Soft-extrusion tea twisting machine

A kneading machine and tea technology, which is applied in the field of tea processing equipment, can solve the problems of unbalanced kneading force, broken tea leaves, and no buffer, etc., and achieve the effect of improving kneading effect, high tea quality, and improving tea quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

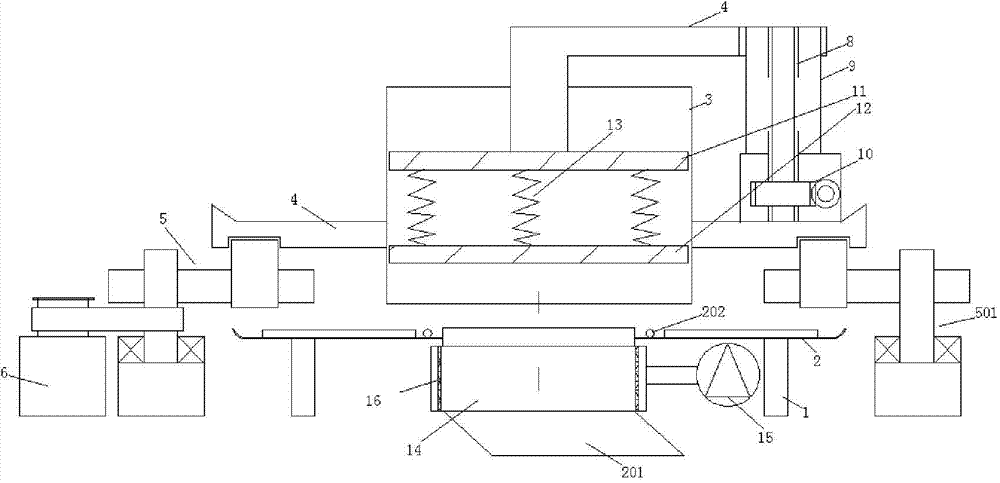

[0012] Referring to the accompanying drawings, a flexible extrusion tea rolling machine includes a bracket 1, a rolling disc 2, and a kneading device 3, the kneading disc 2 is fixedly installed on the bracket 1, and the kneading device 3 includes a kneading cylinder 301 and a gland 302, the outer periphery of the lower end of the kneading cylinder 301 is connected with a plurality of support arms 4, and the lower end of each support arm 4 is provided with a crank rocker mechanism 5, and the lower end of the crank rocker mechanism 5 is provided with a support seat 501, one of which is cranked The rod mechanism 5 is provided with a connection driving device 6, and the upper end of the gland 302 is provided with a connecting rod 7, and the end of the connecting rod 7 is connected to the adjusting screw 8 through a rotating sleeve 701, and the adjusting screw 8 is arranged in the column 9, and the column 9 The lower end is fixed on the support arm 4, and the lower end of the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com