Patents

Literature

39results about How to "Good shock absorber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-sided all-purpose adhesive tape

InactiveCN102965047AGood weather resistanceImprove aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesWeather resistanceMiddle molecular weight

The invention discloses a double-sided all-purpose adhesive tape. The adhesive tape is prepared by taking a fiber fabric as a base material, and respectively coating an adhesive layer on the upper and lower sides of the base material. The adhesive layer comprises the following materials in parts by weight: 30-50 parts of butyl rubber, 10-25 parts of polyisobutylene (middle molecular weight), 5-15 parts of polyisobutylene (low molecular weight), 0-10 parts of operating oil, 10-20 parts of modified terpene resin, 0.3-0.5 part of a colorant, 0-0.5 part of an antioxidant, and 0-15 parts of a filler. When the double-sided all-purpose adhesive tape is applied to construction, an adhesive is not required to be daubed on the scene, the double-sided all-purpose adhesive tape can be directly used just through uncovering release paper, and therefore, the adhesive tape is simple and convenient; the adhesive tape is good in weather resistance, aging resistance, water repellency, anti-skidding property, adsorbability, shock-absorbing property, explosion-proof property and heat insulation property, longer in application time and wider in application range; and the adhesive tape has an excellent bonding capacity to various sheet metals, plastic sheets, plastic films and various pipes, therefore, the adhesive tape is extensive in use.

Owner:吴孟怀

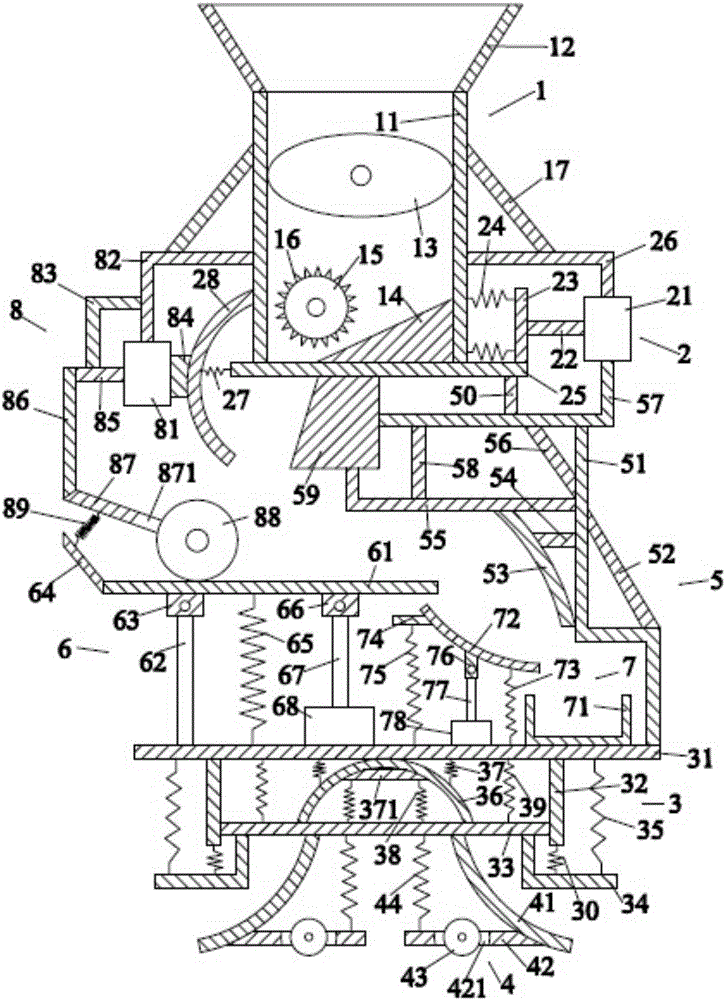

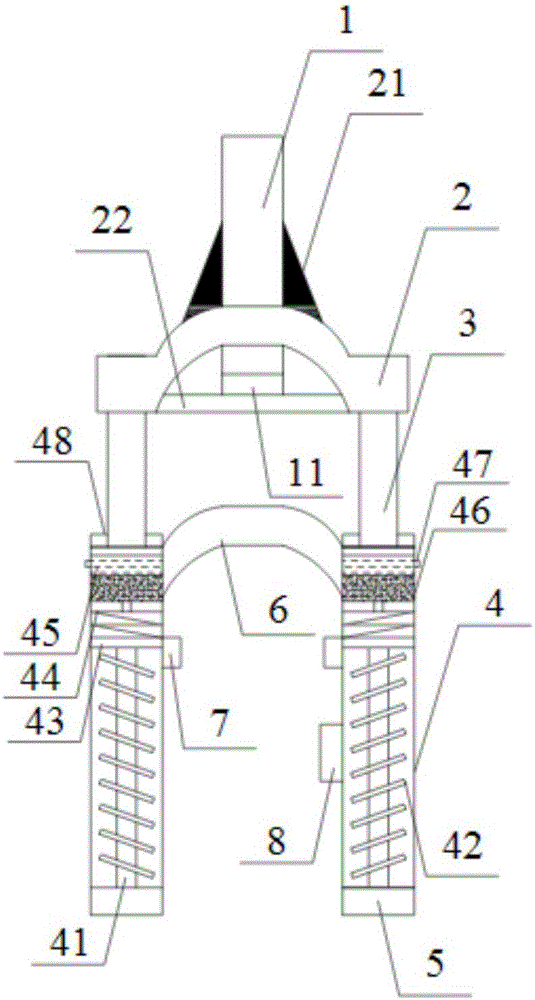

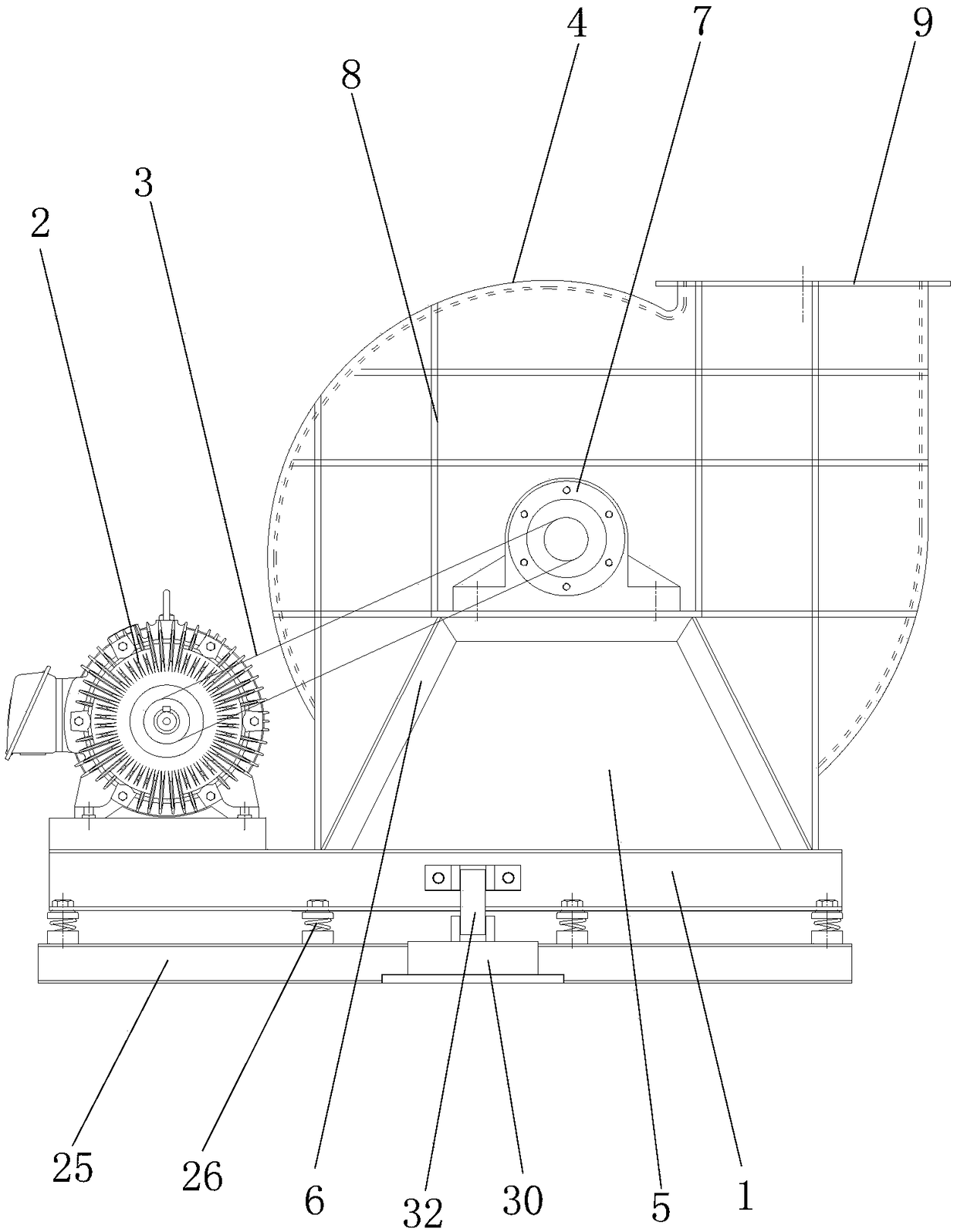

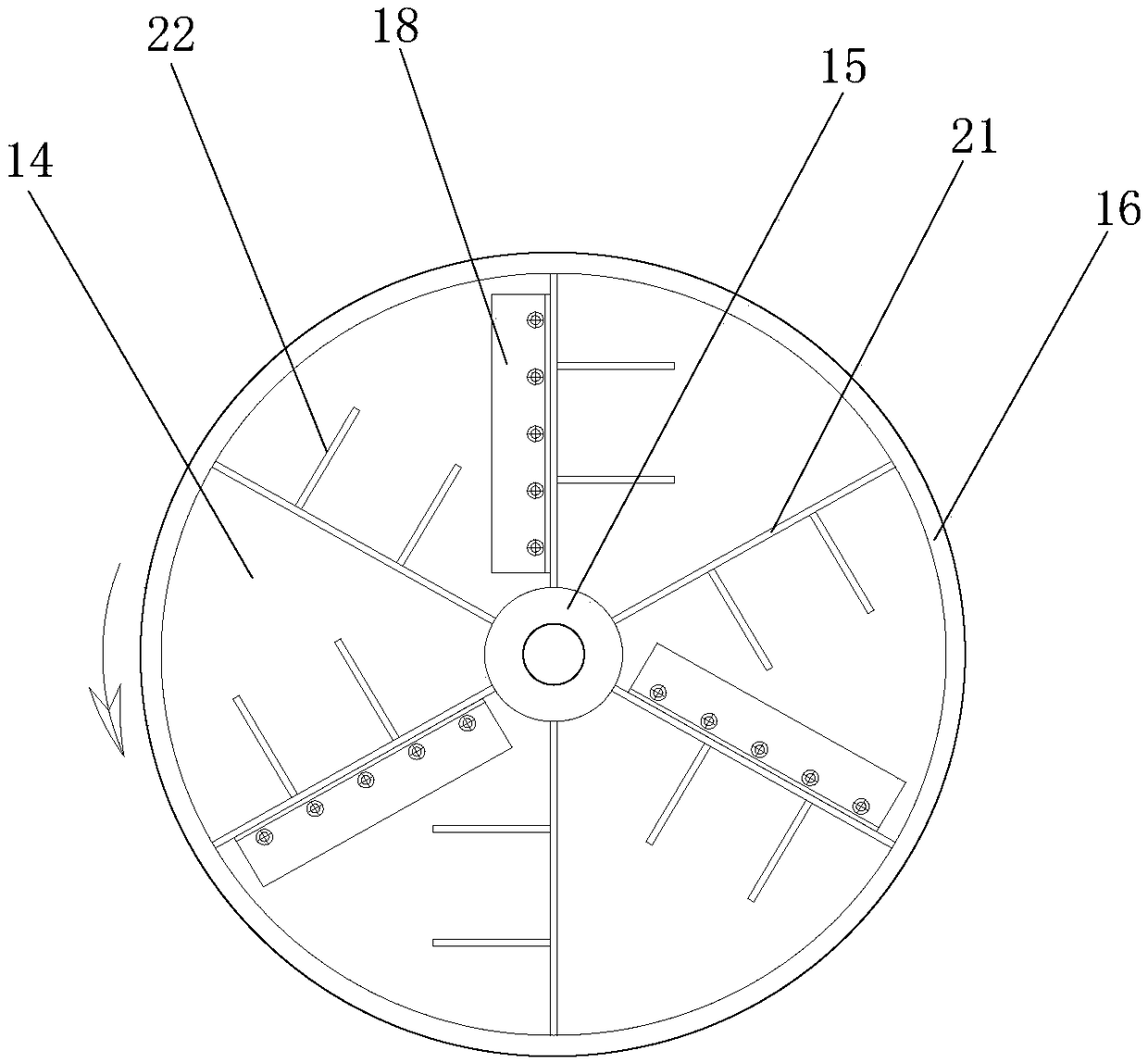

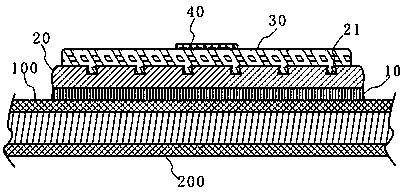

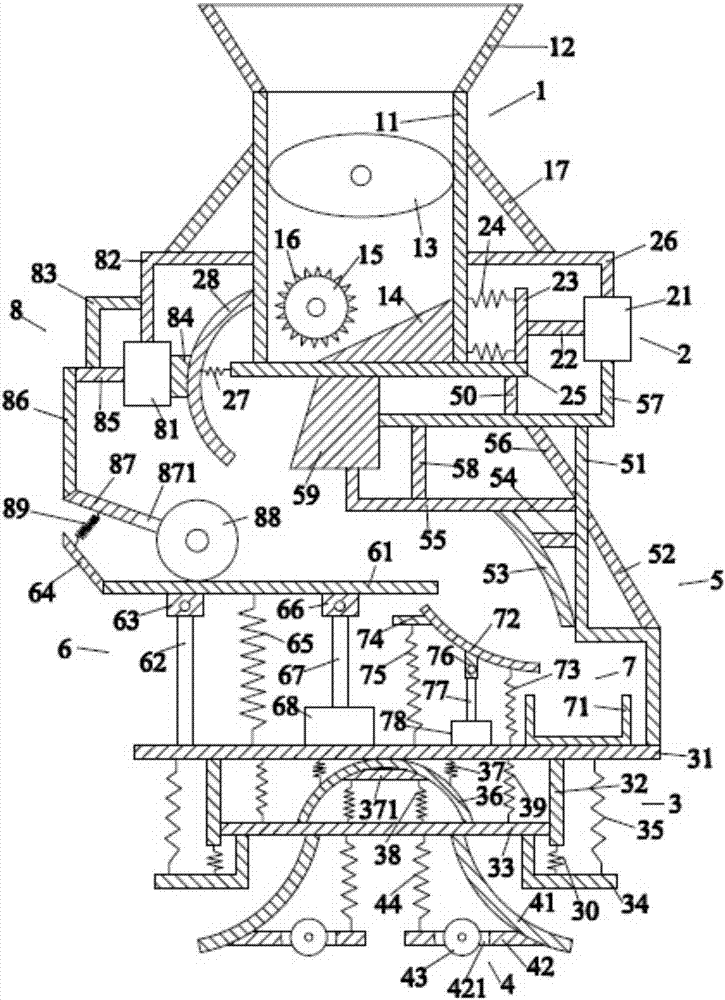

High-efficiency ore crushing device with shock absorption function

ActiveCN105797808AWith shock absorption functionSimple structureGrain treatmentsMechanical engineering

A high-efficiency ore crushing device with a shock absorption function comprises a crushing device body, a baffle device, a shock absorption device, rolling wheel devices, a support device, a supporting plate device, a recovery device and a grinding device. The crushing device comprises a first frame, a feed hopper, a first rolling wheel, a transfer block, a second rolling wheel, crushing teeth and first diagonal rods. The baffle device comprises a first cylinder, a first push rod, a first push plate, first springs, a first baffle, a first support, a second spring and a second baffle. The shock absorption device comprises a first transverse plate, first vertical rods, a second transverse plate, second supports, third springs, a first bent rod, fourth springs, fifth springs, sixth springs and seventh springs. Each rolling wheel device comprises a second bent rod and a second cross rod. The support device comprises a third support, a second diagonal rod, a first bent plate, a third cross rod, a fourth support, a third diagonal rod, a fifth support and a second vertical rod. The high-efficiency ore crushing device can crush ores rapidly and effectively and is high in crushing efficiency.

