Novel computer-controlled bevel wheel roller raising machine

A computer-controlled, helical gear technology, used in textiles and papermaking, roughening, fabric surface trimming, etc., can solve problems such as low production efficiency, large machine vibration, and increased labor intensity, and achieve high production efficiency and transmission. Powerful, damage-avoiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

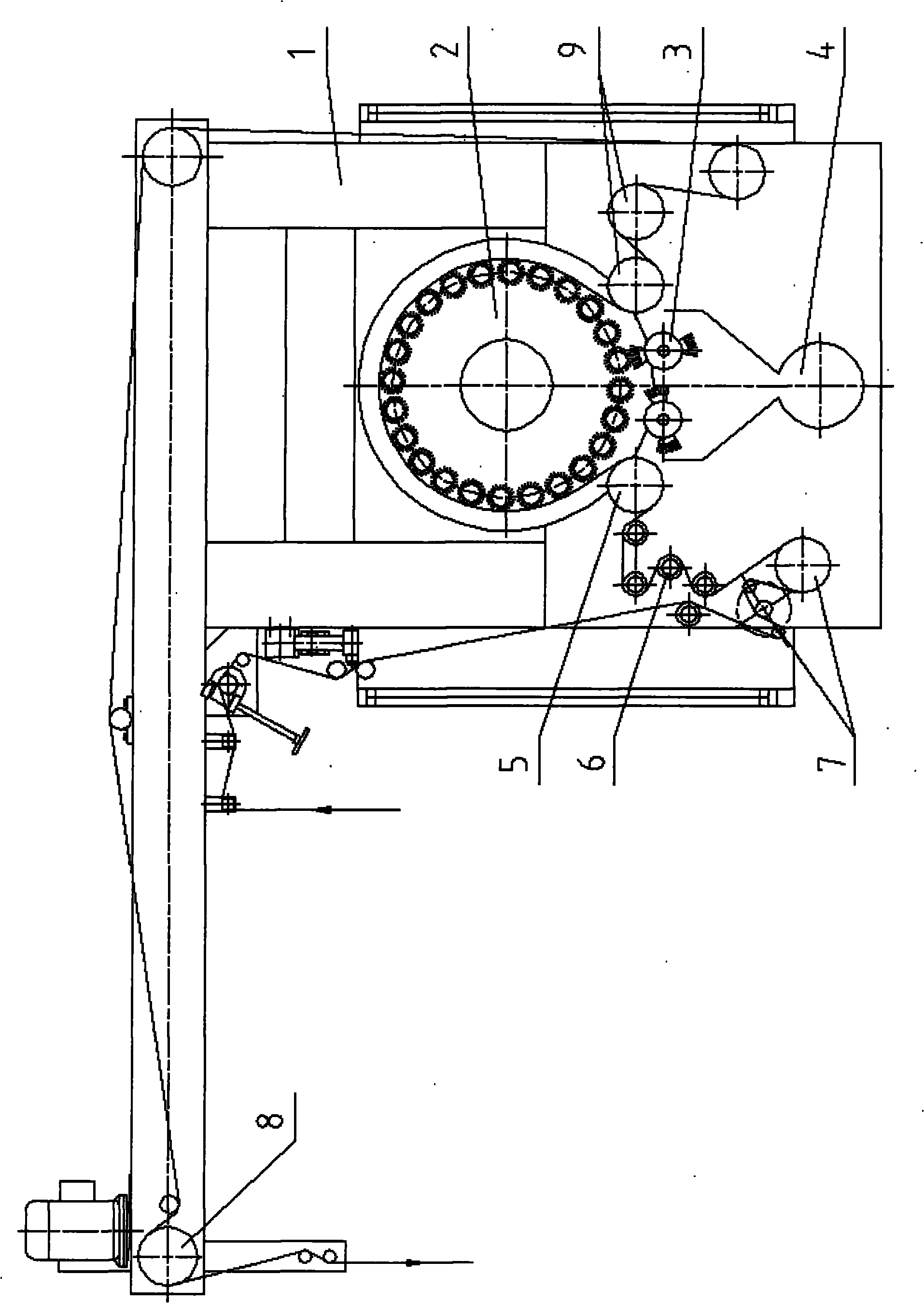

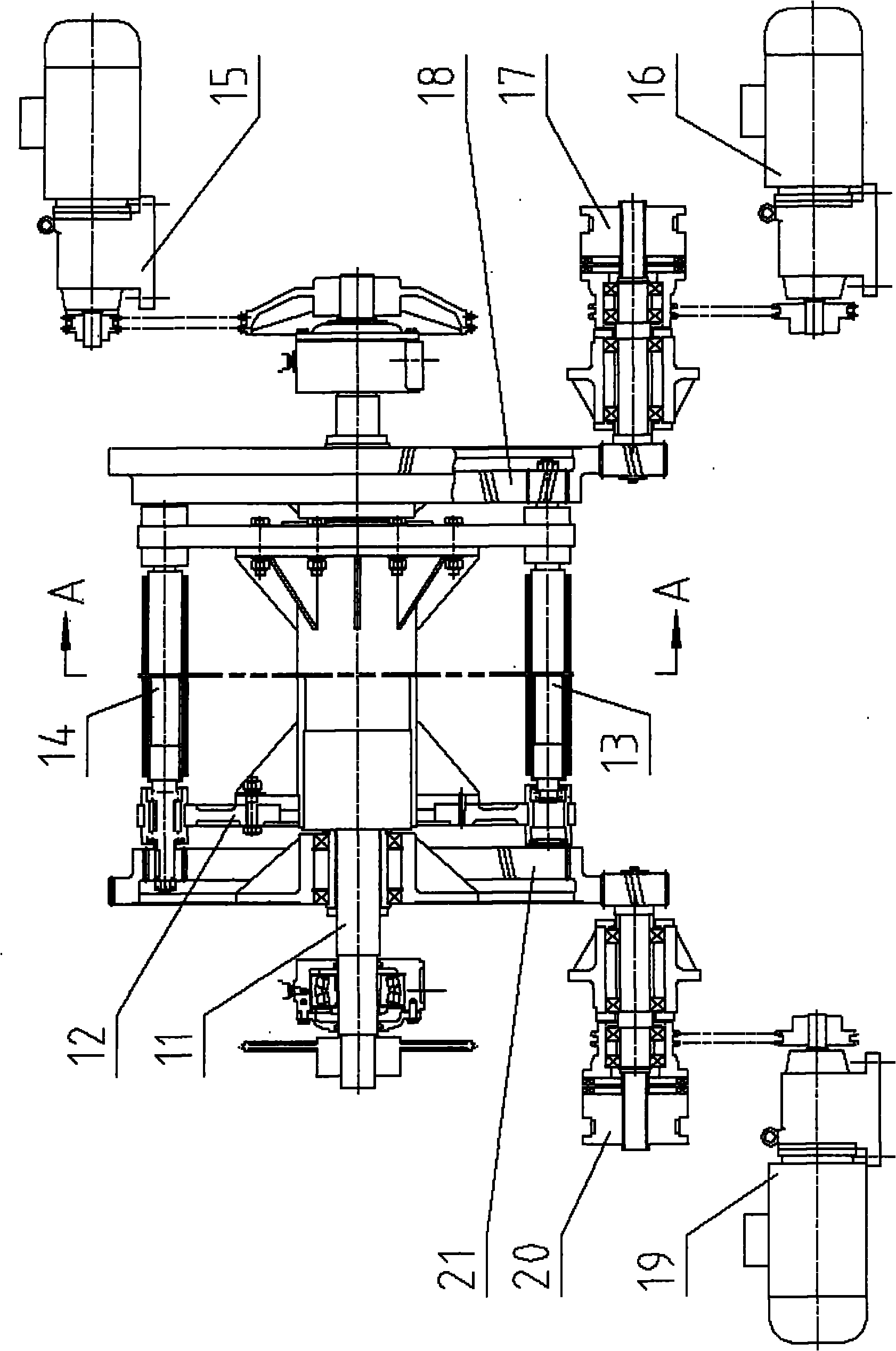

