High-frequency vibration motor for electric toothbrush

A technology of high-frequency vibration and electric toothbrush, applied in electric components, dentistry, electrical components, etc., can solve the problems of short service life, difficult positioning, complex structure, etc., and achieve the effect of long service life, easy manufacturing and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

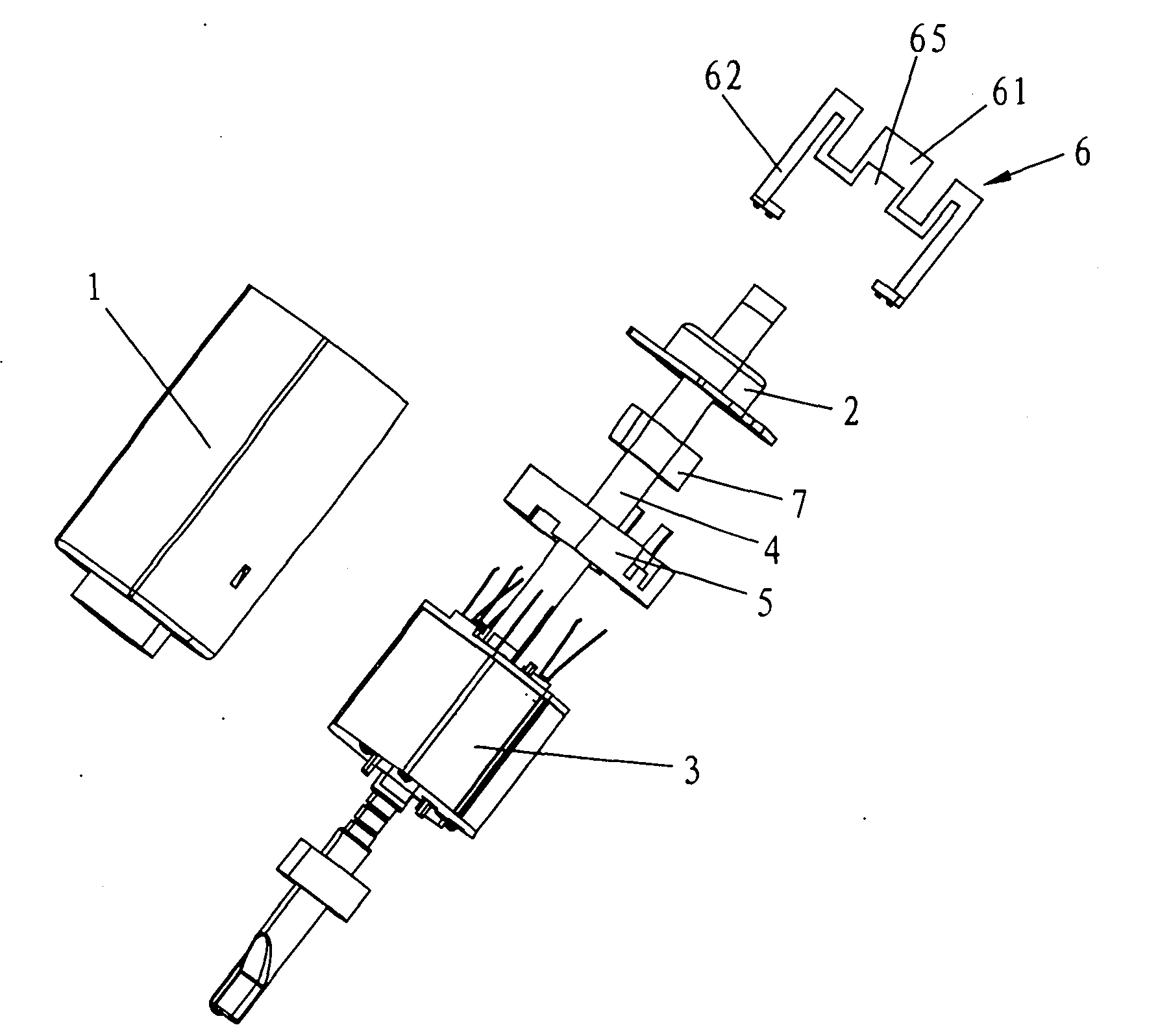

[0039] See figure 1 , 2 , 3, and 19, the present invention includes a casing 1 and a rear cover 2 with a cover on the casing 1, and the casing 1 is provided with a stator 3, a rotating shaft 4, an adjustment pad 5, a bearing 7, a stator 3, and 5 sets of adjustment pads Set on the rotating shaft 4, the output end of the rotating shaft 4 passes through the rear cover 2, and the output end of the rotating shaft 4 is connected with the rear cover 2 through the spring leaf 6.

