Semi-automatic clipping device for solar energy packaging material

A solar energy packaging and cutting device technology, applied in metal processing and other directions, can solve the problems of easily scratched TPT/EVA, high labor costs, and personnel being cut, and achieve the effects of compact structure, reduced labor costs, and small cutting errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

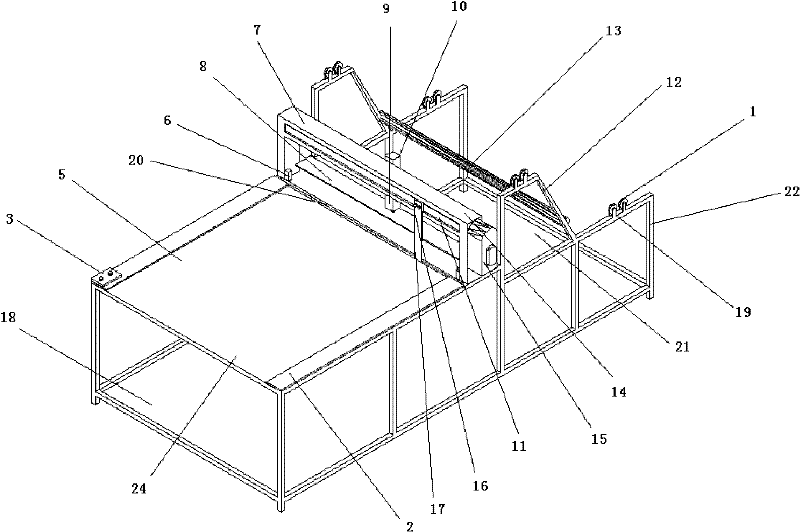

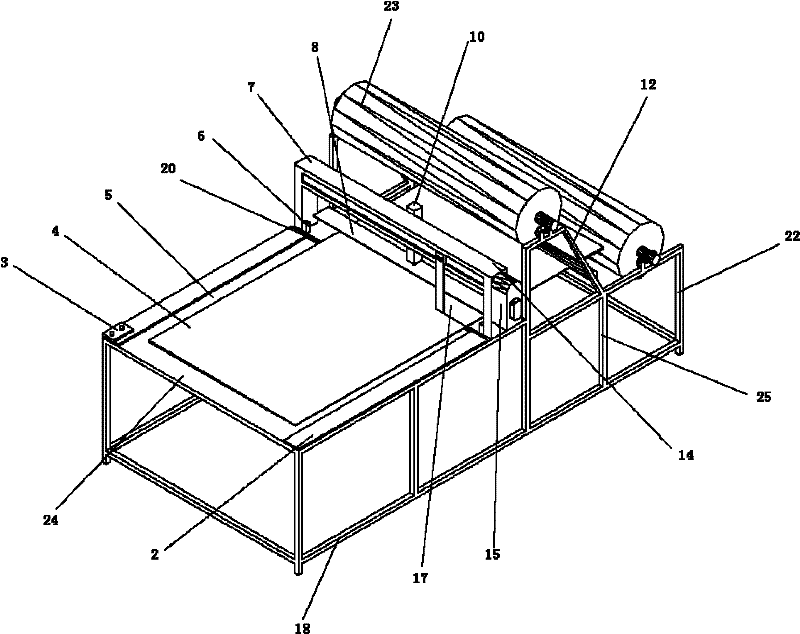

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

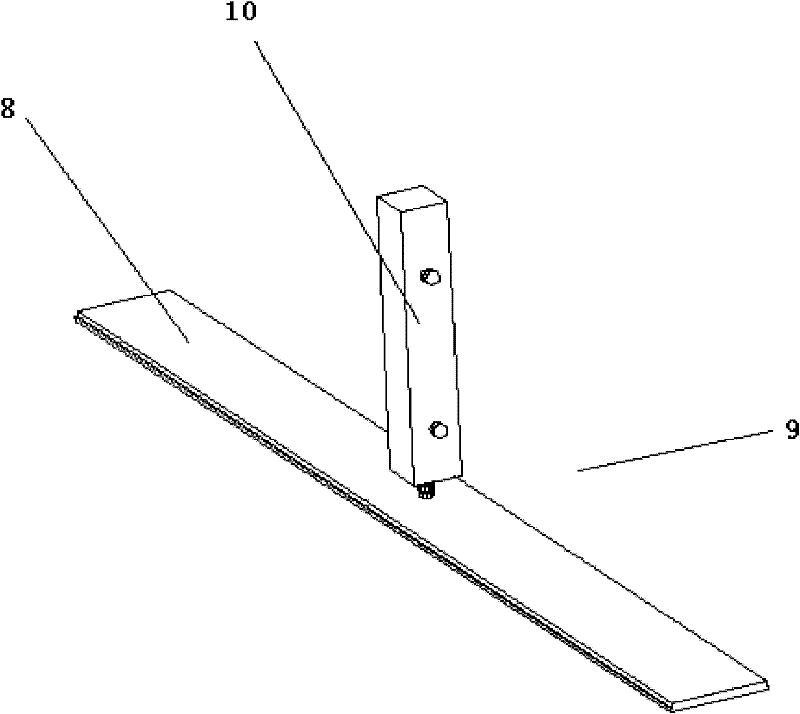

[0019] Such as Figure 1~Figure 4 As shown: the present invention includes a support bearing 1, a scale 2, a control button 3, a TPT / EVA material 4, a first support surface 5, a photoelectric switch 6, a cutting bracket 7, a pressing plate 8, a holding mechanism 9, and a holding cylinder 10. Cutter drive belt 11, first support 12, roller 13, cutting mechanism 14, drive motor 15, slider 16, cutter 17, chassis 18, bearing mount 19, cutting groove 20, second support surface 21 , second support 22 , material roller 23 , table portion 24 and support mechanism 25 .

[0020] Such as figure 1 and figure 2 As shown: the upper end surface of the underframe 18 forms a table portion 24, and the underframe 18 is made of high-strength steel, which ensures the support of the underframe 18 and the safe and reliable operation; the table portion 24 includes a first support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com