Multi-assortment spun yarn proofing machine

A kind of proofing machine and multi-variety technology, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, can solve the problems of shortening the sampling time and reducing the cost of proofing, and achieve efficient and accurate proofing and compact structure , the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

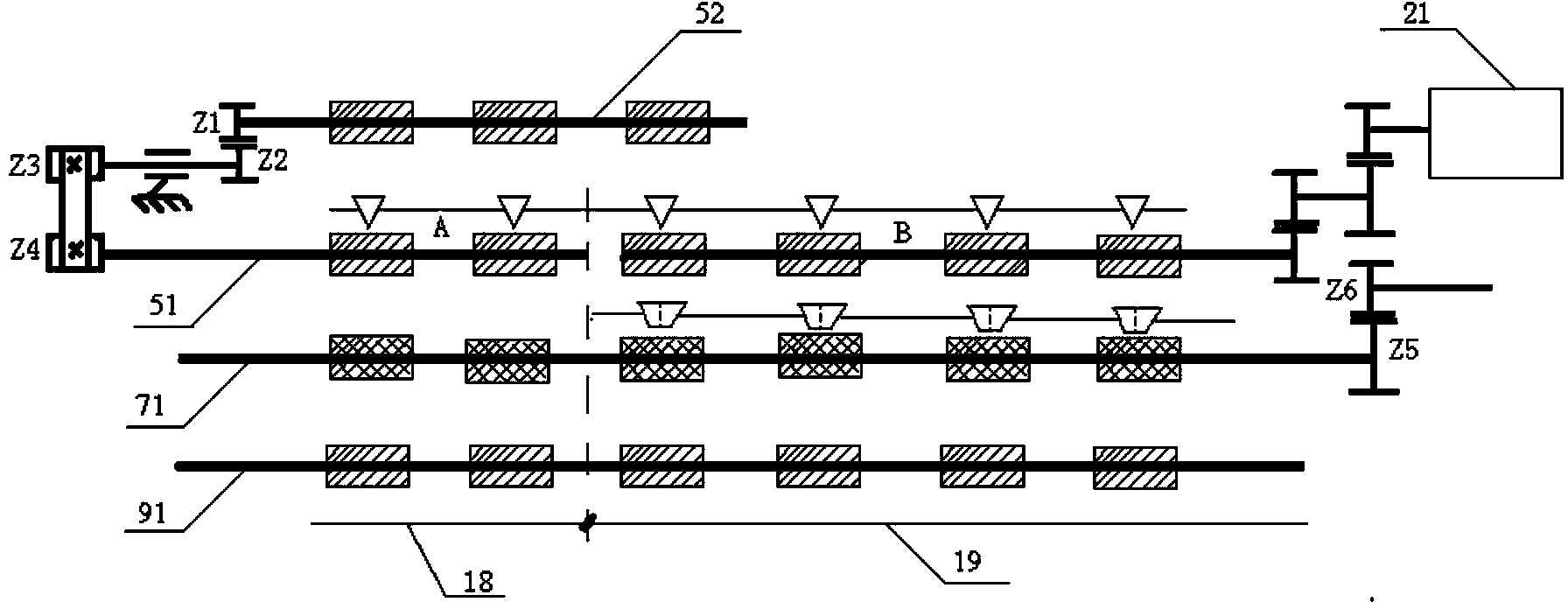

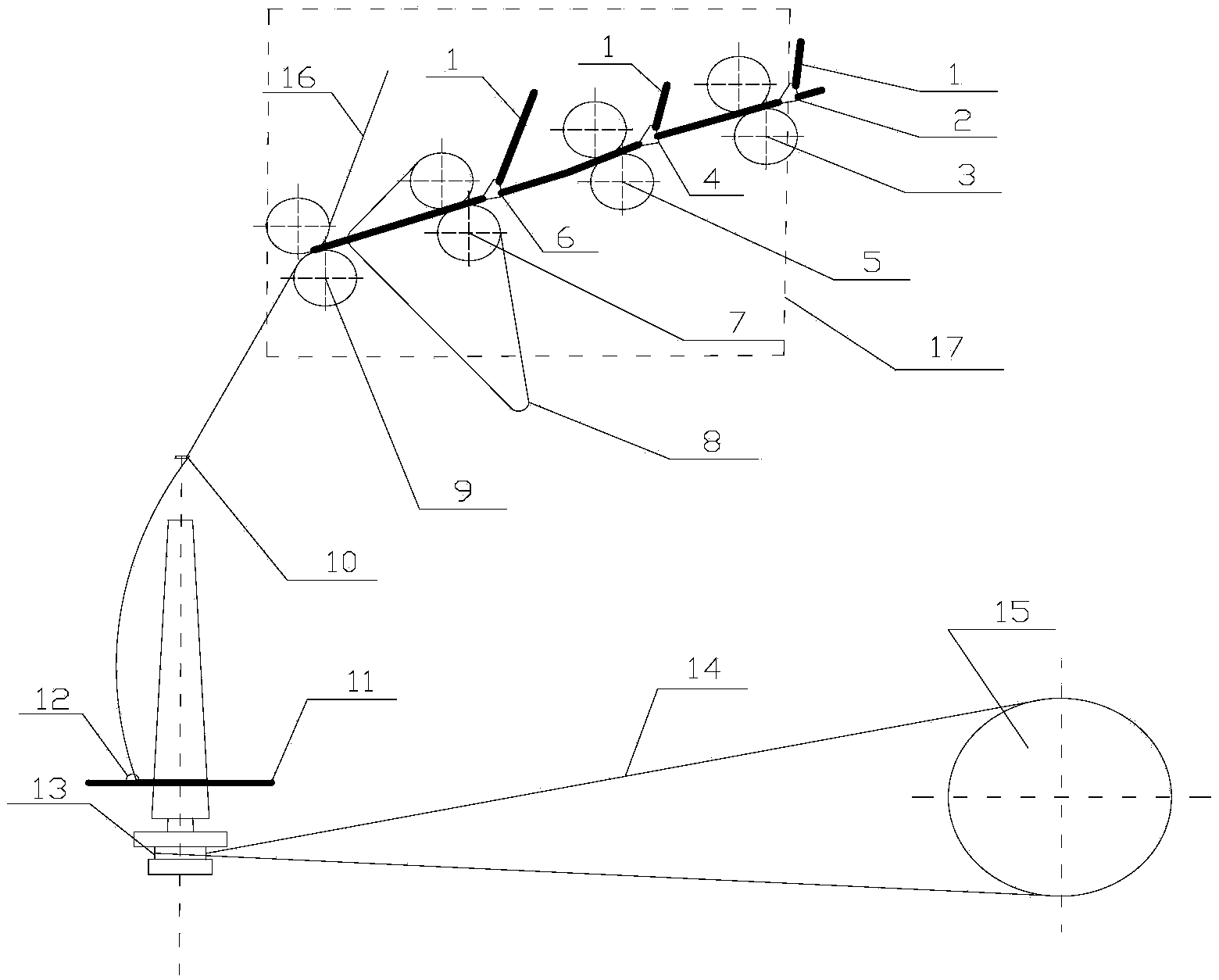

[0097] This embodiment specifically discloses a multi-variety spun yarn proofing machine, which includes a three-roller ring spinning machine body, the three-roller ring spinning machine body is divided into opposite first sides and second sides, and the first side includes The first side drafting zone and the first side twisting zone, the first side drafting zone includes the first side front roller, the first side middle roller, the first side rear roller, the first side twisting zone includes A plurality of spindle disks and rollers; the second side includes a second side drafting zone and a second side twisting zone, the second side drafting zone includes a second side front roller, a second side middle roller, a second side Two side back rollers and fourth rollers, the second side twisting zone includes a plurality of spindle discs and a plurality of rolling discs,

[0098] The first side rear roller is divided into A part and B part which are driven separately, wherein, ...

