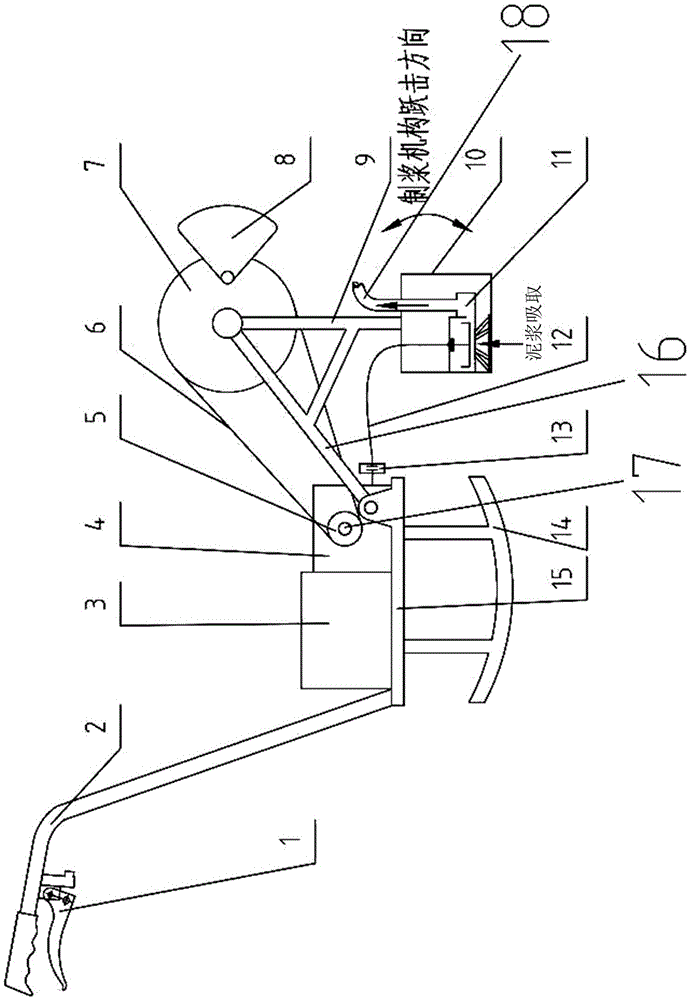

Rice seedling bed frog-type slurry machine

A pulper and frog technology, applied in the field of machinery, can solve the problems of many processes, inflexibility, low efficiency, etc., and achieve the effects of improving the comfort of use, reducing the driving force and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The user starts the pulping machine, and the power mechanism drives the jumping device of the pulping mechanism and the mud pump 11 of the grouting mechanism through the transmission mechanism; wherein the first output shaft 17 drives the jumping device, and the second output shaft drives the mud pump 11, when the jumping device When driven by the power mechanism, the driven wheel 7 with eccentric block rotates to make the connecting frame 16 of the pulping mechanism swing up and down around the machine base 15. When the connecting frame 16 swings up, the pulping mechanism jumps off the ground, and the pulping mechanism pulls the machine base 15 moves forward, when the connecting frame 16 swings down, the pulping mechanism makes the bracket 9 with the filter screen 10 hit the mud ground with its own weight to break the soil and filter the mud; when the mud pump 11 is driven by the power mechanism, the mud pump 11 sucks the filter The mud in the screen 10 is poured to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com