Stocking system and method

A technology of goods and cargo lanes, which is applied in the field of stocking system, can solve the problems of poor anti-fault and anti-interference ability of the stocking system, and affect the normal sorting and transportation of sorting lines, so as to improve the anti-fault and anti-interference ability and reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the solutions of the present invention will be further described in detail below with reference to the accompanying drawings and examples.

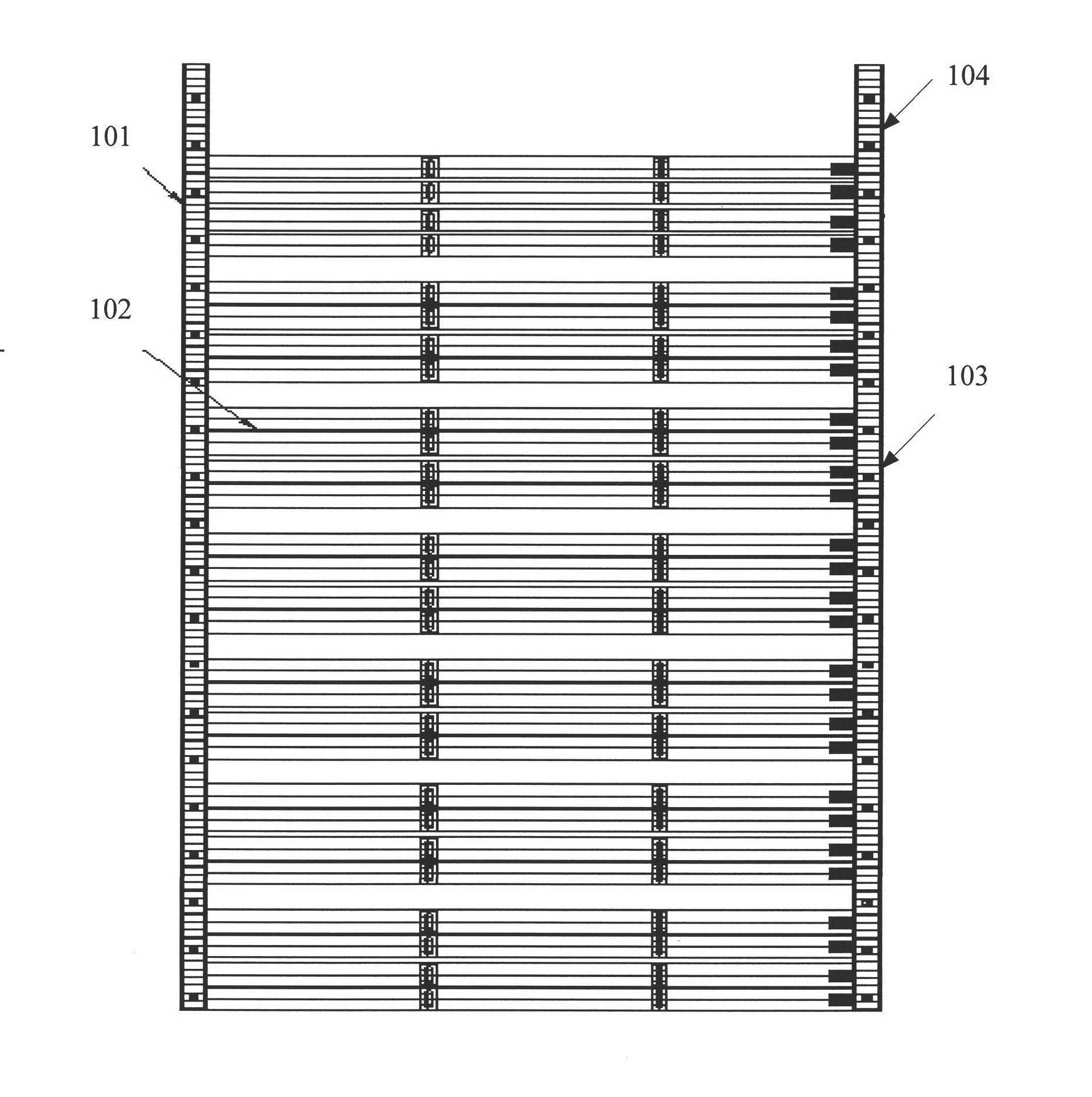

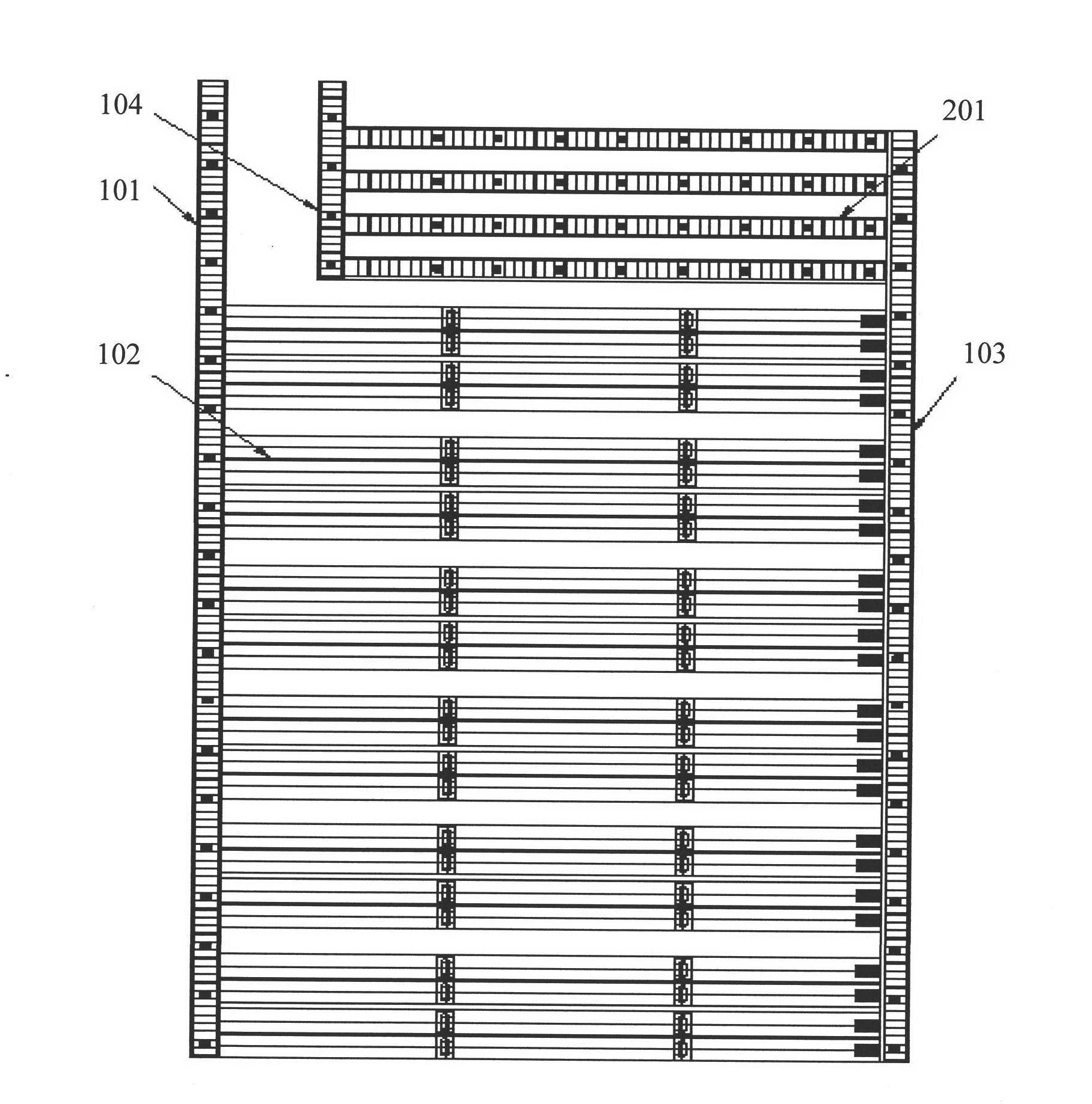

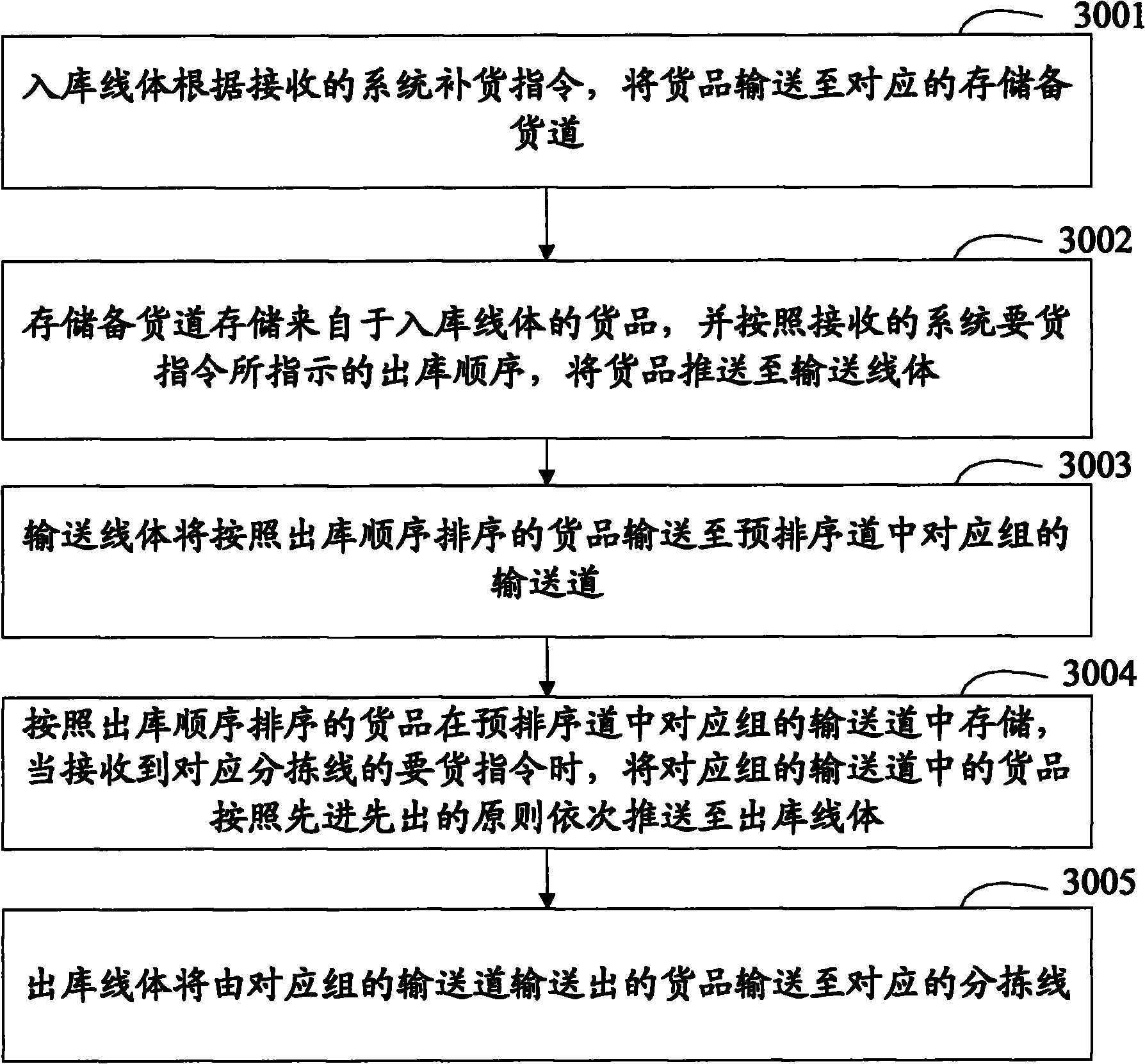

[0046] The core idea of the present invention is: a pre-sorting lane is set between the conveying line body and the outbound line body, and the pre-sorting lane consists of one or more sets of conveying lanes connected in parallel between the conveying line body and the outbound line body Composition, each sorting line corresponds to a group of conveying lanes in the pre-sorting lane, and each group of conveying lanes buffers the sorted goods. When receiving the sorting line request order from the corresponding sorting line, it will The sorted goods are transported to the corresponding sorting line through the outbound line. It can be seen that since the sorted goods have been cached in the pre-sorting lane, the impact of abnormal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com