Jack wheel with shock absorber

A technology of jacks and wheels, applied in the direction of lifting devices, etc., can solve the problems of large impact force on the ground, unevenness of the four wheels, easy damage to the ground plane, etc., and achieve the effect of easy assembly, simple composition, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution, features and advantages of the present invention are described in detail below in conjunction with the accompanying drawings:

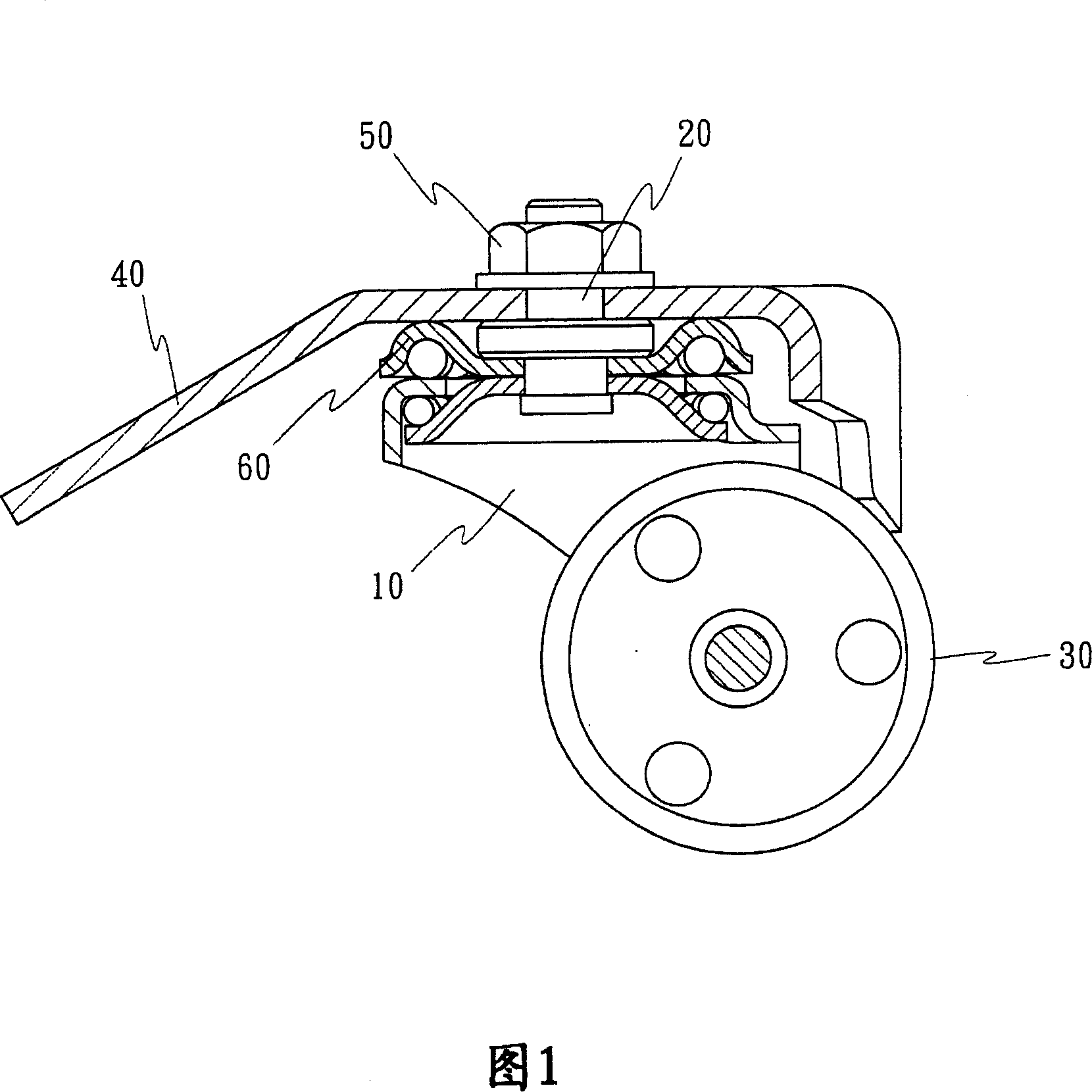

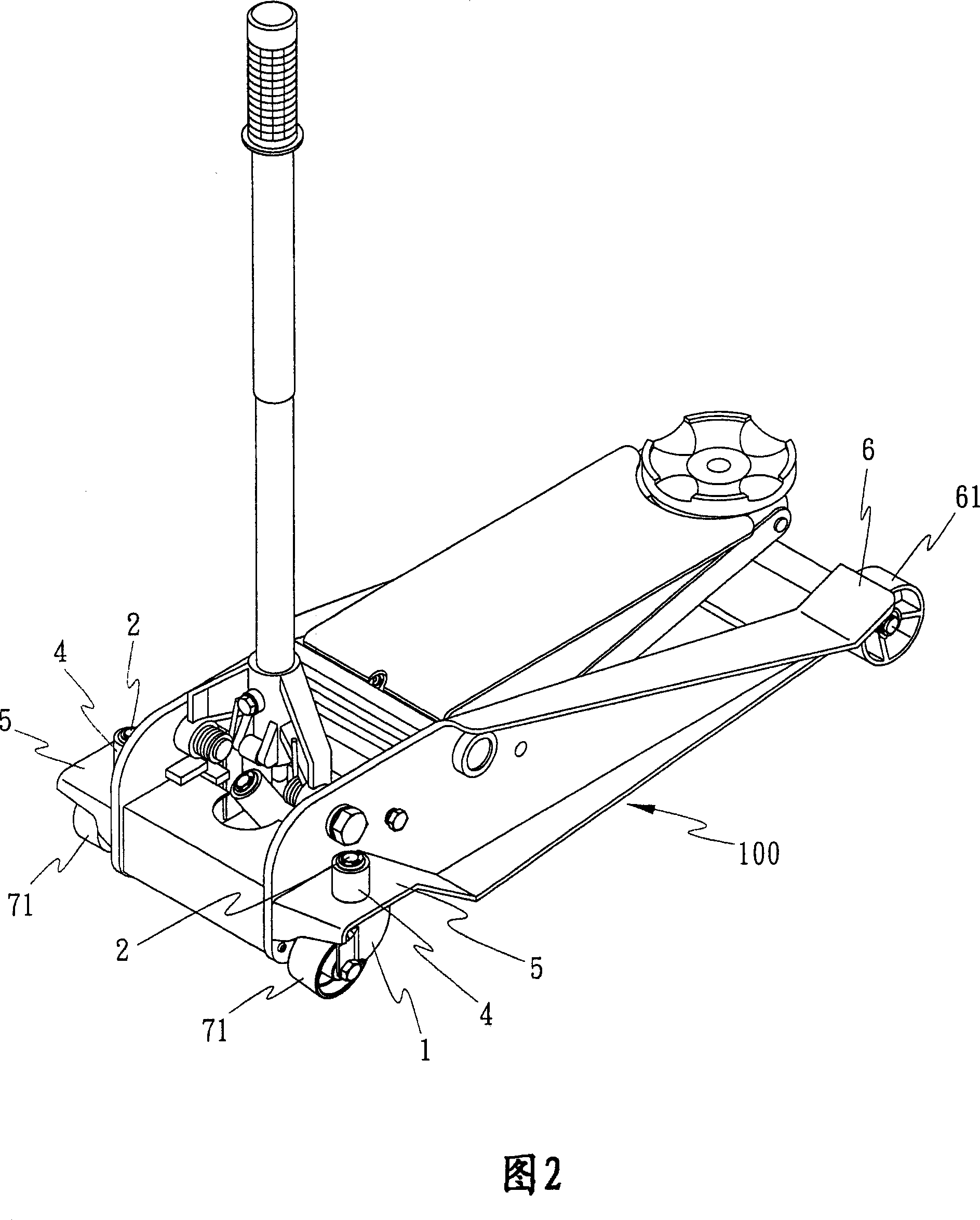

[0012] As shown in Figure 2, the jack wheel with the shock absorber proposed by the present invention is specially used for the attached wheel of the jack, and is especially suitable for providing the combined composition of the rear wheel top cover 5 of the known horizontal jack, so that the horizontal The rear wheel part of the formula jack has a shock-absorbing effect, which can be automatically telescopically adjusted and engaged with the sticking touch of the ground, so as to achieve the purpose that the four wheels (comprising two front wheels 61 and two rear wheels 71) keep on the ground all the time.

