Ultrasonic vibration screen and method for filtering and screening powder by using same

A vibrating screen and ultrasonic technology, which is applied in the fields of filtering, chemical instruments and methods, and solid separation, can solve problems such as low work efficiency, difficulty in cleaning, broken screen, etc., and achieve high work efficiency, small vibration amplitude, The effect of high vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

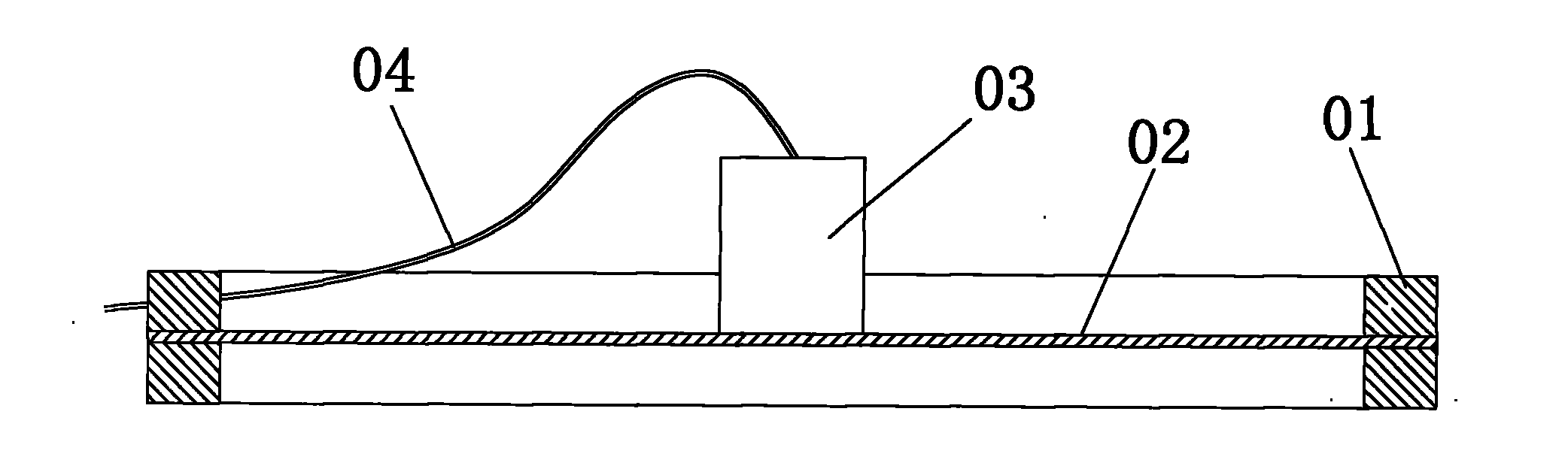

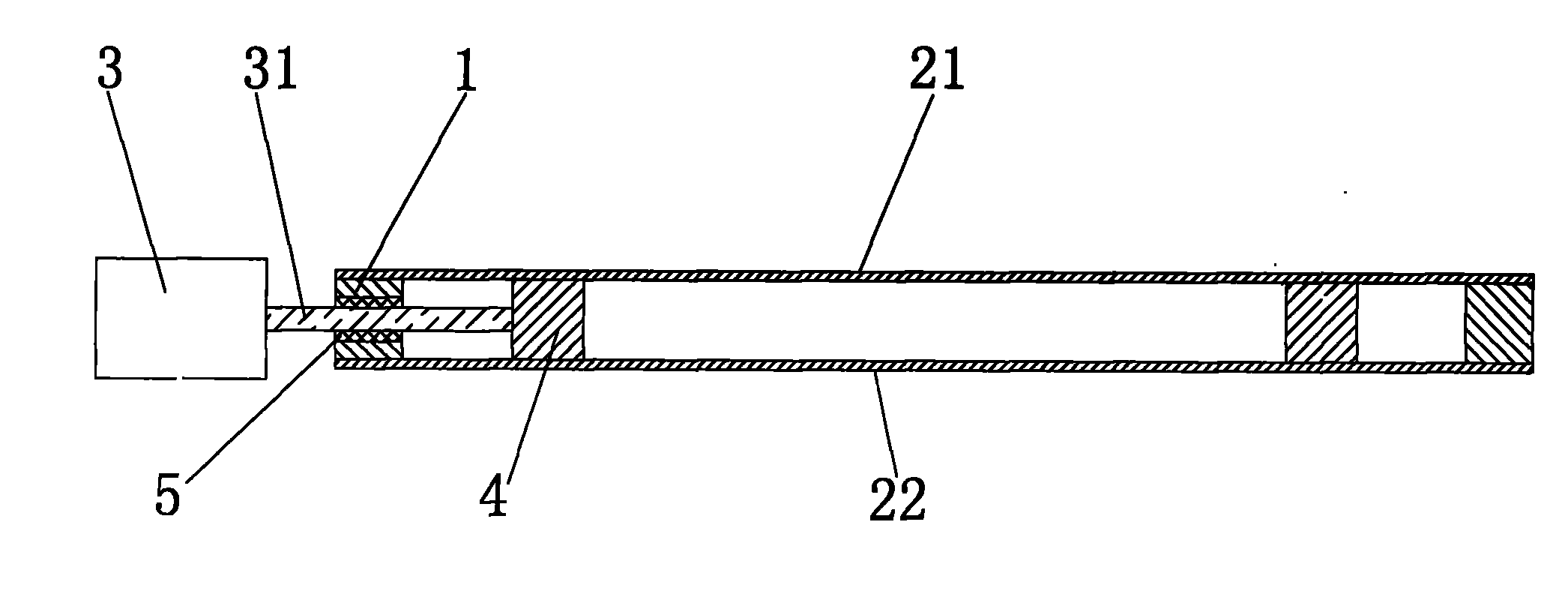

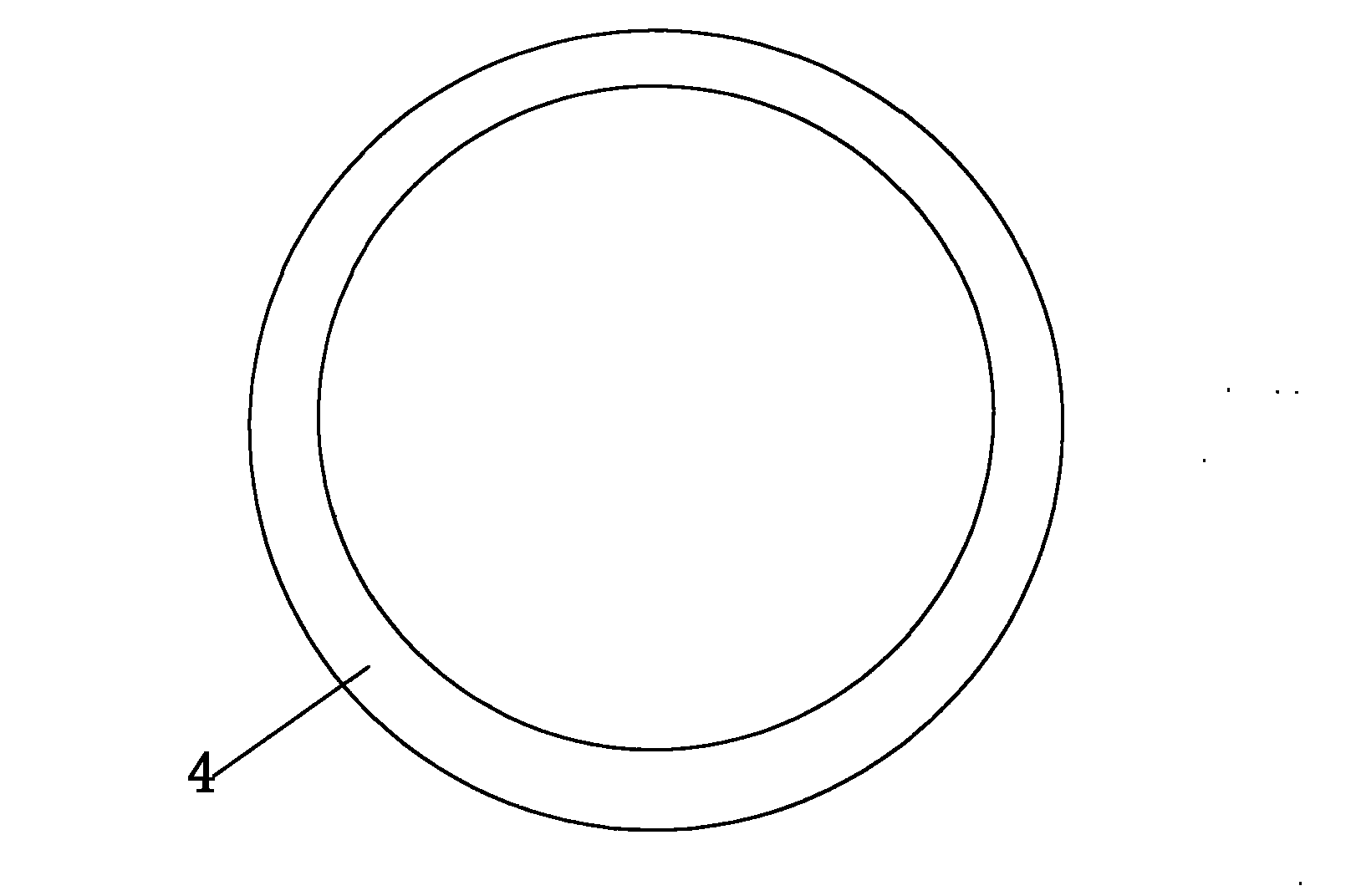

[0017] Embodiment one: if figure 2 , image 3 As shown, a kind of ultrasonic vibrating screen comprises a support 1, an upper screen 21 and a lower screen 22 arranged on the support 1 and an ultrasonic vibrating head 3, and the ultrasonic vibrating head 3 is arranged on the outside of the support 1. The ultrasonic vibration head 3 has a vibration transmission shaft 31, and a shaft hole is provided between the upper screen 21 and the lower screen 22 on the support 1. The vibration transmission shaft 31 is inserted into the shaft hole from the outside of the support 1 and makes the vibration transmission shaft The end passes through the shaft hole, and the end of the vibration transmission shaft 31 is connected with a vibration ring 4 made of elastic material. The vibration ring 4 is arranged between the upper screen 21 and the lower screen 22 and is pasted on the lower and lower screens. The surface of the vibration transmission shaft 31 and the shaft hole is provided with a ...

Embodiment 2

[0019] Embodiment two, such as Figure 4 As shown, the difference from the first implementation is that only the upper screen 21 is provided on the support, and the vibrating ring 4 is screwed with the connecting piece 6 provided on the surface of the upper screen 21 through a bolt 7, so as to use The vibrating ring 4 is fixed below the surface of the upper screen cloth 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com