Intelligent pressure-regulating tea-leaf rolling machine

A kneading machine and intelligent technology, which is applied in the field of intelligent pressure-adjusting tea kneading machine, can solve the problems of high labor intensity, potential safety hazards, differences in tea kneading quality, complicated process, etc., achieve safe and convenient pressurization and discharge operations, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

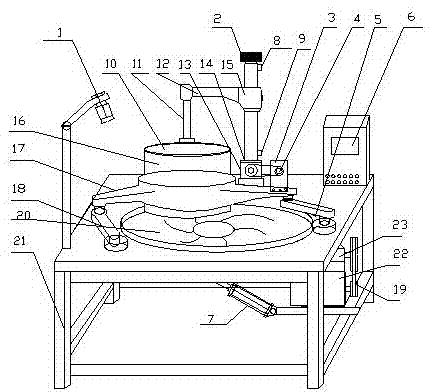

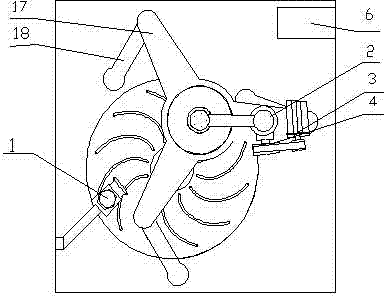

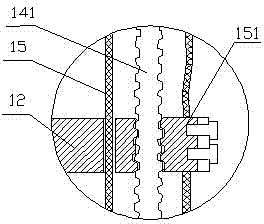

[0032]Start the tea rolling machine, select real-time pressure regulation on the display touch screen, start the tea rolling intelligent control system, and manually select the total tea product, season and type. The tea leaves are loaded into the kneading bucket 16, the system controls the kneading mechanism to start the motor 22, the motor 22 drives the belt pulley 19 to rotate, the belt pulley 19 drives the reduction box 23 to operate, the reduction box drives the kneading bucket frame 17 to rotate through the connecting rod 18, and the kneading bucket 16 is in the kneading bucket Run under the drive of frame 17. At the same time, the intelligent control system for tea rolling starts the stepper motor 3, and the motor 3 drives the synchronous pulley 4 to run. Movement; the intelligent control system for tea rolling after starting starts the high-definition camera 1 to collect the tea image in the center of the kneading plate according to the collection signal provided by th...

Embodiment 2

[0034] Start the tea rolling machine, select the program to adjust the pressure on the display touch screen, start the tea rolling intelligent control system, and manually select the total tea product, season and type. The tea leaves are loaded into the kneading bucket 16, the system controls the kneading mechanism to start the motor 22, the motor 22 drives the belt pulley 19 to rotate, the belt pulley 19 drives the reduction box 23 to operate, the reduction box drives the kneading bucket frame 17 to rotate through the connecting rod 18, and the kneading bucket 16 is in the kneading bucket Run under the drive of frame 17. At the same time, the intelligent control system for tea rolling starts the stepping motor 3, and the motor 3 drives the synchronous pulley 4 to run.

[0035] It moves under the action of the synchronous pulley of the screw input shaft; the control system drives the stepper motor 3 to automatically adjust the pressure of tea rolling according to the selected ...

Embodiment 3

[0037] For ordinary traditional tea rolling, start the tea rolling machine, select the traditional pressure adjustment program on the display touch screen, start the tea rolling intelligent control system, for young leaves, set the rolling time for 20 minutes, gentle for 10 minutes, pressurize for 5 minutes, and decompress 5 minutes; for medium young leaves, set the kneading time for 30 minutes; gently for 10 minutes, pressurize for 15 minutes, decompress for 5 minutes; for old leaves, set the kneading time for 40 minutes; gently for 10 minutes, pressurize for 25 minutes, decompress for 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com