Dumper box body

A technology for dump trucks and boxes, which is applied to vehicle components, upper structures of trucks, upper structures, etc. It can solve problems such as easy damage, large friction and impact of the compartment, and achieve improved structural strength, good impact reduction, and The effect of high chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

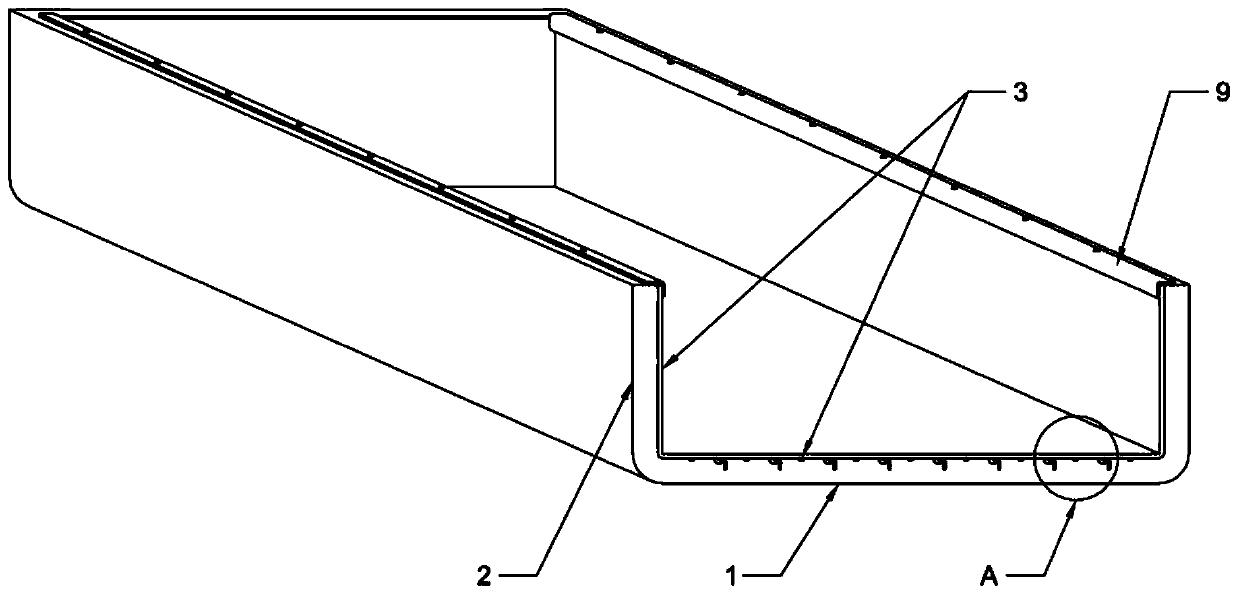

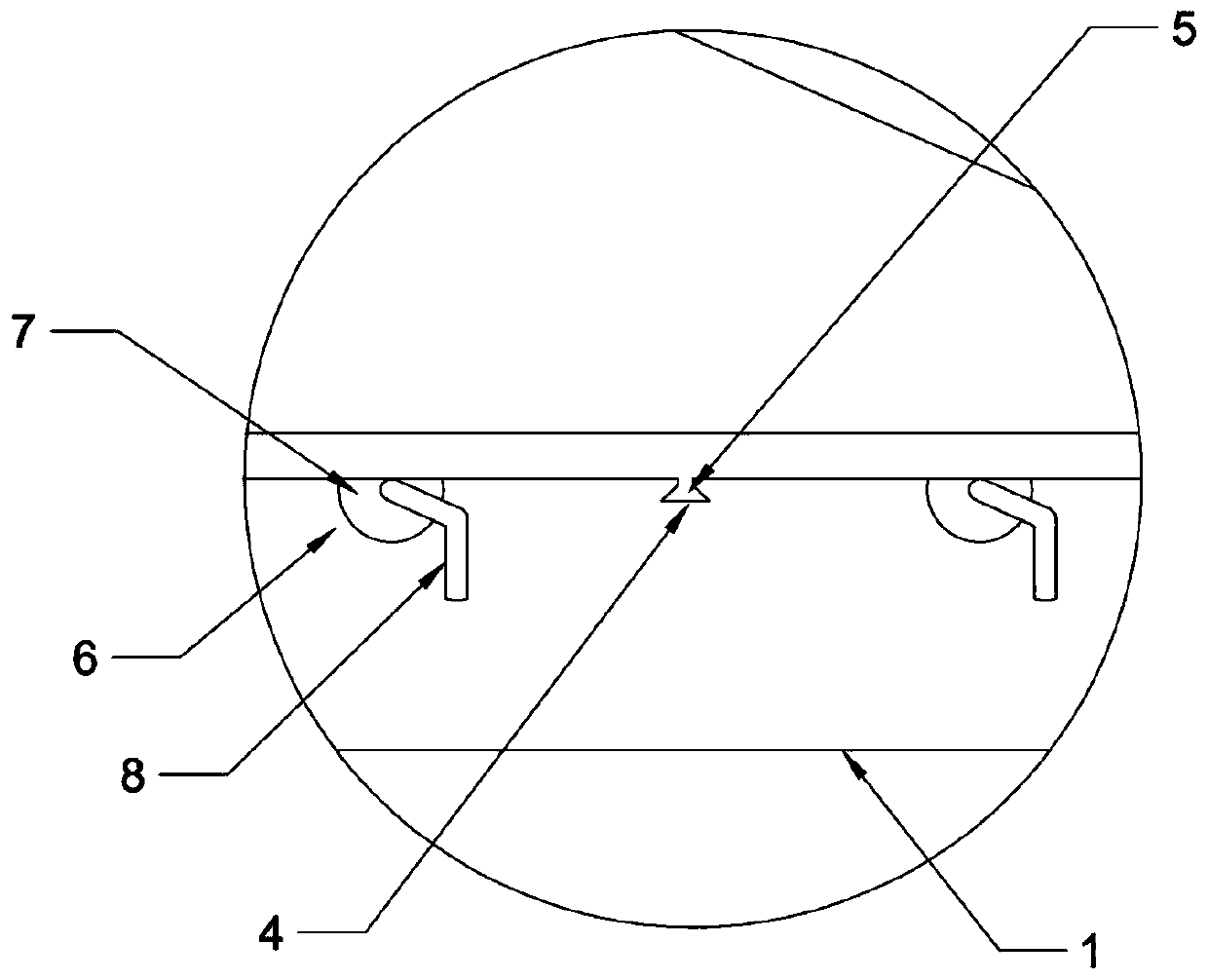

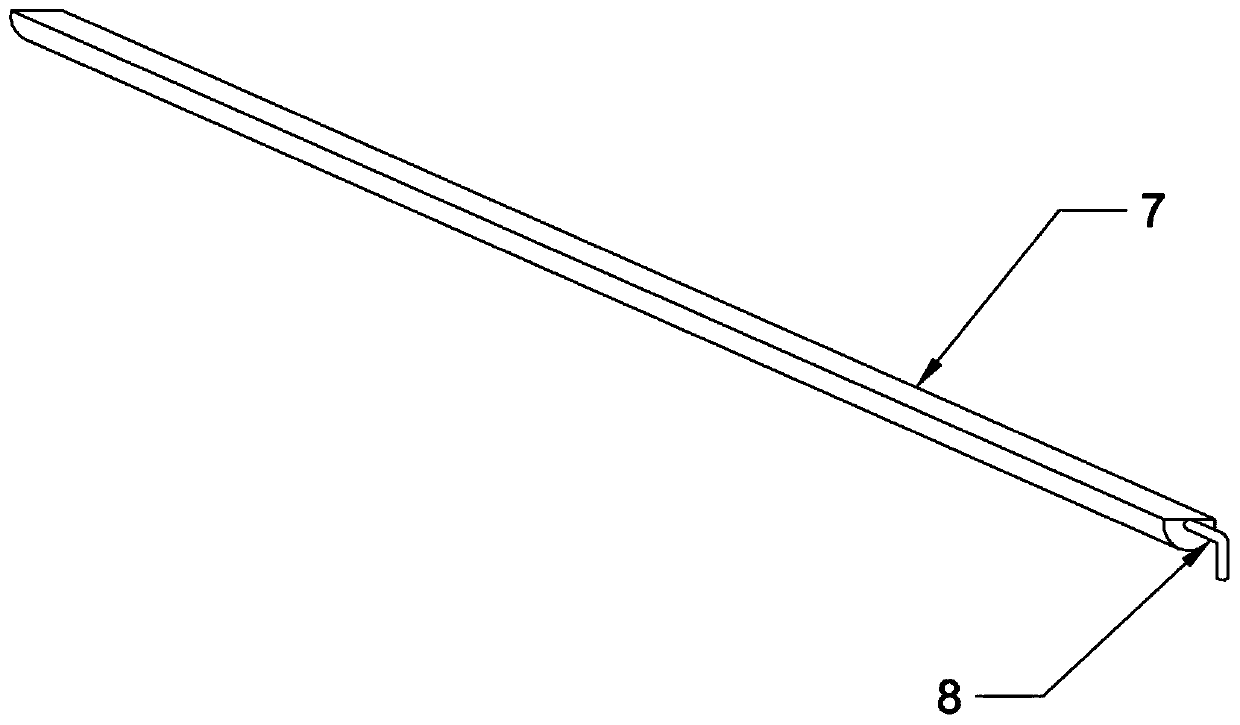

[0027] Such as figure 1 , figure 2 , image 3 As shown, a dump truck box body includes a car body, and the car body includes a bottom plate 1 and two side plates 2, and the bottom plate 1 and the two side plates 2 form a tank structure, and the bottom plate 1 and the two side plates The inner surfaces of the side panels 2 are all covered with polymer liners 3 .

[0028] The polymer liner 3 is made of polyurethane layered coating, and at least includes a bottom layer bonded to the bottom plate 1 and the side plate 2 and a surface layer on the bottom layer and the bottom layer, and the surface layer is mixed with ceramic powder.

[0029] The mixing ratio of polyurethane and ceramic powder in the surface layer is: 1-3 parts by weight of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com