EPS foam forming equipment

A technology of foam molding and equipment, which is applied in the field of EPS foam preparation, can solve the problems of uneven particle size, uneven specific gravity and large influence of pre-expanded beads, and achieve a small product density gradient, particle size and specific gravity. The effect of uniformity and uniform specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

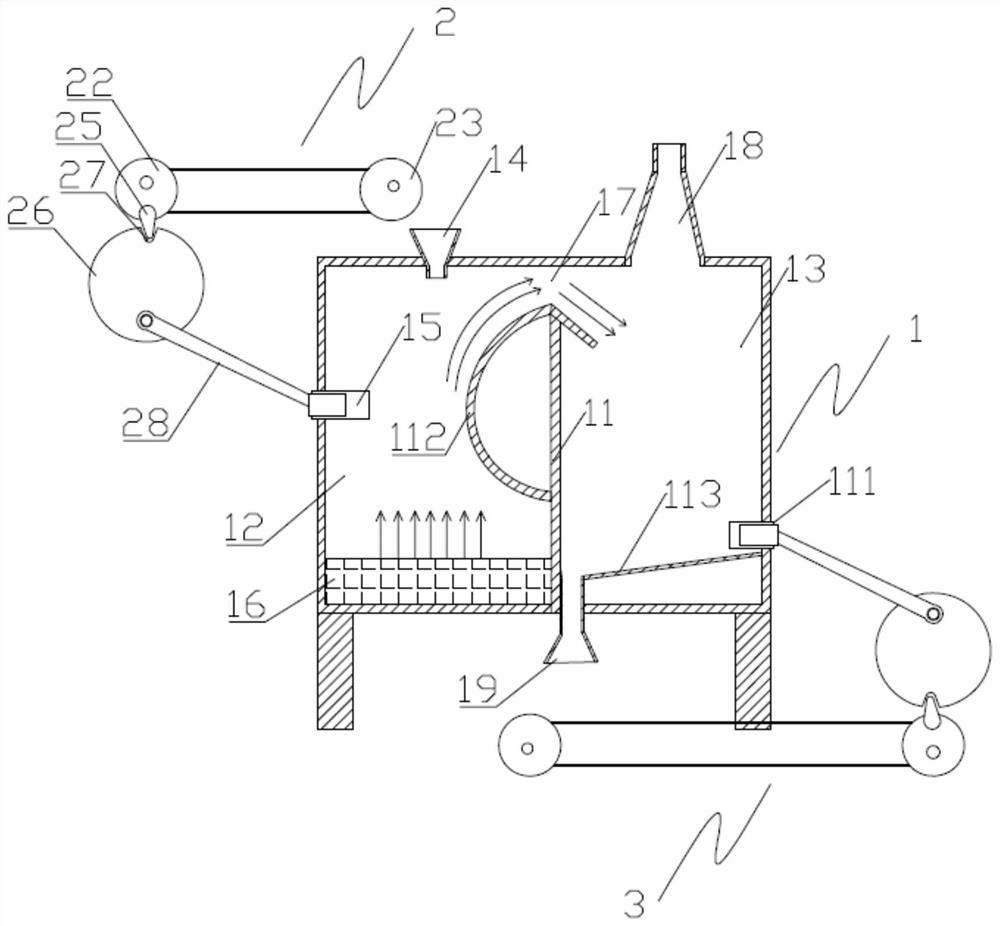

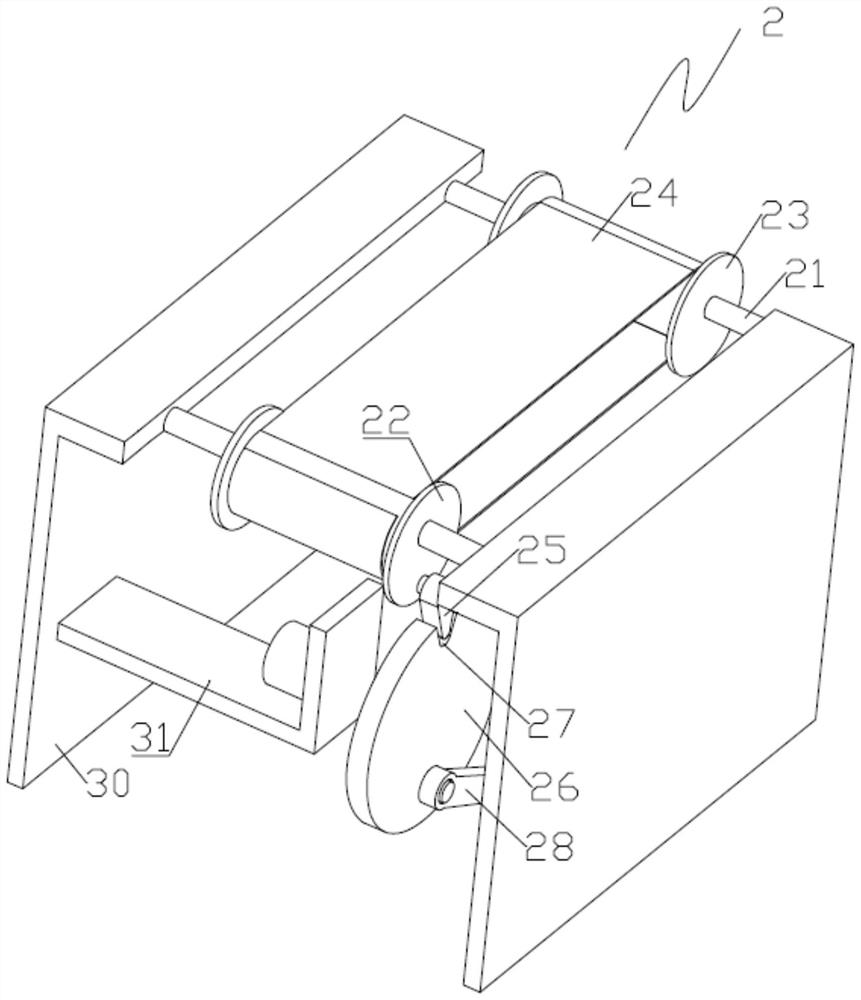

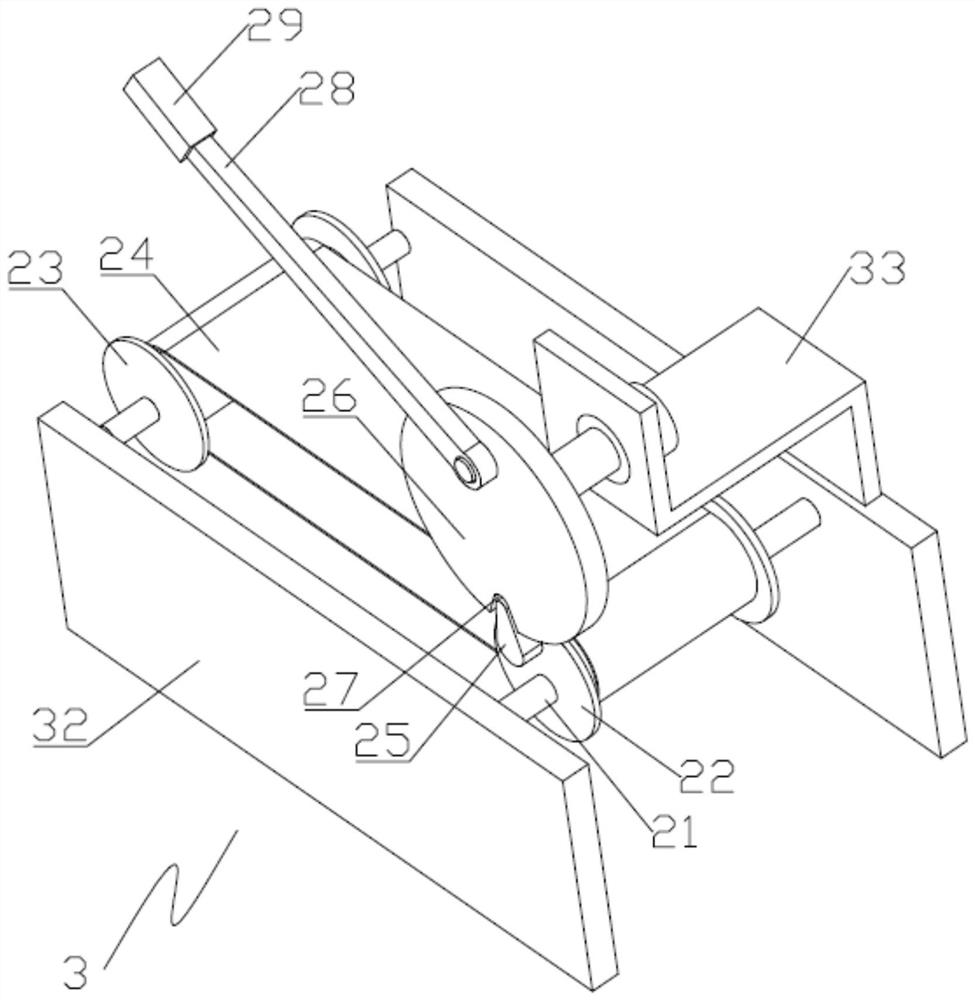

[0017] like Figure 1 to Figure 3 As shown, an EPS foam molding equipment includes a foaming box 1, a driving device 1 for feeding and blowing air to the foaming box 1, and a driving device 2 for discharging and blowing air to the foaming box 1 3 , the foaming box 1 is provided with a partition 11 and is divided into a foaming chamber 12 and a sorting chamber 13 by the partition 11, the top of the foaming chamber 12 is provided with a feed hopper 14 and its outside Air inlet pipe one 15 is provided, the bottom of the foaming chamber 12 is provided with a steam generator 16 and steam is injected into the foaming chamber 12 through the steam generator 16, between the top of the foaming chamber 12 and the dividing plate 11 Form inlet 17, the top of described sorting chamber 13 is equipped with collecting cover 18, and described collecting cover 18 upper end is communicated with negative pressure fan, and the bottom of described sorting chamber 13 is provided with discharge port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com