Owner:锡林郭勒盟山金阿尔哈达矿业有限公司

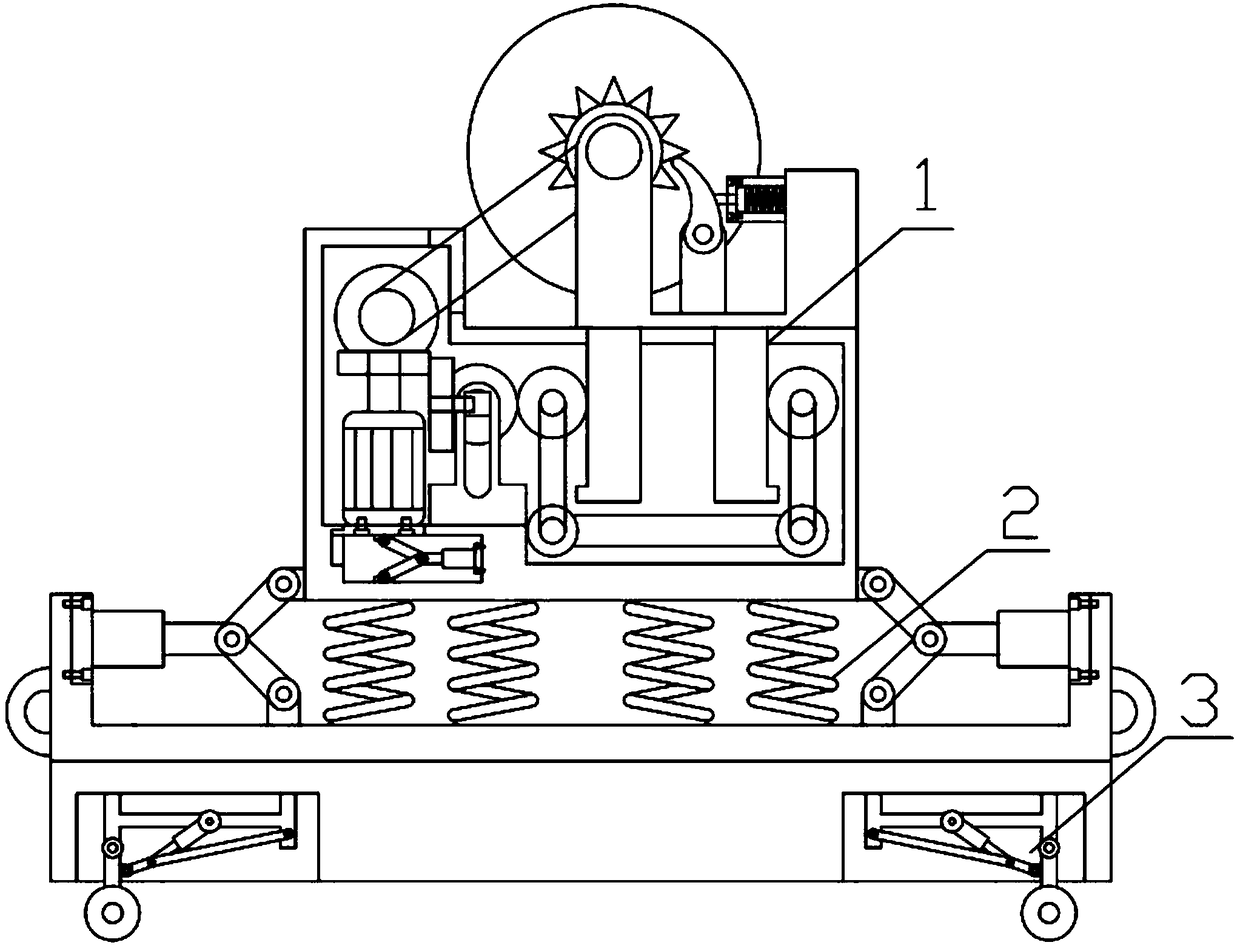

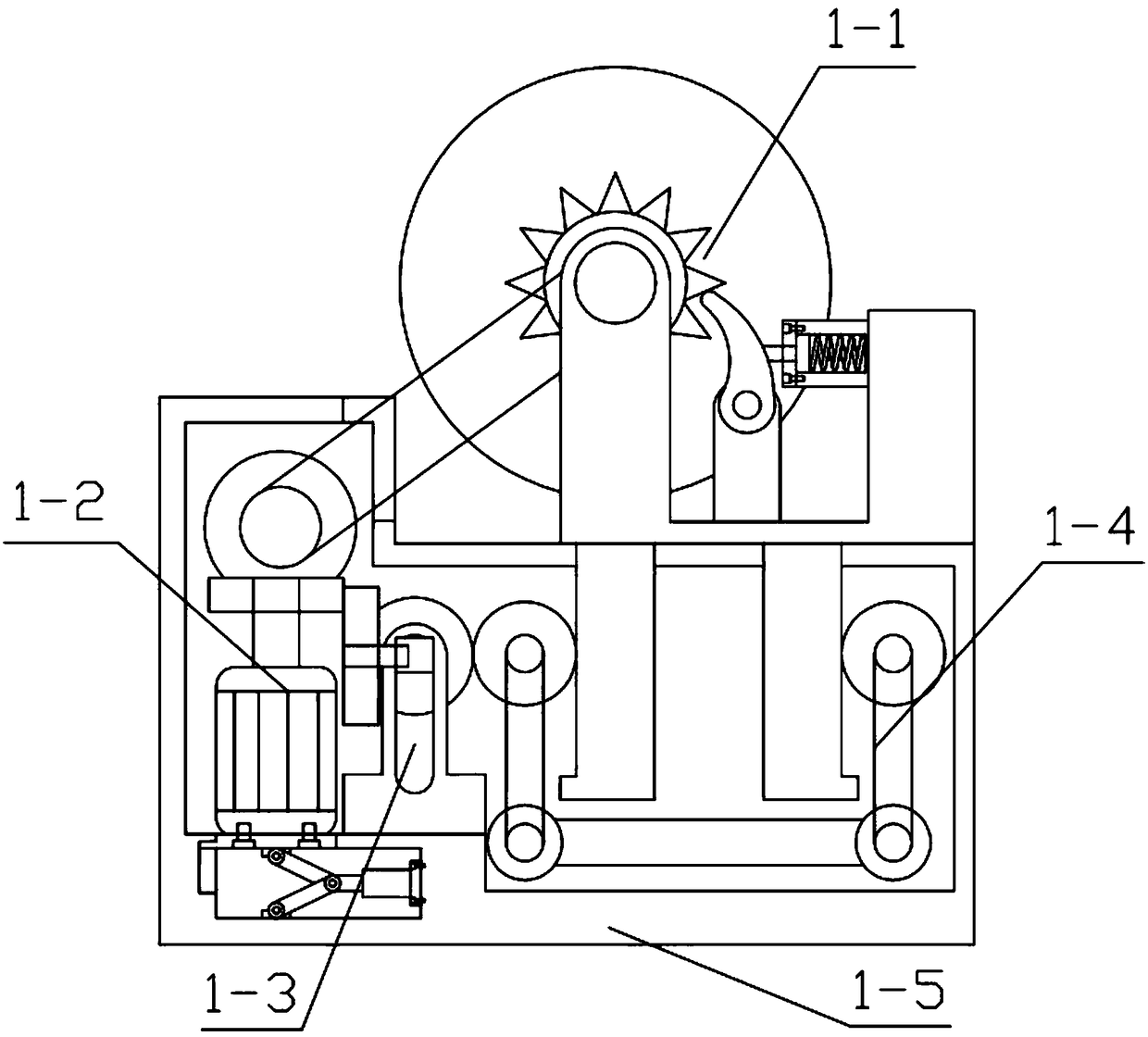

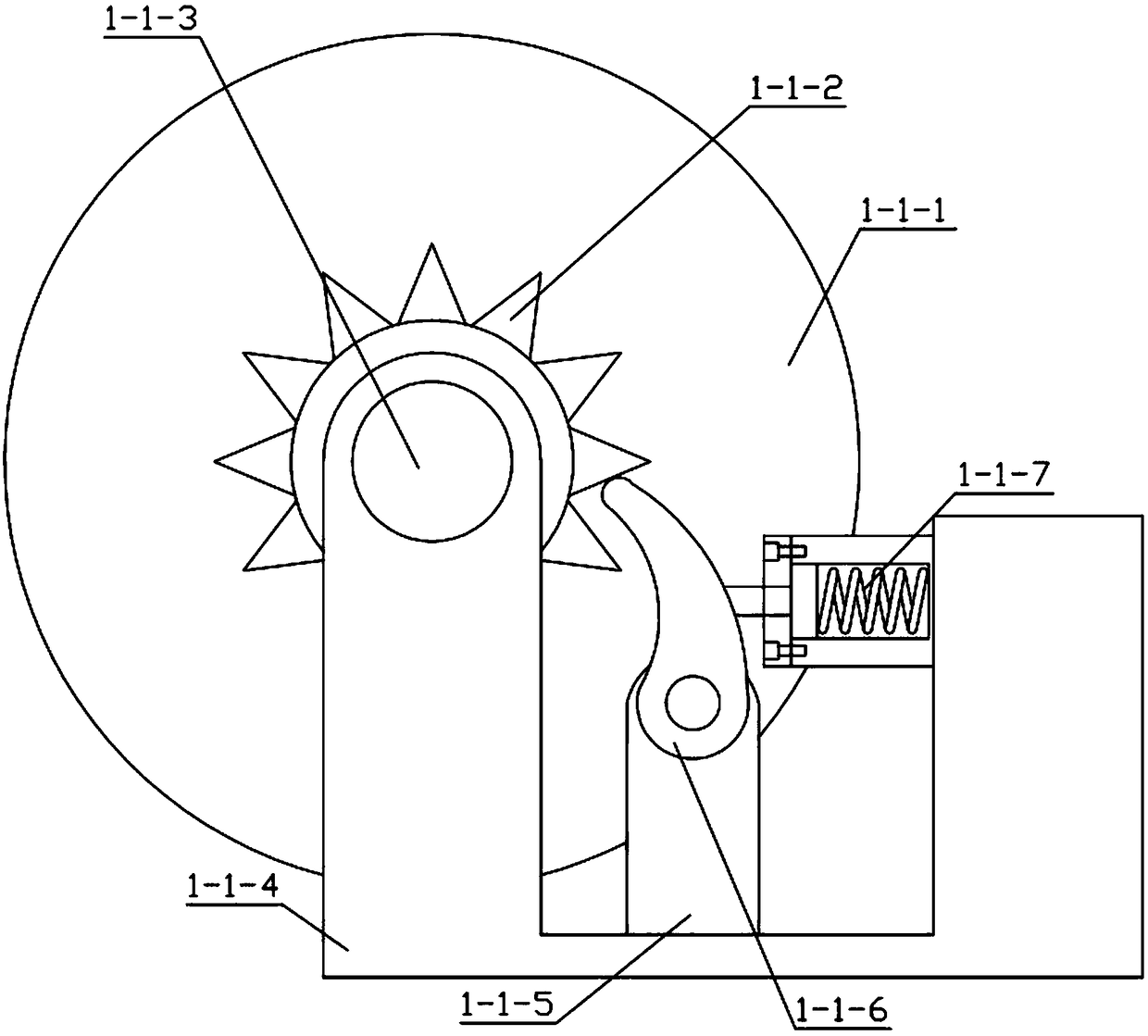

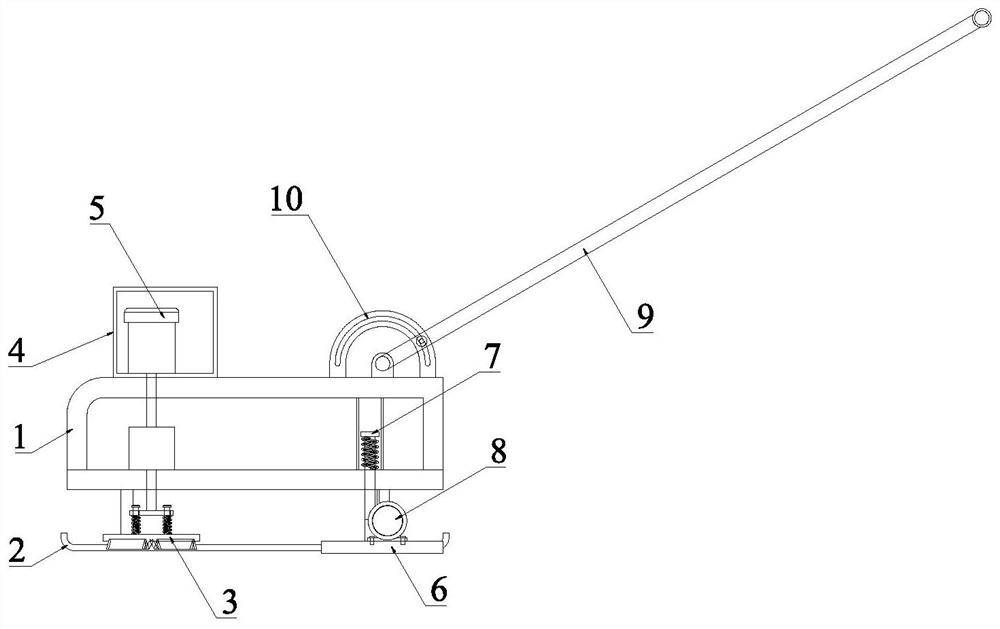

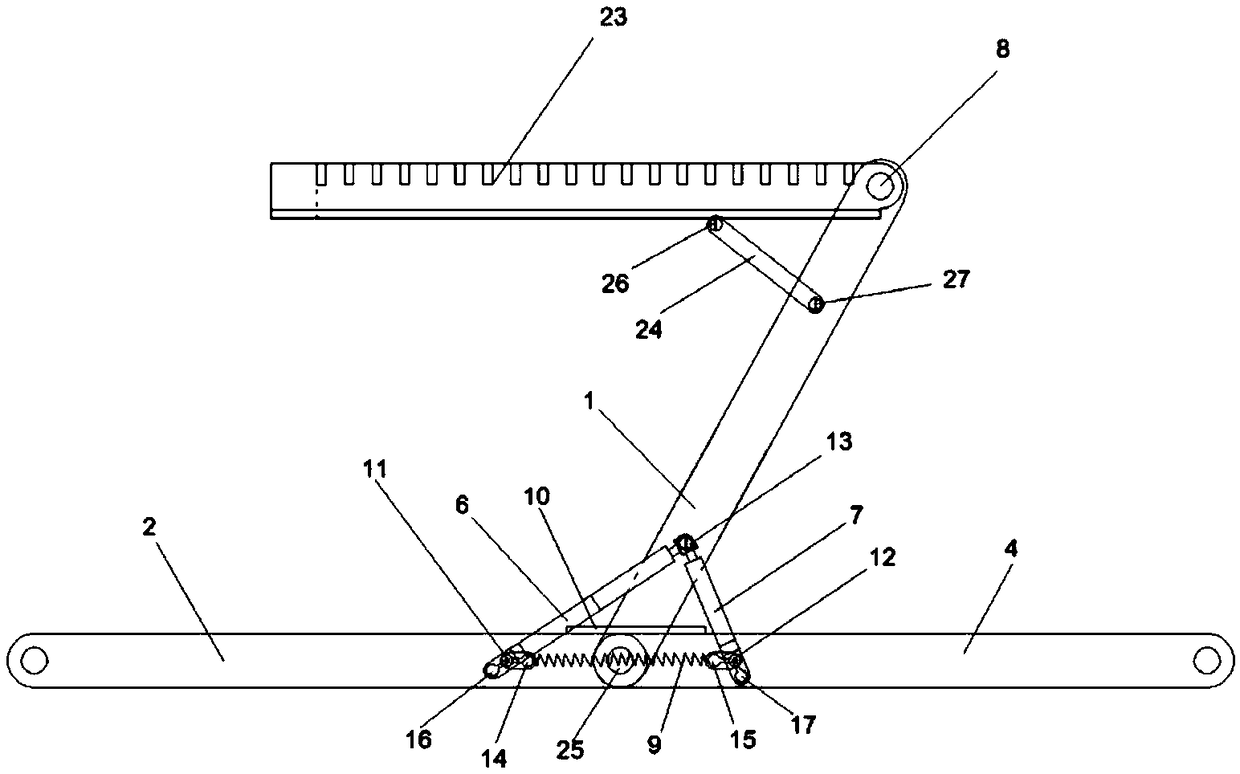

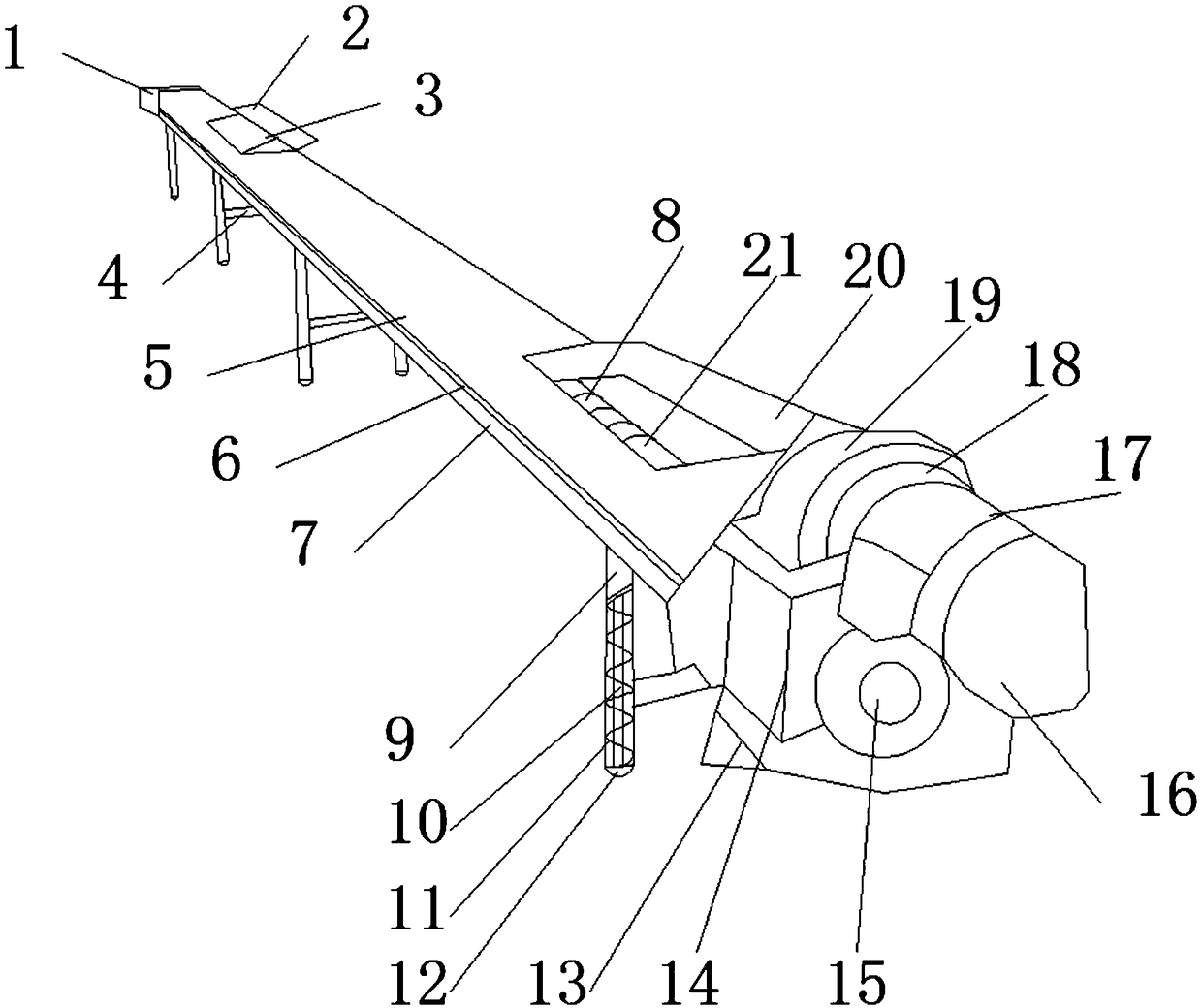

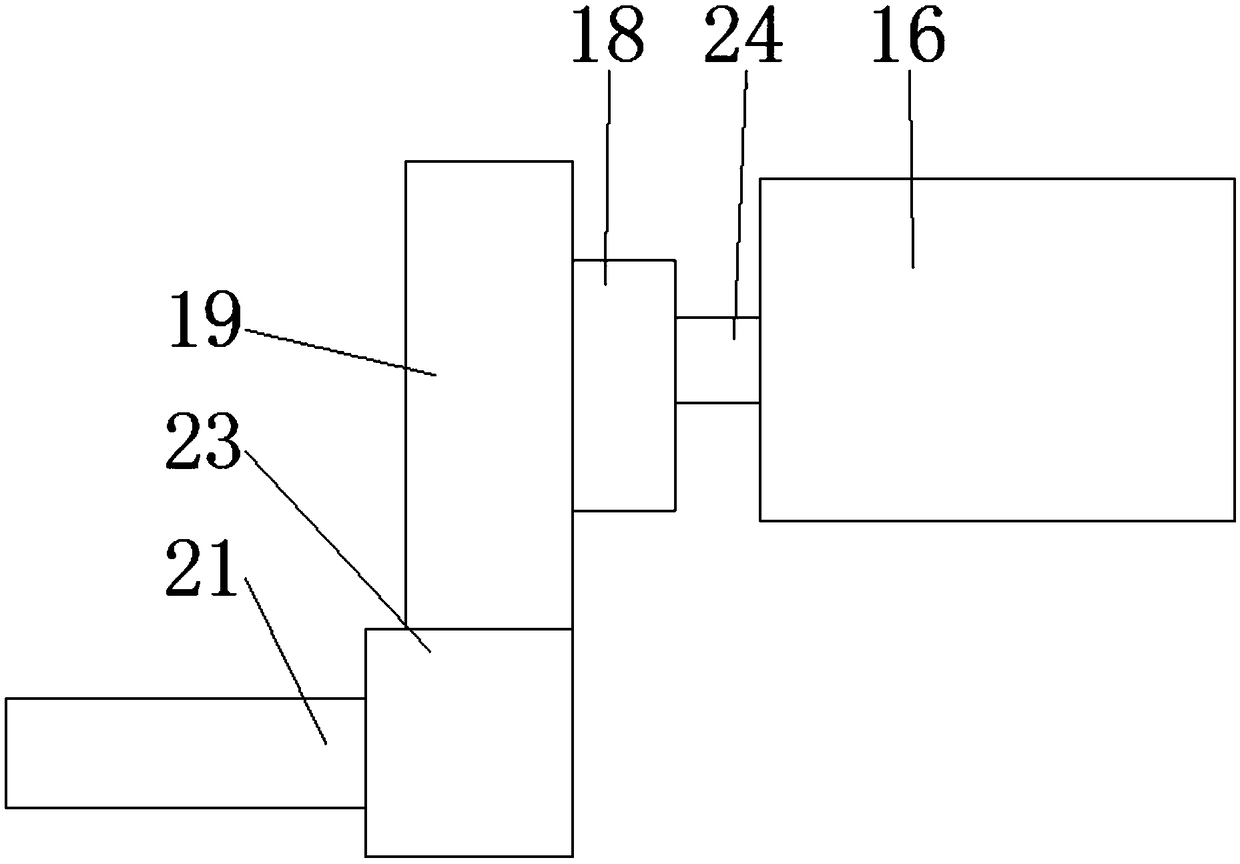

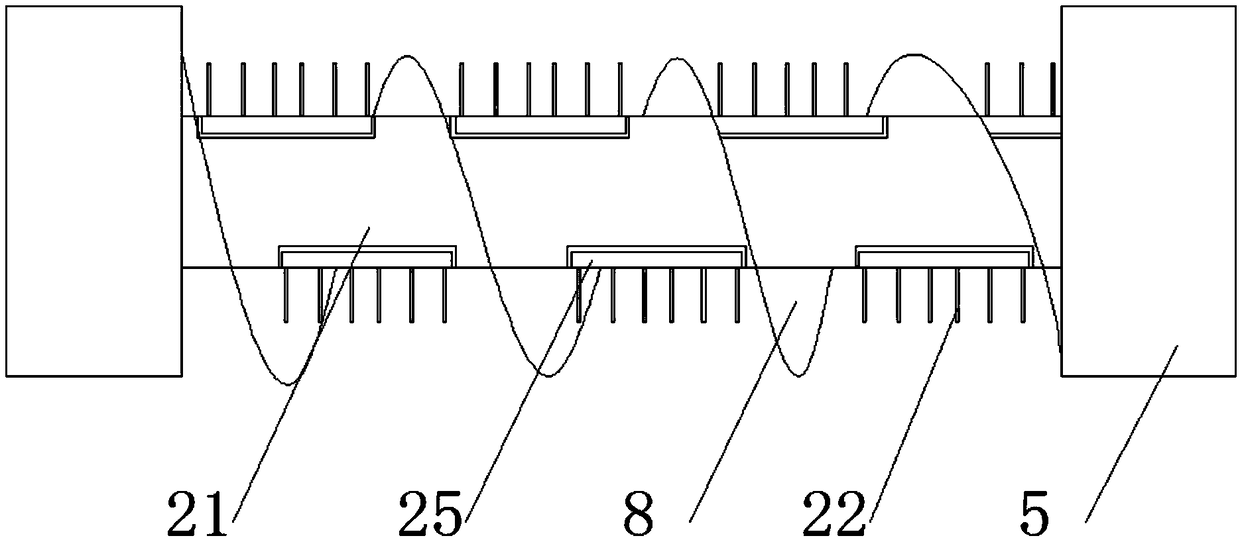

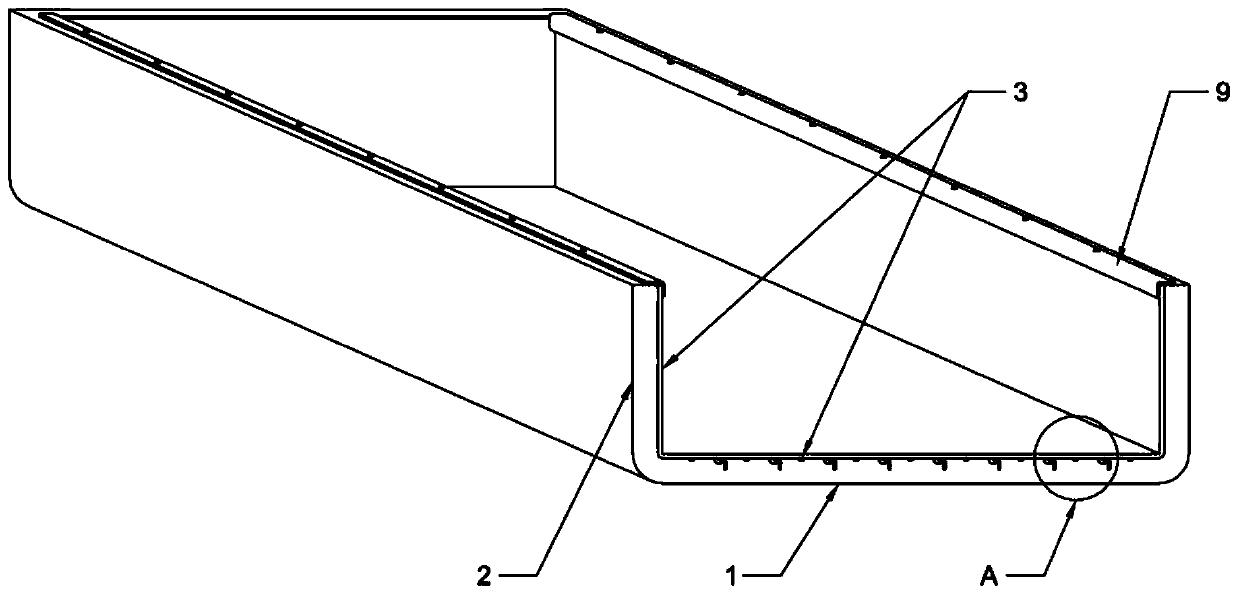

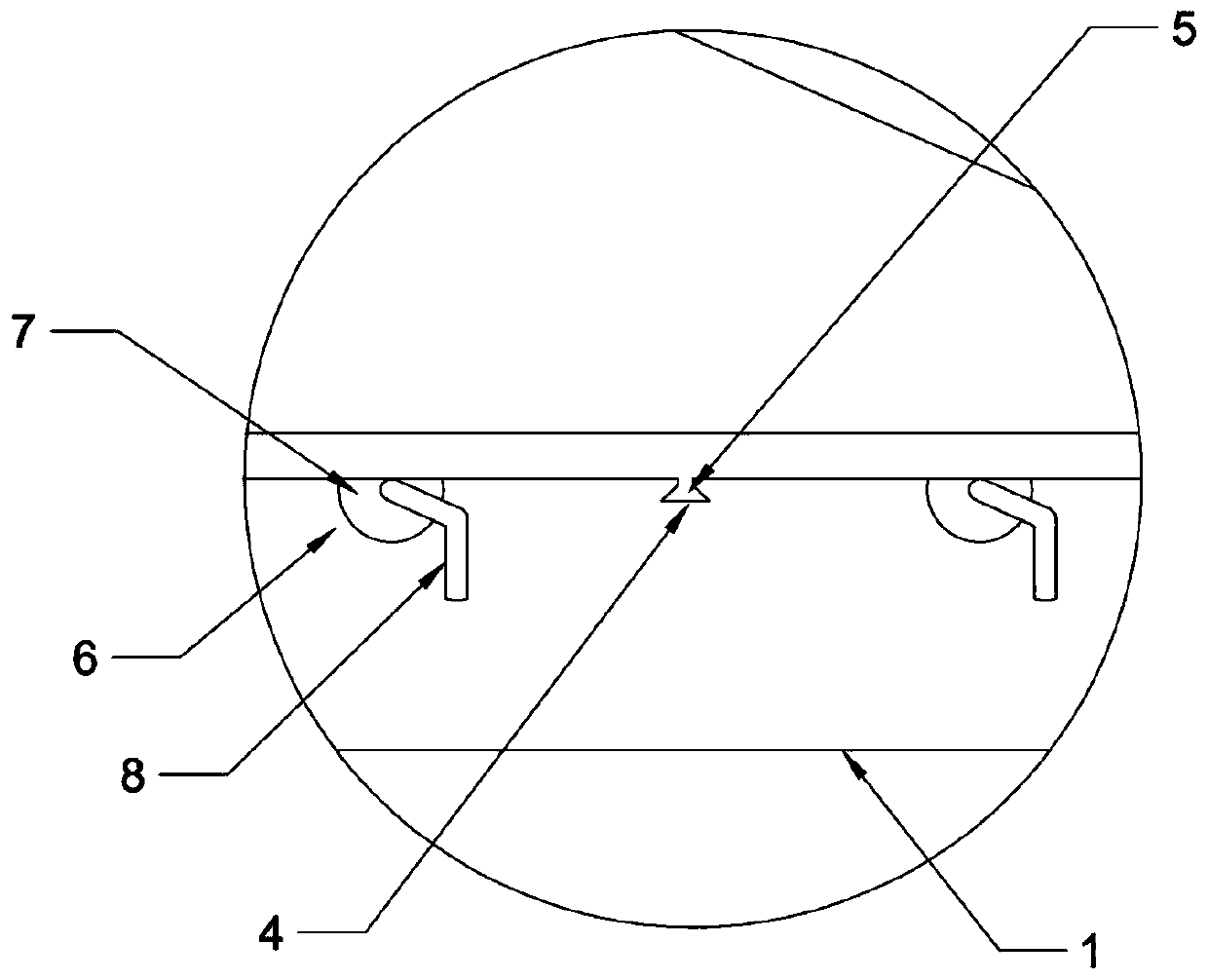

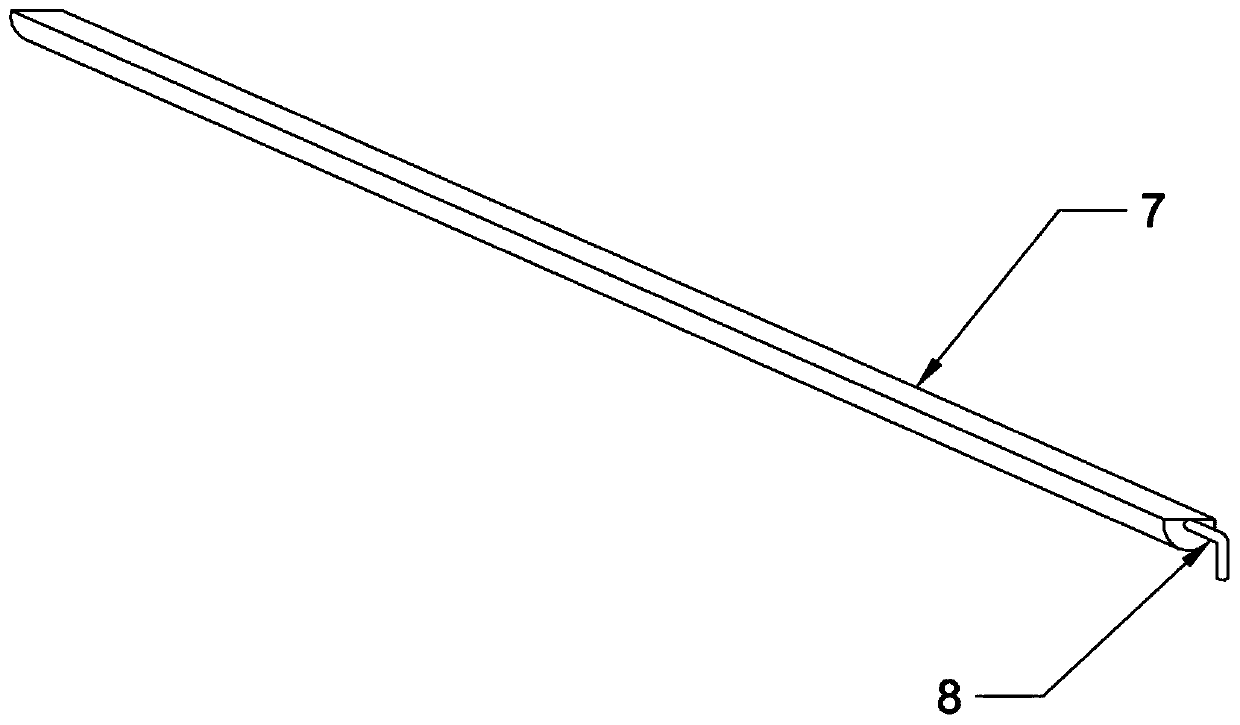

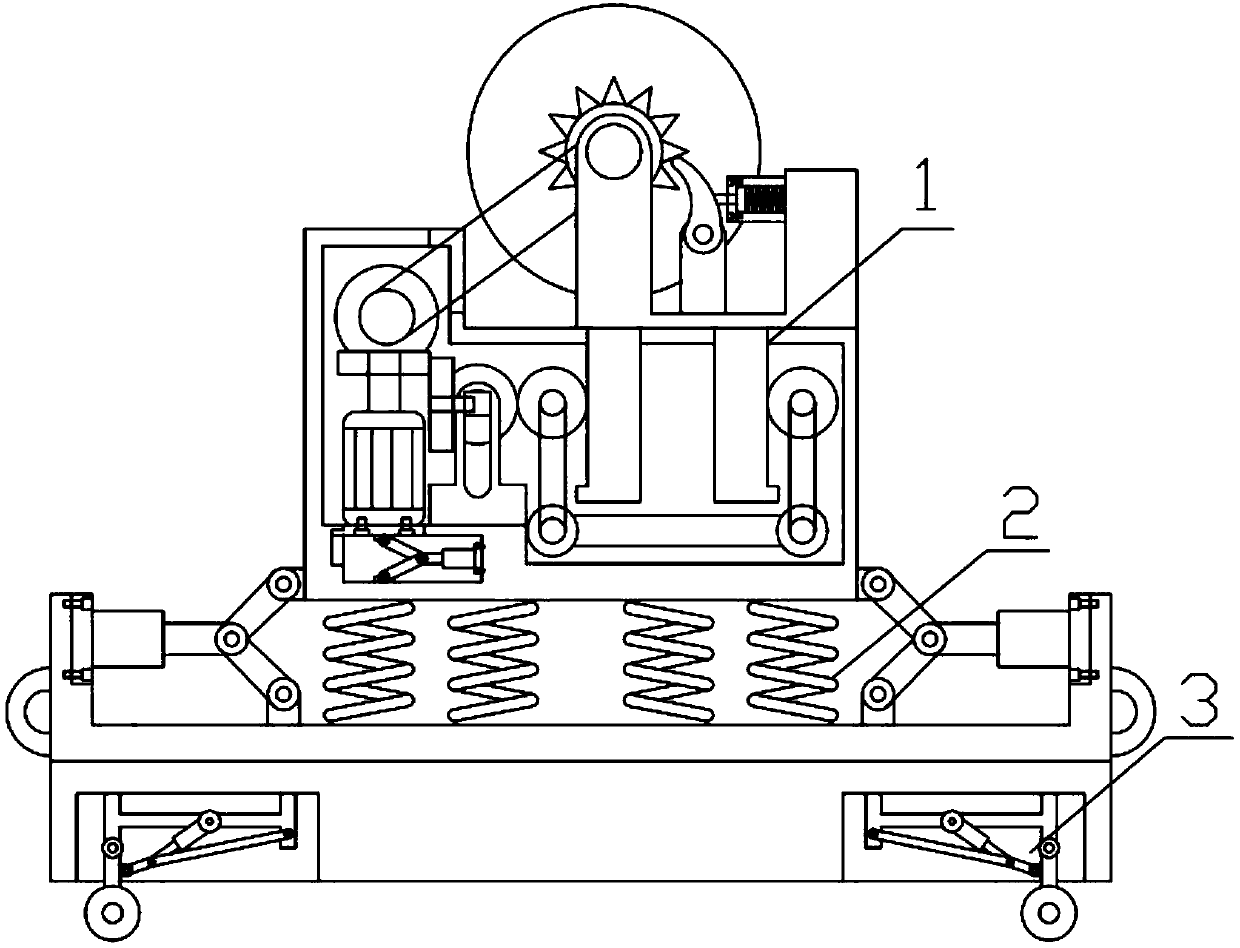

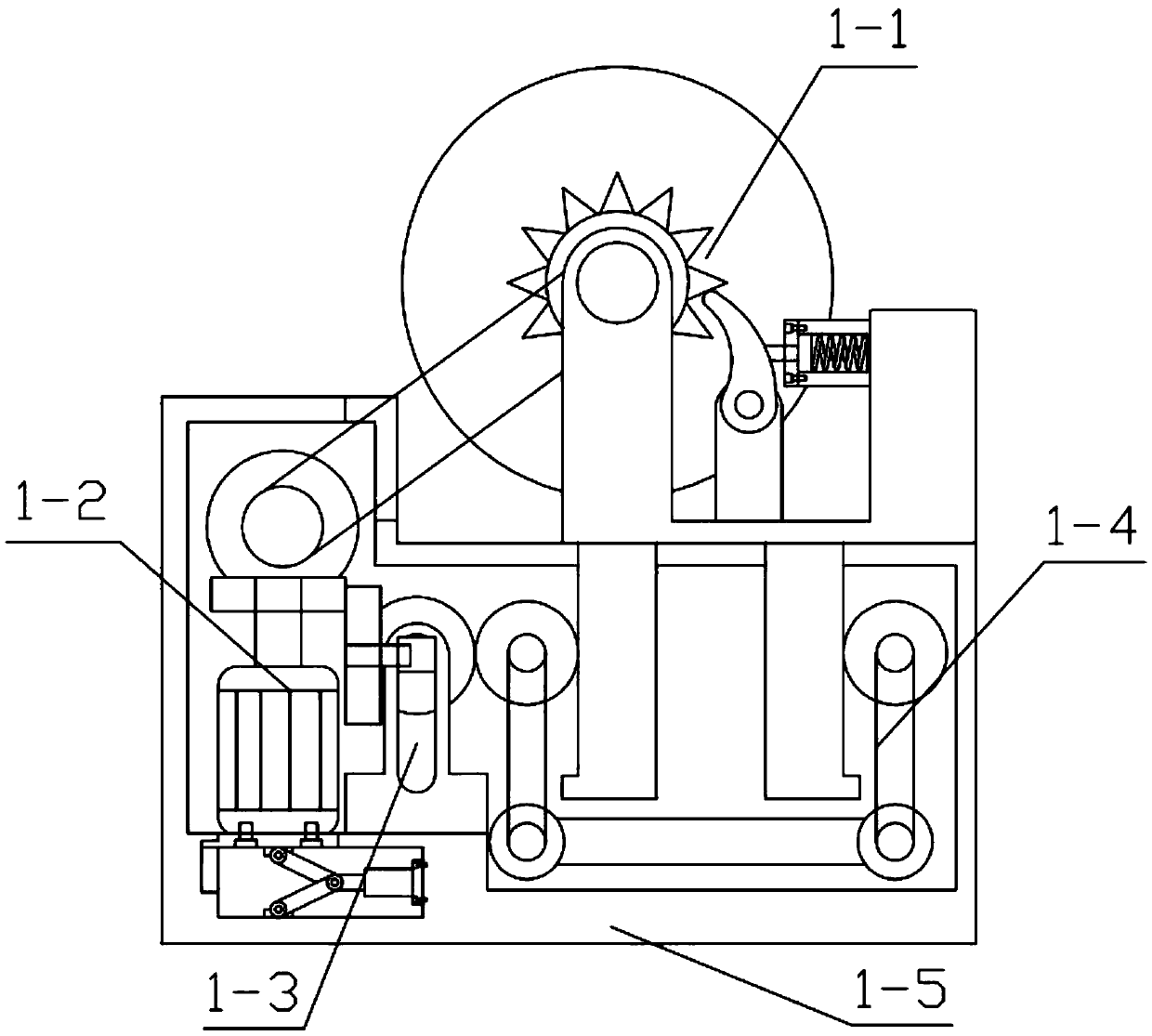

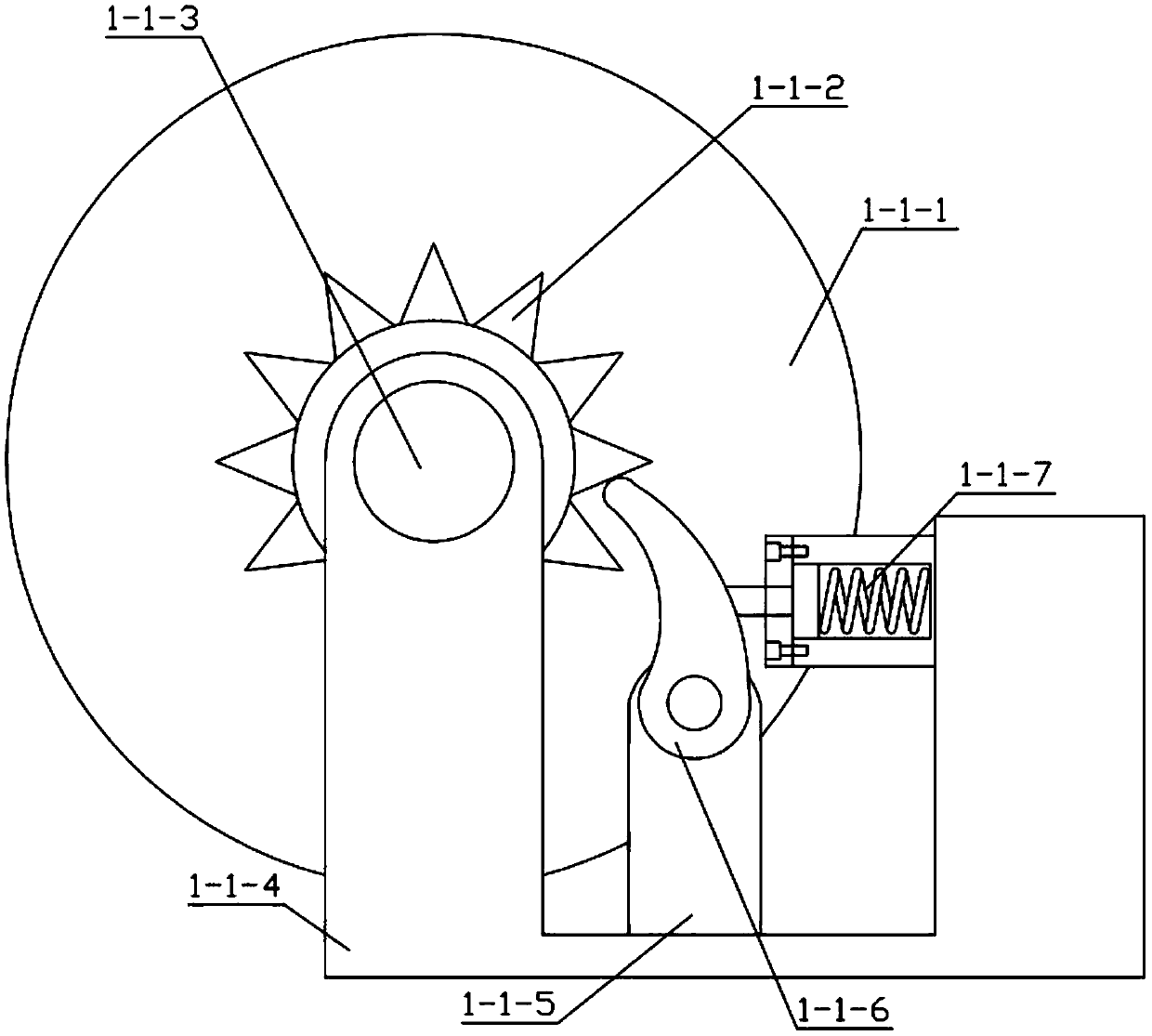

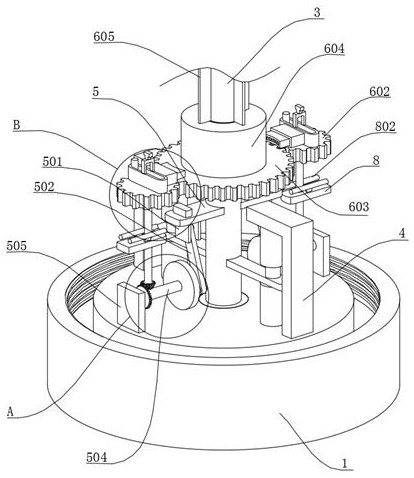

Roller type communication engineering cable collecting device

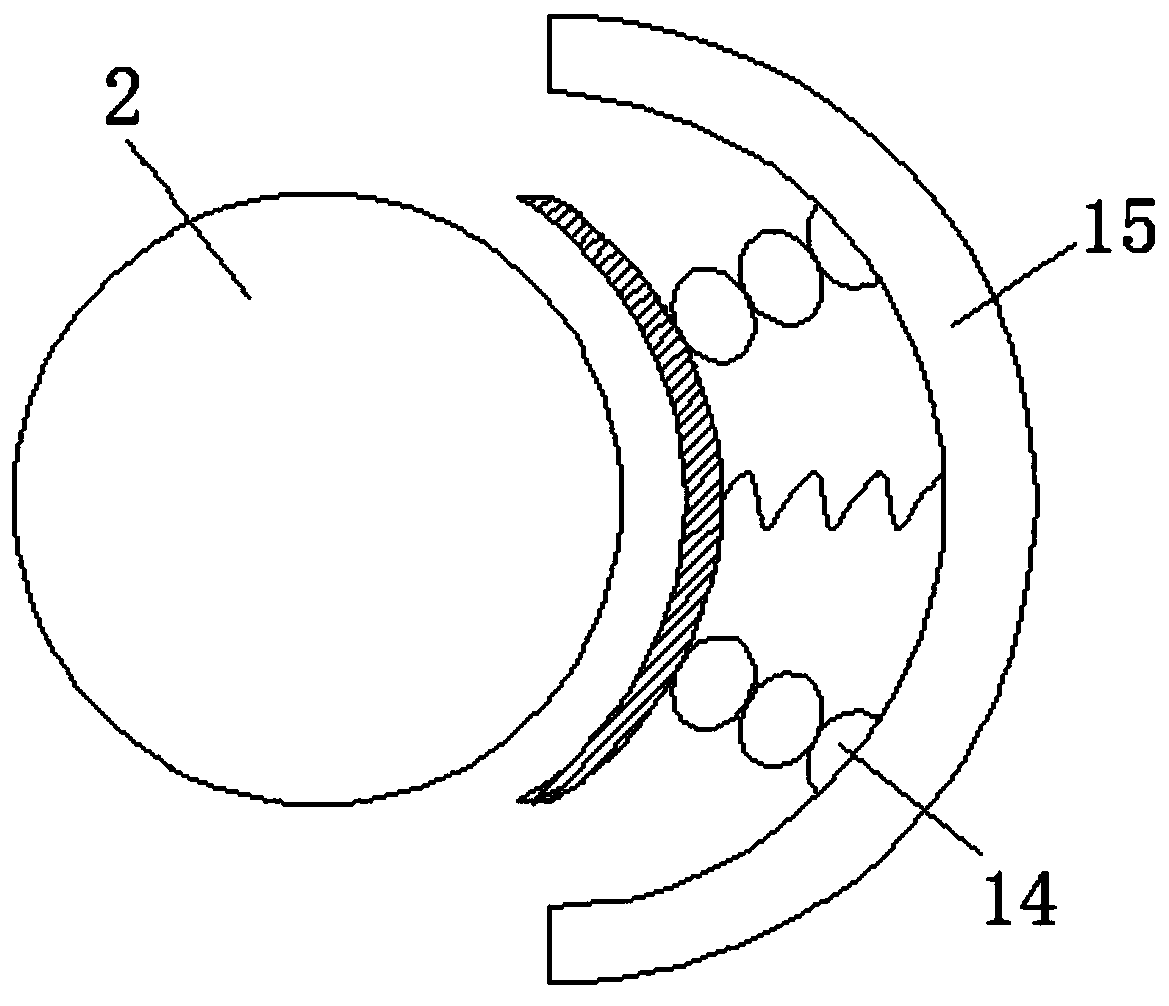

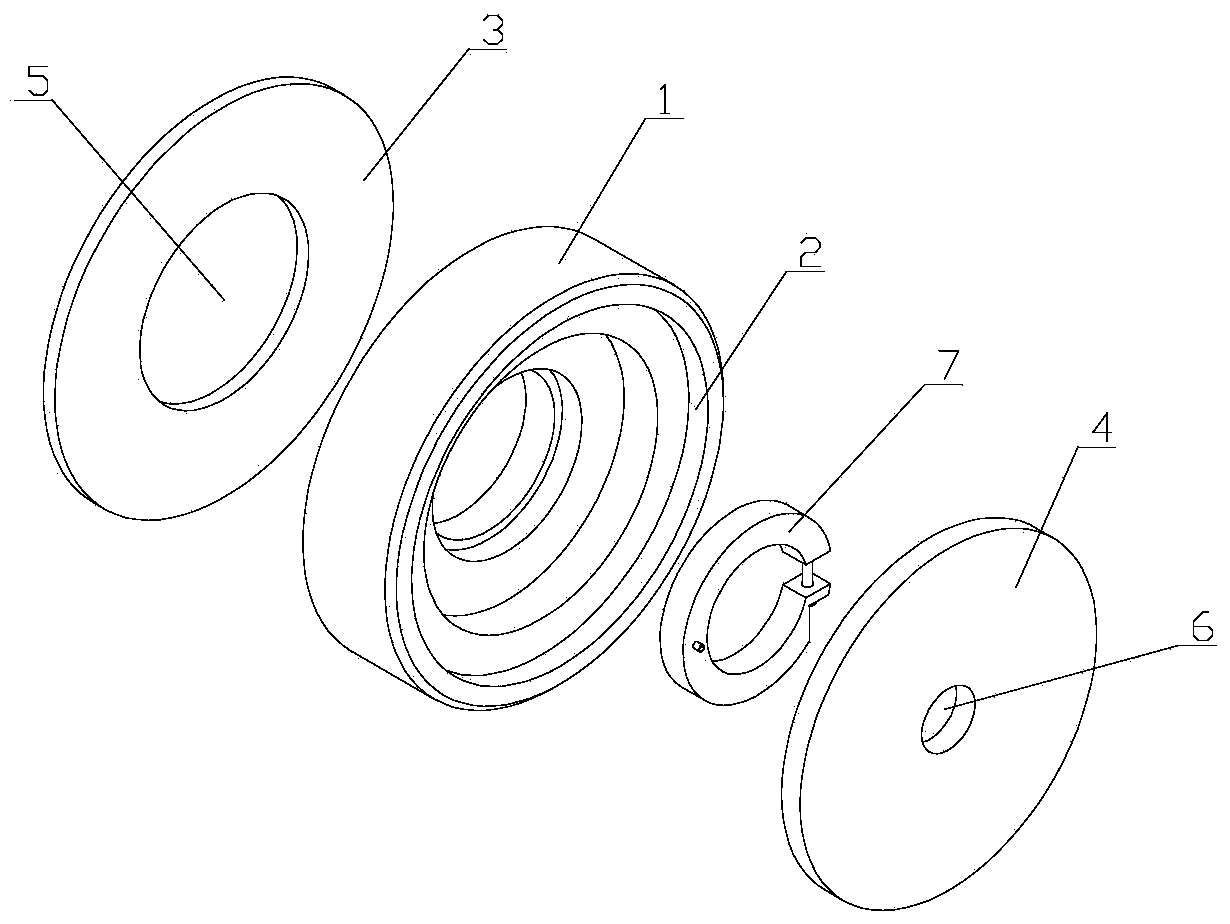

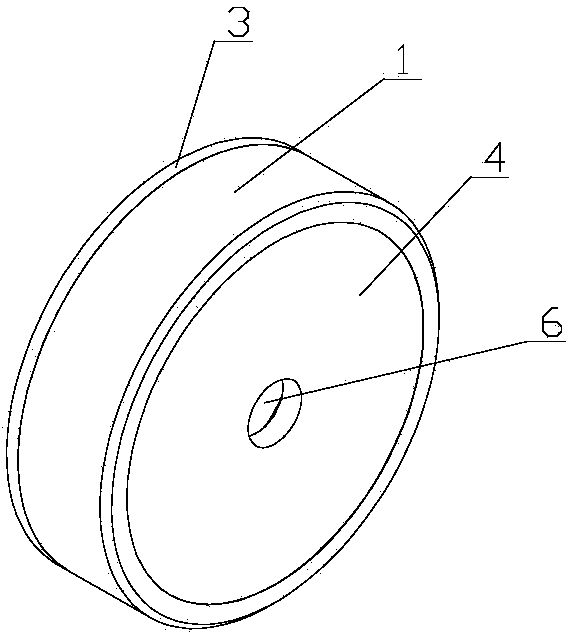

ActiveCN109399369AAvoid reverse rotationGood shock absorberFilament handlingEngineeringTelecommunications engineering

The invention relates to communication engineering equipment, in particular to a roller type communication engineering cable collecting device. The cable collecting device comprises a cable winding mechanism, a damping mechanism and a travel mechanism. An anti-slip mechanism arranged on the device prevents a roller from reversely rotating when cables are sorted; a lifting mechanism arranged on thedevice can be adjusted according to the quantity of the cables; in the process of transportation and cable collection, the device is provided with the good damping mechanism; the device is further provided with the telescopic travel mechanism to facilitate movement of the device, and stable placement of the device is also facilitated. The cable winding mechanism is connected with the damping mechanism through welding and the damping mechanism is connected with the travel mechanism through welding.