Embodiment 2

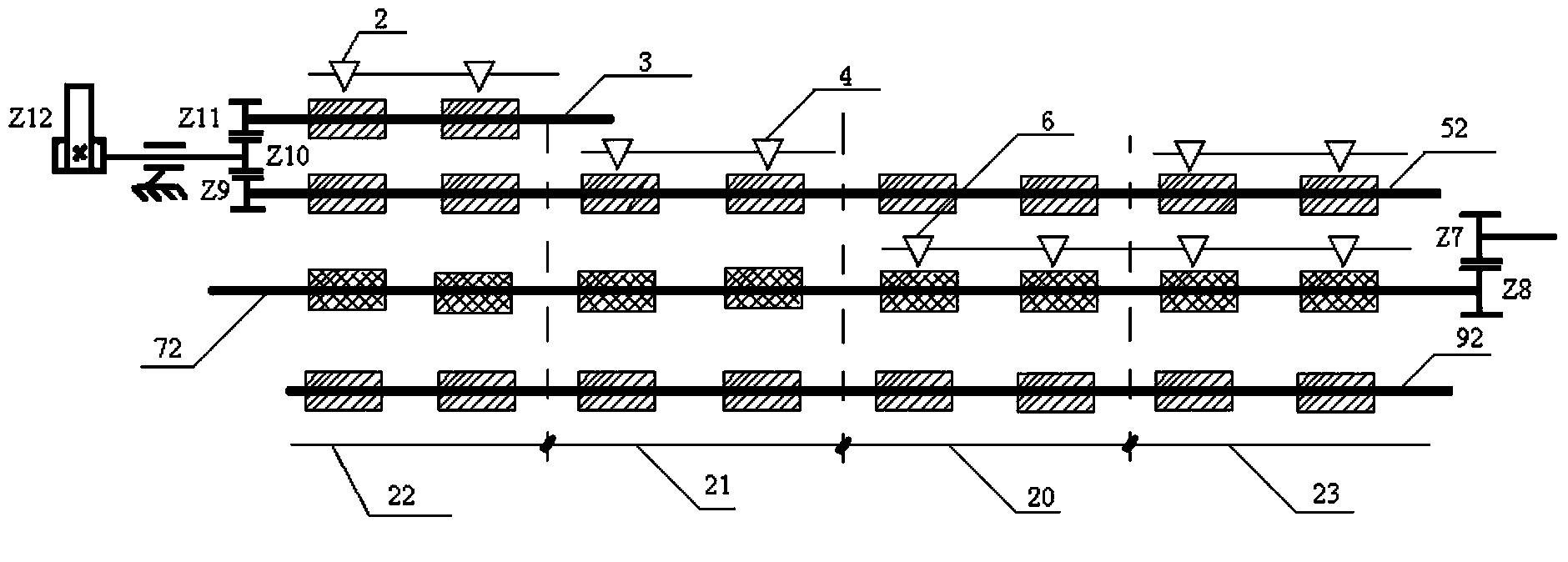

[0116] Example 2 is an example of spinning spun yarns with specifications of 20s / 1, 30s / 1 and 40s / 1 on the same platform.

[0117] For the 5.3g / 10m quantitative roving and the ring-spun yarn in the form of three-roller drafting, in order to realize the spinning of 20s / 1, 30s / 1, and 40s / 1 on the same platform, it is necessary to carry out the following transformation first (see figure 2 ):

[0118] In the prior art, on the main body of the three-roller ring spinning machine, a fourth roller is installed behind the rear roller on the second side, which is used for spinning the thinnest 40S1 area, and the fourth roller is passed through the gear by the rear roller on the second side Transmission system transmission, the gear transmission system includes a pair of roller heads Z9\Z11 and bridge gear Z10. A third draft zone is formed between the fourth roller and the second rear roller, and the draft ratio is designed to be 1.33 times. Install roving feeding horns at the rear of...

Embodiment 3

[0126] Example 3 is an example of spinning 20s / 1, 30s / 1, 40s / 1 spun yarns and 30s / 1 satin colored yarns on the same platform.

[0127] For ring spun yarns that use 5.3g / 10m quantitative roving as raw material and three-roller drafting, in order to achieve 20s / 1, 30s / 1, 40s / 1 spun yarns and 30s / 1 satin colored yarns on the same platform , you need to make the following transformation first (see figure 1 shown):

[0128] A three-roller ring spinning frame in the prior art is adopted, and a fourth roller is installed behind the rear roller on the second side for spinning the 40s / 1 area. The relevant transmission and configuration are the same as those in Embodiment 1. On the first side of the spinning car, add a feeding control mechanism for satin colored yarn auxiliary yarn, that is, a servo motor drive system, which is connected to the first side of the back roller; according to the number of spindles required for satin colored yarn, select the required spindle After a few ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com