Congou black tea rolling and fermentation integrated machine and method for producing congou black tea

A technology of Gongfu black tea and all-in-one machine, applied in the direction of tea treatment before extraction, can solve the problems of affecting tea quality, producing broken tea, time-consuming and labor-intensive, etc., and achieve the effect of reducing equipment purchase cost, saving fermentation time, and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

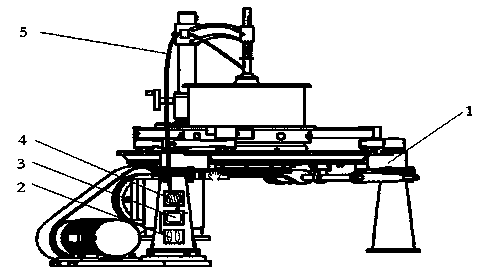

[0029] Example 1: Gongfu black tea kneading and fermentation integrated machine

[0030] like figure 1 As shown, an integrated machine for kneading and fermentation of Gongfu black tea is composed of a main engine 1 , an oxygen generator 2 , an ultrasonic atomizer 3 and a constant temperature air heater 4 .

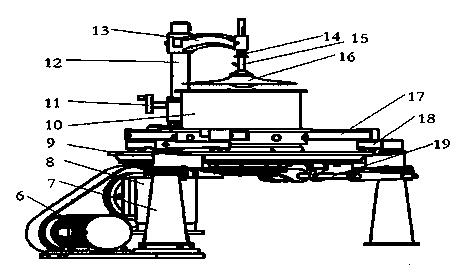

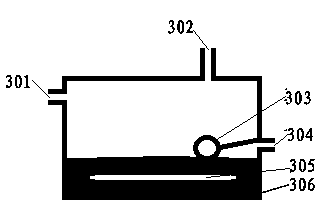

[0031] like figure 2 As shown, the main engine 1 includes a motor 6, a machine foot 7, a reduction box 8, a kneading plate 9, a kneading bucket 10, a pressurizing hand wheel 11, a column 12, a pressurizing arm 13, a spring 14, a pressurizing rod 15, and a kneading cover 16. , tripod 17, crank 18 and door handle 19.

[0032] The motor 6 is drivingly connected to the reduction box 8, the reduction box 8 is drivingly connected to the crank 18, the crank 18 is drivingly connected to the tripod 17, and the tripod 17 is sleeved on the kneading bucket 10. Driven by the motor 6 , the crank 18 and the tripod 17 run, and under the action of the tripod 17 , the kneading barrel 1...

Embodiment 2

[0038] Embodiment 2: the method that utilizes Gongfu black tea kneading and fermentation integrated machine to produce Gongfu black tea

[0039]1) Put the withered fresh tea leaves with a water content of 59-61% into the kneading bucket 10, adjust the position of the kneading cover 16 to the air pressure position 2-3 cm below the 10 mouth of the kneading bucket, turn on the oxygen generator 2, Adjust the oxygen generator 2 to a concentration of 85-90% and a flow rate of 2.8-3L / MIN, then turn on the ultrasonic atomizer 4. After the ultrasonic atomizer 4 produces water mist, turn on the constant temperature air heater 4 to heat the constant temperature air. The device 4 is adjusted to the temperature of 28~30℃ and the relative humidity of 80~87%. At this time, the temperature and humidity of the oxygen flow will be automatically controlled;

[0040] 2) Turn on the main engine 1, and run the air compressor for 7-10 minutes;

[0041] 3) Adjust the kneading cover 16 to the positio...

Embodiment 3

[0046] Comparison of sensory quality and time consumption of kung fu black tea by different kneading and fermentation processes

[0047] By comparing the integrated kneading and fermentation process of the present invention and the traditional kneading and fermentation process, it can be seen that the total sensory score of the kung fu black tea prepared by the present invention is higher than that of the kung fu black tea prepared by the traditional process, and the production efficiency is improved by about 52%. The kneading and fermentation process is obviously advanced. The results are shown in Table 1

[0048] Table 1 Comparison of sensory quality and time consumption of kung fu black tea by different kneading and fermentation processes

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com