Tea leaf rolling device

A rolling device and tea technology, which is applied in the field of tea rolling, can solve problems such as inconvenience, and achieve the effects of high sliver forming rate, reduced non-forming rate, and good rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

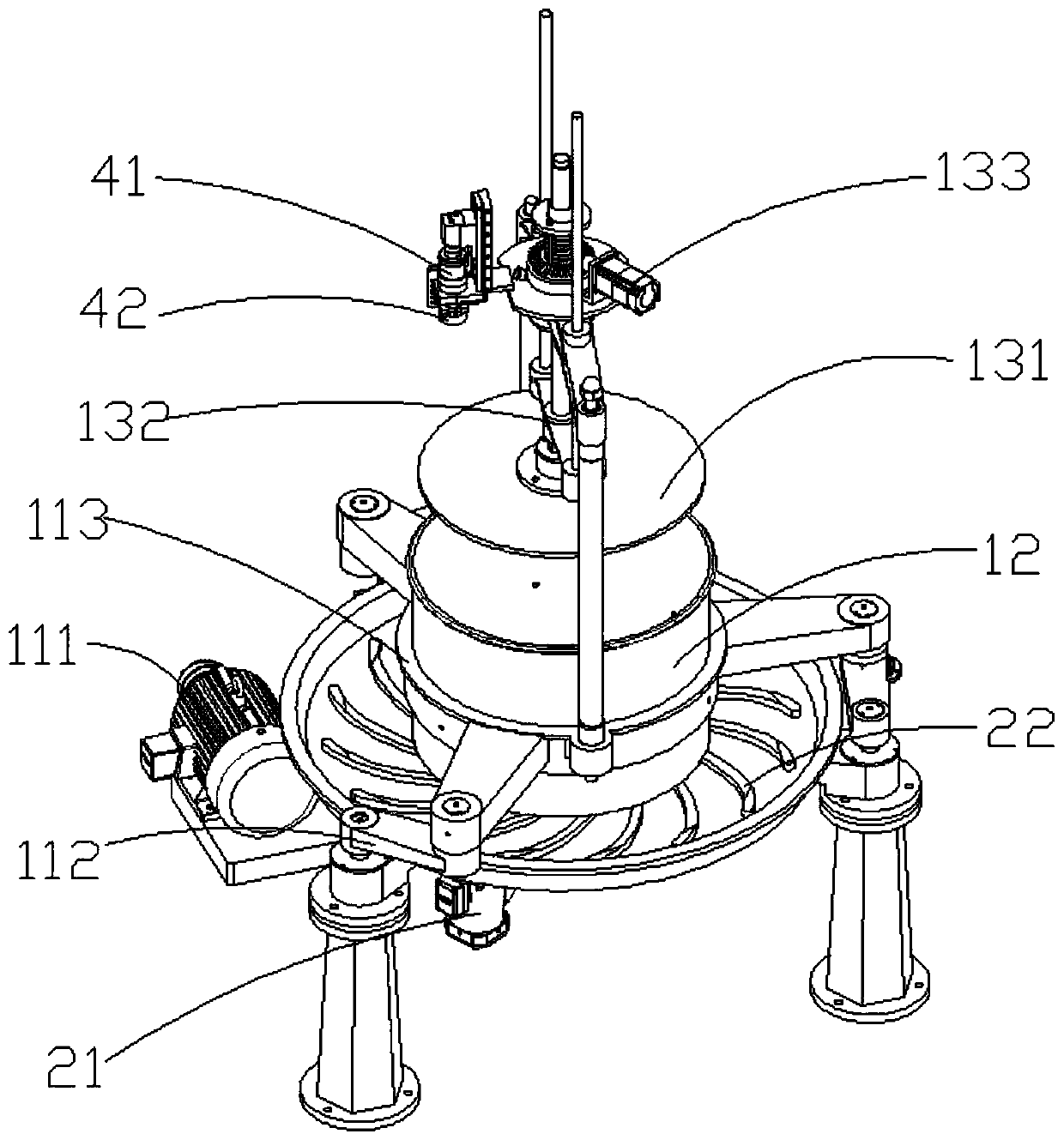

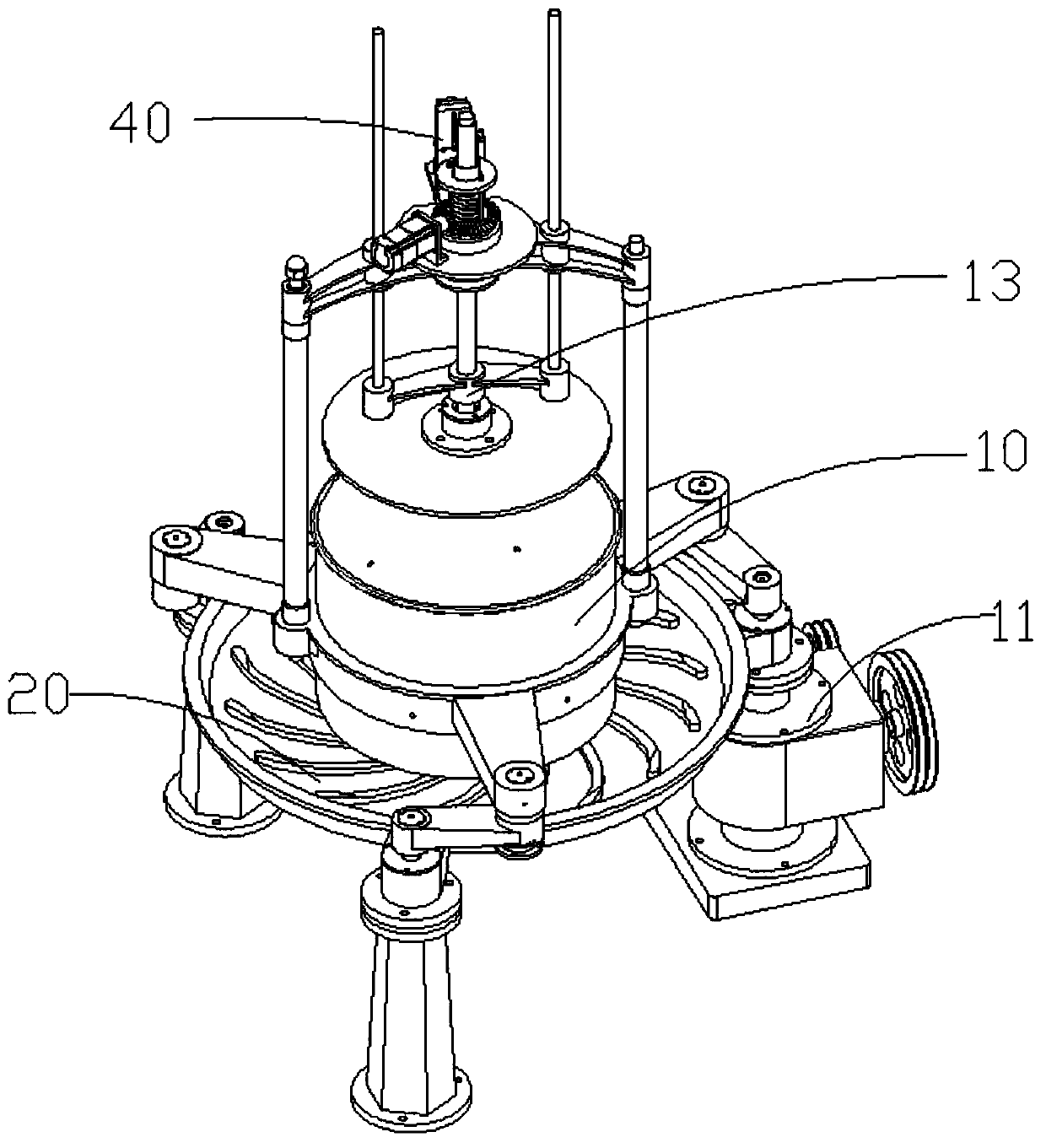

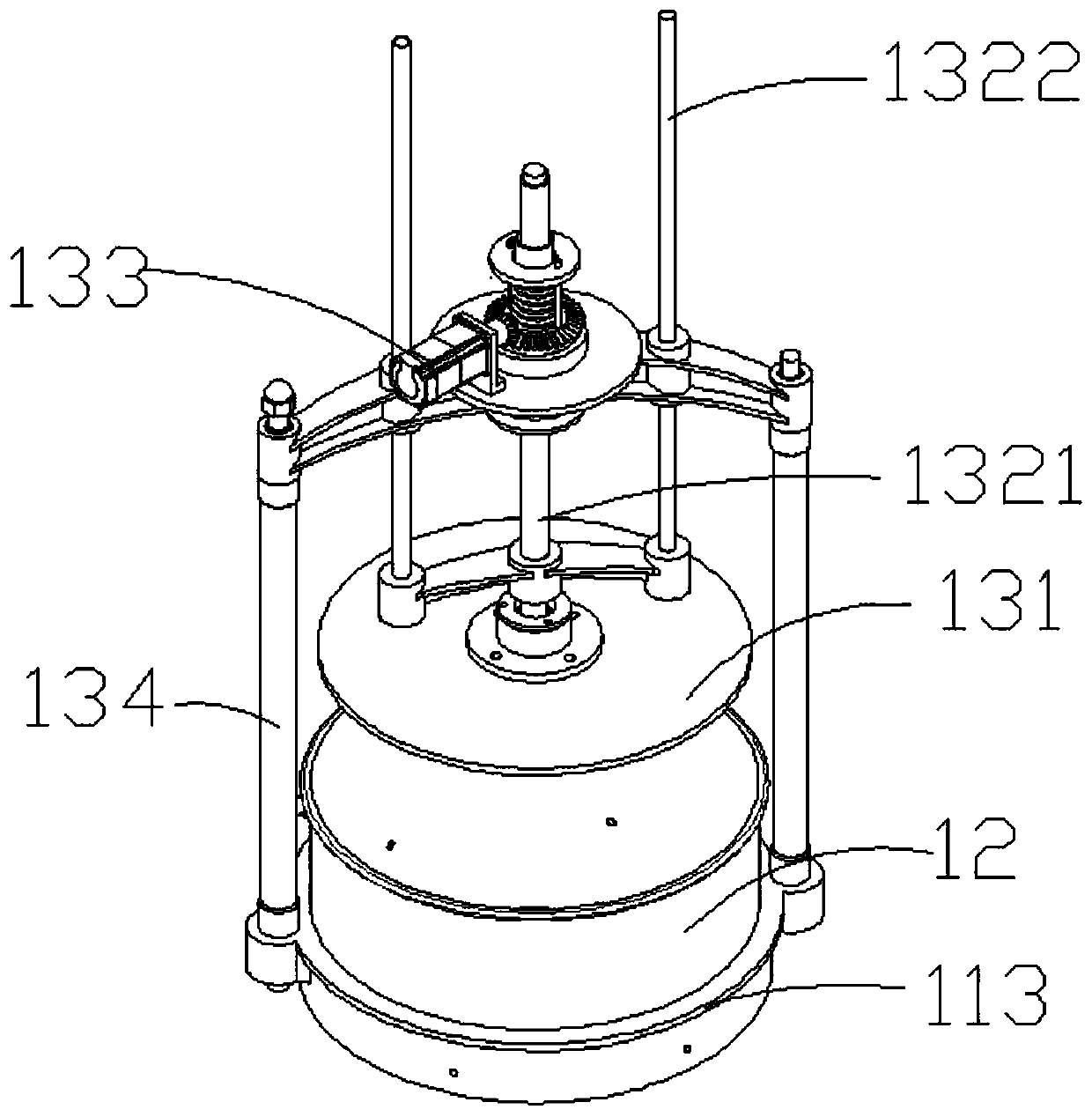

[0037] In one embodiment of the present invention, refer to Figure 1 to Figure 8 , provide a tea rolling device, kneading bucket 10, kneading plate 20 and control system 30, kneading bucket 10 is driven by the first transmission mechanism 11 to do rotary motion in the horizontal direction, kneading bucket 10 includes barrel body 12 and The pressure mechanism 13 located above the barrel body 12 is used to hold the tea leaves; the rotary motion makes the tea leaves roll in the kneading barrel 10 . The pressure mechanism 13 can extend into the barrel body 12 from the top of the barrel body 12, and apply a vertical downward pressure to the tea leaves; the kneading disc 20 is located below the kneading barrel 10, and the top of the kneading disc 20 is provided with a rib frame 22, and the ribs The frame 22 is driven by the second transmission mechanism 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com