Owner:HEBEI VOCATIONAL & TECHN COLLEGE OF BUILDING MATERIALS

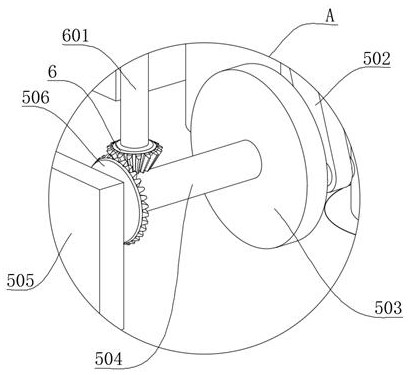

Bicycle front fork

InactiveCN105947079AGuaranteed stabilityImprove stabilityCycle springsSteering deviceEngineeringPiston

The invention relates to a bicycle front fork. The bicycle front fork comprises a vertical pipe, a fork shoulder, stroke pipes, outer pipes, fork feet and a fork bridge. The vertical pipe is connected with the fork shoulder. The stroke pipes comprise the left stroke pipe and the right stroke pipe and are installed at the two ends of the fork shoulder in a sleeving mode correspondingly. The lower ends of the stroke pipes are sleeved with the outer pipes. The fork feet are arranged under the outer pipes. The fork bridge is in bridge joint with the position between the outer pipes. A sealed oil storage chamber, a shock-proof spring, a gasket and a spring rod are sequentially arranged in each outer pipe from top to bottom. The periphery of each spring rod is provided with a negative-pressure spring. A piston is arranged between each sealed oil storage chamber and the corresponding shock-proof spring. Each sealed oil storage chamber is internally provided with an oil absorption sponge and is provided with an oil filling port. The bicycle front fork is good in stability, shockproof effect and damping effect and capable of meeting using requirements.

Owner:天津市嘉德宇通科技发展有限公司

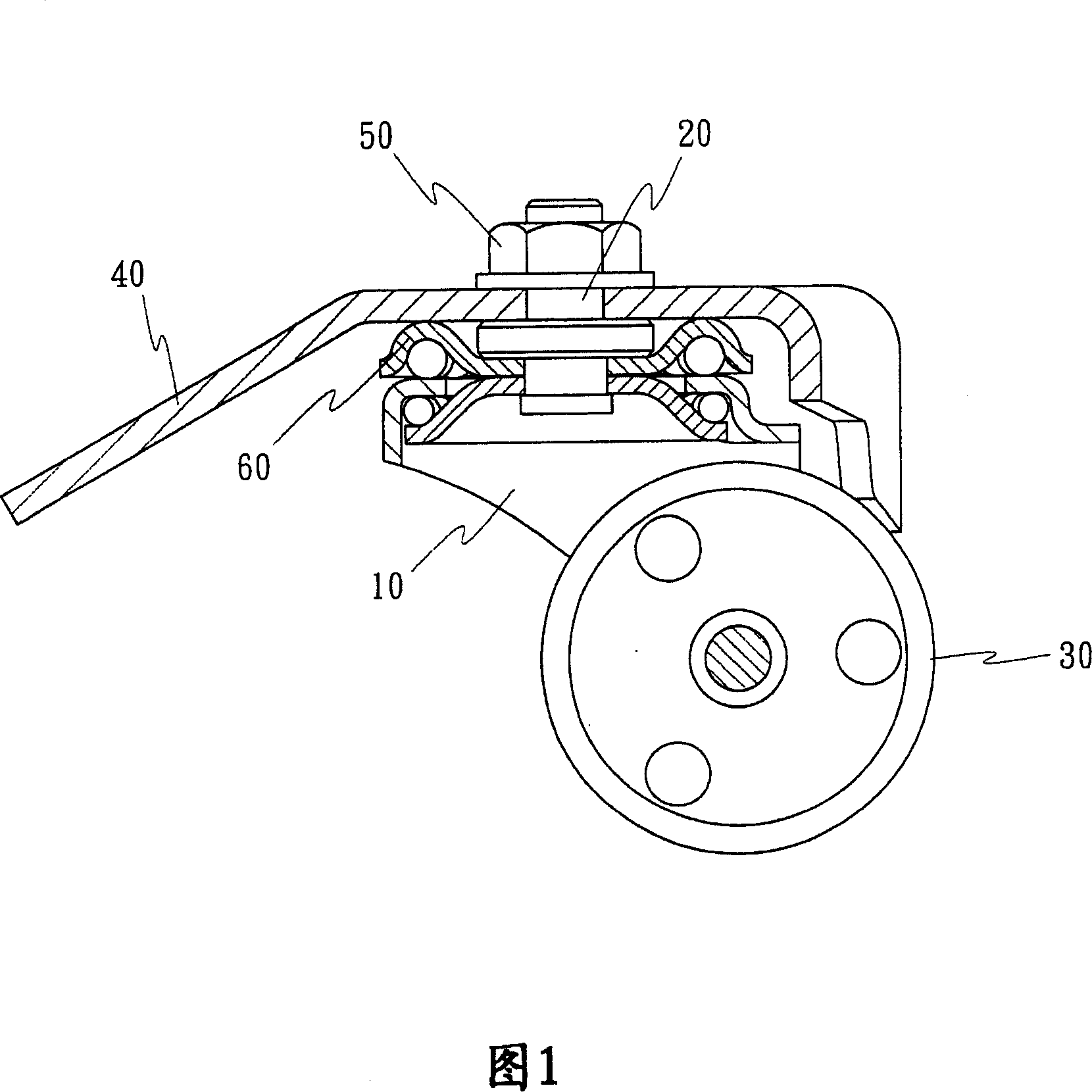

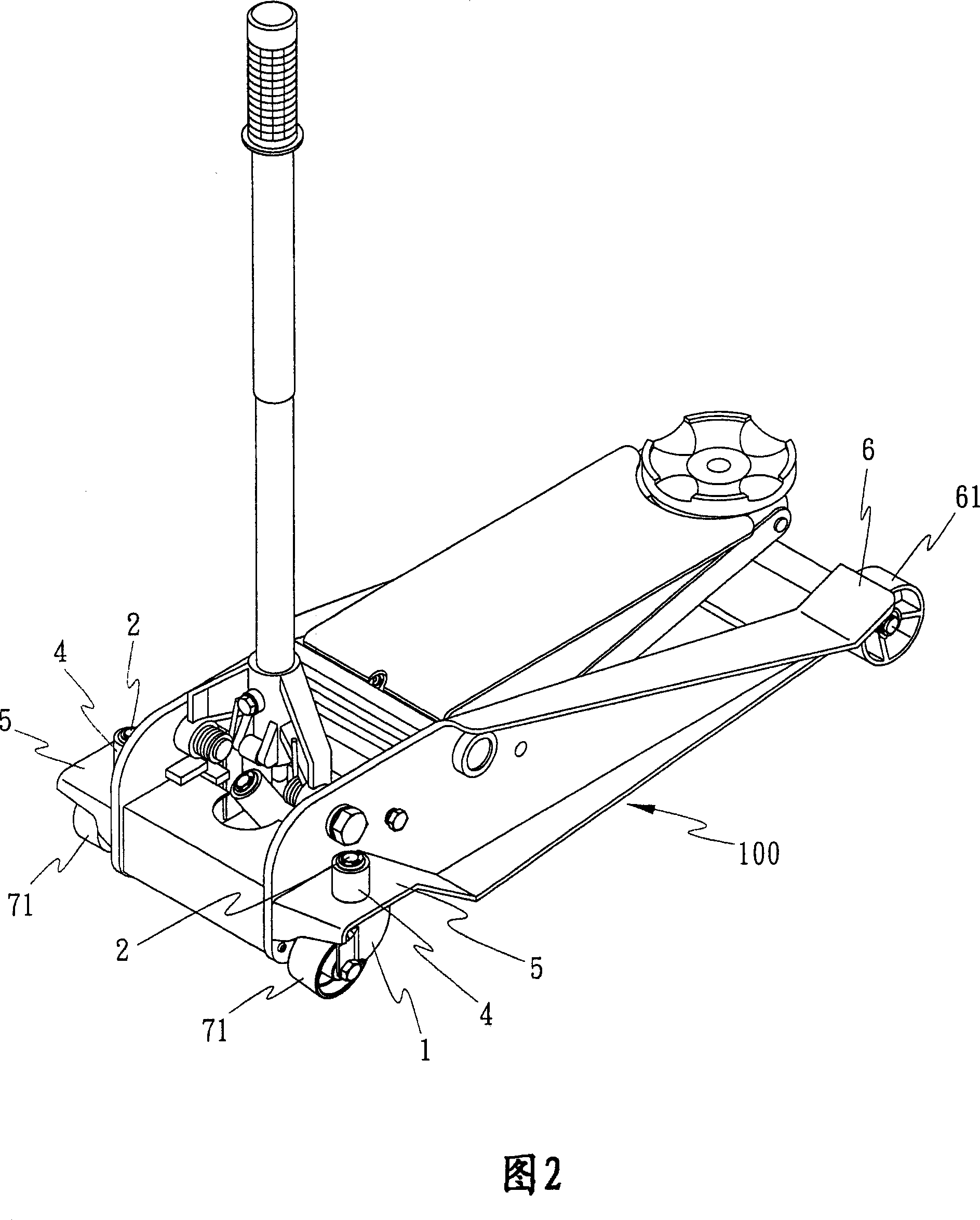

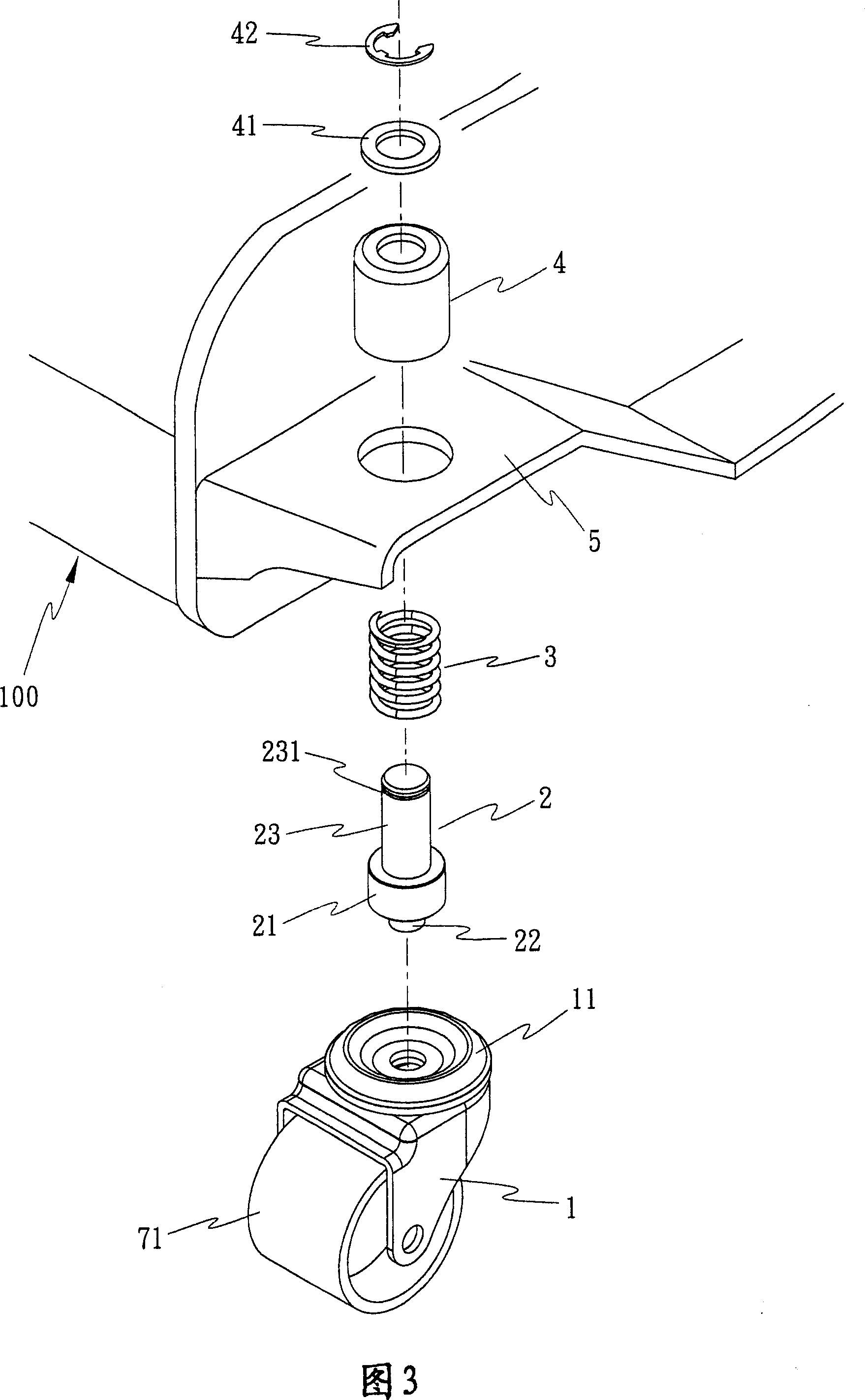

Jack wheel with shock absorber

Owner:SHINN FU

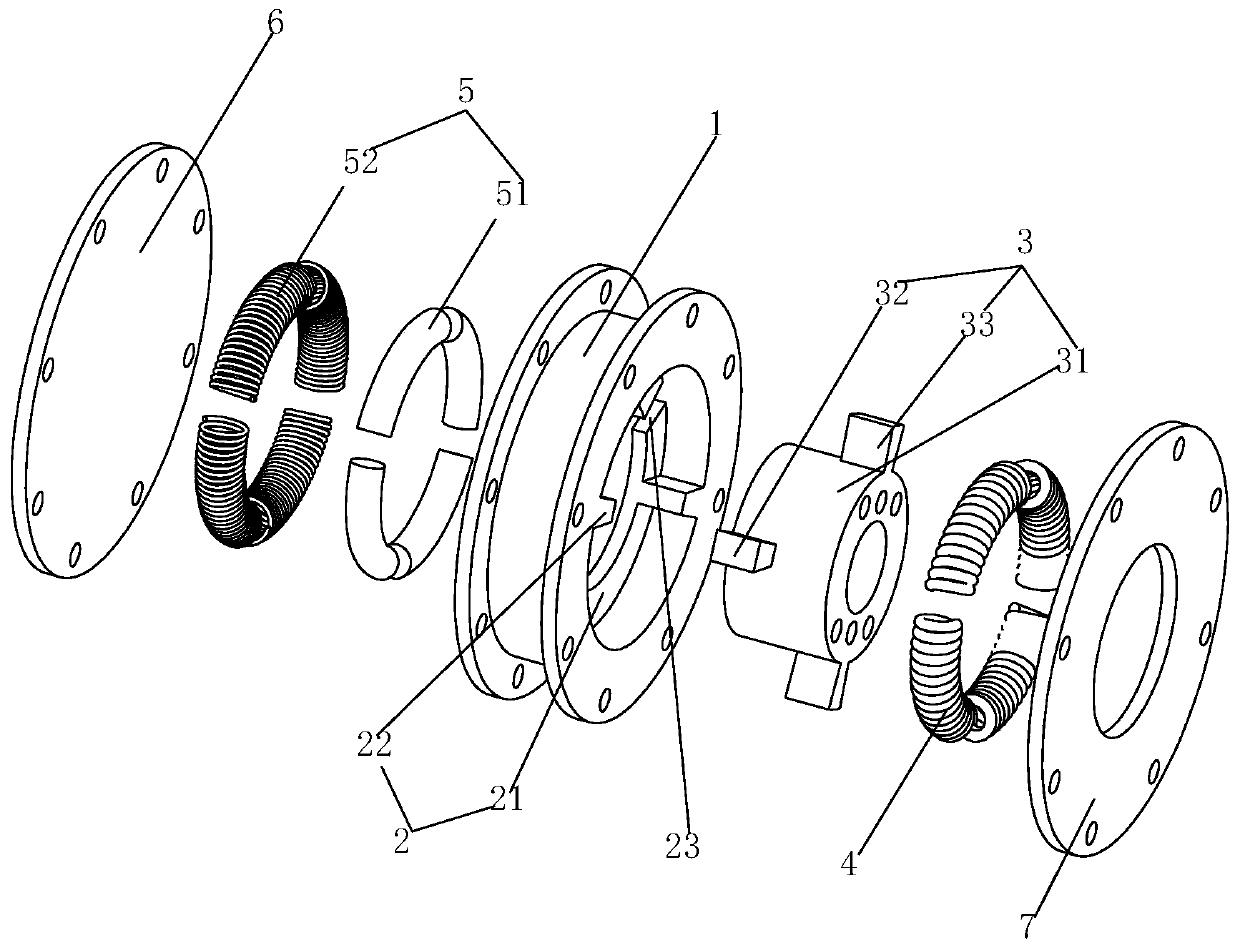

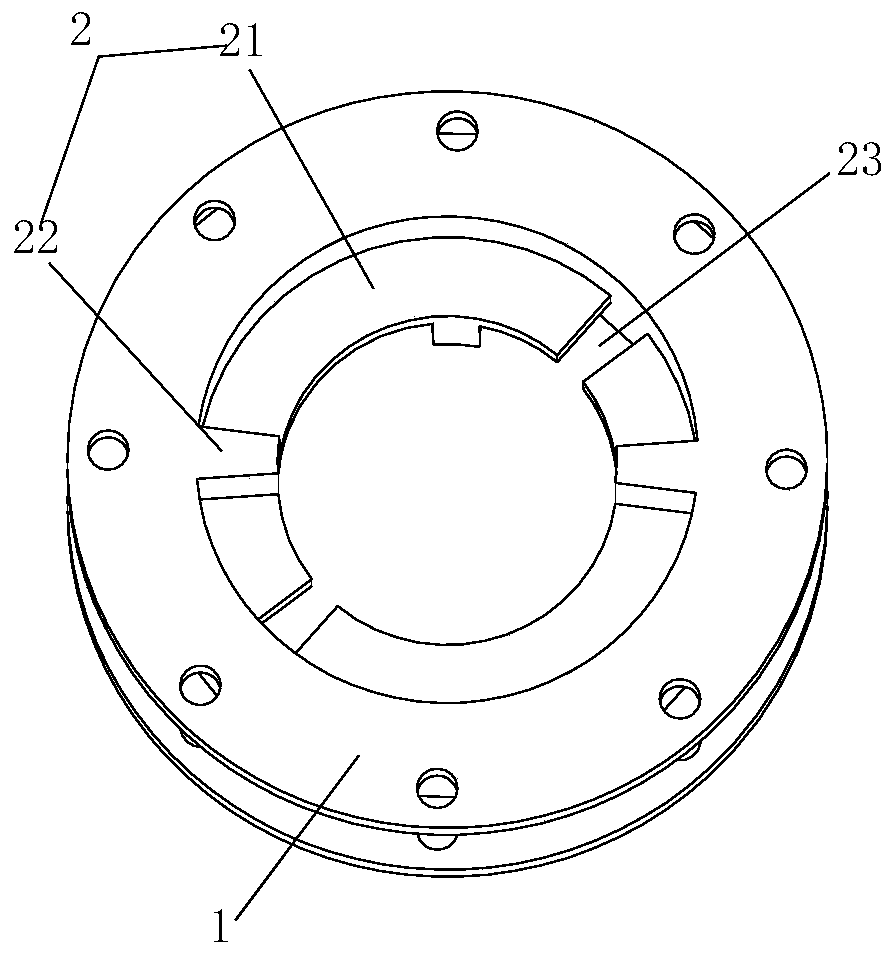

Industrial robot joint active damping device and robot

The invention discloses an industrial robot joint active damping device. The device comprises a shell, a stop ring part, a connecting element, an elastic element and an active damping and vibration reducing module, wherein the stop ring part is arranged on the inner side wall of the shell; the connecting element is matched and embedded in an inner ring of the stop ring part and capable of being rotated relative to the stop ring part; the elastic element is embedded in a cavity formed among the shell, the connecting element and the stop ring part, and is positioned on the right end surface of the stop ring part; and the active damping and vibration reducing module is sleeved in the cavity formed among the shell, the connecting element and the stop ring part, and is positioned on the left end surface of the stop ring part. The industrial robot joint active damping device can realize both damping and buffering to achieve an excellent effect of buffering vibration impact. The invention further provides a robot with the industrial robot joint active damping device.

