Equipment for cleaning sizing agent on surface of fabric

A technology for cleaning equipment and slurry, which is used in fabric surface trimming, textile material carrier treatment, and spraying/jetting textile material processing. Kneading effect, simple structure, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

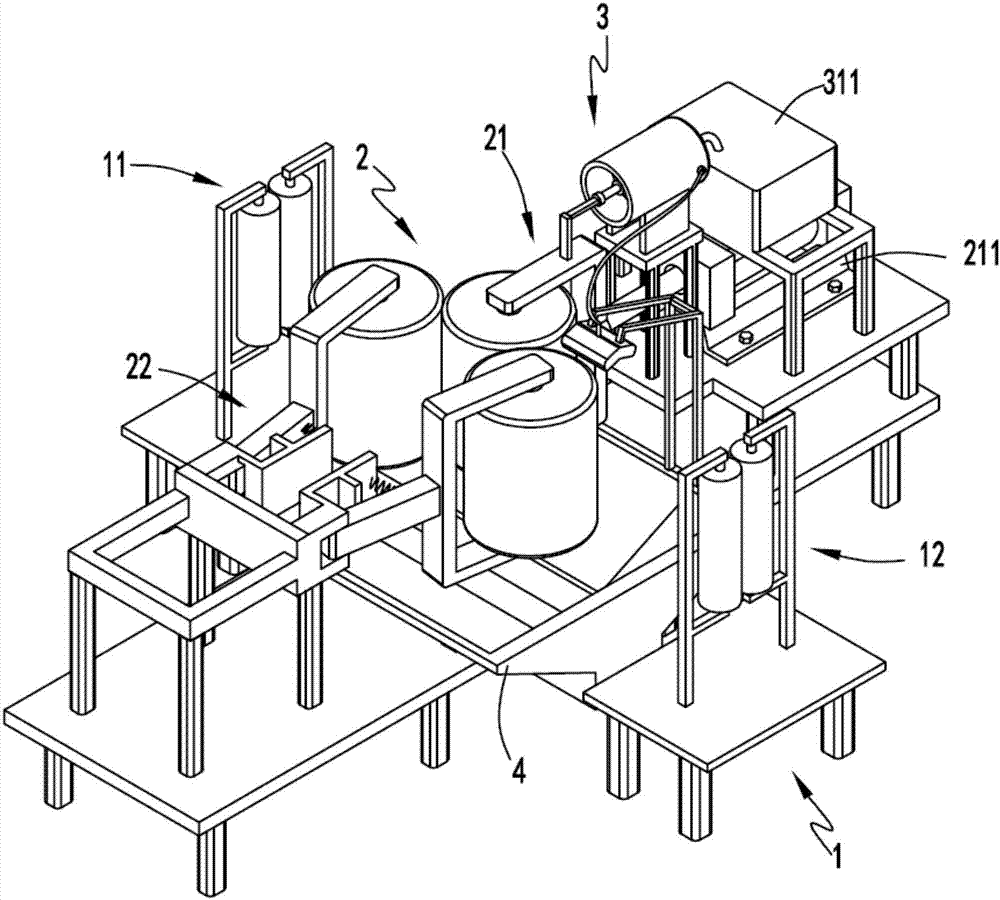

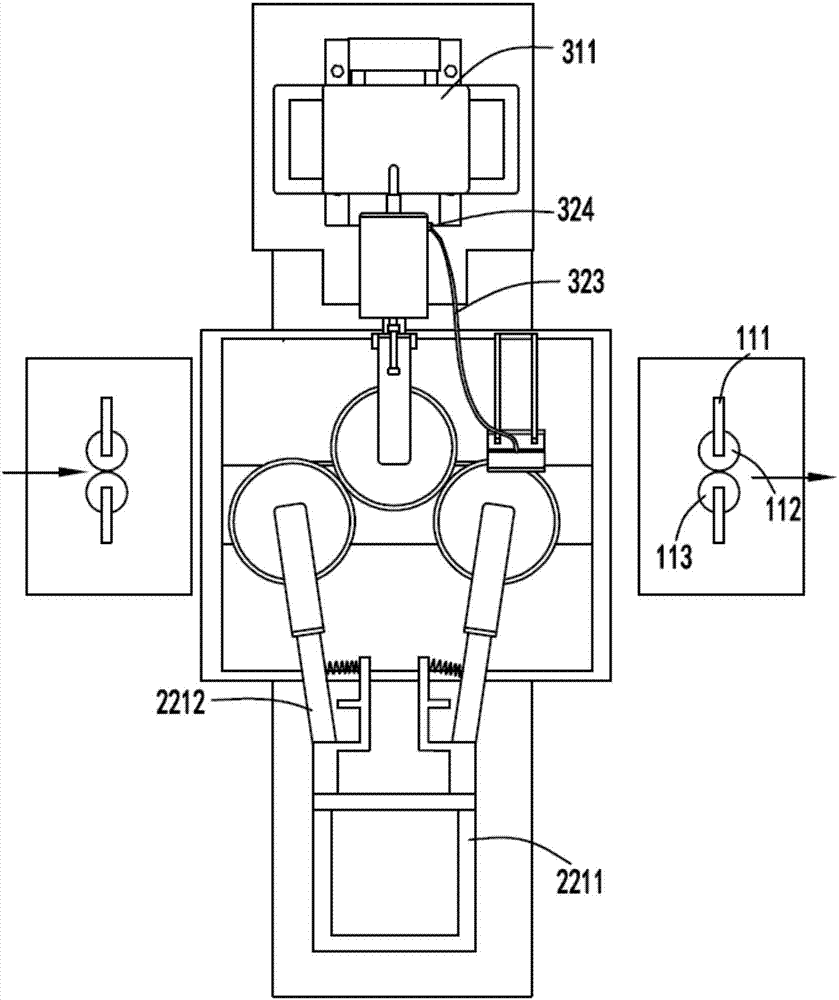

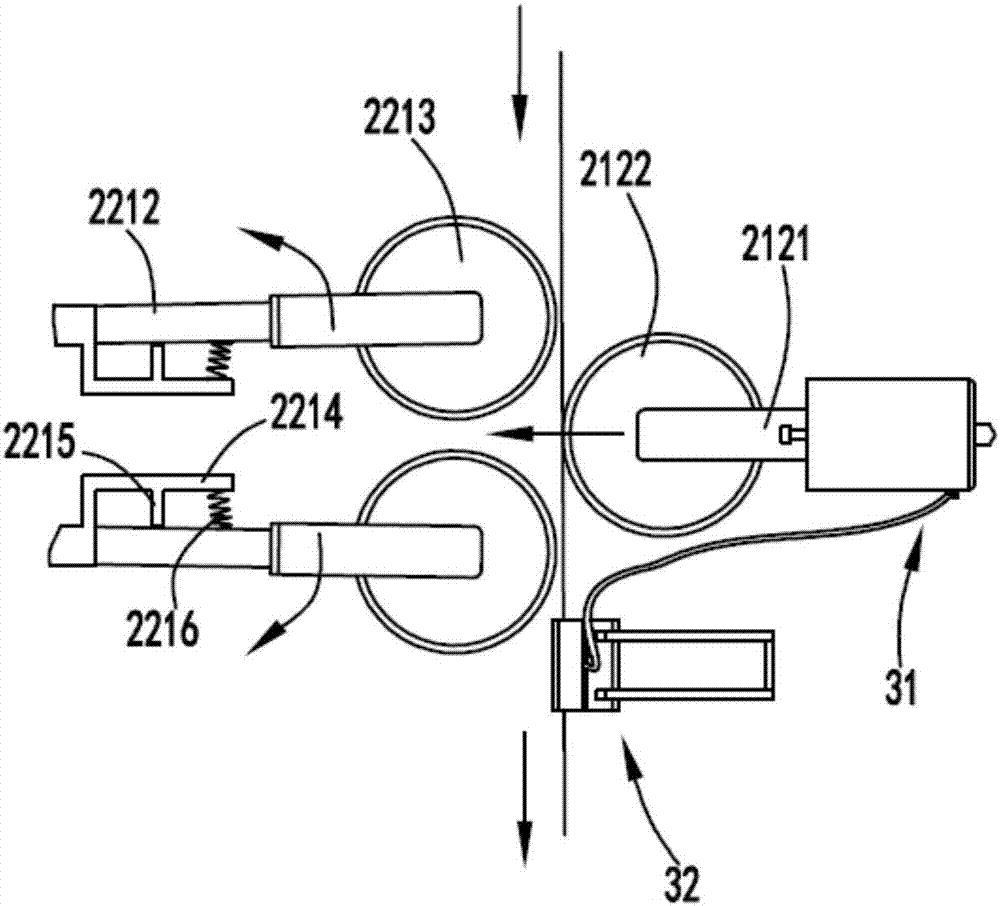

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a fabric surface slurry cleaning equipment includes a conduction part 1, the conduction part 1 includes an introduction device 11 and an export device 12 for conducting textile fibers; a rubbing part 2, and the rubbing part 2 is arranged on the introduction device 11 and the exporting device 12, the rubbing part 2 includes a pushing mechanism 21 and a rolling mechanism 22 respectively arranged on both sides of the textile fiber in the transmission process, and the pushing mechanism 21 is used to push the textile fiber toward the rolling mechanism 22. Direction movement, the rolling mechanism 22 is used to cooperate with the pushing mechanism 21 to roll the surface of the textile fiber synchronously forward and backward; the cleaning part 3, the cleaning part 3 includes a water supply device arranged above the pushing mechanism 21 The mechanism 31 and the spraying me...

Embodiment 2

[0049] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the spraying member 322 is set in an inverted V shape, and several spray holes 3221 are opened on the V-shaped surface of the spraying member 322;

[0050] On the one hand, this kind of setting makes it possible to spray water on the front and rear sides of the cloth through a spraying member 322. In addition, because of its inverted V-shaped setting, it also makes it possible to say that the jets are sprayed obliquely from one side of the cloth. onto the fabric for better cleaning results.

[0051] Working process: the cloth is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com