Bundling mechanism of roll disk type round bundle pick-up bundling machine

A technology of a baler and a roller disc, which is applied in the field of agricultural machinery, can solve the problems of increasing the resistance of the rotation movement of straw or pasture bales, the machine cannot work normally, and the work load is increased, and achieves the elimination of accumulation blockage failure, simple structure, and easy operation. The effect of fewer failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

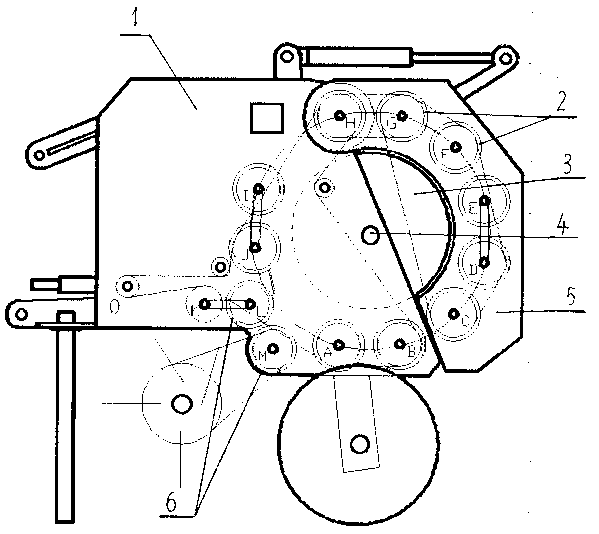

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The roll-and-disc round baler pick-up and baler mechanism includes a baling front chamber 1 and a baling rear chamber 5, and the baling steel roller system 2 is fitted in the baling front chamber 1 and the baling rear chamber 5. In the front chamber 1, a feeding roller assembly 6 is installed at the lower part of the front side of the coiling steel roller system 2. On the left and right side walls of the bundling front chamber 1, the drive shafts 4 are respectively equipped with coaxial symmetry and rotatable, Two grass-rolling side discs 3 are fixedly mounted on the drive shaft 4 on the left and right side walls of the bundling front chamber 1 respectively, and the front side and rear side parts of the two grass-rolling side discs 3 They are respectively placed in the baling front chamber 1 and the baling rear chamber 5, and are located inside the grass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com