Owner:GREE ELECTRIC APPLIANCES INC

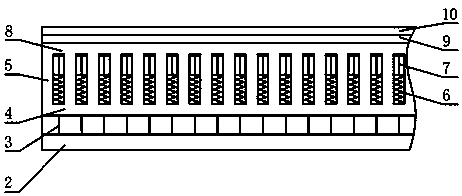

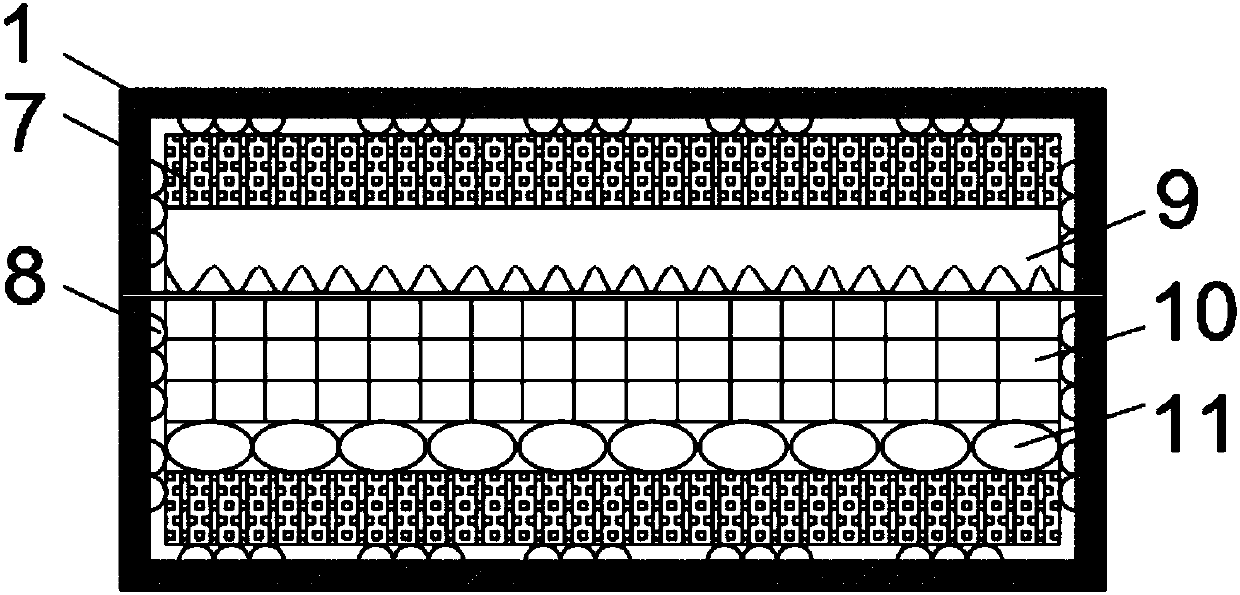

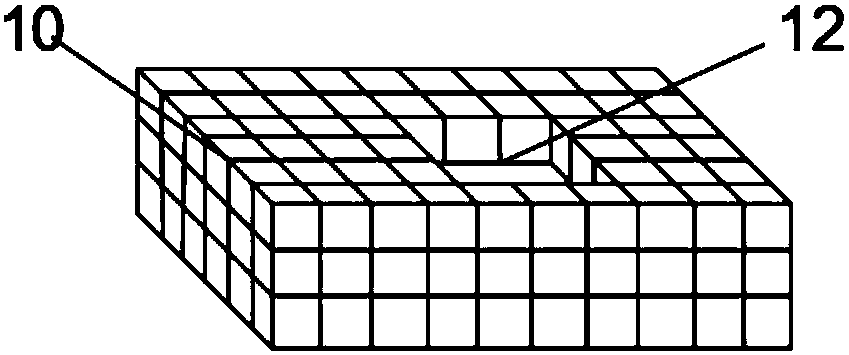

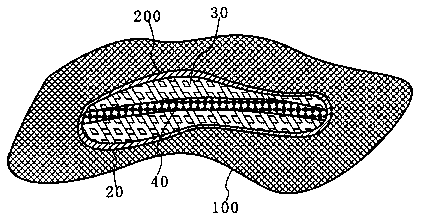

Manufacturing method of carbon fiber reinforced damping and buffering material based on microcellular foaming technology

The invention discloses a manufacturing method of a carbon fiber reinforced damping and buffering material based on a microcellular foaming technology. The damping and buffering material comprises a PET film and a foaming material arranged on a base material. The foaming material comprises the following raw materials: a waterborne polyurethane emulsion, waterborne polyacrylate, carbon fibers, a foam stabilizer, a foaming agent, sodium polyacrylate, polyethylene glycol, ammonia water, isopropanolamine, a catalyst, a cross-linking agent and a thickening agent. The waterborne polyurethane emulsion and the waterborne polyacrylate are limited as main raw materials, the other components and the foaming ratio of the foaming material are limited, so that uniformly distributed bubbles are formed inthe foaming material, the closed-cell rate of the bubbles reaches 80% or above, the prepared material has good shock absorption and shock avoidance functions, and can be used for dust prevention sealing, shock absorption buffering, elastic supporting and the like of electronic products.

Owner:斯匹格科技(厦门)有限公司

Anti-collision cellular side wall plate

PendingCN107618457AIncrease elasticityWith fire performanceBumpersRubber layered productsEngineeringAlloy

The invention provides an anti-collision cellular side wall plate comprising a car side wall plate. The cellular side wall plate is characterized in that the car side wall plate comprises an alloy stainless steel panel, an external cellular core, an external rubber layer, a rubber fence layer, a rubber sponge spring layer, an internal cellular core, an internal rubber layer, a fluoro-carbon flameretardant paint layer and a fabric layer which are successively connected from outside to inside; the rubber fence layer is inserted in the holes of the internal cellular core. Traditional car cellular side wall plates are improved; the fluoro-carbon flame retardant paint layer which is fireproof is added to avoid combustion of fabric layer.

Owner:天津富松汽车零部件有限公司

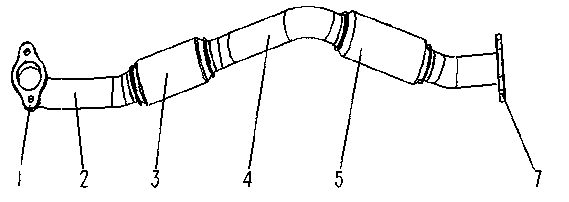

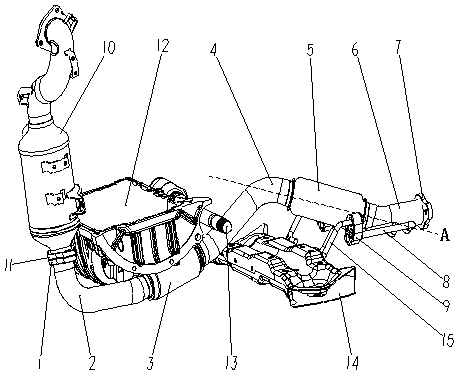

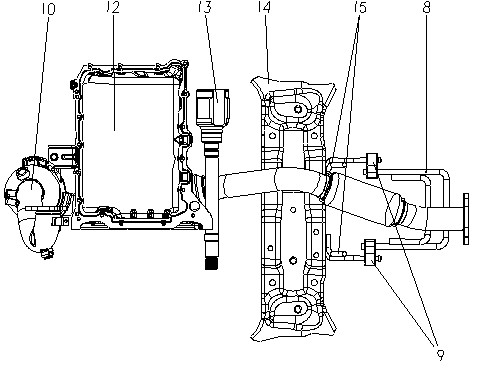

Automobile silencer inlet pipe assembly and arrangement structure thereof

ActiveCN103410595AAvoid swingingImprove stabilityExhaust apparatusSilencing apparatusVehicle frameDrive shaft

The invention discloses an automobile silencer inlet pipe assembly and an arrangement structure thereof. The automobile silencer inlet pipe assembly is formed by an inlet pipe, a first bellows, a connecting pipe, a second bellows and an outlet pipe which are connected in sequence. The inlet end of the inlet pipe is provided with a first flange used for being connected with a three-way catalytic converter, and the outlet end of the outlet pipe is provided with a second flange used for being connected with a silencer. The first bellows is arranged below an engine oil pan and a transmission shaft, and the second bellows is arranged above the rear of an auxiliary frame. According to the automobile silencer inlet pipe assembly, vibration generated by an engine and the silencer is effectively eliminated, reliability of a whole exhaust system is improved, and spatial safety distances of the exhaust system and parts such as the engine oil pan, the transmission shaft and the silencer and the heat damage requirements are met.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Concrete troweling device

ActiveCN111980414AImprove smoothing effectAvoid rigid contactBuilding material handlingArchitectural engineeringElectric machinery

The invention discloses a concrete troweling device which comprises a shell, wherein sliding plates are fixedly mounted at two sides of the bottom of the shell, troweling disks are symmetrically mounted at the front end of the bottom of the shell, a motor box is fixedly mounted at the front end of the top of the shell, a servo motor is fixedly mounted in the motor box, the troweling disks are driven by the servo motor, a pressing plate is arranged at the rear end of the bottom of the shell and is connected with the shell through a vibration isolation mechanism, a vibration motor is fixedly mounted at the top of the pressing plate, a push-pull rod is hinged to the rear end of the top of the shell, and limiting seats are arranged at two sides of the end, close to the shell, of the push-pullrod. According to the device, the concrete surface is trowelled through the symmetrically arranged troweling disks, and the pressing plate is vibrated through the vibration motor to level the concretesurface, thereby reducing scratches when the concrete surface is trowelled and improving the troweling efficiency of the concrete surface.

Owner:安徽亚遥工程机械有限公司

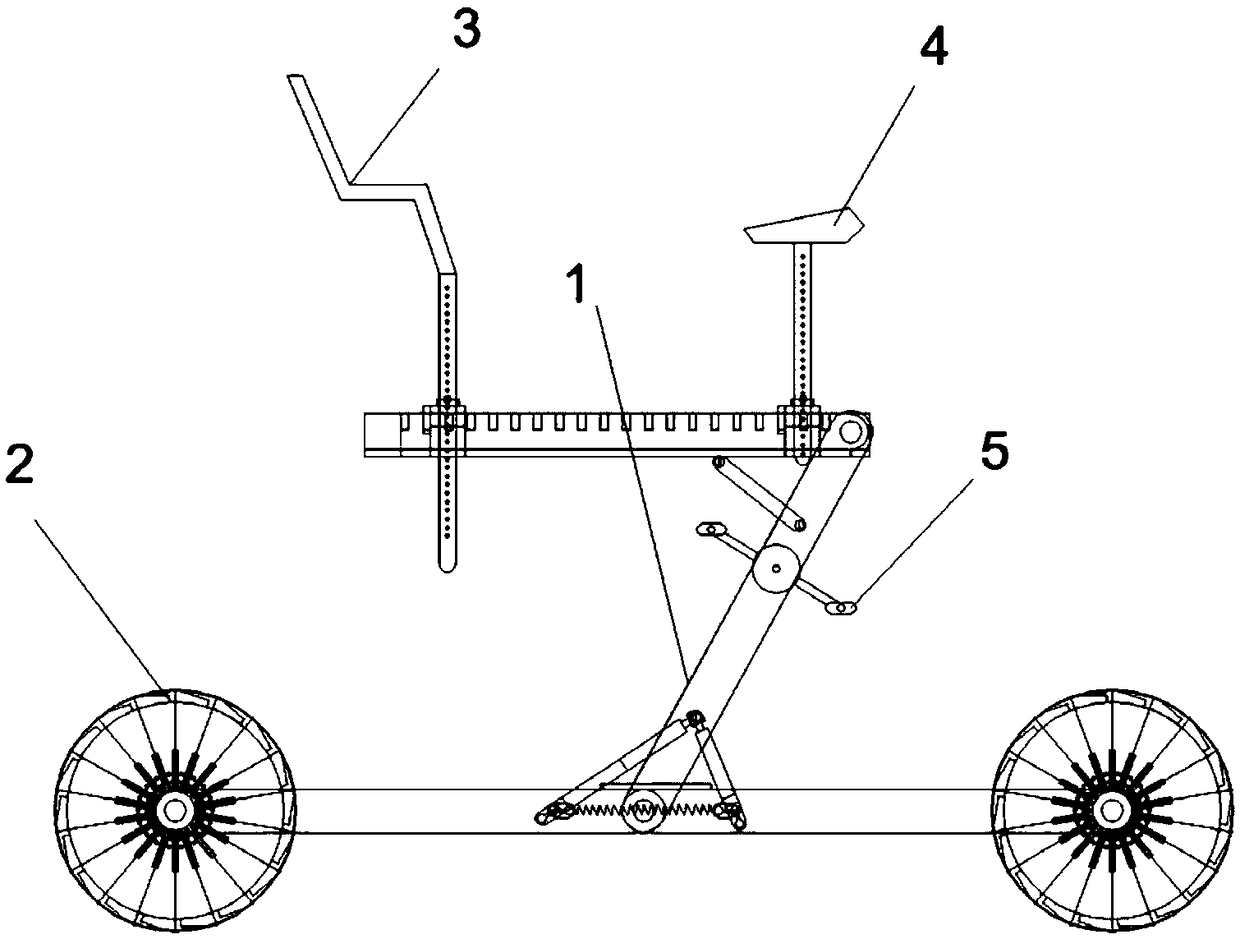

Foldable all-terrain bicycle

InactiveCN109110029AComfortable rideEasy to assemble and disassembleFoldable cyclesTerrainVehicle frame

The invention discloses a foldable all-terrain bicycle including a frame, wheels mounted on the frame, a seat, a handle, pedals, a wheel drive transmission system, and a wheel differential system, theframe includes a frame rail, a frame rail and a wheel support frame, and the frame rail, the frame rail, the frame rail and the wheel support are connected by a frame hinge. The handle and a seat aremount on that cross bar of the frame, a wheel comprises a hub, a tire plate unit and a tire drive shaft, the wheel drive transmission system comprises a center drive mechanism, a front wheel drive mechanism and a rear wheel drive mechanism, a wheel differential system comprises a differential and a differential locking mechanism, and a differential comprises a differential housing, a differentialdrive shaft, a differential drive shaft and a drive gear set. The invention is convenient to disassemble, assemble and fold, convenient to travel and carry, stable to ride, good in shock absorbing effect, capable of passing through various bad road conditions and switching between different road conditions, good in safety and reliability, and wide in application range.

Owner:杭州宝骊科技有限公司

Waterproof and moistureproof object placing device

InactiveCN107814097AEfficient removalAvoid enteringSealingContainers preventing decayActivated carbonAutomatic balancing valves

The invention discloses a waterproof and moisture-proof placement device for articles, which comprises a storage box, a box cover and a box body. There is a handle in the middle, and locks are snapped on both sides of the handle, an automatic balance valve is arranged above the handle, a spherical rubber layer is bonded to the inner wall of the storage box, and the inner wall of the box cover is fixed below the spherical rubber layer A moisture-proof layer is connected, and a wave sponge is bonded under the moisture-proof layer, and a mesh sponge is arranged on the inner wall of the box under the wave sponge. In the present invention, the outer shell of the storage box is made of waterproof material, and then a waterproof sealing strip is used around the opening of the storage box, which can effectively prevent the external water flow from entering the inside of the box body. , can effectively remove moisture and prevent mildew.

Owner:CHENGDU FUZHONGCHENG TECH CO LTD

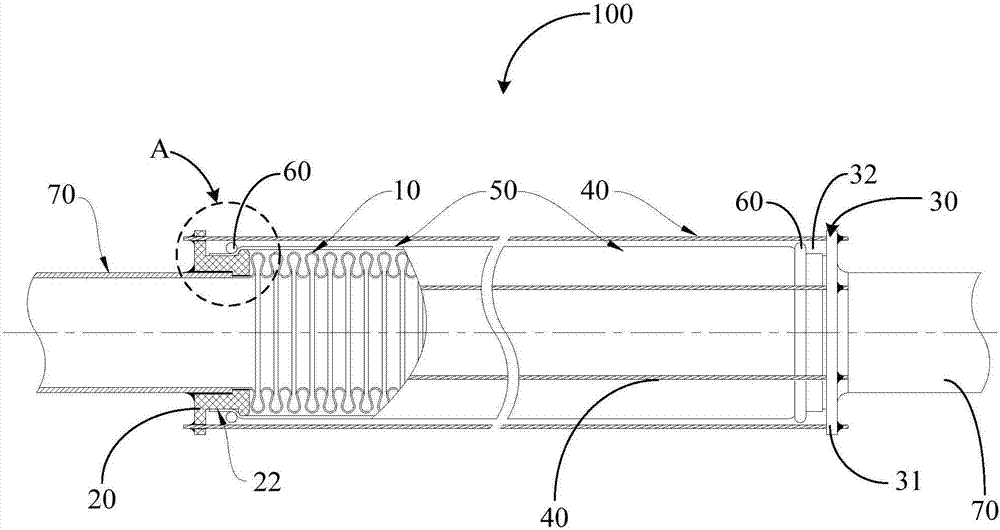

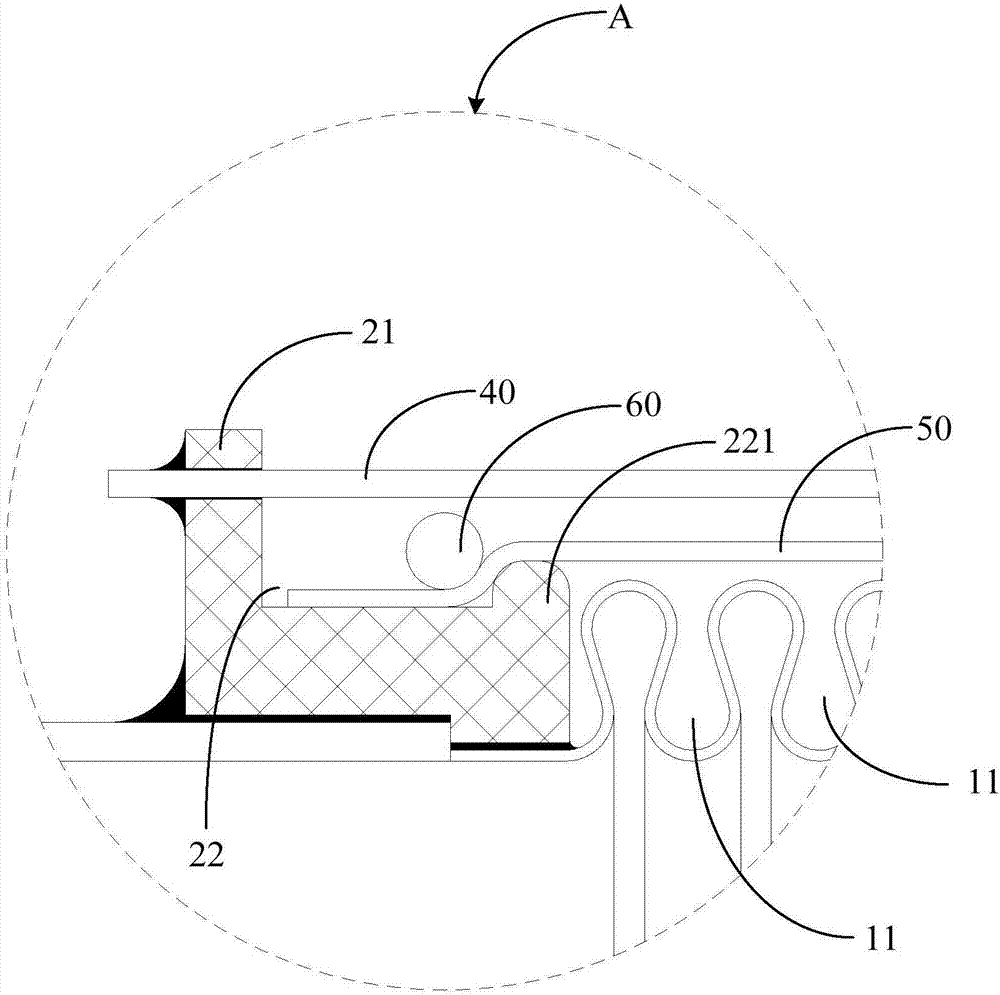

Suspension pipe and air conditioner

The invention discloses a suspension pipe which comprises a corrugated pipe, a first connection ring and a second connection ring. The first connection ring and the second connection ring are connected to the two ends of the corrugated pipe correspondingly. The suspension pipe further comprises at least two flexible ropes. One end of each flexible rope is connected to the first connection ring, and the other end of each flexible rope is connected to the second connection ring. According to the technical scheme, the suspension pipe is good in suspension effect and long in service life. The invention further provides an air conditioner applying the suspension pipe.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

