Prepressing method for hanging basket jack

A jack and preloading technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of difficult operation and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

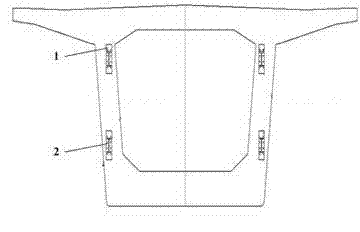

[0038] In Embodiment 1, a hanging basket jack preloading method is provided, please refer to Figure 1-Figure 7 , the method includes:

[0039] Step 1: During the construction process of the continuous beam A0# section, pre-embed the embedded parts for the construction of the reaction force frame. The embedding position is on the end web plate of the A0# section. Specifically, it is the first cast-in-place segment at the top of the middle pier;

[0040] Step 2: Assemble the I-beam components according to the size, and weld with one side of the embedded steel plate;

[0041] Step 3: Install the jack. The upper and lower ends of the jack are equipped with I-beams to distribute the force. Between the double I-beams at the lower part of the jack and the bottom form, N roads of wooden boards placed at equal intervals are laid longitudinally. The said N is greater than or equal to A positive integer of 2, and carry out jack debugging;

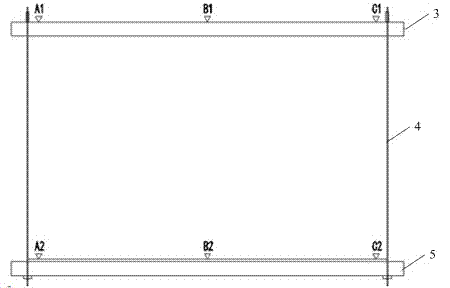

[0042] Step 4: Set up the control points fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com