Test device and test method for bending, fracture and creep of layered rock cantilever

A cantilever bending and creep test technology, applied in the direction of using a stable bending force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of insufficient tensile and pressure stability, unreliable test data, and insufficient test accuracy. Improve test reliability, facilitate long-term use and replacement, and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

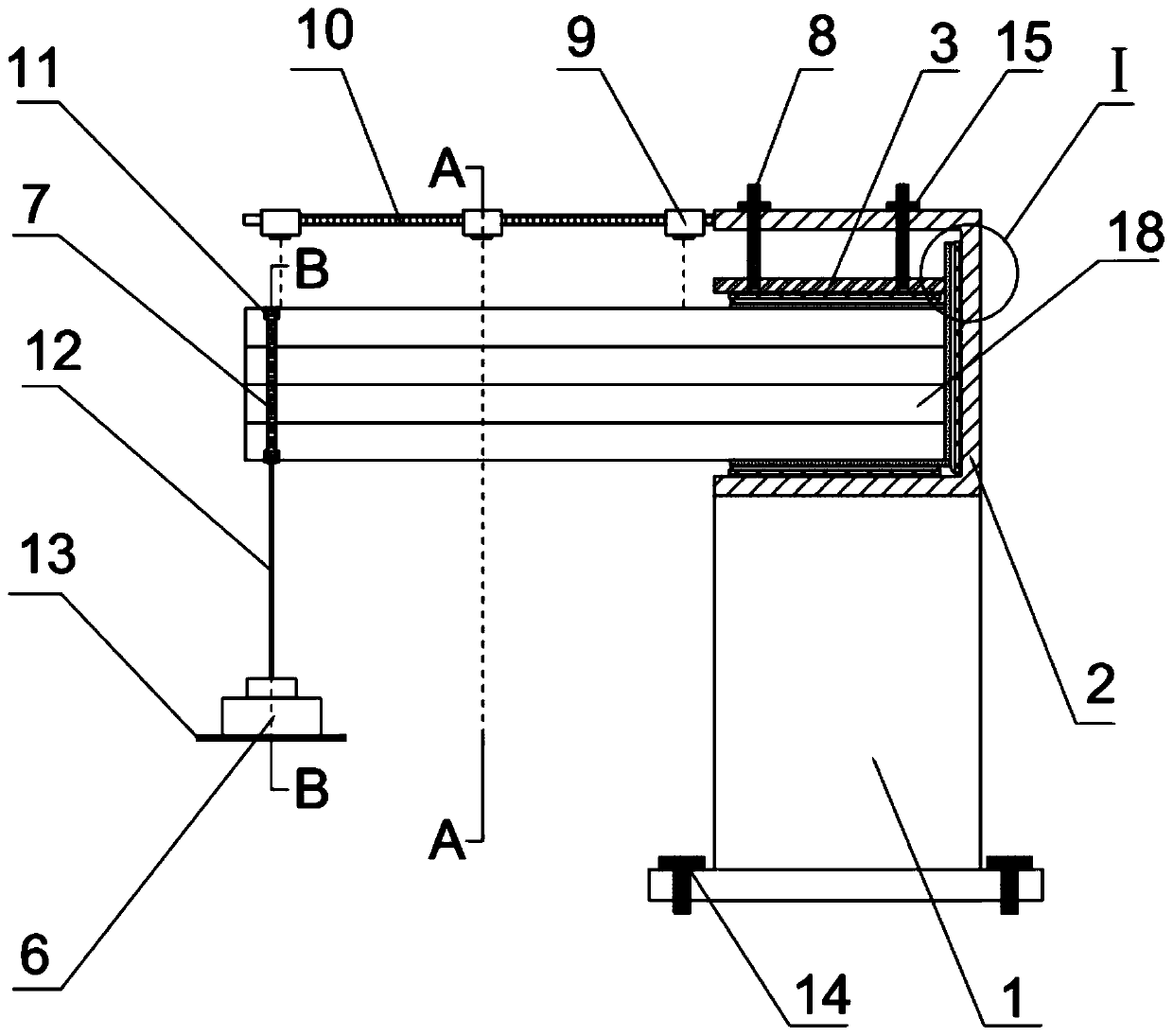

[0067] Step 1. Preparation of the rock specimen to be tested:

[0068] (1) Cut the red sandstone block to be tested into a rectangular plate rock specimen of regular shape required for the test. The specimen size is 1750mm×300mm×150mm, and its natural weight is 25kN / m 3 .

