Quantitative analysis experiment device of influence rule on tooth surface friction force by torsional vibration of shaft system

A shafting torsional vibration, quantitative analysis technology, applied in the direction of measuring devices, vibration testing, machine/structural component testing, etc., can solve the problems that have not been found to study the torsional vibration of shafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

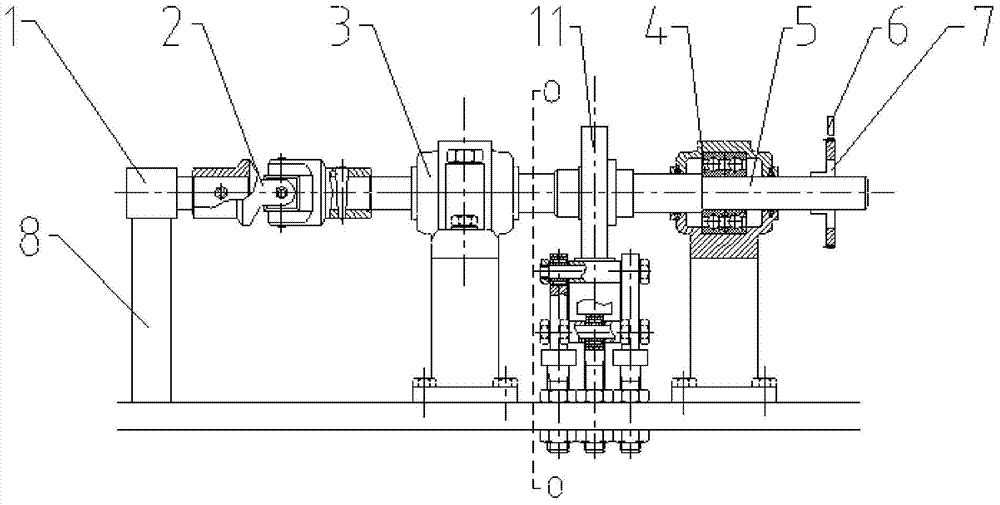

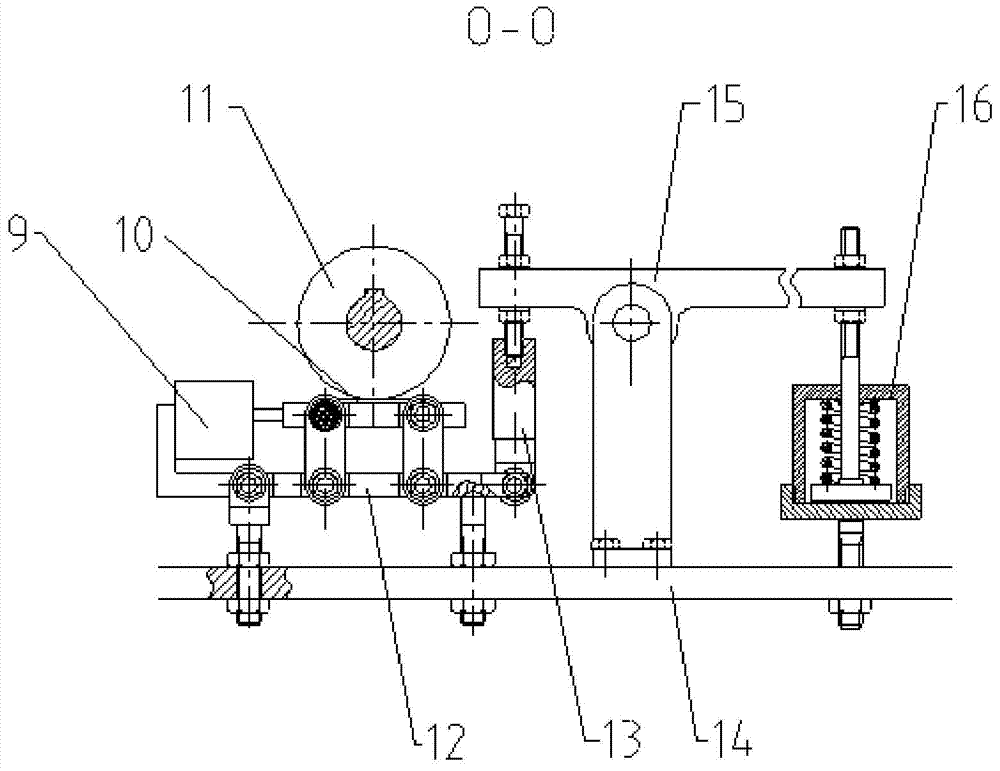

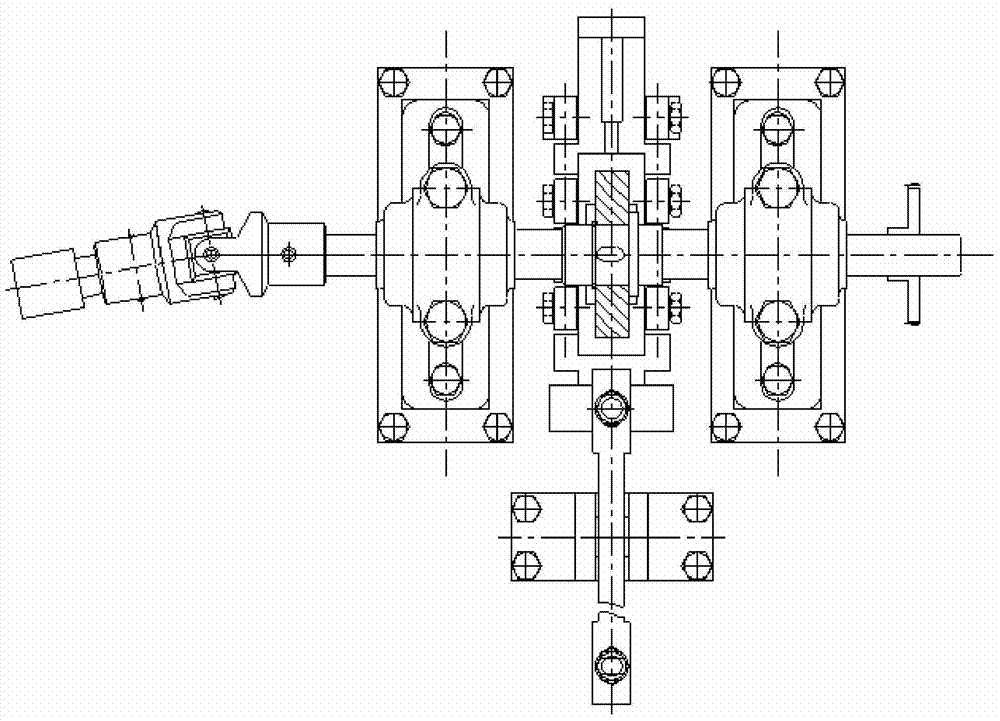

[0032] combine as figure 1 , figure 2 and image 3 , the quantitative analysis system includes motor 1, universal joint coupling assembly 2, front bearing assembly 3, rear bearing assembly 4, shaft 5, magnetoelectric sensor 6, gear plate 7, motor base 8, lateral force sensor 9, friction plate 10, rolling plate 11, friction lining support assembly 12, vertical force sensor 13, base 14, lever assembly 15 and load assembly 16. The motor 1 is fixed on the base 14 through the motor base 8 , and the output shaft of the motor 1 is connected with the shaft 5 through the universal joint assembly 2 . The shaft 5 is supported by deep groove ball bearings; the rolling disc 11 is fixed on the shaft 5 , and the rolling disc 11 is in contact with the friction plate 10 . The friction plate 10 is placed on the friction plate support assembly 12 , and the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com