Driving device for wool spinning machine

A transmission device and spinning frame technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve the problems that cannot meet the requirements of fine spinning technology, it takes a lot of time to change gears, and the range of transmission speed is different. Large and other problems, to achieve the effect of convenient design of model changes, reduction of machining costs and assembly workload, and reduction of overall machine power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

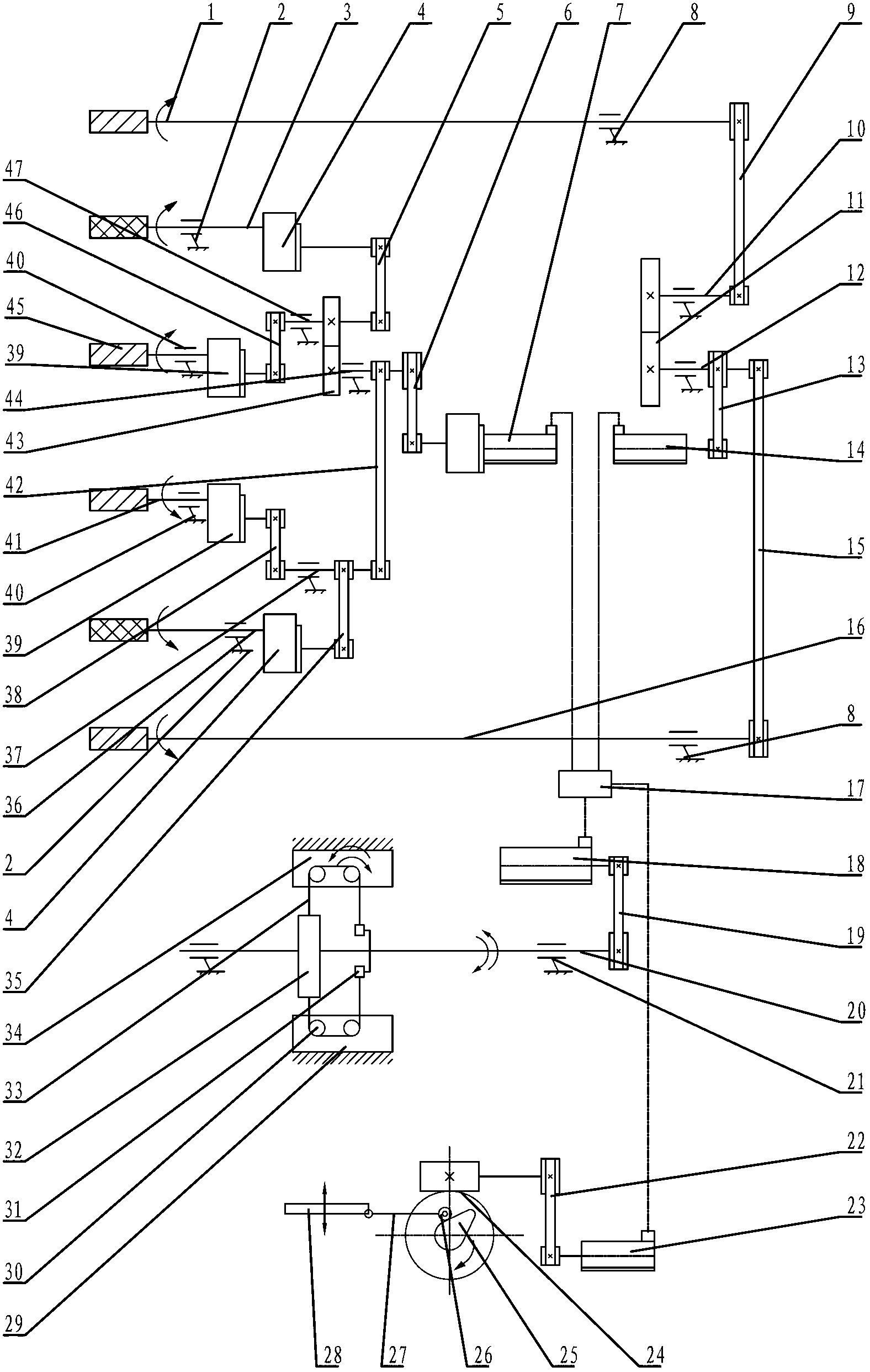

[0019] See figure 1 As shown, the transmission device of the wool spinning frame of the present invention includes a drafting transmission mechanism composed of a front roller transmission mechanism and a middle rear roller transmission mechanism, as well as a spindle transmission mechanism and a lifting transmission mechanism.

[0020] See figure 1 As shown, the front roller transmission mechanism of the present invention includes front roller motor 14, left front roller 1 and right front roller 16 installed on the front roller seat 8 respectively, and front roller motor 14 decelerates all the way through first belt drive 15 and right front roller 16 or The left front roller 1 is connected, and the other road is connected with the left front roller 1 or the right front roller 16 through the first bridge gear transmission pair 11 and the second belt drive 9, and the front roller motor 14 is connected with the first speed reduction belt drive 13, and the first speed reduction b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com