Industrial robot joint active damping device and robot

An industrial robot and active vibration reduction technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of slow attenuation vibration speed, poor reliability, and shortened service life, and achieve good vibration impact, buffer vibration impact, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further described in conjunction with the following examples.

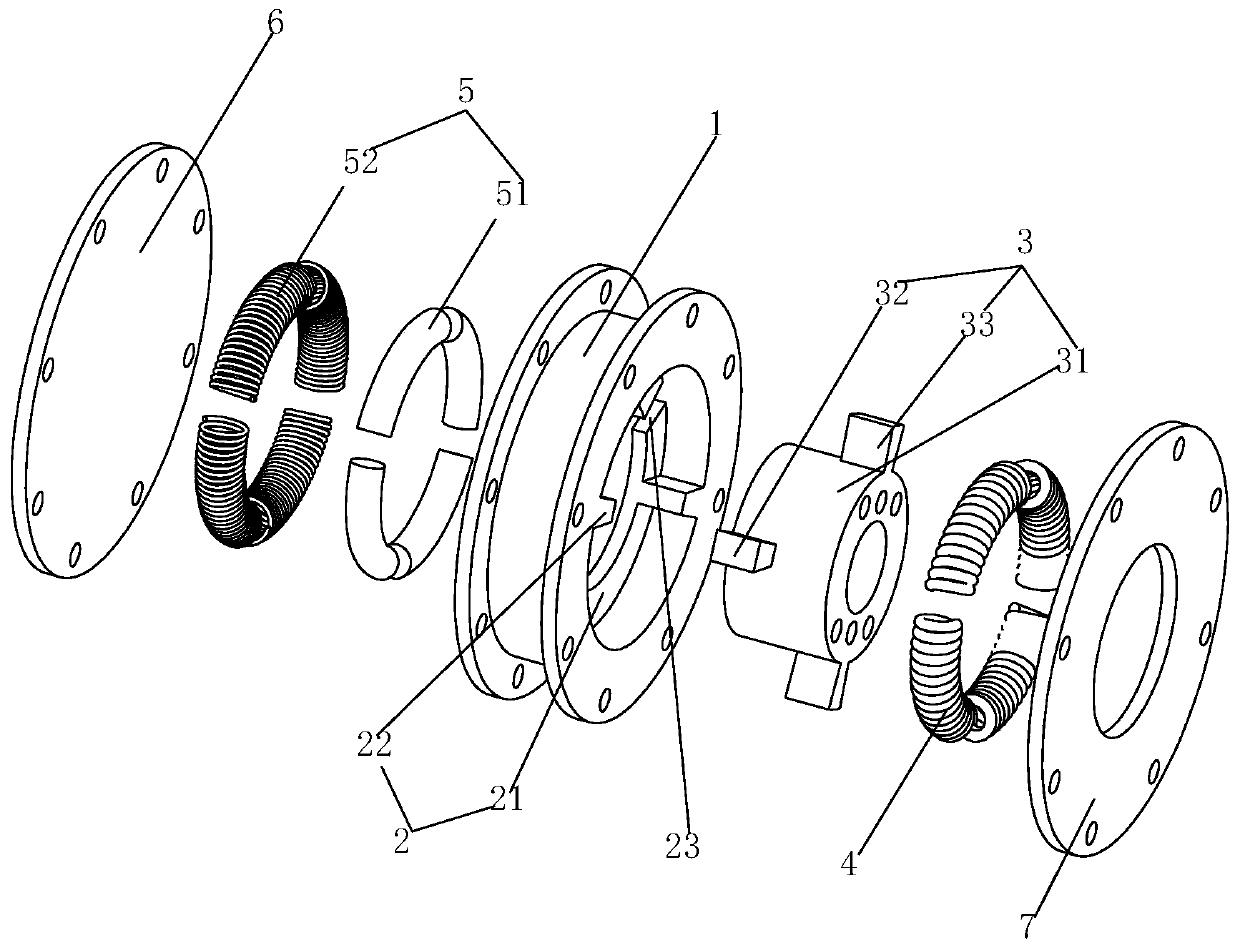

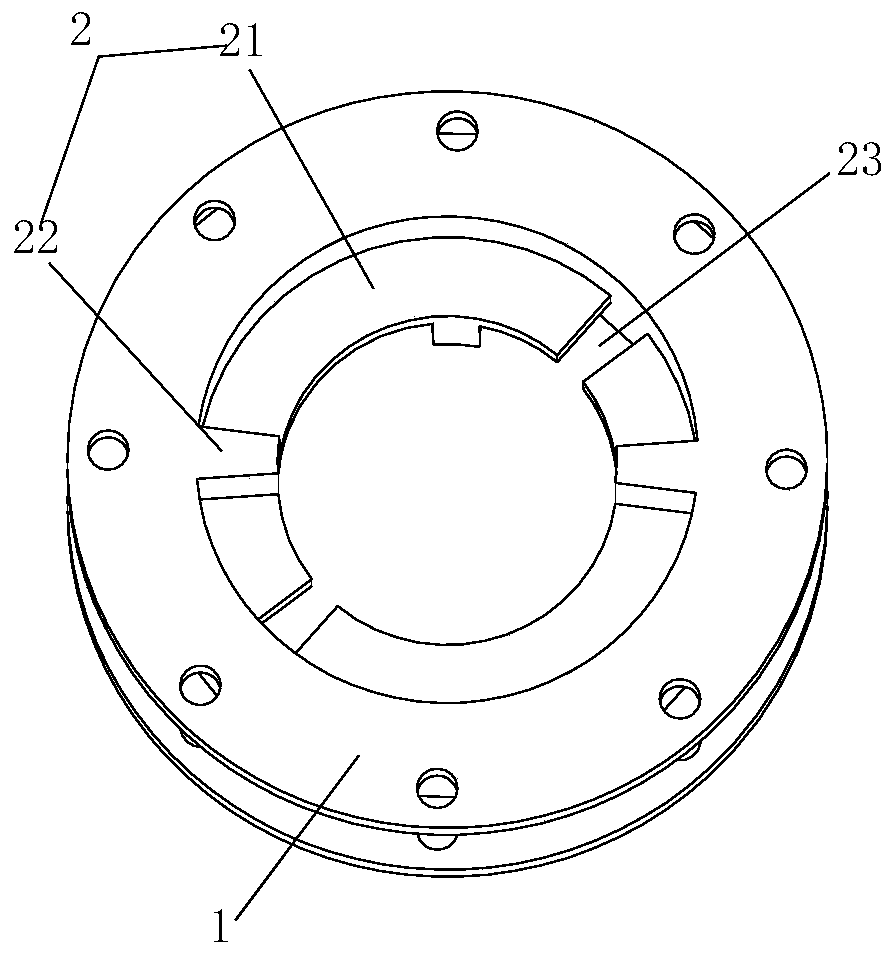

[0039] like Figure 1 to Figure 2 , an active damping device for an industrial robot joint, comprising a housing 1 , a retaining ring part 2 , a connecting element 3 , an elastic element 4 and an active damping and vibration damping assembly 5 . Wherein, the housing 1 has a cavity; the cavity is cylindrical. The retaining ring part 2 is arranged on the inner side wall of the housing 1 and is located in the cavity; the connecting element 3 is matched and nested in the inner ring of the retaining ring part 2 and can rotate relative to the retaining ring part 2; elastic The element 4 is nested in the cavity formed between the housing 1, the connecting element 3 and the retaining ring part 2 and is located on the right end surface of the retaining ring part 2; the active damping and vibration reduction assembly 5 is nested in the The cavity formed between the housing 1 , the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com