Broken plastic regeneration plasticizer

A technology of plastic and machine base, applied in the field of crushed plastic recycling plasticizer, can solve the problems of poor toughness of plastic recycled raw materials, poor extrusion and kneading effect, difficult gas discharge, etc. The effect of improving plasticizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

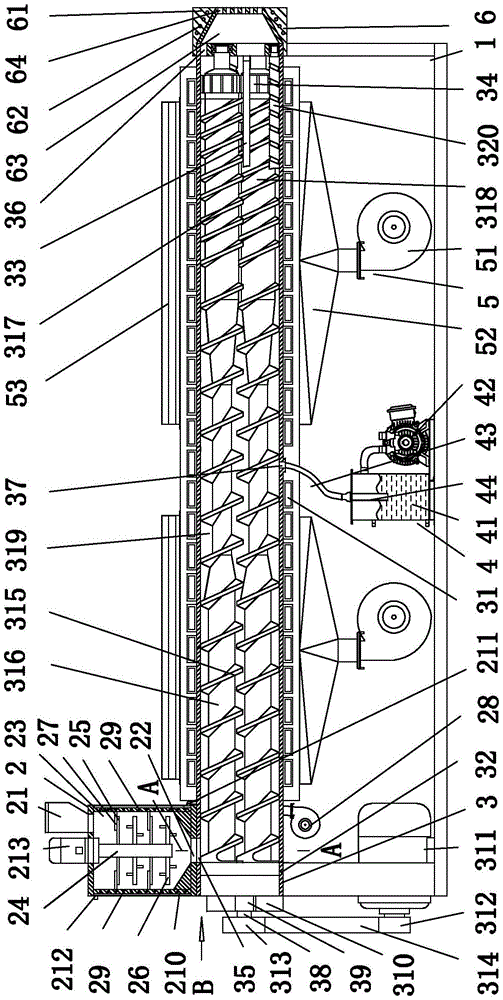

[0018] as attached figure 1 , attached figure 2 , attached image 3 Shown: a crushed plastic recycling plasticizing machine, including: a machine base 1, a chopping and stirring pre-plasticizing device 2 equipped with a feed hopper 21 and a discharge port 22, a main plasticizing device 3, and a vacuum suction filter device 4. Cylinder cooling device 5, discharge heat preservation device 6.