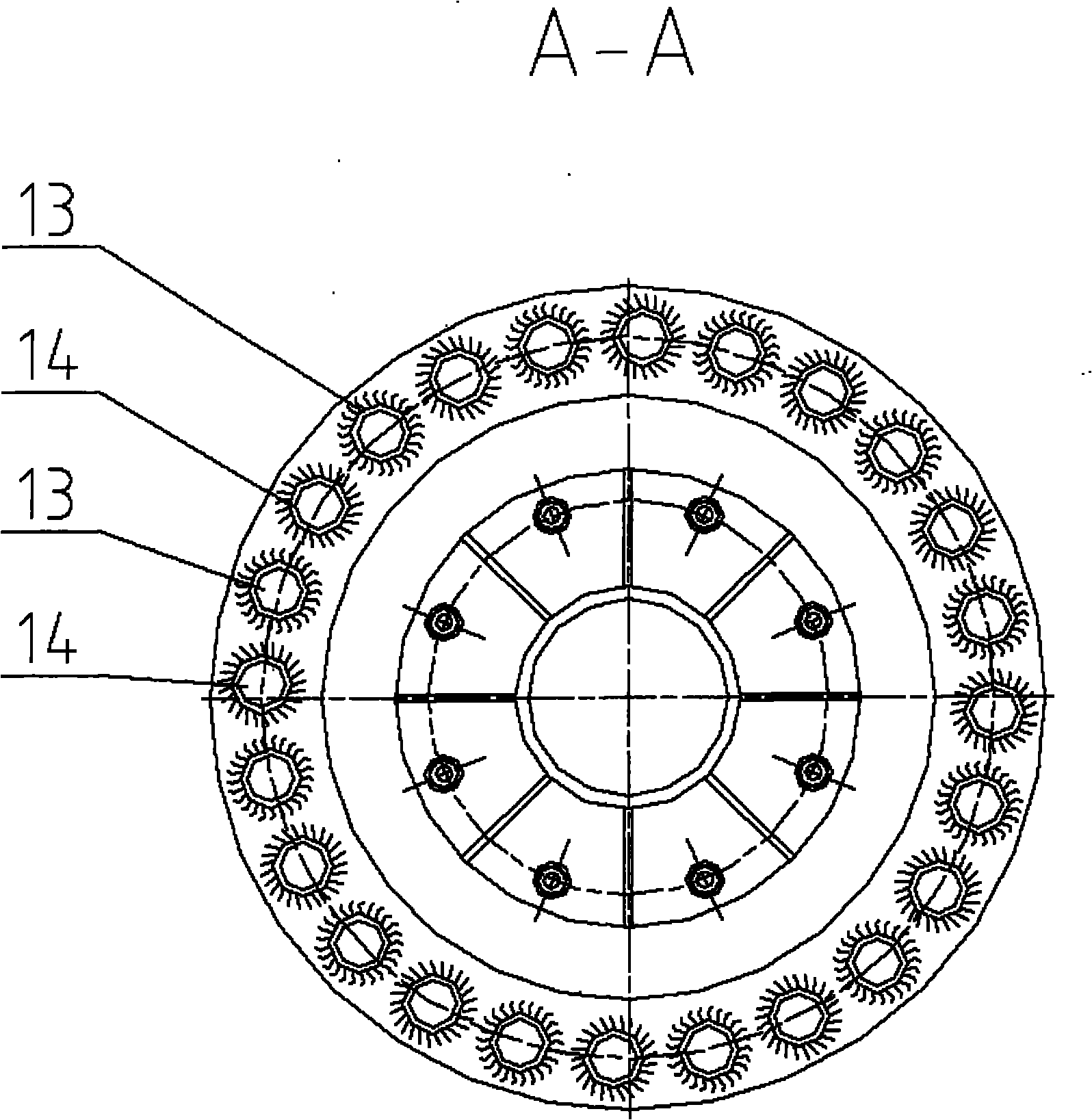

[0013] As shown in each figure, a new type of computer-controlled helical gear napping machine includes a frame 1, a cylinder 2, two sets of needle roller cleaning devices 3 installed under the cylinder 2, and a dust suction device 4, which are respectively installed on the cylinder 2. Tension device 7 in front, multiple groups of cloth feeding and spreading devices 6, cloth feeding and pulling device 5, cloth feeding and pulling device 9, and cloth discharging and arranging device 8 arranged above the frame, the cylinder 2 is fixed by the main shaft 11, Two rollers 12 on the main shaft 11 and the needle roller installed on the rollers 12 form, the main shaft 11 is driven by a motor 15 through a belt and a chain to realize the revolution of the cylinder 2 . The needle roller consists of a roller body 22 with a diameter of 70 mm and uniformly distributed steel needles 23 wrapped around the roller body 22. The needle roller includes two groups of raising roller 13 and squatting r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com