Deformation correcting method of circumferential weld of thin-wall titanium alloy welding casing

A technology of annular welds and welding casings, applied in the field of product weld correction, which can solve problems such as difficulty in heat correction, bulging deformation at the butt joint, affecting the appearance of parts and product delivery, etc., to meet the repair and rescue of faulty parts, increase Material plasticity, effect of reducing material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

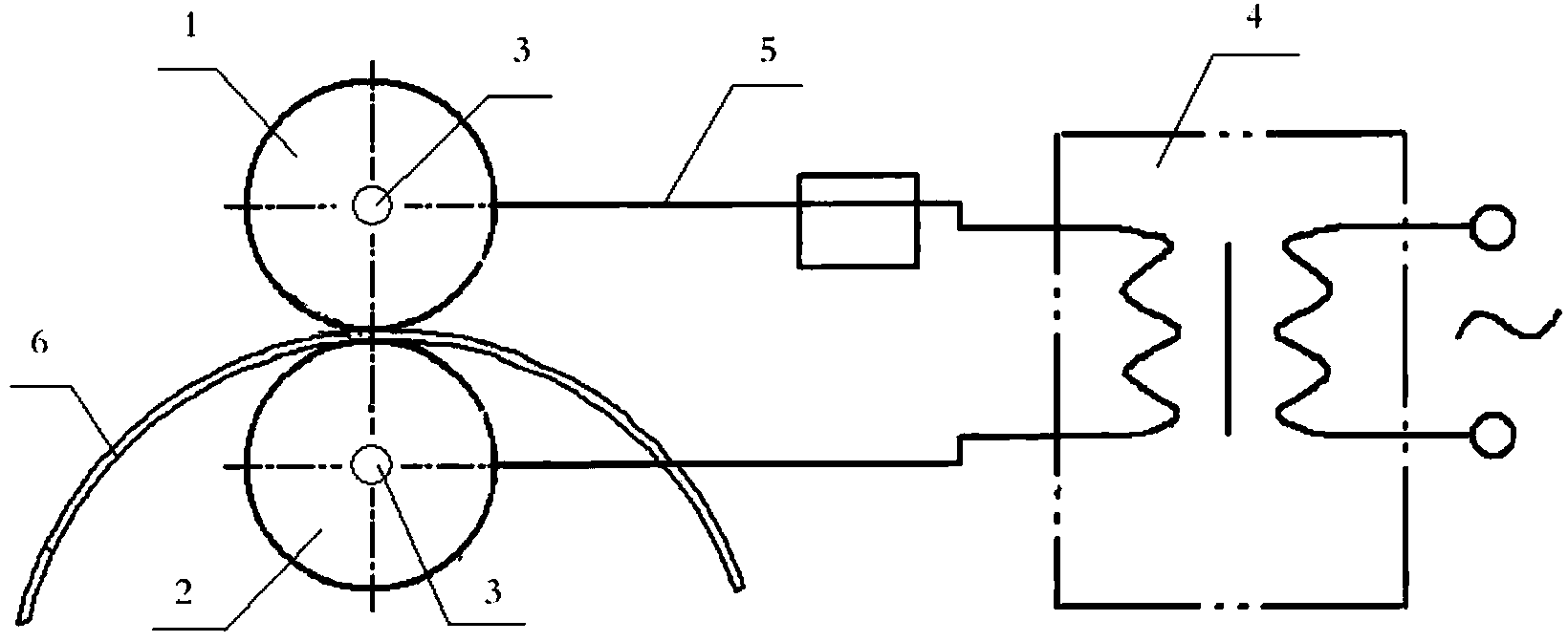

[0013] A rectification method for the deformed part of the annular weld of a thin-walled titanium alloy welding casing, using a device such as figure 1 As shown, the hot rolling correction device comprising an upper rolling plate 1, a lower rolling plate 2, an afterburning rod 3, a power supply 4 and a circuit 5 is carried out, including the following steps:

[0014] (1) Place the deformed part of the thin-walled titanium alloy welded casing ring weld between the upper rolling plate 1 and the lower rolling plate 2, and the booster rod 3 is directed toward the upper rolling plate 1 and the lower rolling plate 2 put pressure on;

[0015] (2) When the upper rolling plate 1, the lower rolling plate 2 and the deformed part are in full contact, the power supply 4 energizes the upper rolling plate 1 and the lower rolling plate 2 through the circuit 5, and the current passes through the The upper rolling plate 1, the deformed part and the lower rolling plate 2 form resistance heat to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com