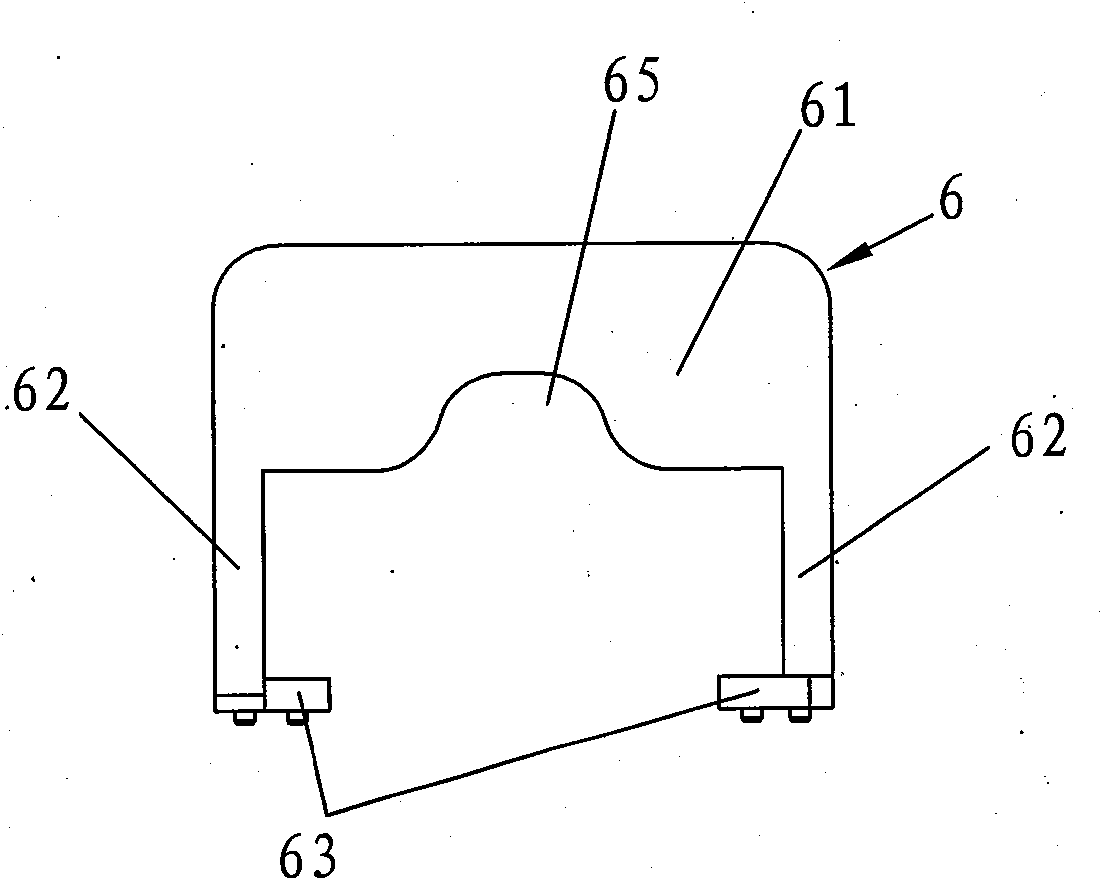

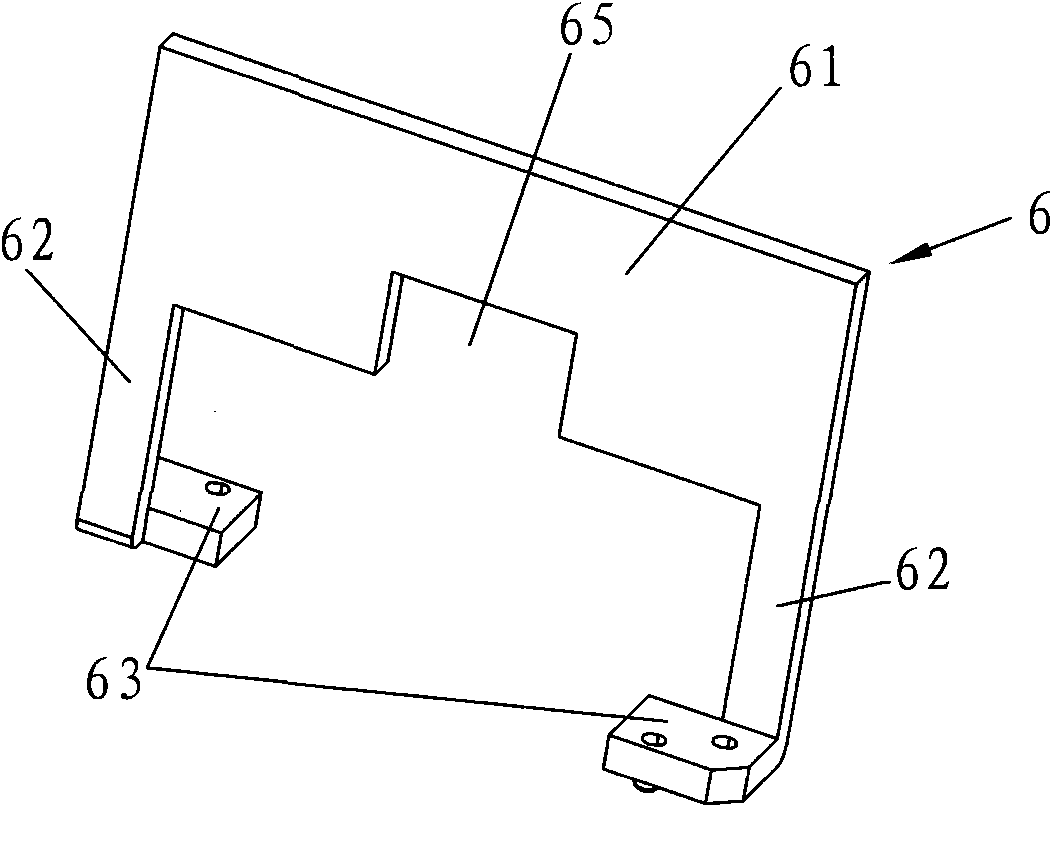

[0040] Between the left and right parts of the spring piece 6 is a rotationally symmetrical structure along the center of the spring piece main body 61. The spring piece 6 includes a spring piece main body 61, and the left and right sides of the spring piece main body 61 are respectively formed with elastic arms 62 that can be twisted and deformed as the rotating shaft 4 rotates. , the output end of the rotating shaft 4 is clamped at the center of the spring body 61, the top of the elastic arm 62 is connect...

Embodiment approach 2

[0044] See Figure 4 , 5 As shown, the difference between this embodiment and Embodiment 1 is that the top of the elastic arm 62 is connected to the spring body 61 by a connecting arm 64. The connecting arm 64 is arranged vertically, and its top is connected to the top of the elastic arm 62. Its bottom is connected to the bottom of the main body 61 of the elastic piece, and the addition of the connecting arm 64 can increase the elastic deformation range of the spring piece 6 . Of course, the top of the elastic arm 62 may also be connected to the spring body 61 through a plurality of end-to-end connection arms 64 , and other structures and principles are the same as those in the first embodiment.

Embodiment approach 3

[0046] See Figure 6-8As shown, the difference between this embodiment and Embodiment 1 is that the elastic body 61 of the spring 6 is a sheet structure located on a plane perpendicular to the elastic arm 62 , and the elastic body 61 is perpendicular to the elastic arm 62 . The output end of the rotating shaft 4 is formed with a flat post 41, and the center of the shrapnel main body 61 is provided with a bayonet 66 that matches the post 41. The bayonet 66 can be a flat hole, a Z-shaped hole or a hole of other shapes. , the clamping column 41 is clamped in the bayonet socket 66, and other structures and principles are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com