Tea water-removal rolling device

A kneading device and de-enzyming technology, which is applied in tea treatment before extraction, can solve the problems of reducing volume, time-consuming and laborious, etc., and achieve the effects of simplifying the device structure, good de-enzyming effect, and increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

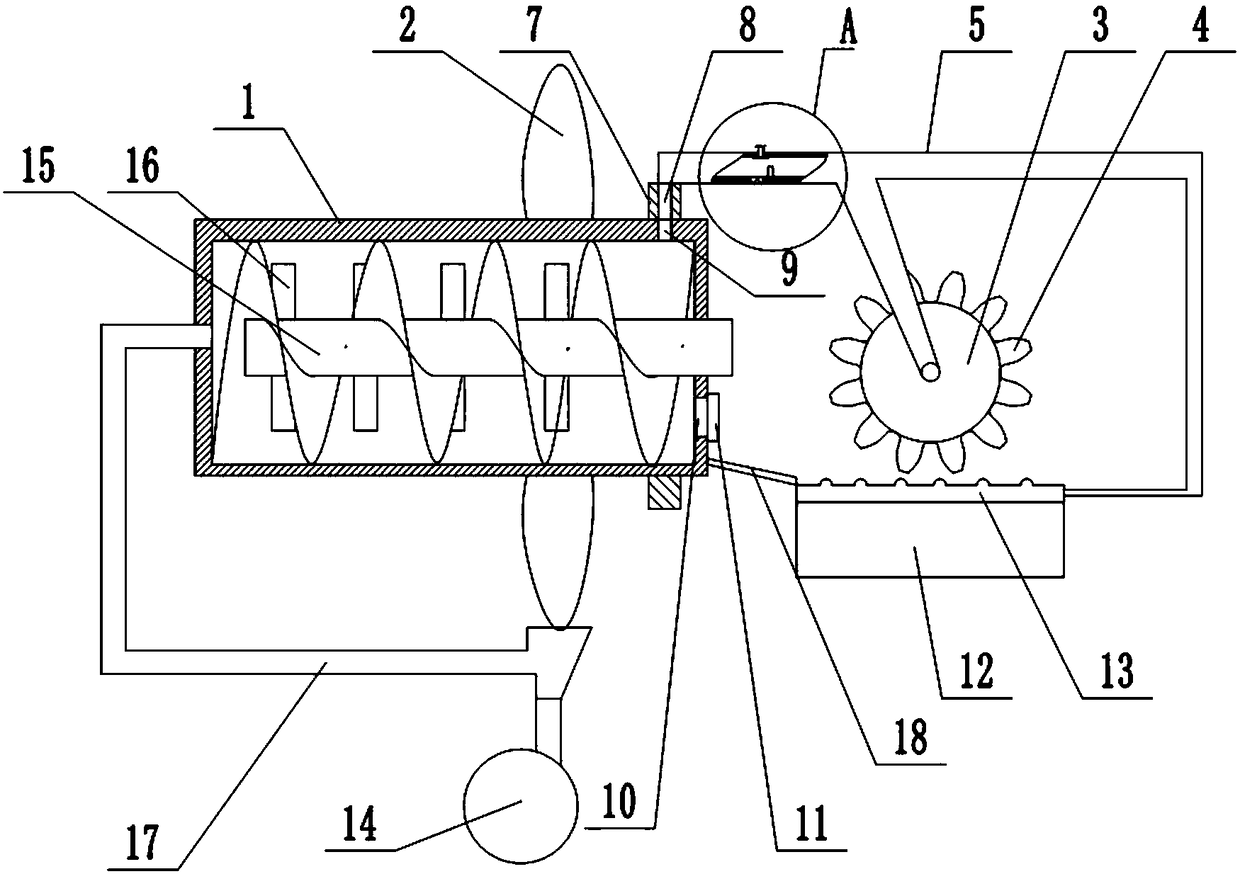

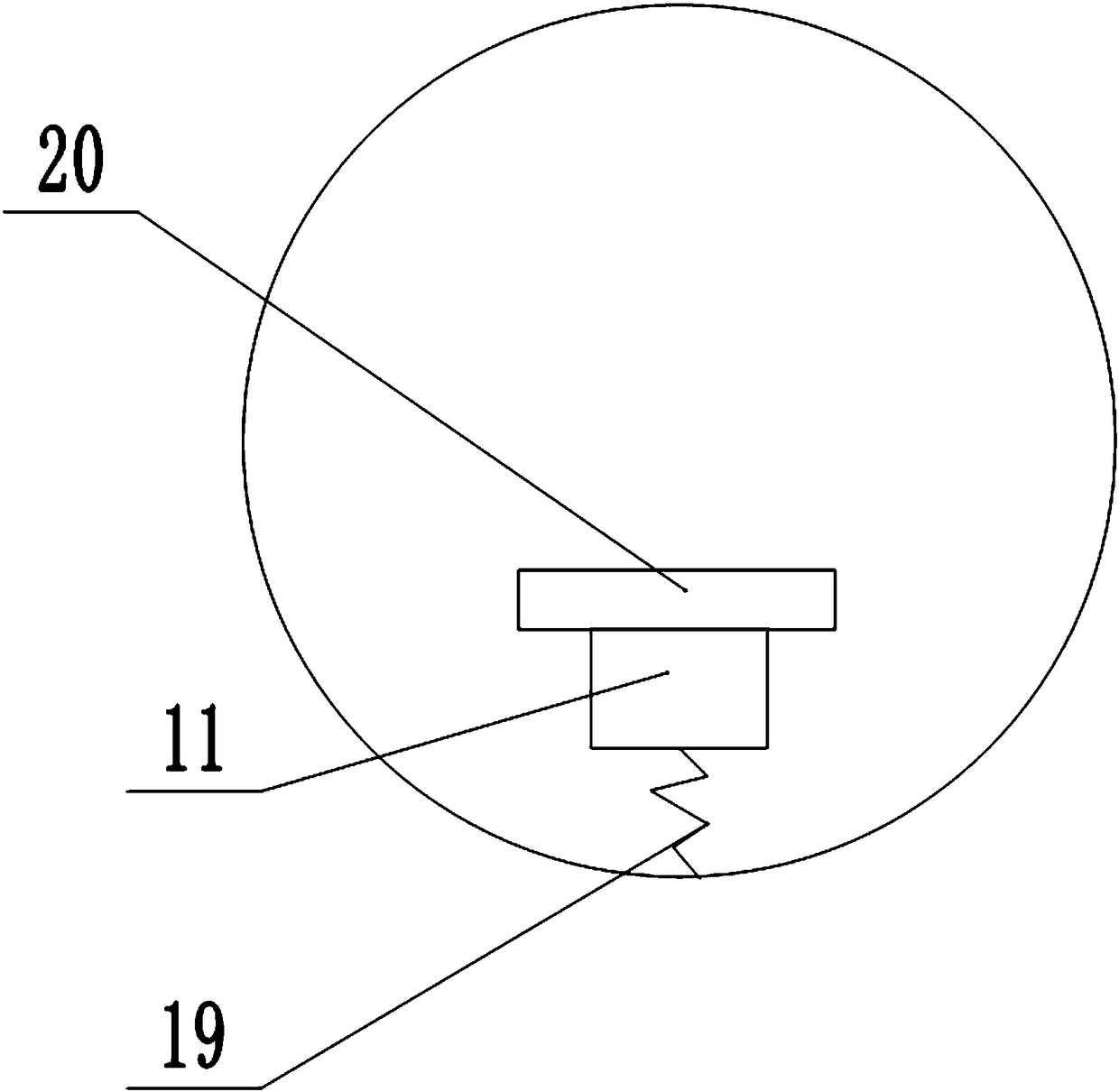

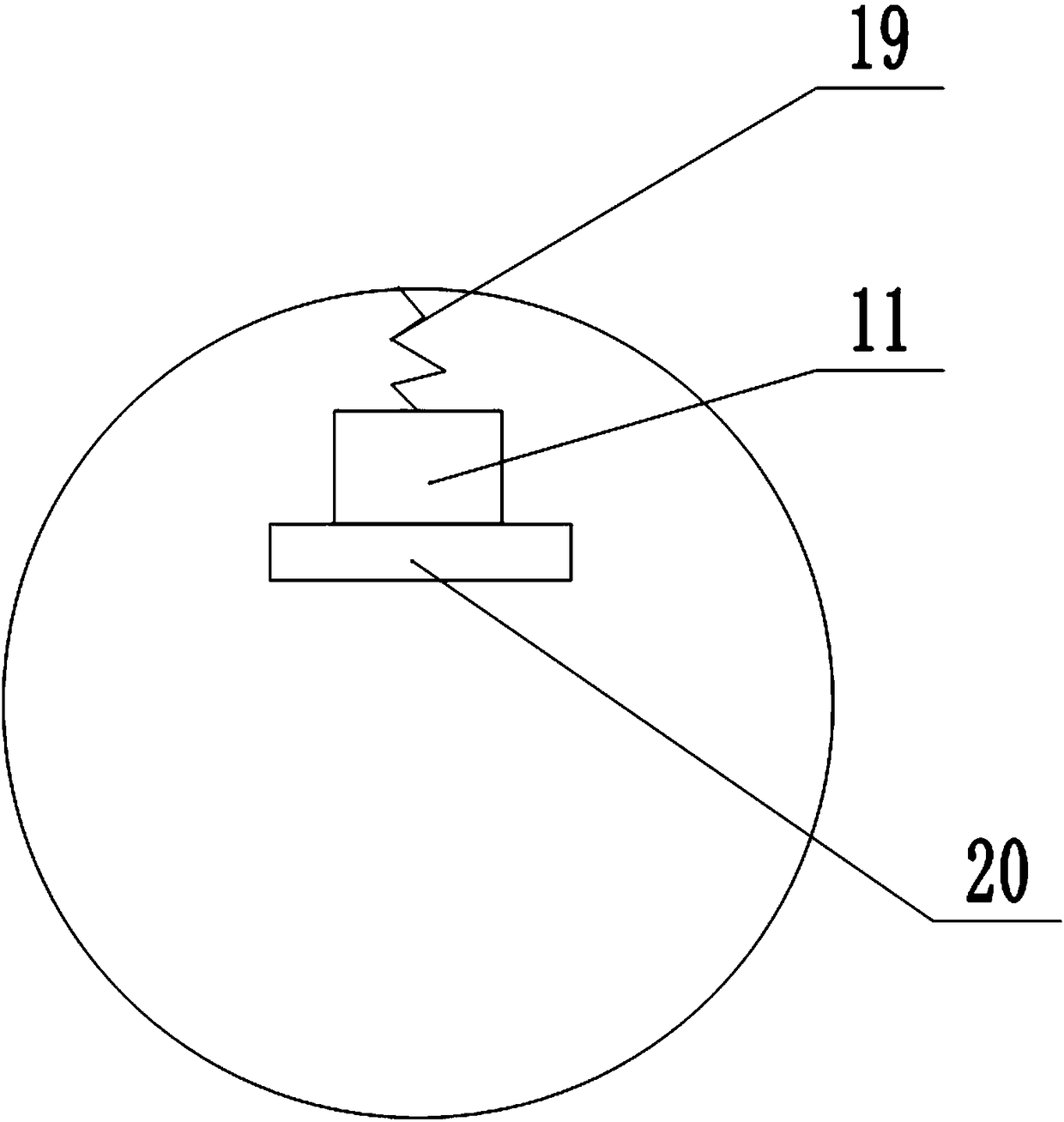

[0026] The reference signs in the drawings of the description include: drum 1, fan blade 2, kneading roller 3, protrusion 4, second Y-shaped tube 5, baffle piece 6, raised disc 7, air outlet 8, through hole 9, discharge Hole 10, baffle plate 11, kneading disk 12, air bag layer 13, hot air blower 14, stirring rod 15, stirring blade 16, first Y-shaped pipe 17, feeding table 18, spring 19, limit block 20, filter screen 21, slide 22.

[0027] Such as figure 1 As shown, the tea fixing and kneading device includes a frame on which a fixing unit and a kneading unit located on the right side of the fixing unit are arranged, and the fixing unit includes a drum 1 that is rotatably connected to the frame and a heat transfer unit that is fixedly connected to the frame. Fan 14, the outer wall of drum 1 is evenly distributed with fan blades 2 along the circumference, the hot air blower 14 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com