Stereoscopic vamp ornament with density gradient and preparation method thereof

A density gradient and vamp technology, which is applied to shoe uppers, footwear, clothing, etc., can solve the problems of unreliable fixation of trim and inner structure, insufficient bonding strength, and low structural stability, and achieve rich colors and patterns Design, strong three-dimensional effect, not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

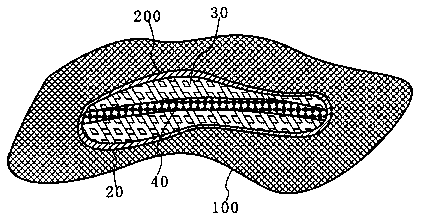

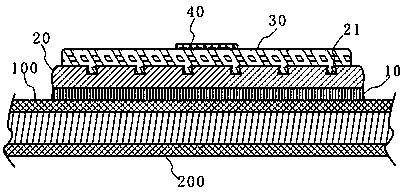

[0027] Such as Figure 1-2 As shown, this embodiment provides a three-dimensional vamp veneer with a density gradient. The vamp veneer 100 is molded and foamed on the surface of the vamp main body 200 , and the vamp veneer 100 and the vamp main body 200 The joint position is adjusted according to product design requirements. It is generally set at the inner waist position of the upper body 200, and some may be set at the outer waist position or the toe of the upper body 200, etc. The upper veneer 100 is formed from the inner waist The water-based resin joint layer 10 , the foamed bottom layer 20 and the foamed color paste layer 30 are arranged in sequence on the outside.

[0028] The water-based resin bonding layer 10 is combined with the surface layer of the upper body 200. In order to enhance the bonding firmness of the water-based resin bonding layer 10 and the upper bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com