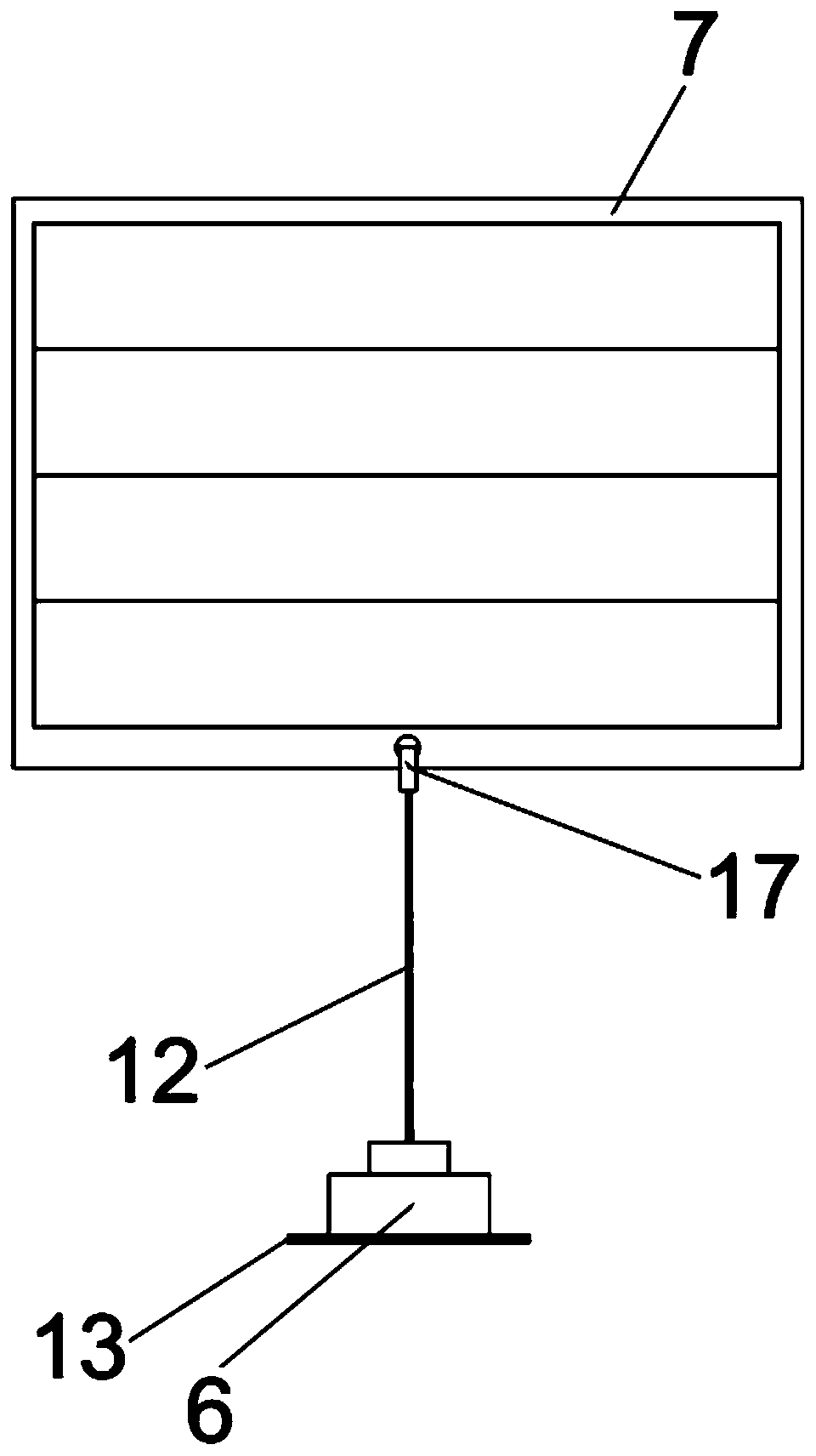

[0069] (2) Grinding the surface of layered rock specimen 18, and then performing speckle image processing on its side surface, to provide reference points for DIC imaging technology in the test process;