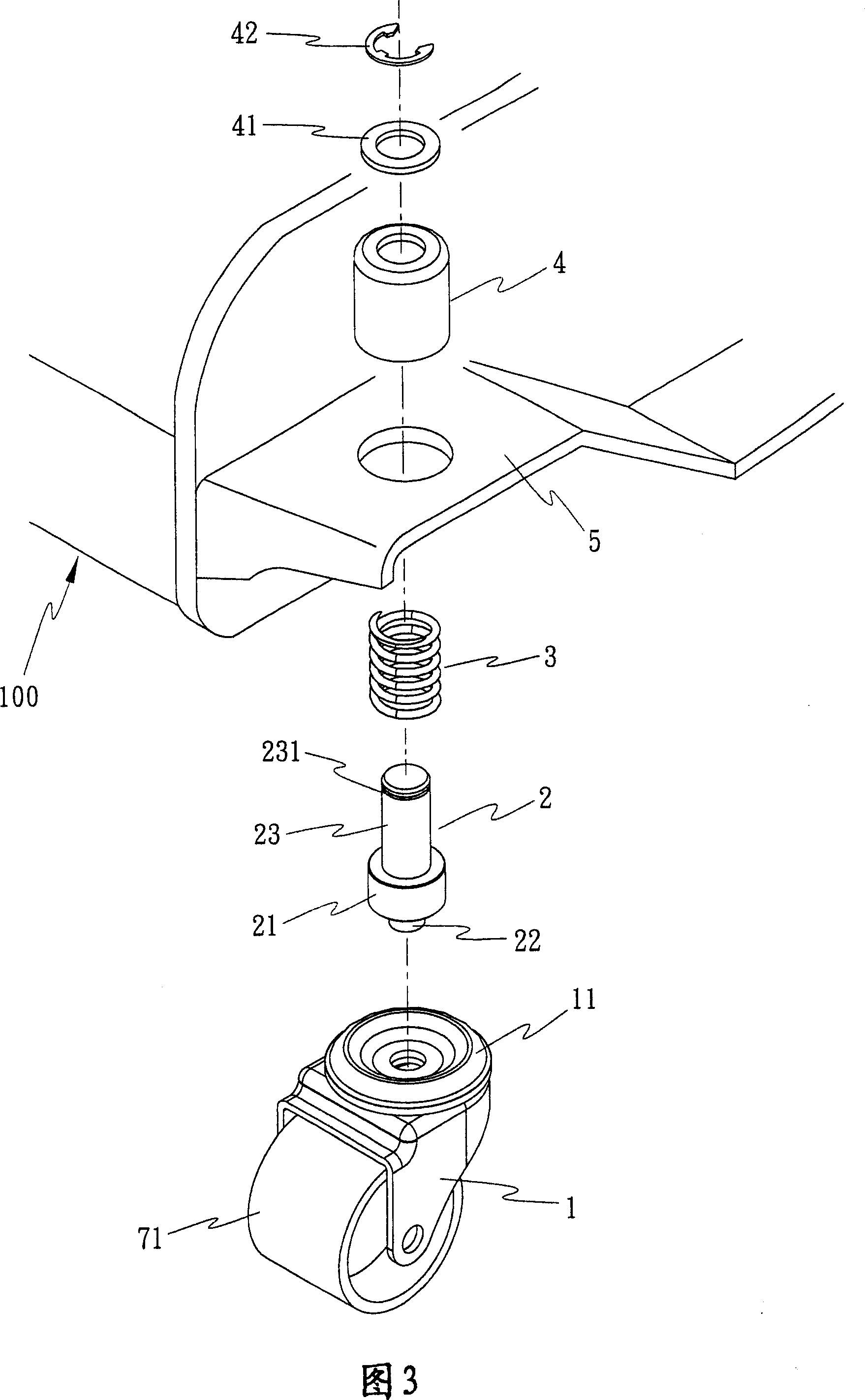

[0013] As shown in Figure 3, the composition of the present invention mainly includes a bracket 1, a straight shaft 2, a compression spring 3 and a shaft sleeve 4; wherein:

[0014] Bracket 1, which is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com