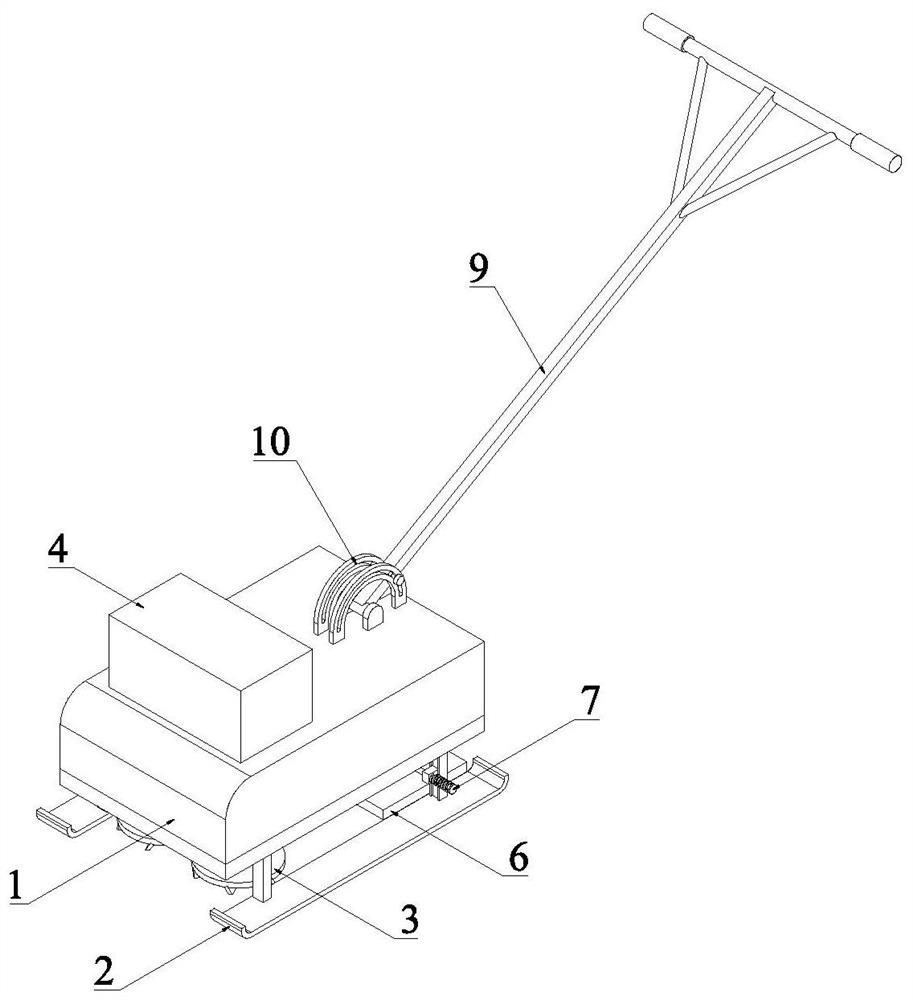

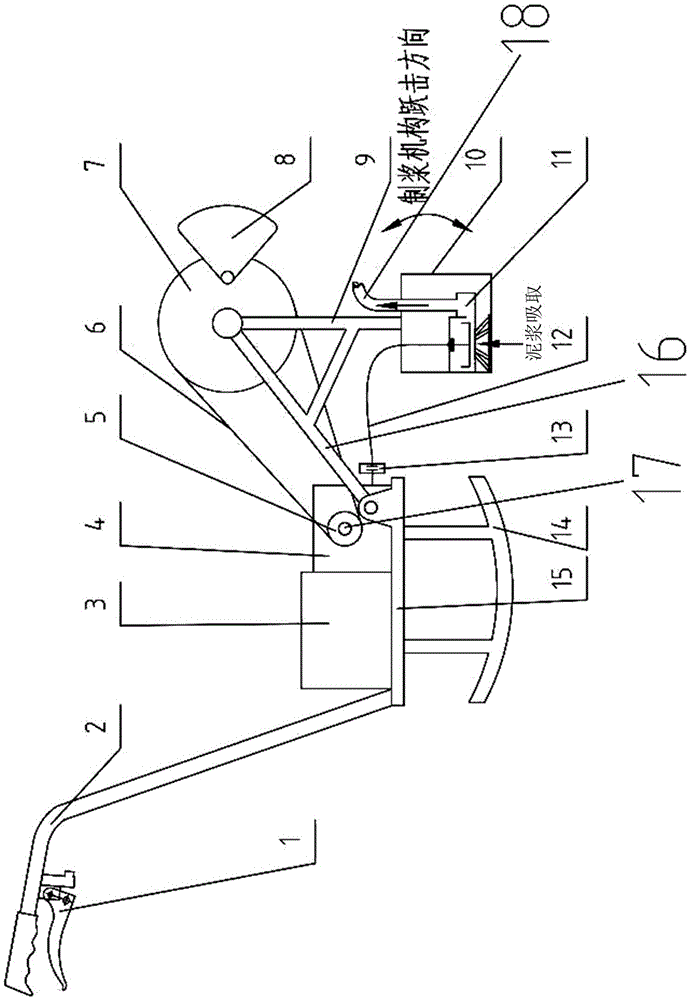

Rice seedling bed frog-type slurry machine

InactiveCN105532305AGood shock absorberExtended service lifeCultivating equipmentsRice cultivationSlurry pumpSeedling

The invention discloses a rice seedling bed frog-type slurry machine. The slurry machine comprises a base, a power mechanism, a slurry making mechanism, a slurry pouring mechanism and a transmission mechanism. The base is supported on the ground through a pry plate to move, and the slurry making mechanism is hinged to the front portion of the base through a connection frame and provided with a jumping device. The slurry making mechanism comprises a driven wheel with an eccentric block and stands on the ground through a support with a filter screen. The slurry pouring mechanism comprises a slurry pump which is connected with the filter screen of the slurry making mechanism. The power mechanism is fixed to the base and comprises a motor and a gearbox. The power mechanism transmits the jumping device of the slurry making mechanism and the slurry pump of the slurry pouring mechanism through the transmission mechanism. During slurry making, the connection frame of the slurry making mechanism swings up and down around the base, when the connection frame swings upwards, the slurry making mechanism jumps away from the ground, and when the connection frame swings downwards, the slurry making mechanism smashes earth and filters slurry through dead weight. The slurry pump sucks the slurry in the filter screen and pours the slurry to external rice seedling plates. By means of the slurry machine, slurry making and pouring of a slurry seedling raising method can be completed in a mechanical mode.

Owner:FUJIAN AGRI & FORESTRY UNIV

Three-dimensional pattern layer manufacturing method for vamp

ActiveCN109203743AHigh tensile strengthImprove crispnessShoemaking devicesOther printing apparatusWater basedMixing ratio

The invention relates to a three-dimensional pattern layer manufacturing method for a vamp. The method is characterized in that a three-dimensional pattern layer is lightweight and subjected to buffering protection while high three-dimensional vision effect is realized. The method comprises the following steps: manufacturing at least one silk-screen board based on a designed pattern; performing silk-screening on the vamp through one of the silk-screen boards, and drying to obtain a water-based resin combining layer; performing silk-screening before an outer layer of the water-based resin combining layer is completely dried, and drying to form a water-based foamed ink layer, wherein the water-based foamed ink layer contains an ultraviolet attenuator; irradiating the surface of the water-based foamed ink layer for 15-20s through UV to obtain a modified foamed ink layer of which the melt strength is gradually reduced from outside to inside; physically processing the surface of the modified foamed ink layer to form a plurality of pre-mixing concave areas, drying; performing silk-screening on the outer surface of the modified foamed ink layer through any one of the silk-screen boards, and drying to obtain a foamed color paste layer, wherein the foamed color paste layer is divided from inside to outside through three layers which are formed by coating with different mixing ratio; andthen pressing through a die, and foaming.

Owner:FUJIAN MEIMINGDA SHOES DEVING

Stable air suction paper shredding fan

The invention creatively discloses a stable air suction paper shredding fan. The stable air suction paper shredding fan comprises a supporting bottom plate, a centrifugal machine shell, an impeller mechanism, a conical air inlet channel, a fixed support, a rotating shaft cooler, a driving shaft, a driving motor, a damping supporting base and two inclined supporting mechanisms. A fixed blade is arranged on a blade mounting flange, a movable blade is arranged on the side, close to the fixed blade, of the impeller mechanism, according to the stable air suction paper shredding fan, the fixed bladeand the movable blade close to the fixed blade are used for achieving shear type waste paper shredding, in the waste paper pneumatic transportation process, cutting up is carried out, two functions can be finished synchronously, the structure is simple, and the waste paper recycling cost is reduced. A damping pressure spring is arranged between the damping supporting base and the supporting bottom plate to achieve elastic supporting, the whole fan has the damping property, and the two inclined supporting mechanisms are used for achieving effective control over the damping shaking range of thesupporting bottom plate.

Owner:江苏贝莱德风机制造有限公司

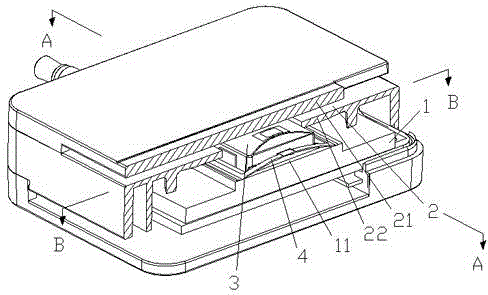

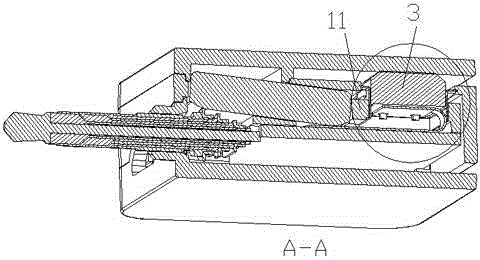

Mini card swiping device

Owner:FUJIAN NEWLAND PAYMENT TECH

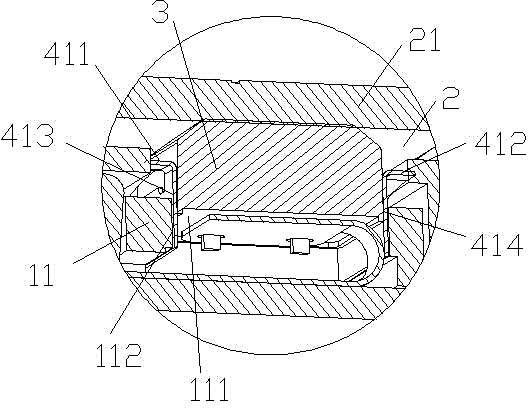

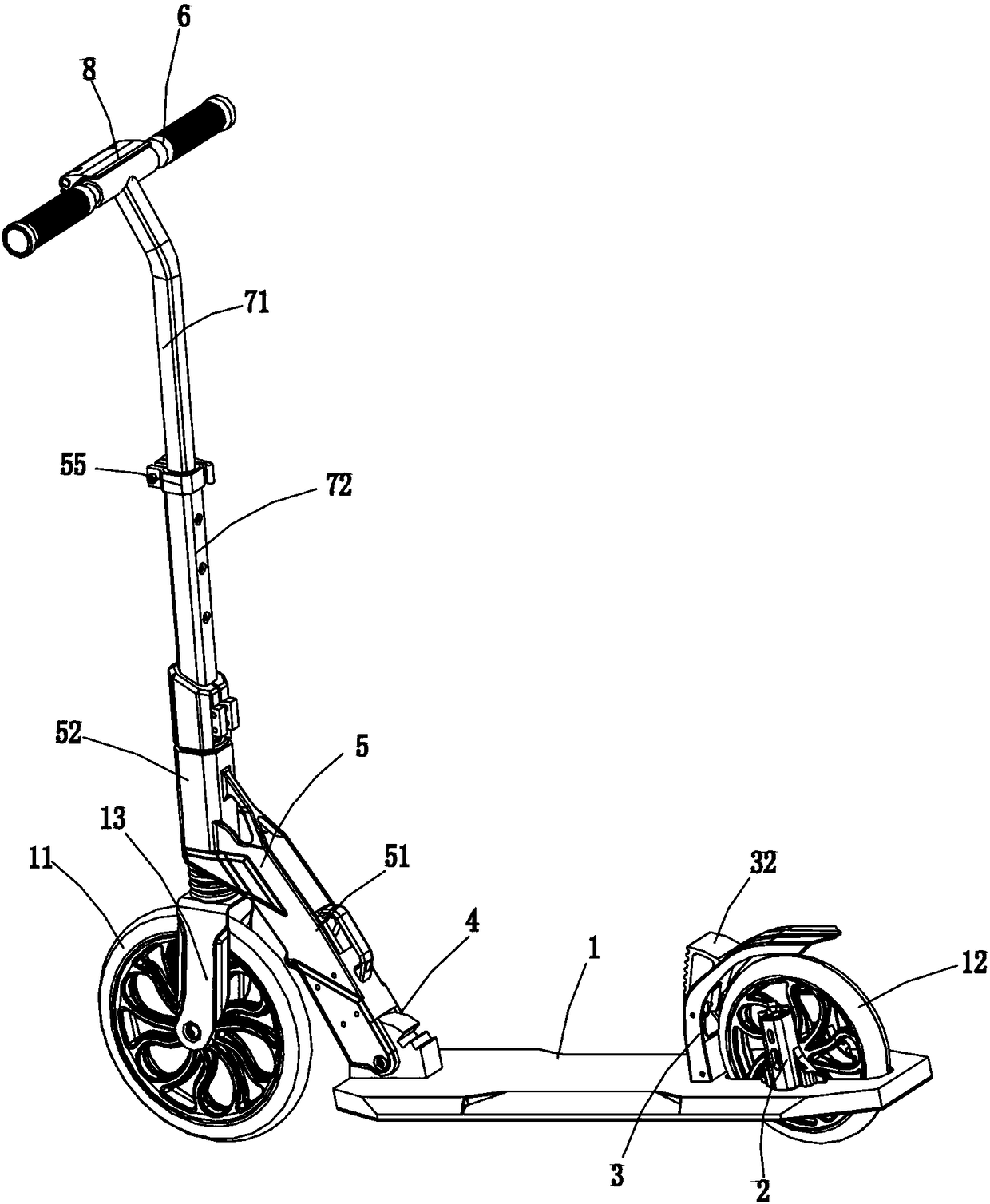

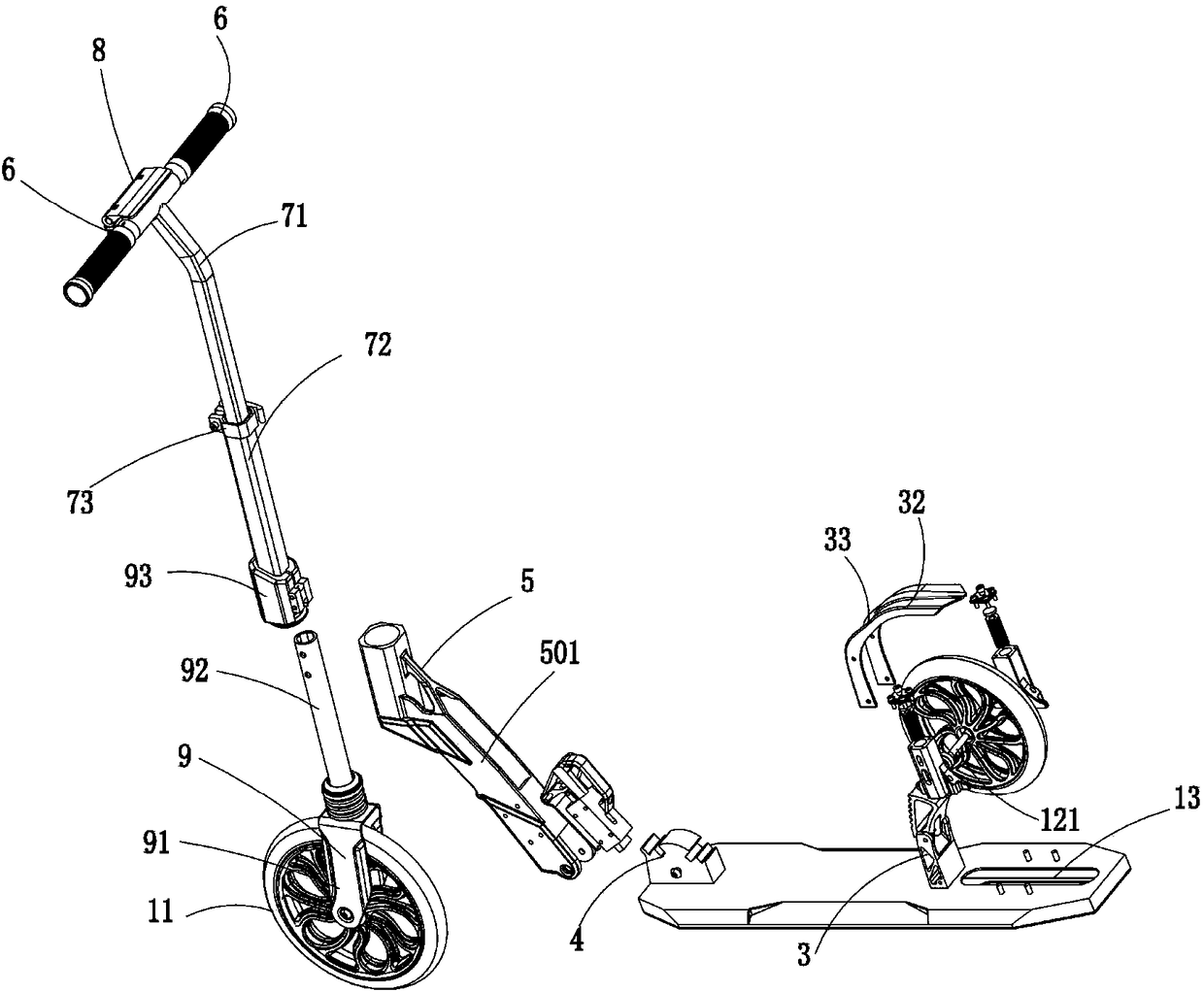

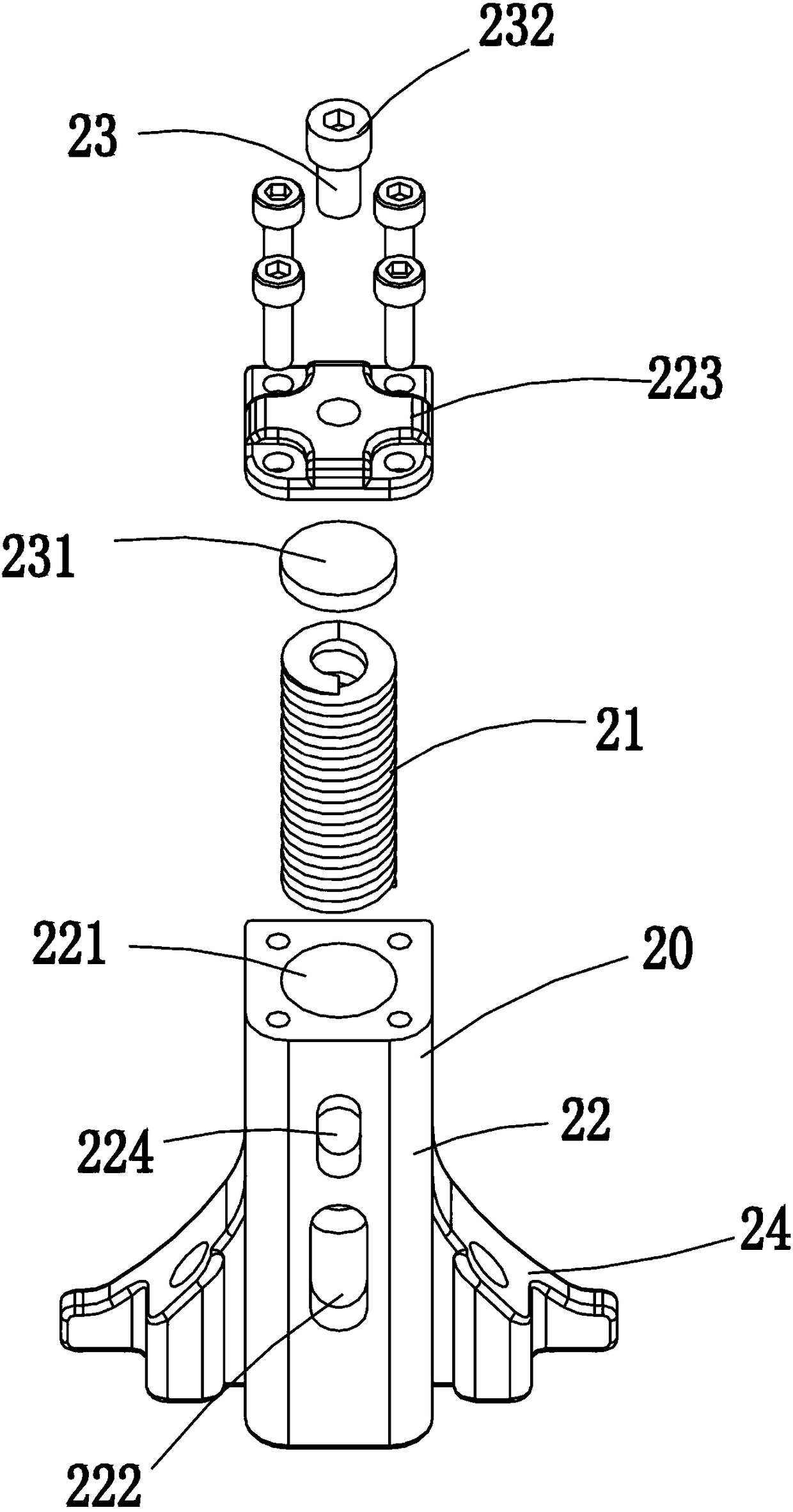

Scooter

PendingCN108313183AImprove the safety of useGood shock absorberAxle suspensionsCycle brakesEngineeringFootplate

Owner:金华星康体育用品有限公司

Stereoscopic vamp ornament with density gradient and preparation method thereof

The invention relates to a stereoscopic vamp ornament with a density gradient and a preparation method thereof. A foamed bottom layer covers and is adhered to the outer surface of a waterborne resin junction layer and a pre-mixing concave region is formed on the outer surface of the foamed bottom layer; a foamed color paste layer covers and is adhered to the outer surface of the foamed bottom layer and the inside of the pre-mixing concave region; the joint of the foamed color paste layer and the foamed bottom layer in the pre-mixing concave region has the density gradient. The preparation method comprises carrying out silk-printing and drying to form the waterborne resin junction layer, carrying out silk-printing and drying to form the foamed bottom layer and processing to form the pre-mixing concave region, carrying out silk-printing and drying to form the foamed color paste layer and enabling part of the foamed color paste layer to permeate into the pre-mixing concave region, and carrying out die-pressing foaming. According to the invention, the foamed color paste layer and the foamed bottom layer are partially bonded in the pre-mixing concave region and the joint has the densitygradient, so that bonding between a waterborne foamed oil layer and the foamed color paste layer is more tight and firm and difficult in causing delamination, and meanwhile, the stress between the foamed color paste layer and the foamed bottom layer in the pre-mixing concave region can be alleviated, and thus, a stereoscopic pattern layer has excellent properties of excellent tensile resistance and folding resistance, impact damping and the like.

Owner:FUJIAN MEIMINGDA SHOES DEVING

Preheating apparatus for limestone in lime production

InactiveCN108975733AWorkaround for features that don't have free movementGood dredging and carrying capacityHeat conductingEngineering

The invention discloses a preheating apparatus for limestone in lime production. The preheating apparatus comprises a feeding opening, a cover plate, an observation hole, a transverse supporting rod,a top cover, a sliding groove, a foundation support, a conveying groove, a supporting column, a limiting supporting rod, a shock-absorption spring, a roller, an installation table, a speed reducer shell, a fastener, a motor, a motor anti-collision shell, a first bevel gear, a second bevel gear, a material inlet, a screw rod, a heat conducting tooth, a connecting member, a motor output shaft and aheater, wherein the bottom of the foundation support is fixedly provided with the supporting column, the bottom of each supporting column is provided with the roller in an embedding manner, the middleparts of the two supporting columns are provide with the transverse supporting rod, and the top of the sliding groove is provided with the top cover in a sliding manner. By adopting the preheating apparatus, the problems that the existing lime production preheating apparatus does not have the freely moving function, the existing preheating apparatus is of an integrated closed structure, when a great amount of pollutants exist inside the preheating apparatus and the preheating apparatus needs to be further cleaned, the complicated cleaning work is needed, and the manpower is wasted can be solved.

