Stable air suction paper shredding fan

A stable and shredding technology, which is applied in grain processing and other fields, can solve the problems of high cost and complexity of the recycling system, and achieve the effect of ensuring stability, simple structure and reducing the degree of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

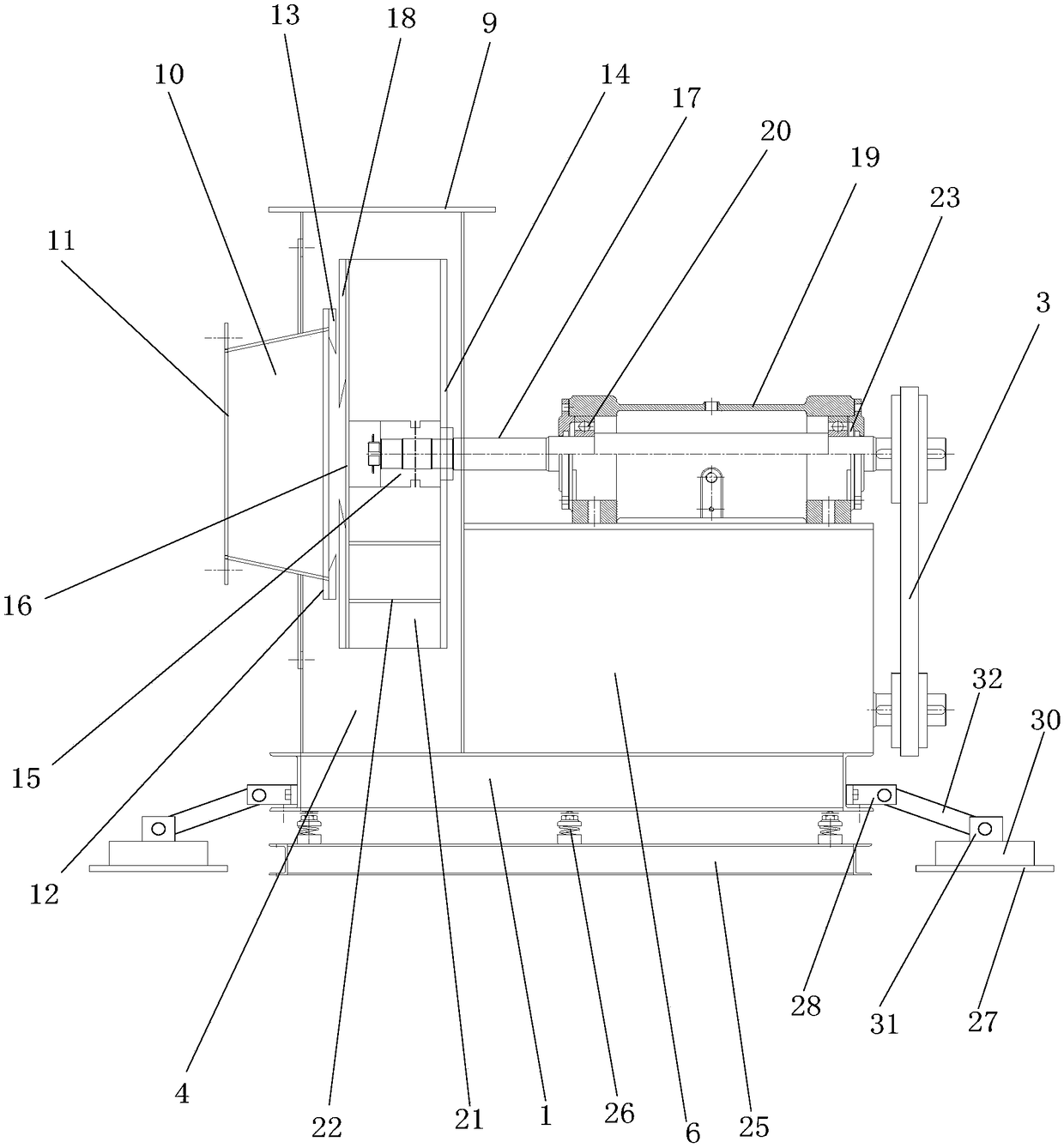

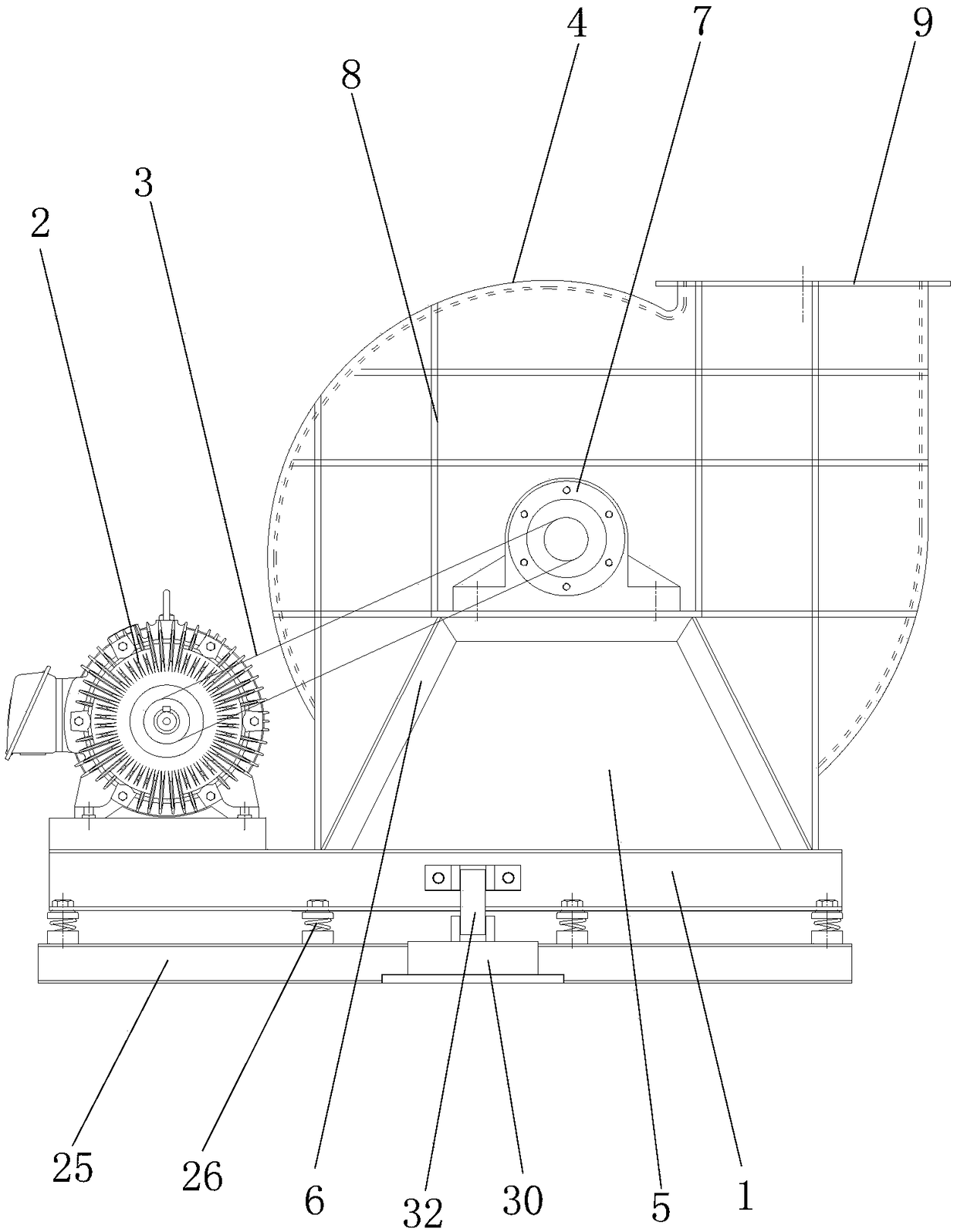

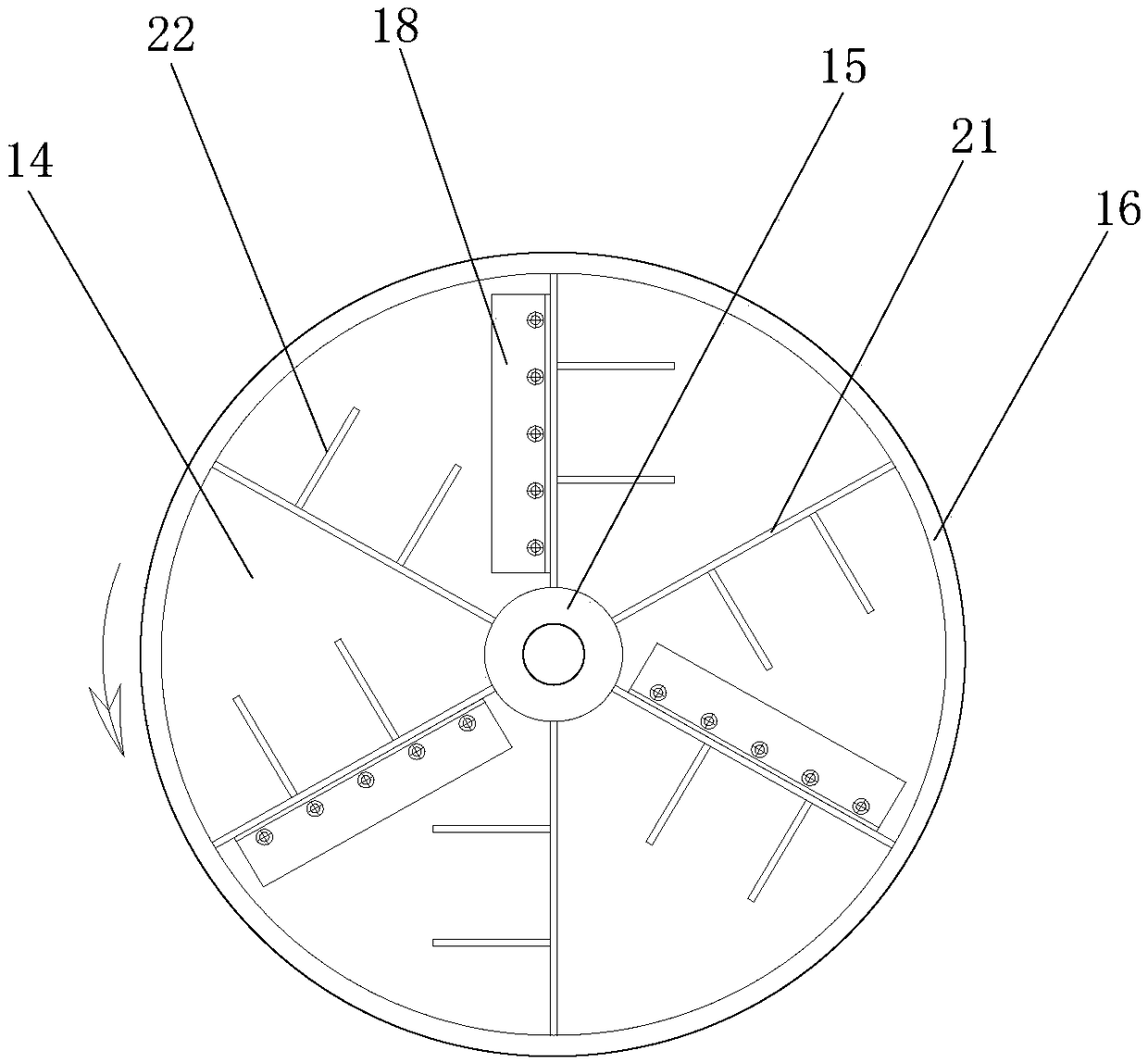

[0020] Such as Figure 1-5 As shown, the stable suction shredding fan disclosed by the present invention includes: a support base plate 1, a centrifuge casing 4, an impeller mechanism, a conical air inlet channel 10, a fixed bracket 6, a shaft cooler 7, a drive shaft 17, and a drive shaft. Motor 2, shock-absorbing support base 25 and two diagonal bracing mechanisms; centrifuge case 4 is installed vertically on the support base plate 1; fixed bracket 6 is installed on the support base plate 1 and is located on the right side of the centrifuge case 4; the rotating shaft is cooled The device 7 is fixedly installed on the fixed bracket 6; the middle part of the drive shaft 17 is rotatably installed on the shaft cooler 7; an air inlet is provided on the left side of the centrifuge casing 4, and the tapered air inlet channel 10 is fixedly installed on the air inlet. ; The top of the centrifuge casing 4 is provided with an air outlet 9; the left inlet of the conical air inlet passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com