Rolling formation method for large and medium size solid plate-shape forge piece

A disc-shaped forging, large and medium-sized technology, applied in the field of rolling and forming of forgings, can solve the problems of poor working environment, waste of metal materials, uneven deformation of forgings, etc., to achieve manufacturing difficulty and investment reduction, saving mold cost, performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

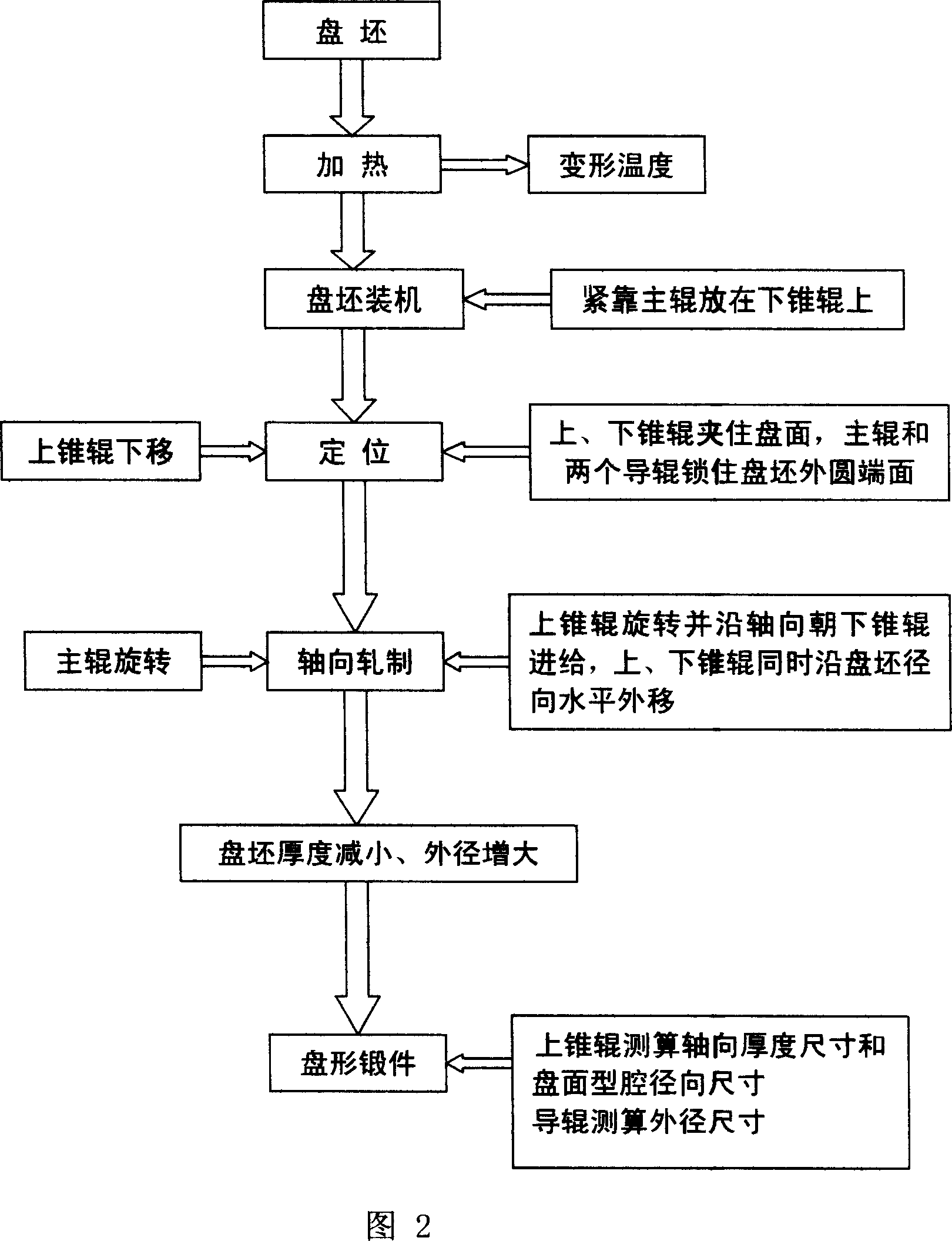

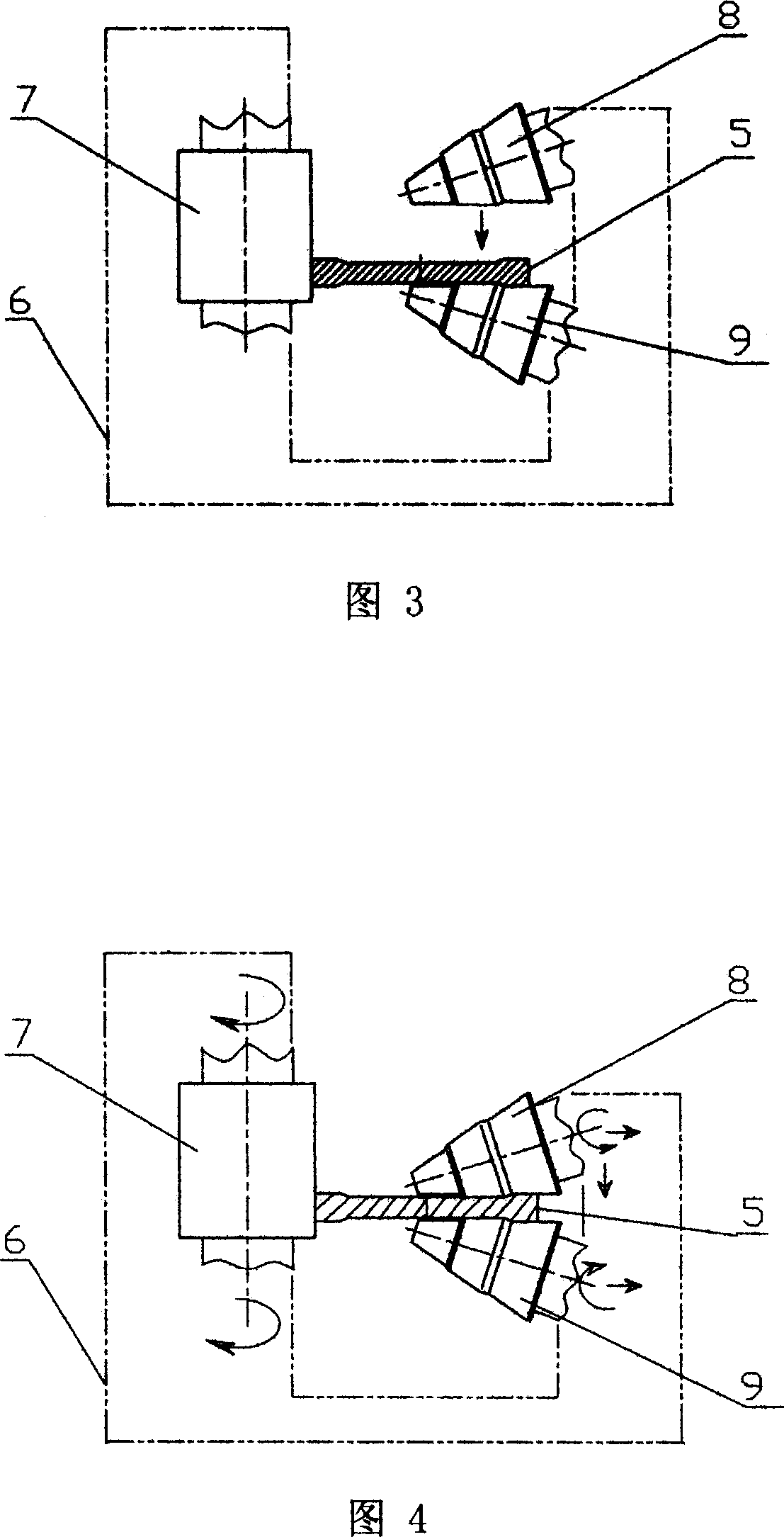

[0040] To implement the roll-forming method of large and medium-sized solid disk-shaped forgings described in the present invention, it is necessary to provide a main roll 7 shown in Figures 3 to 5, an upper tapered roll 8, a lower tapered roll 9 and two guide rolls 10. Rolling machine 6, the rolling machine 6 should be equipped with a control device that makes the above-mentioned rolling parts rotate or move in the direction shown in the figure and can adjust the speed of rotation or movement, and measure the outer diameter and axis of the disk through the rotation or movement of the above-mentioned parts. Measuring device for thickness dimension and disc cavity dimension. At the same time, it is also necessary to provide ordinary forging presses for blanking of forgings. Then follow these steps:

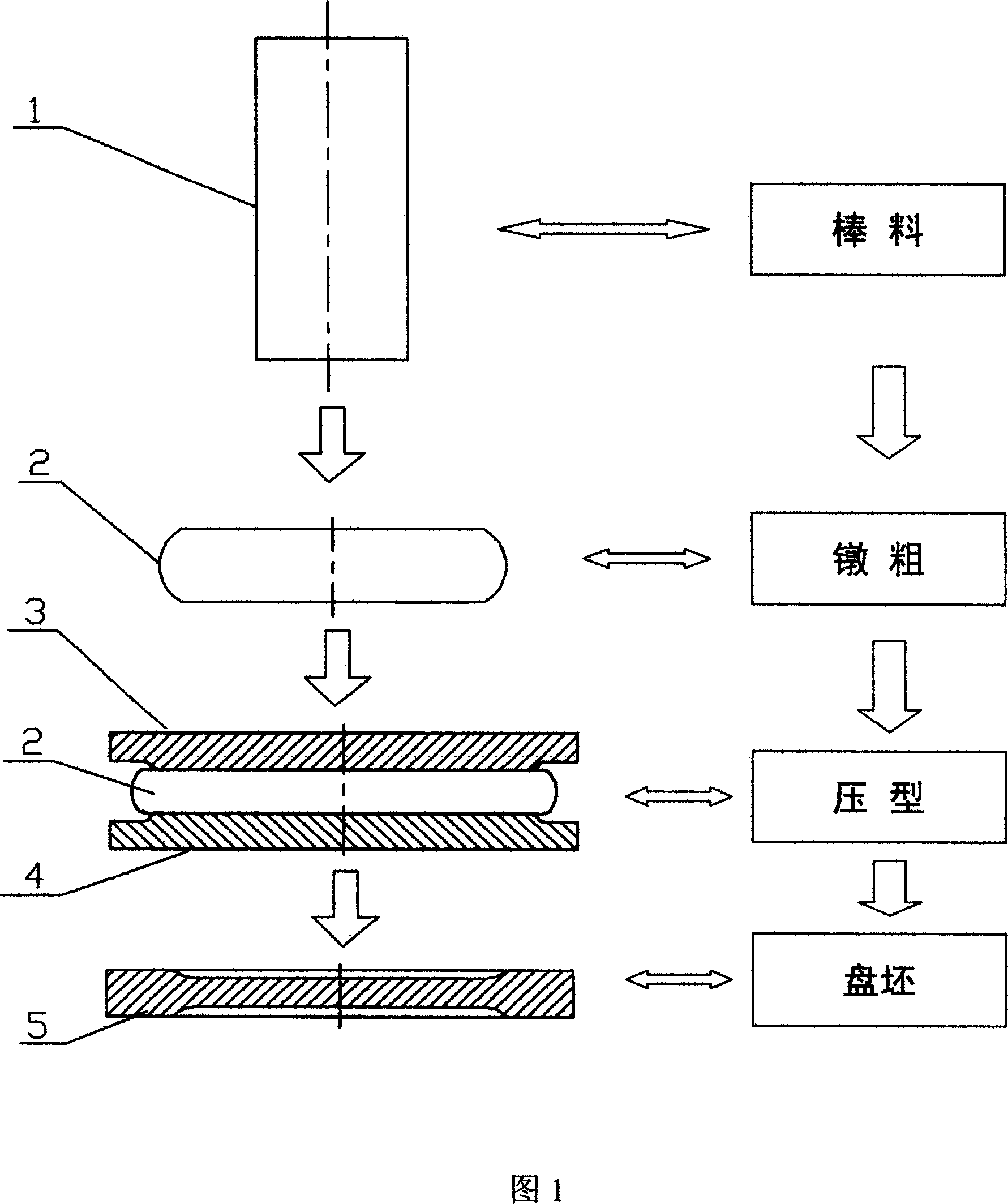

[0041] Step 1: Fabrication of the solid disc blank 5 . Figure 1 shows the production process of the solid plate blank. The bar 1 of the deformed metal material cut according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com