Owner:朱治杰

Dumper box body

InactiveCN111409707AGood chemical resistanceEffective protectionLoading-carrying vehicle superstructuresChemical corrosionCarriage

The invention discloses a dumper box body. The dumper box body comprises a carriage body, wherein the carriage body comprises a bottom plate and two side plates, the bottom plate and the two side plates form a groove structure, and macromolecule lining plates are laid on an inner surface of the bottom plate and inner surfaces of the two side plates. The dumper box body is advantaged in that the macromolecule lining plates formed by coating polyurethane in a layered mode is advantaged in that impact is well relieved, friction generated when goods slide out is reduced, the carriage body is effectively protected, moreover, polyurethane has high chemical corrosion resistance, and diversity of goods transported by the carriage can be improved, furthermore, the ceramic powder is mixed in a surface layer of the macromolecule lining plates combined with the bottom plate, so hardness can be effectively improved, and structural strength is improved.

Owner:湖南铁华精斧汽车集团股份有限公司

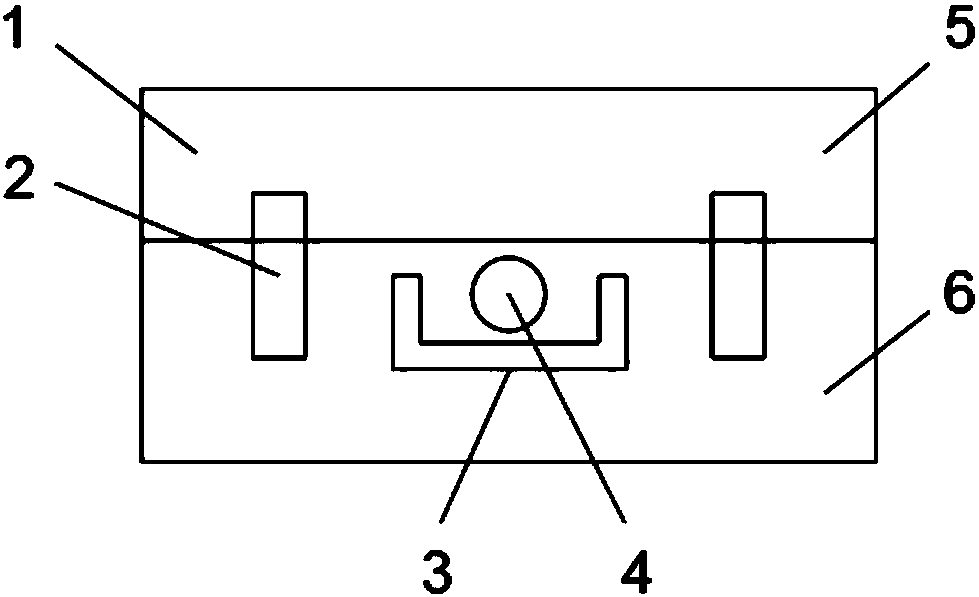

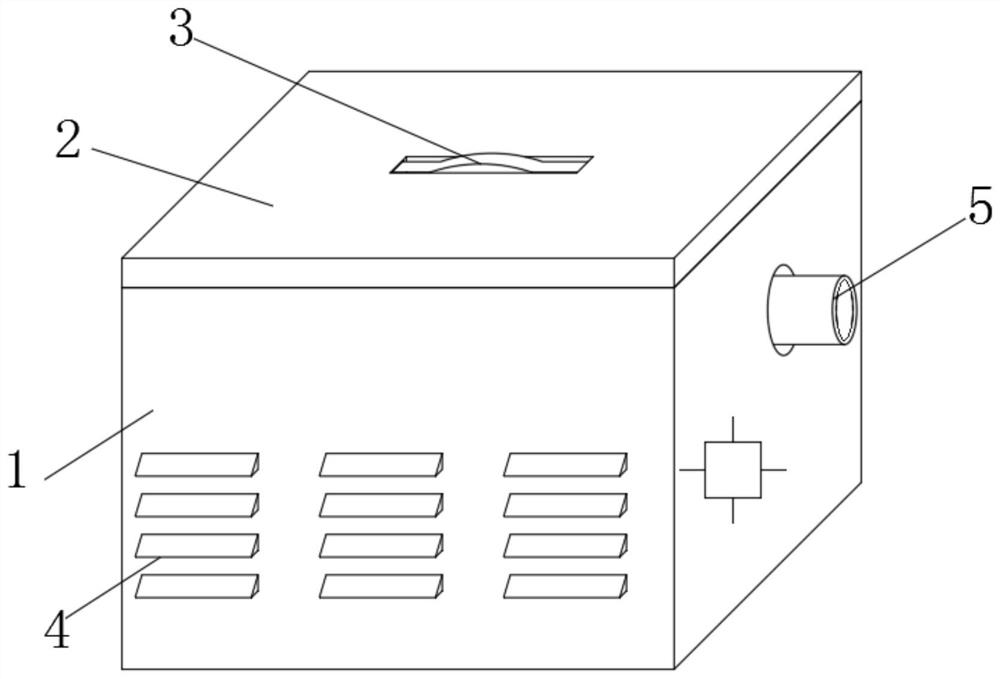

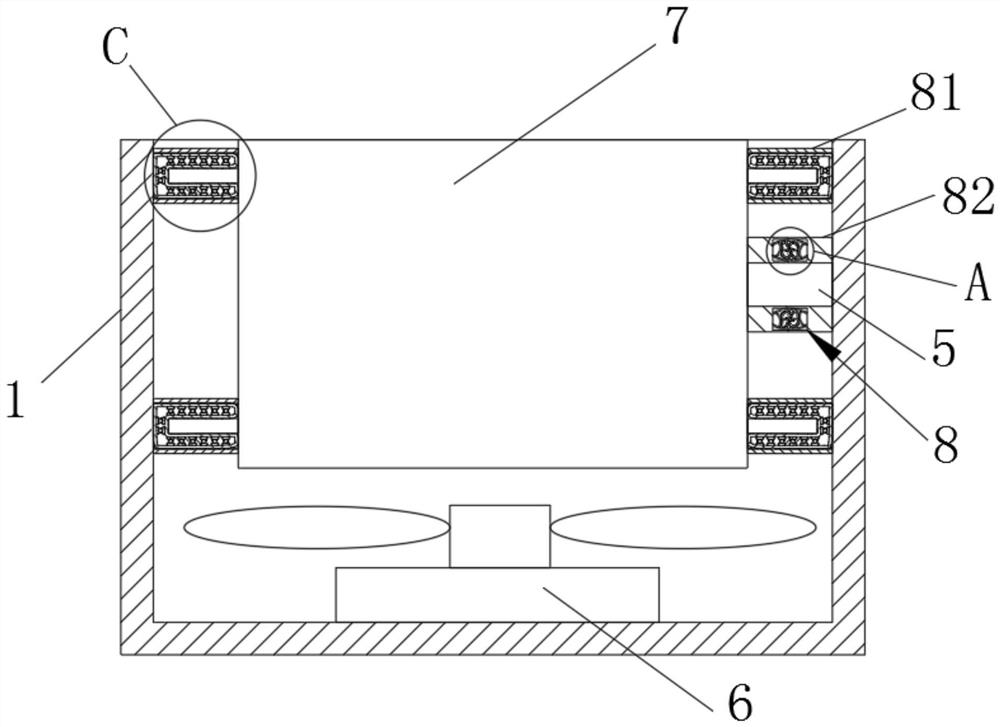

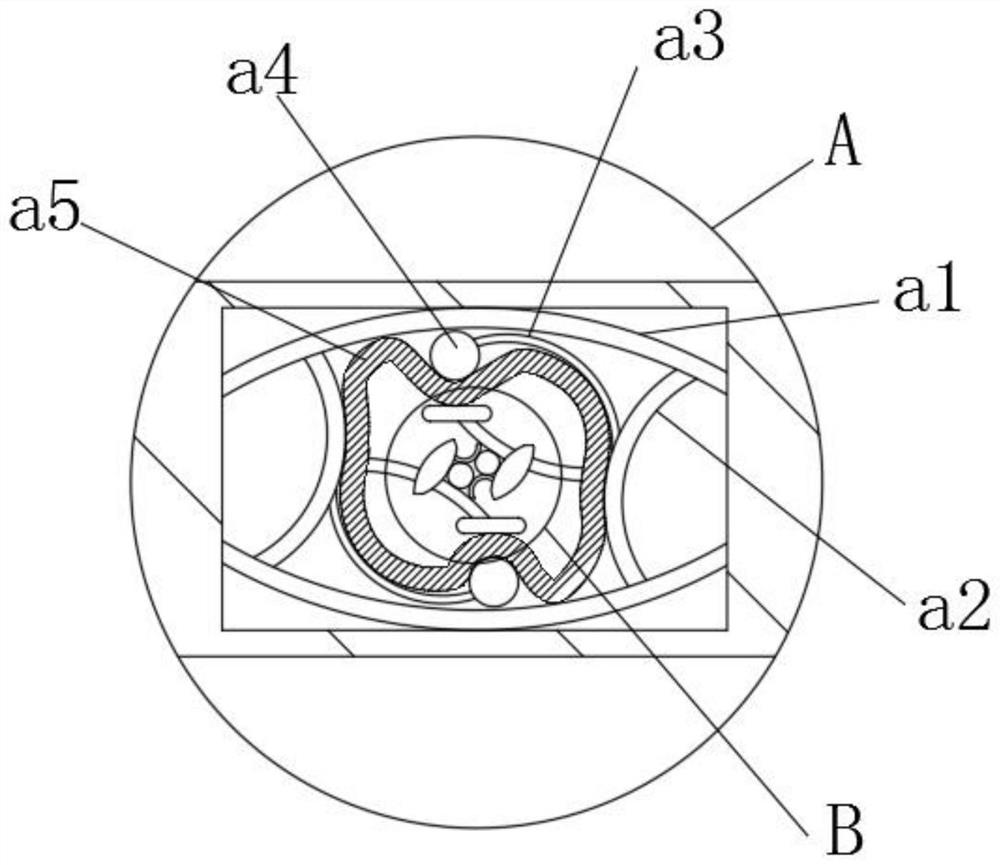

Battery safety protection equipment of new energy automobile

InactiveCN113725545AGood shock absorberConvenience to workSecondary cellsCell component detailsEngineeringStructural engineering

The invention relates to the technical field of protection equipment, and discloses battery safety protection equipment of a new energy automobile. The battery safety protection equipment comprises a protection box, a box cover, a telescopic handle, a ventilation opening, a line pipe, a radiator and a battery box, a connecting mechanism is arranged in the protection box, and the connecting mechanism comprises a connecting support and a line pipe sleeve; an elastic plate, an elastic extrusion plate, an arc-shaped support, a magnetic attraction ball and a first air bag are arranged on the inner wall of the line pipe sleeve, a push rod, an iron plate, an extrusion block, an extrusion support and a first elastic ball are arranged in the first air bag, and the connecting support is composed of a connecting base, a second air bag and a connecting rod. The battery box is stably arranged in the protection box through the connecting mechanism, so that heat dissipation and shock-proof protection is performed on the battery box, and the battery box is suspended in the protection box through the connecting mechanism, so that the shock-proof and heat dissipation work effects are better, and the equipment has good protection performance.

Owner:孙远潇

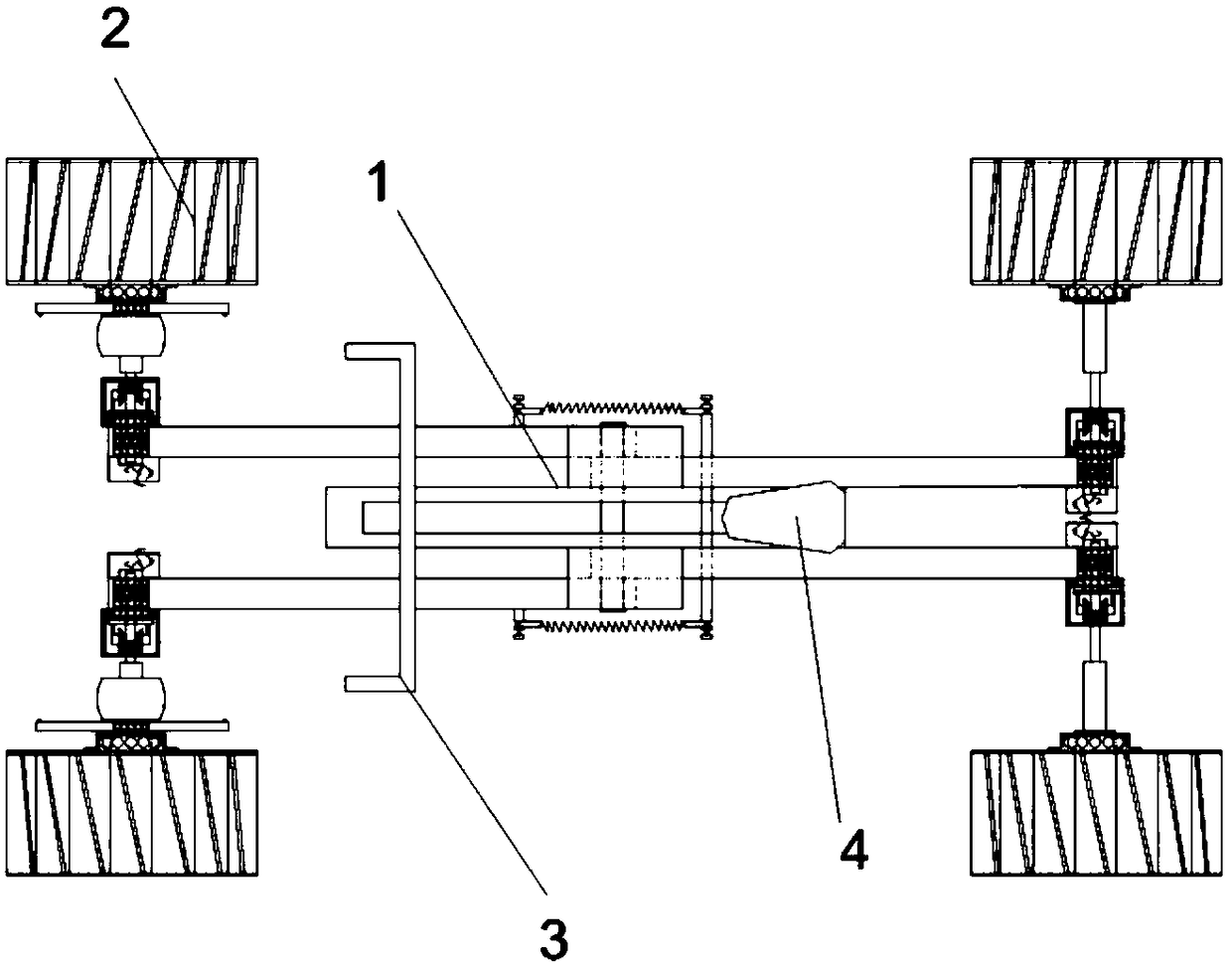

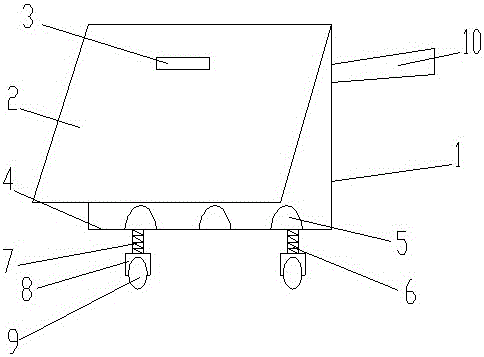

Special vibration-proof trolley for bricks and tiles

InactiveCN105882710AGood shock absorberAvoid bump damageCastorsHand carts with multiple axesEngineeringBrick

The invention discloses a special vibration-proof trolley for bricks and tiles. The special vibration-proof trolley for the bricks and tiles comprises a trolley main body, wherein surrounding plates are arranged outside the trolley main body, the surrounding plate at one end of the trolley main body is a turnover cover plate, a pull handle is arranged on the turnover cover plate, a base is arranged at the lower end of the trolley main body, multiple tile stacking blocks are arranged on the base, and uniformly arranged with one another at intervals, multiple roller devices are arranged at the lower end of the base, vibration-proof springs are arranged at the upper ends of the roller devices, roller frames are fixedly connected at the lower ends of the vibration-proof springs, roller bodies are mounted on the roller frames, and a push rod is further arranged at one end of the trolley main body. According to the invention, the special vibration-proof trolley for the bricks and tiles disclosed by the invention can be specially used for stacking the bricks and tiles, and vibration proofing can be well performed to avoid bumpiness and damage in the transportation process of the bricks and tiles.

Owner:无锡瑾宸表面处理有限公司

A drum-type cable collection device for communication engineering

ActiveCN109399369BAvoid reverse rotationGood shock absorberFilament handlingStructural engineeringControl theory

The invention relates to communication engineering equipment, in particular to a roller type communication engineering cable collecting device. The cable collecting device comprises a cable winding mechanism, a damping mechanism and a travel mechanism. An anti-slip mechanism arranged on the device prevents a roller from reversely rotating when cables are sorted; a lifting mechanism arranged on thedevice can be adjusted according to the quantity of the cables; in the process of transportation and cable collection, the device is provided with the good damping mechanism; the device is further provided with the telescopic travel mechanism to facilitate movement of the device, and stable placement of the device is also facilitated. The cable winding mechanism is connected with the damping mechanism through welding and the damping mechanism is connected with the travel mechanism through welding.

Owner:HEBEI VOCATIONAL & TECHN COLLEGE OF BUILDING MATERIALS

Three-dimensional pattern layer manufacturing method for shoe upper

ActiveCN109203743BHigh tensile strengthImprove crispnessShoemaking devicesOther printing apparatusScreen printingUltraviolet lights

The invention relates to a method for manufacturing a three-dimensional pattern layer for shoe uppers, which enables the three-dimensional pattern layer to have the functions of light weight and cushioning protection in addition to a strong three-dimensional visual effect. Steps: Make at least one screen printing board according to the design pattern; use one of the screen printing boards to screen print on the shoe surface and dry to form a water-based resin bonding layer; then silk screen and dry before the outer layer of the water-based resin bonding layer is completely dried to form Water-based foaming ink layer, the water-based foaming ink layer contains an ultraviolet light attenuator, and the surface of the water-based foaming ink layer is irradiated with ultraviolet light for 15 to 20 seconds to obtain a modified foam whose melt strength gradually decreases from the outside to the inside Ink layer; physical processing on the surface of the modified foaming ink layer to form a number of premixed concave areas, drying; then use any of the screen printing plates to screen print on the outer surface of the modified foaming ink layer and dry to form a foaming color paste layer , and the foaming color paste layer is set from the inside and the outside to form three layers of distribution and layering formed by scraping with three different proportions; molded foaming.

Owner:FUJIAN MEIMINGDA SHOES DEVING

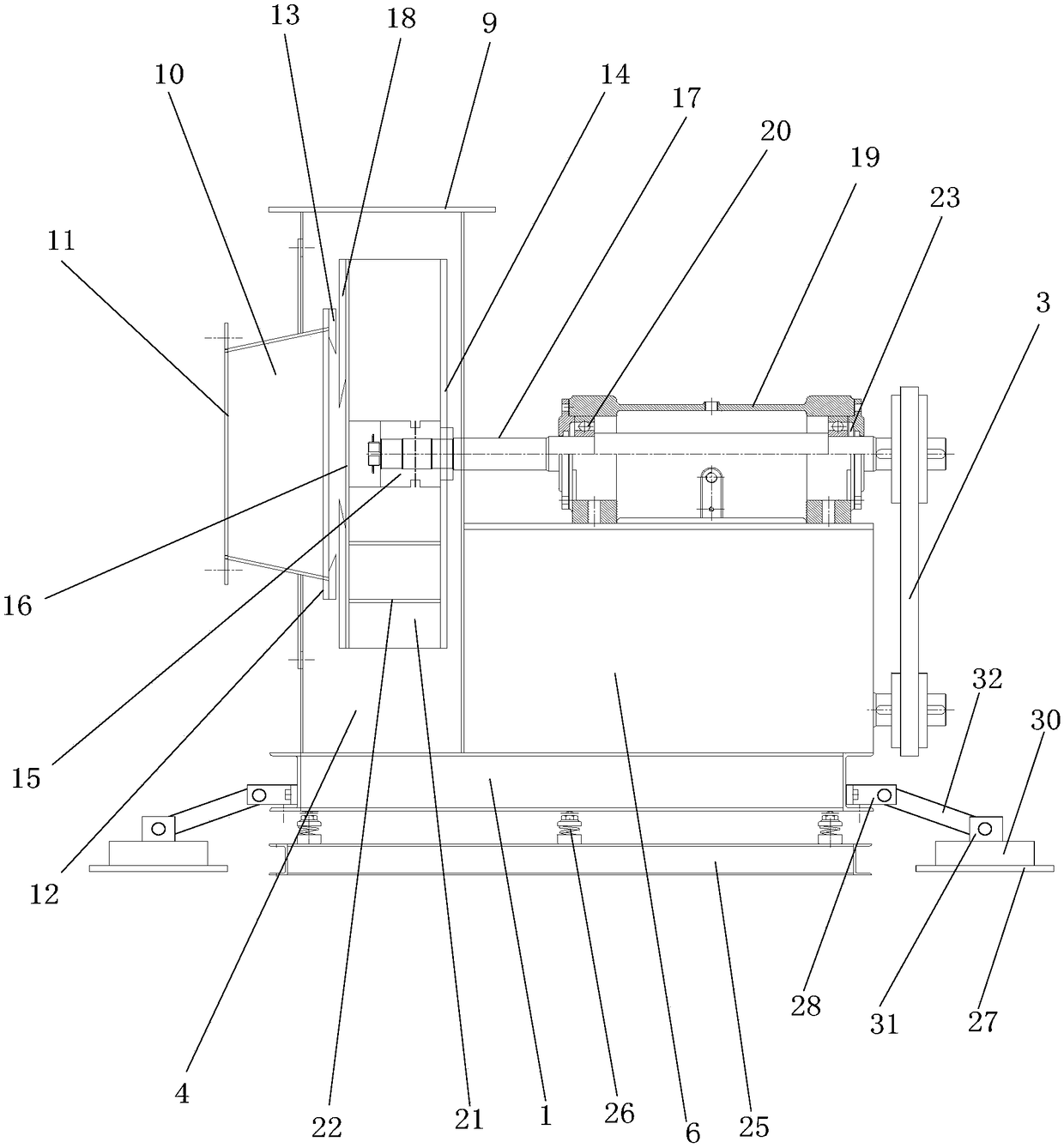

A high-efficiency ore crushing device with shock-absorbing function

ActiveCN105797808BWith shock absorption functionSimple structureGrain treatmentsEngineeringMechanical engineering

A high-efficiency ore crushing device with a shock absorption function comprises a crushing device body, a baffle device, a shock absorption device, rolling wheel devices, a support device, a supporting plate device, a recovery device and a grinding device. The crushing device comprises a first frame, a feed hopper, a first rolling wheel, a transfer block, a second rolling wheel, crushing teeth and first diagonal rods. The baffle device comprises a first cylinder, a first push rod, a first push plate, first springs, a first baffle, a first support, a second spring and a second baffle. The shock absorption device comprises a first transverse plate, first vertical rods, a second transverse plate, second supports, third springs, a first bent rod, fourth springs, fifth springs, sixth springs and seventh springs. Each rolling wheel device comprises a second bent rod and a second cross rod. The support device comprises a third support, a second diagonal rod, a first bent plate, a third cross rod, a fourth support, a third diagonal rod, a fifth support and a second vertical rod. The high-efficiency ore crushing device can crush ores rapidly and effectively and is high in crushing efficiency.

