Steel Roller Round Baler

A technology of balers and steel rollers, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problem of inability to achieve high-density baling of complete rice straw, difficult to form rotating grass cores, and blockage of balers, etc. problem, to achieve the effect of simple structure, less power consumption and less operation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

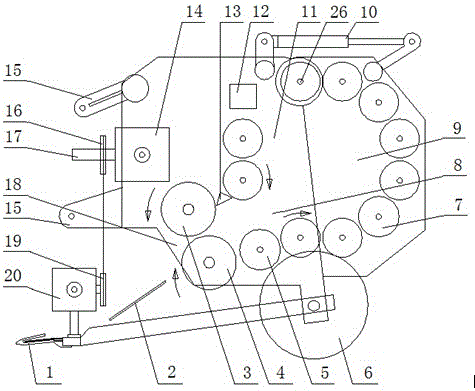

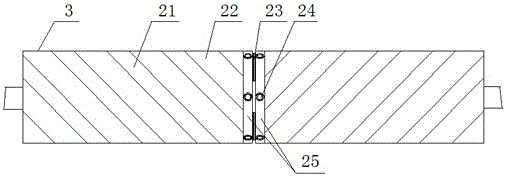

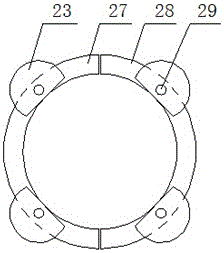

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The cutting mechanism 1 is assembled at the front lower part of the steel roller type round baler, and the cutting mechanism 1 is driven by the power output shaft of the tractor through the power input shaft 17, the first sprocket 16, the second sprocket 19, and the bevel gear 20; The rear part of the mechanism 1 is provided with a grass guide plate 2; the modulation mechanism is fitted on the rear upper part of the grass guide plate 2, and is composed of a modulation upper roller 3 and a modulation lower roller 4, and the surface of the modulation upper roller 3 is provided with herringbone teeth 21 and wherein The middle part is equipped with a round knife 23 to adjust the upper roller 3. The middle part is provided with a steel ring 25. The steel ring 25 is composed of a front half ring 27 and a rear half ring 28. The round knife 23 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com