Automatic stretch film winding device

A winding device and stretch film technology, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of low work efficiency, inapplicability, and troubles for enterprise benefits, so as to reduce labor costs and reduce the frequency of manual operations and the effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe in detail the technical content, structural features, achieved objectives and effects of the stretch film automatic winding device of the present invention, the following further descriptions are combined with embodiments and accompanying drawings.

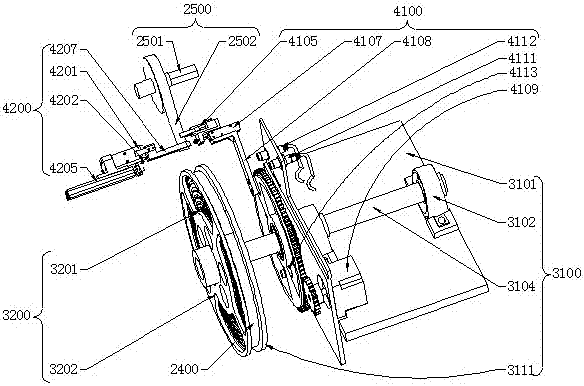

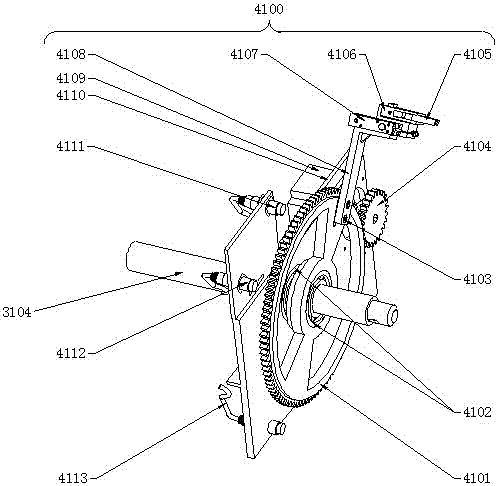

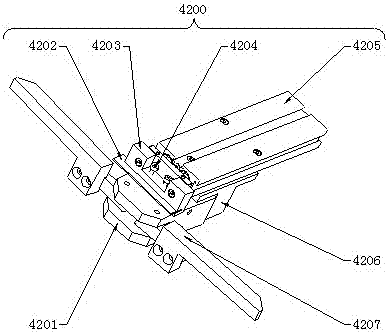

[0034] Such as Figure 1 to Figure 3 As shown, an embodiment of an automatic stretch film winding device of the present invention is disclosed, including: flat tube 2400, film feeding mechanism 2500, power mechanism 3100, winding reel 3200, film clamping and feeding mechanism 4100, and film cutting mechanism 4200, and is integrated into a whole set; the stretch film 2501 of the film feeding mechanism 2500 is clamped by the film clamping claw 4207 of the film cutting mechanism 4200, and is drawn by the stretch film winding rod 4108 of the film feeding mechanism 4100 to be wound. On the surface of the roll, the center hole of the stretched film 2501 is in clearance fit with the stretched film axis 2502, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com