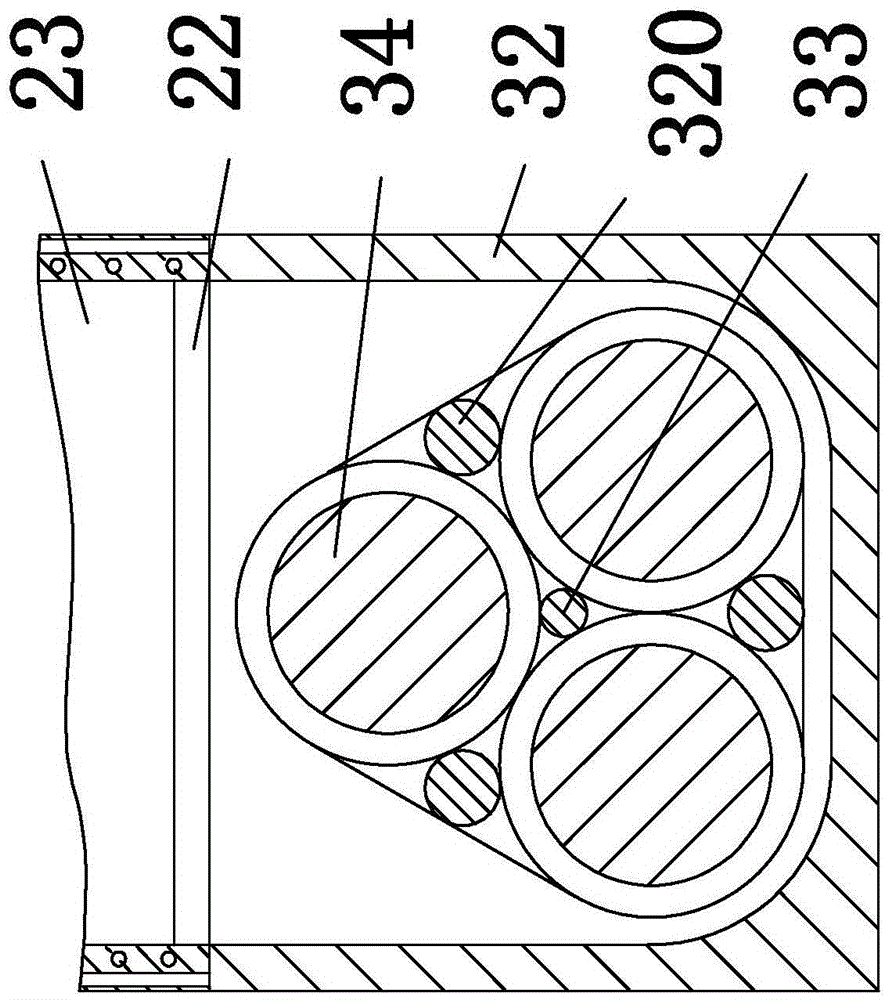

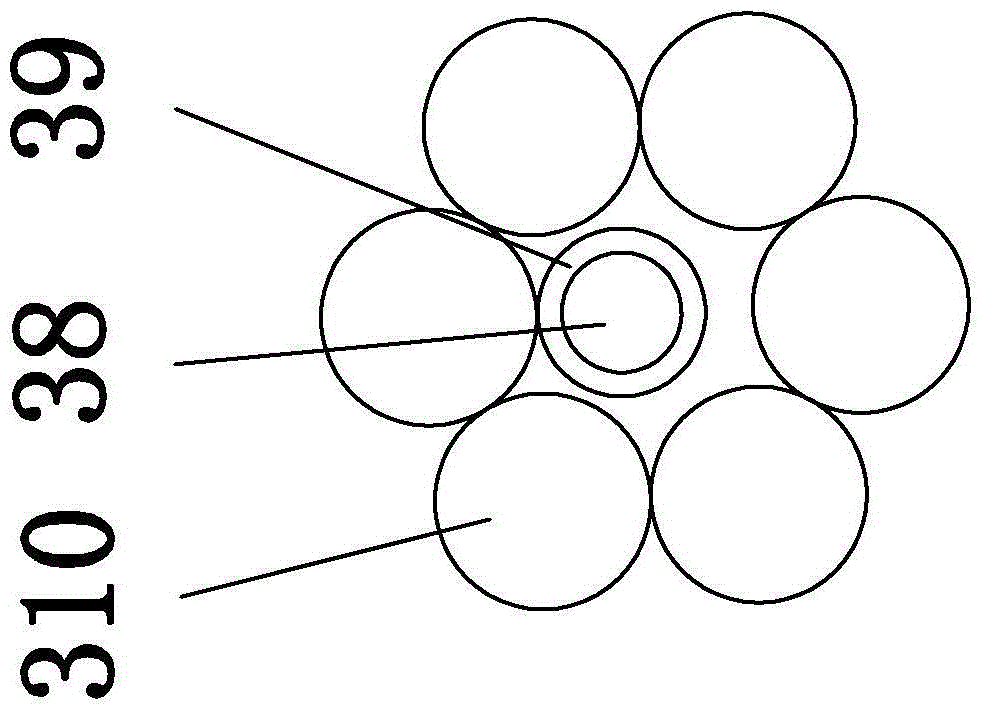

[0019] The main plasticizing device 3 includes: a cylinder body 32 provided with a cylinder body heating device 31 and connected to the machine base 1, a middle rod 33 whose two ends are connected to the two ends of the cylinder body 32 in one-to-one correspondence, three along the middle rod Circumferentially distributed and the main screw push rods 34 pivotally connected to the two ends of the cylinder body 32 at both ends, the push rod driving device; an auxiliary screw push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com