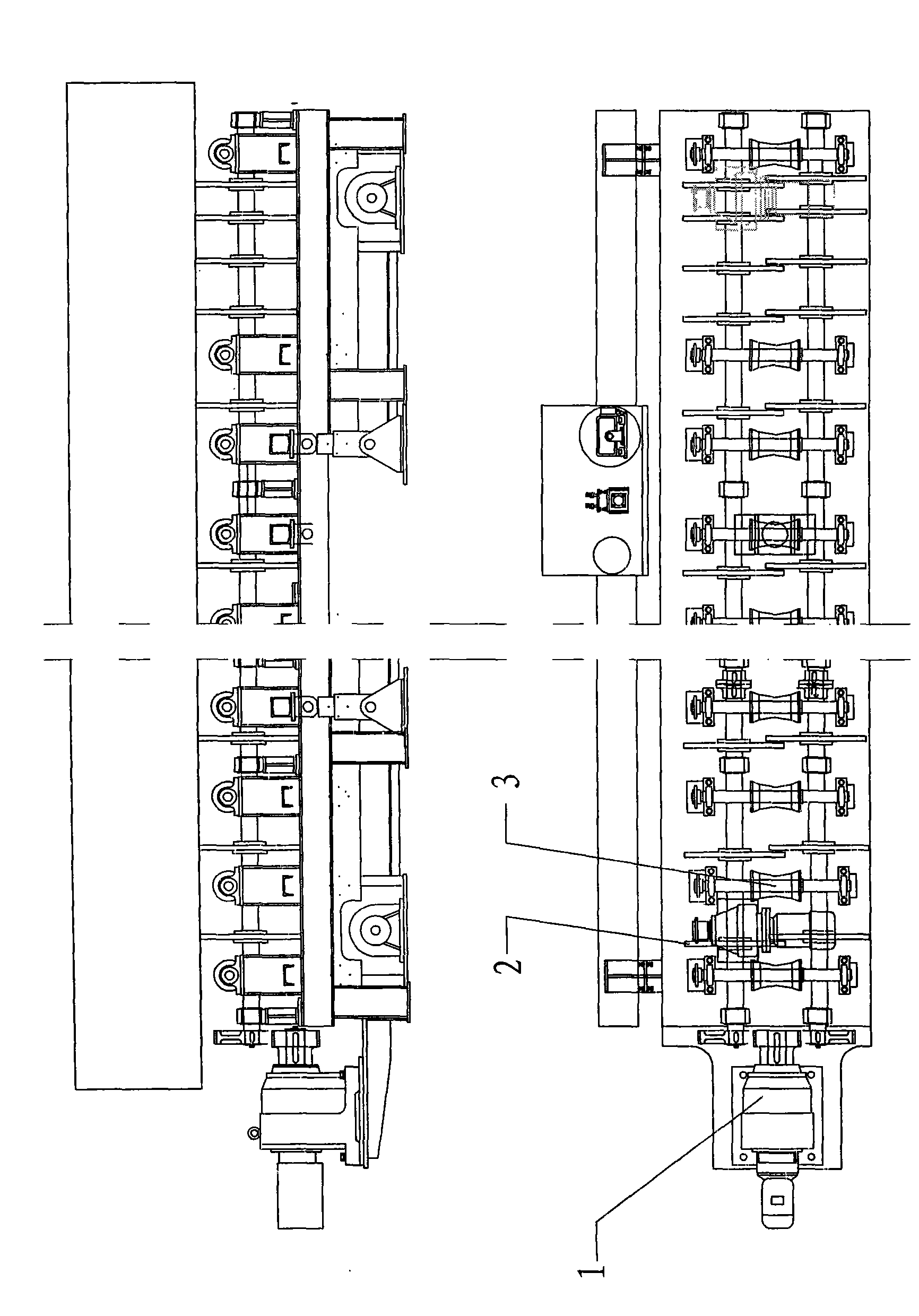

[0017] The rolling disc two-axis CNC pipe cutting machine includes a numerical control controller, a plasma power supply, a pair of rolling discs and their rotating devices at the same level on the working surface of the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com