Owner:锡林郭勒盟山金阿尔哈达矿业有限公司

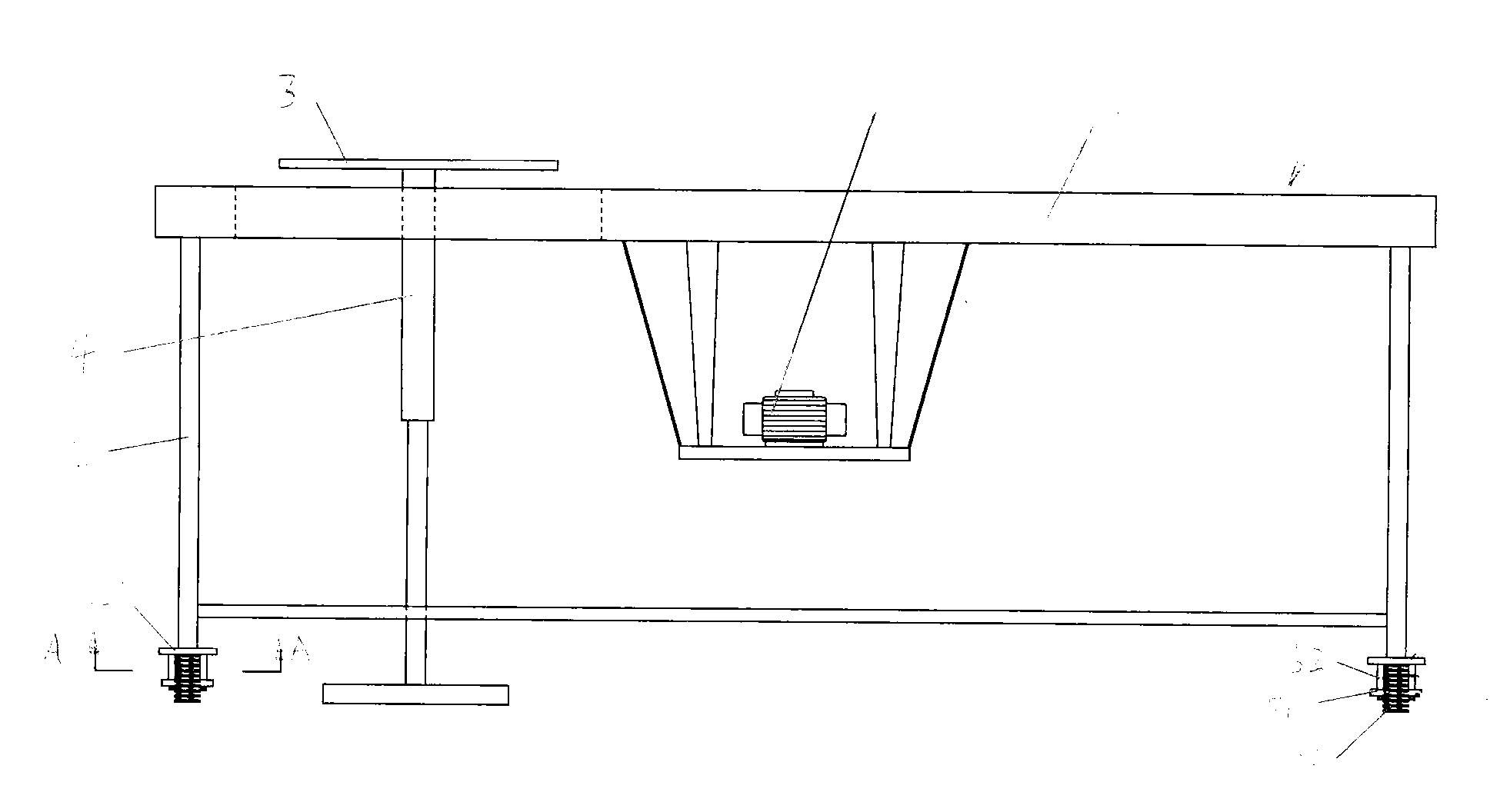

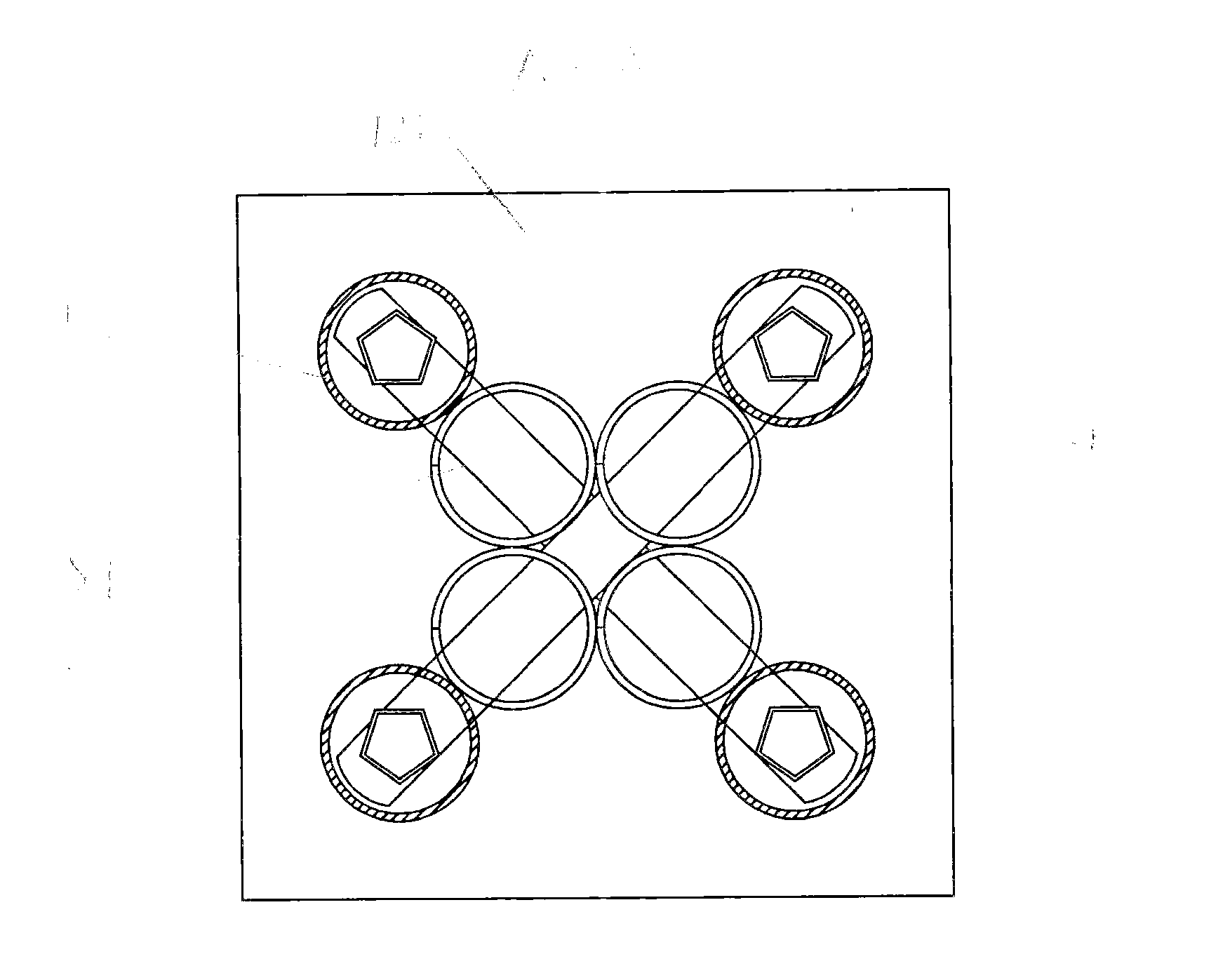

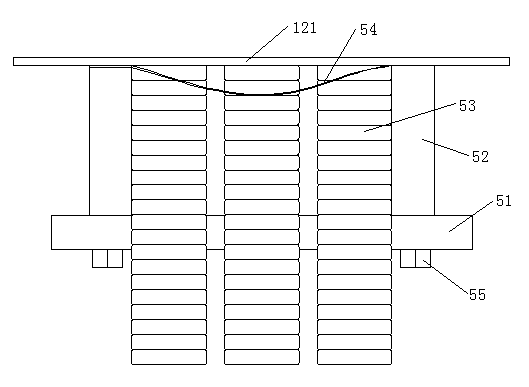

Vibration bed

The invention relates to a vibration bed, which comprises a bed body comprising a bed plate and bed feet, wherein a vibration generator is arranged inside the bed body, a head supporting plate is arranged on a bed head position of the bed plate, and is connected with a support directly penetrating through the bed plate and standing on the ground, and the bottom of the bed foot is provided with a pressure spring type vibration prevention structure. According to the present invention, with arrangement of the pressure spring type vibration prevention structure on the bottom of the bed foot, when the vibration generator works to drive the bed body to vibrate, the bottom of the bed foot does not contact the ground, such that vibration noise generated by the whole bed body is subjected to sound deadening through the pressed pressure spring; and the vibration bed has characteristics of simple and reasonable structure, good vibration prevention effect and good sound deadening effect, such that vibration massage and vibration noise reduction can be concurrently ensured, and effects of fatigue elimination through vibration and quiet rest are really provided.

Owner:陈建毅

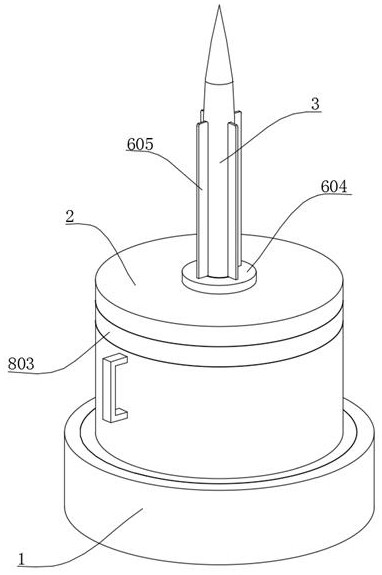

A lightning protection system for a wind power generating set

The invention discloses a lightning protection system for a wind power generating set, comprising a base and a buffer device, the base is threadedly connected with a protective cover, the base is penetrating and slidingly connected with a lightning receptor, and the lightning receptor penetrates the top wall of the protective cover , the buffer device is connected with the base and the air-termination device, and the air-termination device is located in the protective cover and is symmetrically connected with two follower plates, and the lower surfaces of the two follower plates are fixedly connected with vertical plates , the vertical plate is rotatably connected with a connecting rod, and the upper surface of the base is fixedly connected with two fixed plates. The advantage is that: compared with the prior art, the lightning protection system of the present invention has a better buffering effect, can better resist larger vibrations, and at the same time can scrape off the sundries on the surface of the lightning receptor through vibration to keep the lightning protection The performance of the flasher, and the scraper can be cleaned while scraping to maintain a good scraping effect, and at the same time can indicate the internal operation of the system.

Owner:深圳普泰电气有限公司

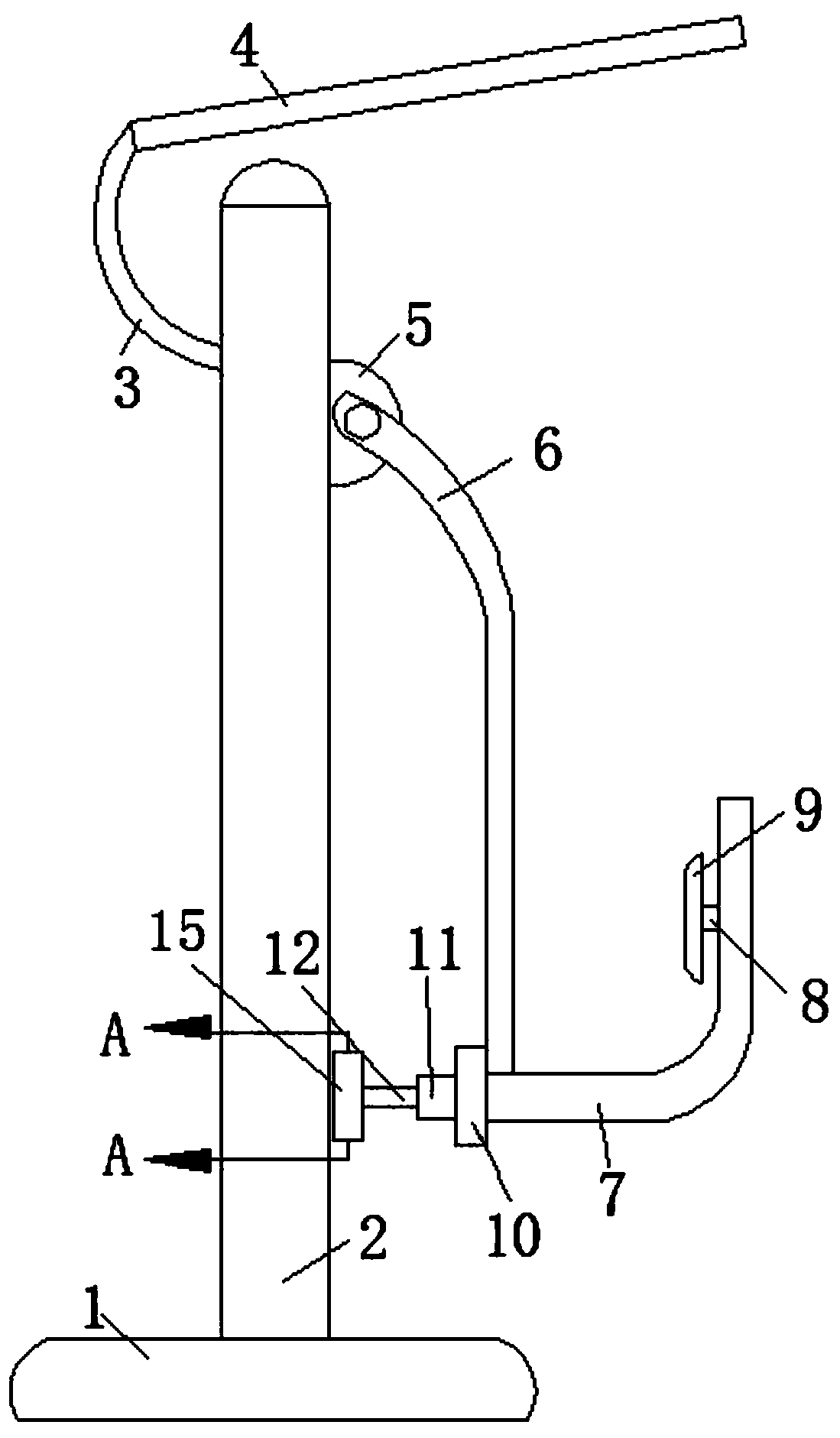

A kind of sports equipment with cushioning device

ActiveCN108992903BImprove buffering effectGood shock absorberSport apparatusGear wheelSports equipment

The invention discloses a sports apparatus with a buffering device. The buffering device comprises a buffering frame; the inner side wall of the buffering frame is slidably connected with a bufferingplate; one end of the buffering plate is fixedly connected with a connecting rod, and the other end of the buffering plate is fixedly connected with a first buffering rod; a magnet ball is fixed to one end of the first buffering rod; a magnet block matched with the magnet ball is arranged in the buffering frame; and therefore, a buffering effect can be realized. The movement of the buffering platedrives gears to rotate through second buffering rods and spur racks, so that an elastic rope is wound around rotating rods, and therefore, a buffering effect can be achieved on the basis of the features of the elastic rope; and the second buffering rods move so as to contact sliding blocks and push the sliding blocks to move, and therefore, a buffering effect can be achieved under the action of second airbags. Thus, with the plurality of buffering measures adopted, the apparatus can be protected, and the effect of an impact force can be decreased.

Owner:扬州吉威体育用品有限公司

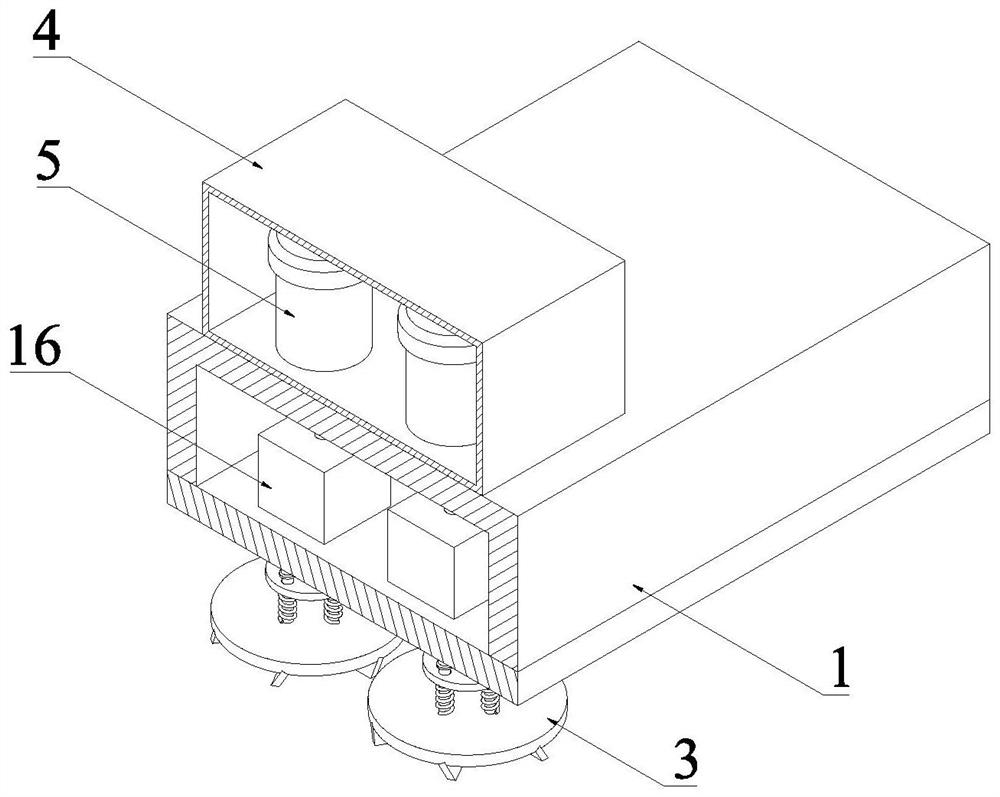

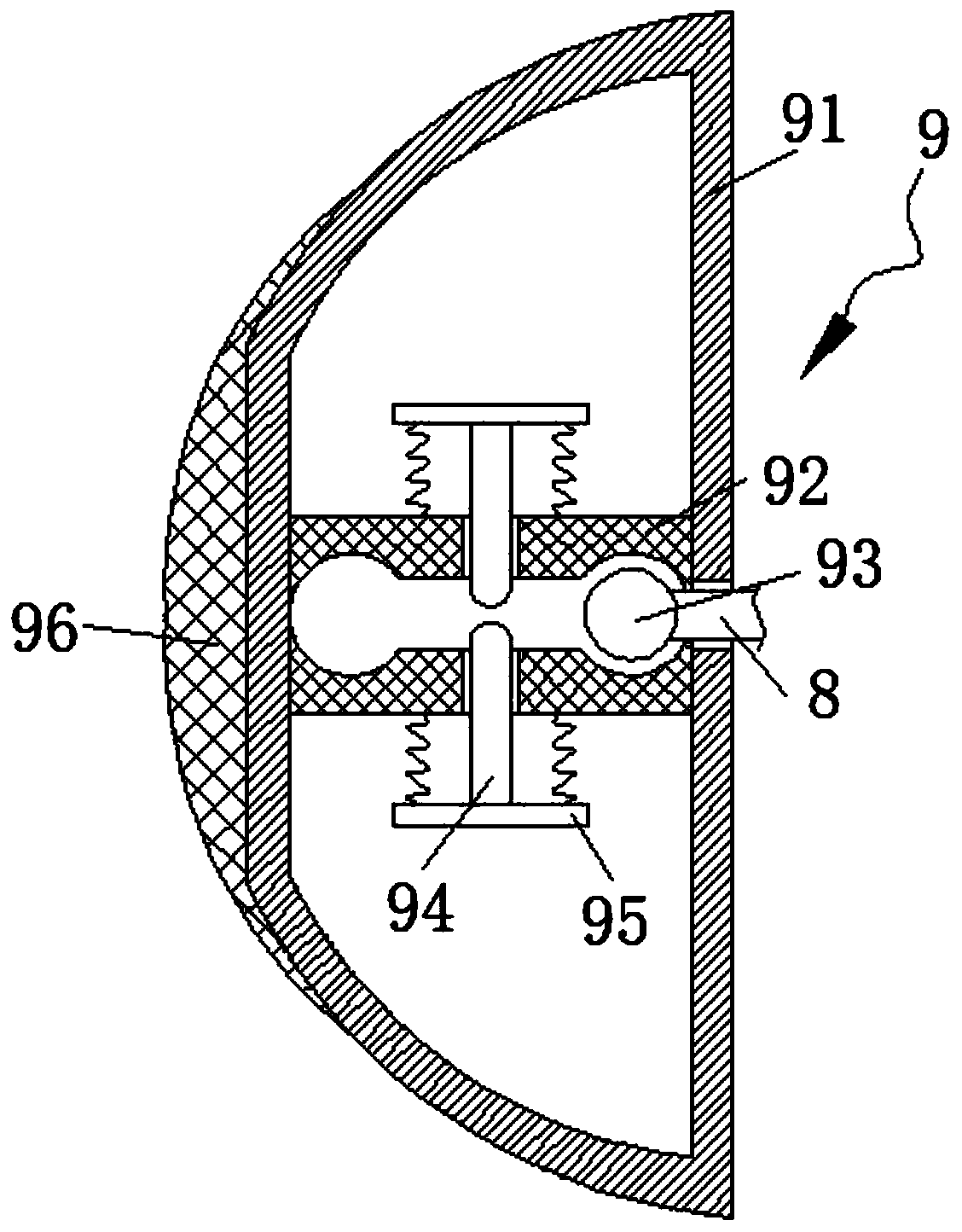

Shock absorption device for air compressing pump

InactiveCN103994052AGood shock absorberExtended service lifePositive displacement pump componentsPositive-displacement liquid enginesEngineering

The invention relates to the technical field of shock absorption devices, in particular to a shock absorption device for an air compressing pump. The shock absorption device comprises a gasket installed on a supporting leg of the air compressing pump. Step-shaped annular grooves formed in a turning mode are formed in the inner wall of the gasket, and the diameter dimensions of the annular grooves are successively increased from top to bottom. An upper spacer and a lower spacer are arranged on the upper end surface and the lower end surface of the gasket respectively. The upper spacer is provided with an installation hole, and the lower spacer is provided with a shock absorption hole. The shock absorption device for the air compressing pump can well absorb shock of the air compressing pump, protect a motor and prolong the service life of the air compressing pump.

Owner:徐亚珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com