Anti-collision cellular side wall plate

A side wall, anti-collision technology, applied in the field of auto parts, can solve the problems of insufficient safety, flammability, personal injury to drivers, etc., to achieve the effect of buffering vibration and avoiding burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

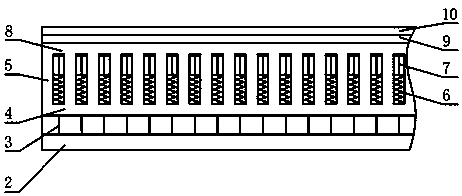

[0010] The present invention is an anti-collision honeycomb side panel, comprising: an automobile side panel 1, an alloy stainless steel panel 2, an outer honeycomb core 3, an outer rubber layer 4, a rubber fence layer 5, a rubber sponge spring layer 6, and an inner honeycomb core 7 , inner rubber layer 8, fluorocarbon fireproof paint layer 9, fabric layer 10, alloy stainless steel panel 2, outer honeycomb core 3, outer rubber layer 4, rubber sponge spring layer 6, inner honeycomb core 7, inner rubber layer 8, The fluorocarbon fireproof paint layer 9 and the fabric layer 10 are sequentially connected from outside to inside. The honeycomb core 7 of the inner layer penetrates the honeycomb layer 5 of the rubber barrier. The honeycomb core 7 of the inner layer does not move with the movement of the barrier layer 5 of the rubber. The outer rubber layer 4 and the inner A rubber sponge spring layer 6 is installed in the middle of the layer honeycomb core 7, and the rubber sponge spri...

Embodiment 2

[0012] When the car side panel 1 is hit, the impact object hits the alloy stainless steel panel 2, the alloy stainless steel panel 2 breaks down a part of the force and deforms, the outer rubber layer 4 compresses the rubber sponge spring layer 6, and the rubber barrier layer 5 moves inward, driving The inner rubber layer 8, the fluorocarbon fireproof paint layer 9, and the fabric layer 10 move inward, because the inner rubber layer 8, the fluorocarbon fireproof paint layer 9, and the fabric layer 10 are all soft materials, and they will not cause harm when they hit the human body. When the protective effect is reached, the rubber sponge spring layer 6 rebounds, driving the outer rubber layer 4 and the rubber barrier layer 5 to return to their original positions, and simultaneously drives the inner rubber layer 8, the fluorocarbon fireproof paint layer 9, and the fabric layer 10 to return to their original positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com