Preheating apparatus for limestone in lime production

A preheating device and limestone technology, applied in the field of limestone preheating device, can solve the problems of labor-intensive, no free movement, complicated cleaning actions, etc., and achieve the effect of reducing labor intensity, weakening compressive strength, and reducing manual handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

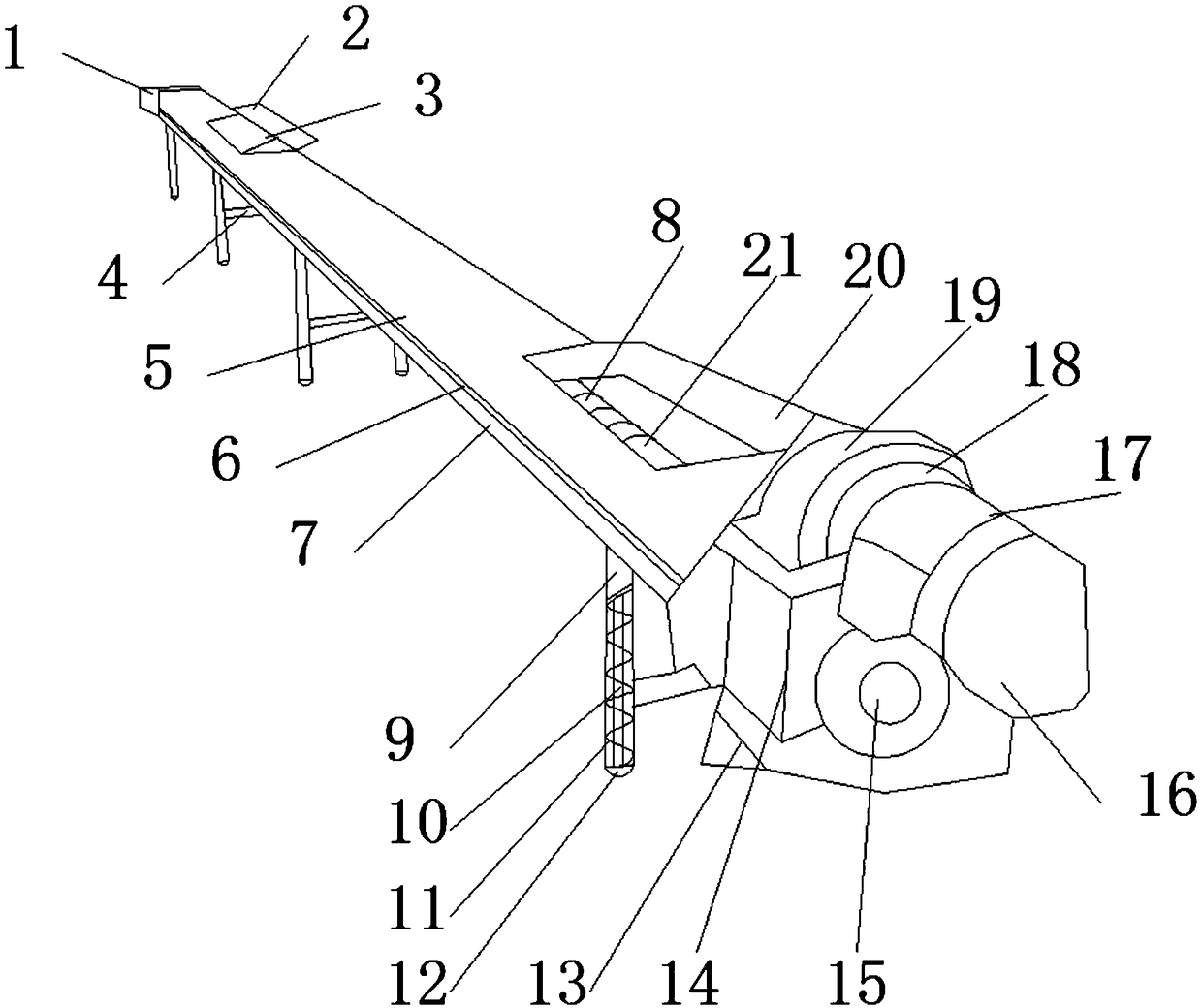

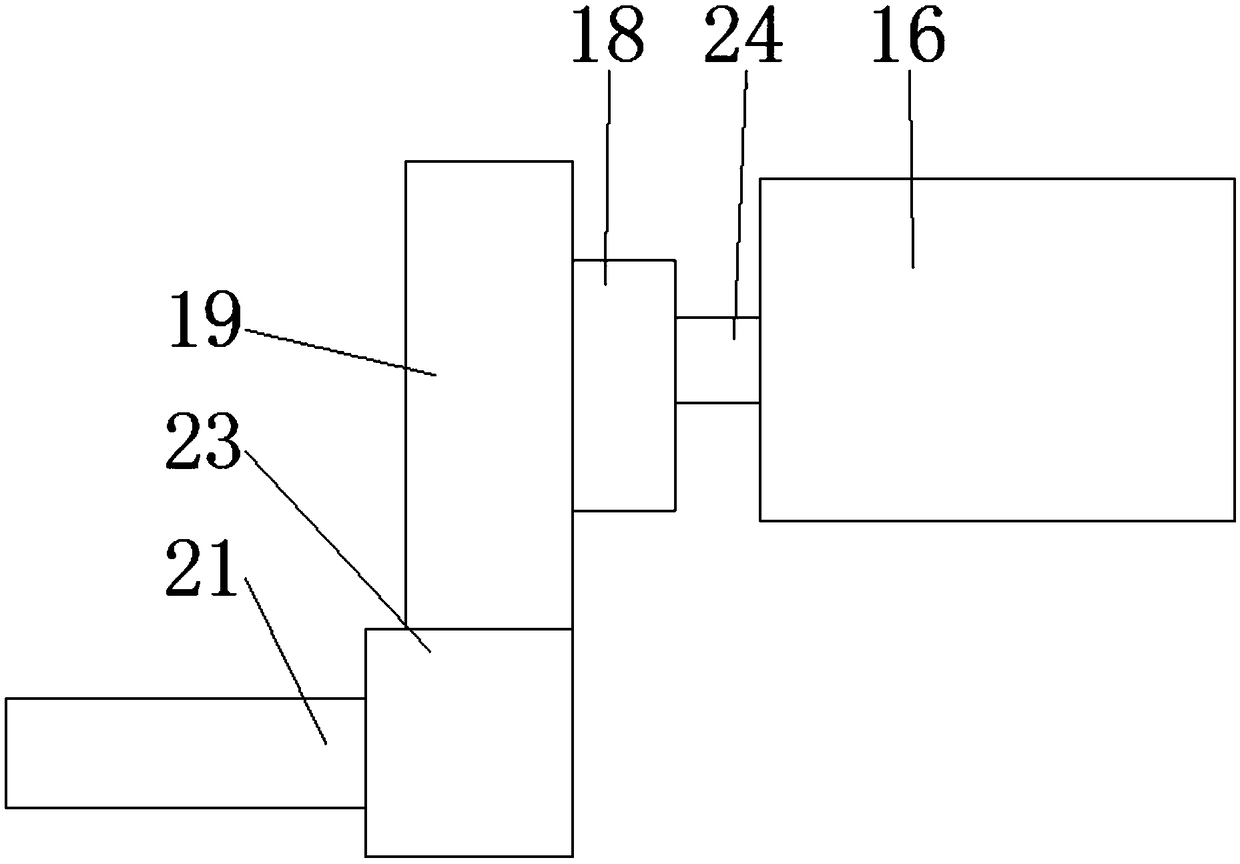

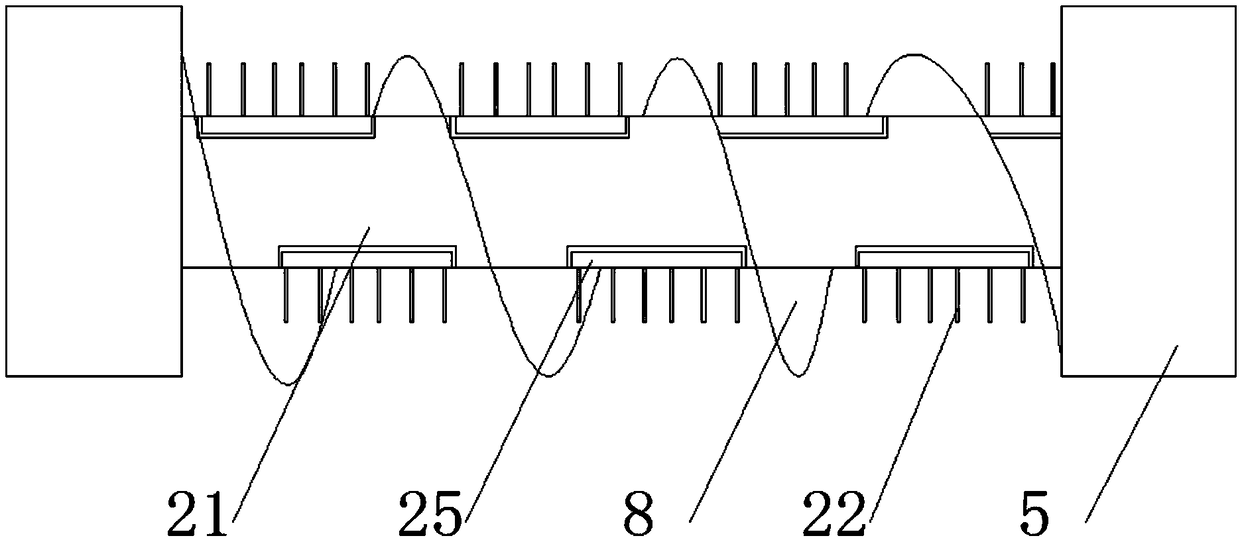

[0021] see Figure 1-3 , the present embodiment provides a limestone preheating device in lime production, including a feeding port 1, a cover plate 2, an observation hole 3, a cross rod 4, a top cover 5, a chute 6, a base 7, and a feeding chute 8. Support column 9, limit pole 10, shockproof spring 11, roller 12, mounting