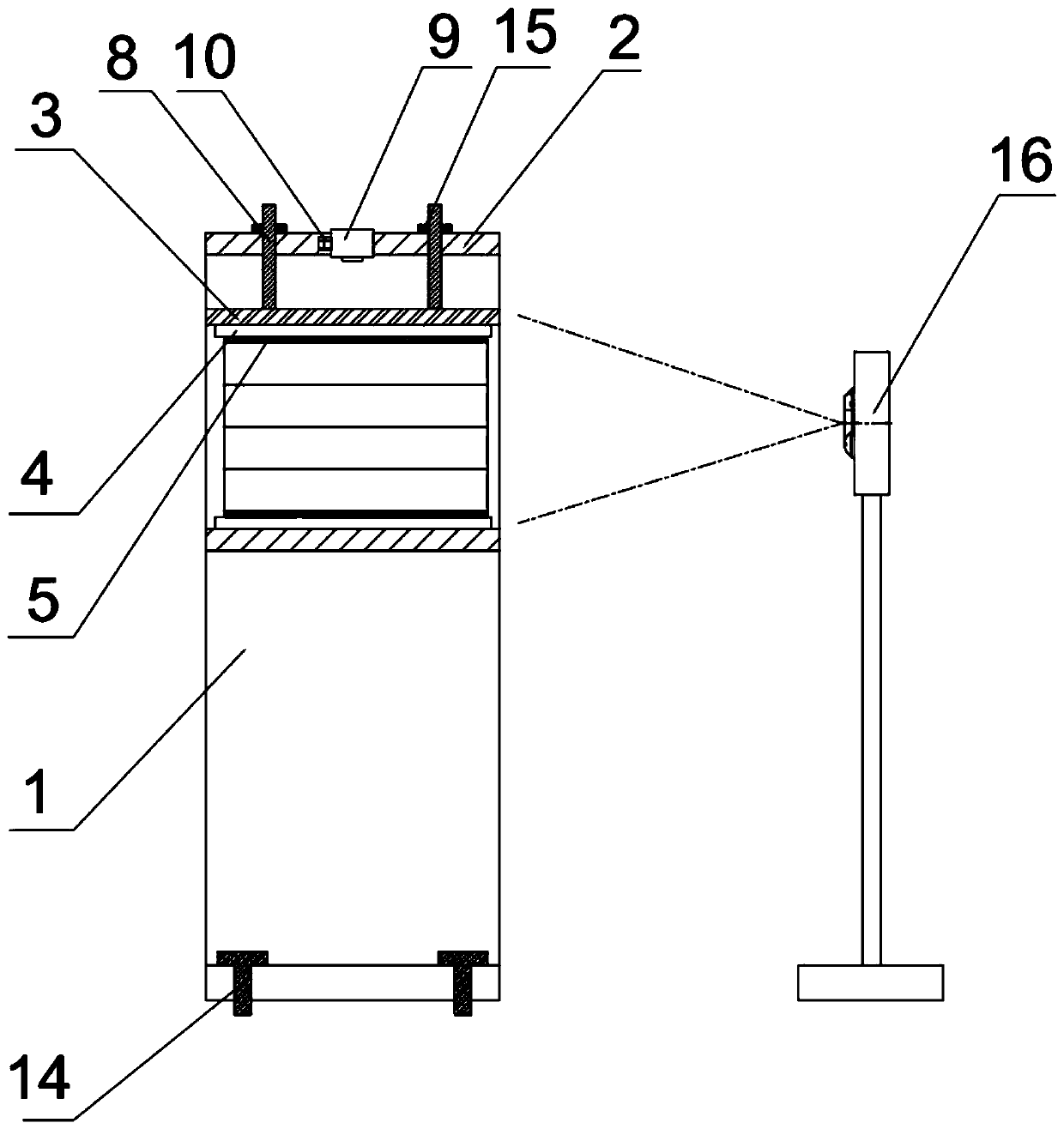

[0070] Step 2. Installation of the test device:

[0071] (1) One end of the layered rock test piece 18 of step 1 is put into the reaction force frame 2, so that one end of the layered rock test piece 18 is closely fitted with the flexible cushion layer 5 on the inner side of the bottom of the reaction force frame and the inner side of the side; then The flexible cushion 5 is placed between the limiting plate 3 and the layered rock test piece 18, and the limiting plate 3 is lowered to a suitable height by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com