table 13, reducer housing 14, fixing piece 15, motor 16, motor anti-collision shell 17, first bevel gear 18, second Bevel gear 19, feed inlet 20, screw rod 21, heat conduction gear 22, coupling 23, motor output shaft 24 and heater 25, the bottom of base 7 is fixedly installed with support column 9, and the bottom of support column 9 is embedded and installed There are rollers 12, the rollers 12 are provided with a number that matches the support columns 9, and the top of the rollers 12 is equipped with a limit platform, and the inside of the limit platform is equipped with a limit buckle, and the middle of the two support columns 9 is provided with a horizont...

Embodiment 2

[0024] see Figure 1-3 , on the basis of Embodiment 1, a further improvement has been made: no less than six heat conduction teeth 22 are provided, and the fineness of stirring is improved, and the heat conduction teeth 22 are a member of an alloy steel material, which has good thermal conductivity, and at the same time avoids the heat conduction teeth 22 Due to the high hardness of limestone, it is very easy to cause damage to the heat conduction teeth 22. The groove wall of the feeding trough 8 is used in conjunction with the top cover 5 and the base 7, and the gap is small. It is only used to complete the rotation task and prevent incoming materials. drop problem.

[0025] Wherein, the heater 25 is embedded and installed in the inside of the installation block, and the installation is tight. The side of the installation block in contact with the heater 25 is provided with a heat insulation layer for heat insulation protection, preventing internal heat from escaping and caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com